| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.019339

ARTICLE

BaTiO3/Polyurethane Dielectric Composites with Diels-Alder Bond for Improved Self-Healing Properties

1Hubei Key Laboratory of Plasma Chemistry and Advanced Materials, School of Materials Science and Engineering, Wuhan Institute of Technology, Wuhan, 430205, China

2Ministry-of-Education Key Laboratory for the Green Preparation and Application of Functional Materials, Hubei University, Wuhan, 430062, China

3Key Laboratory of Green Chemical Engineering Process of Ministry of Education, Wuhan Institute of Technology, Wuhan, 430205, China

4School of Chemistry and Environmental Engineering, Jianghan University, Wuhan, 430056, China

5State Key Laboratory of Advanced Technology for Materials Synthesis and Processing, and School of Materials Science and Engineering, Wuhan University of Technology, Wuhan, 430070, China

*Corresponding Authors: Huan Yang. Email: yangh@wit.edu.cn; Chuanxi Xiong. Email: cxiong@whut.edu.cn

Received: 18 September 2021; Accepted: 25 October 2021

Abstract: In general, self-healing dielectric composites are mainly composed of polar hydrogen bonds, which have high hydrophilicity and are unsuitable for humid environment. Dielectric composite with Diels-Alder (D-A) bond contains covalent bonds, it can be adopted as an efficient self-healing material. Here, we construct self-healing barium titanate (BT)/polyurethane (PU) dielectric composites by adopting PU with D-A bond as matrix (BT/PU-DA). The prepared 10% BT/PU-DA composite exhibits superior self-healing ability than that of PU-DA. Moreover, its dielectric constant can reach 9.3 with a loss of only 0.04 at 1000 Hz and maintain 93% repair efficiency of tensile strength. The experimental analysis suggests the introduction of D-A bond can enhance the thermostability and self-healing ability of BT/PU-DA composite. In addition, the incorporation of BT nanoparticles and D-A bond in the self-healing composite contributes to the lower dielectric loss and excellent tensile strength after healing. The adopted strategy is a promising and facile approach to develop highly efficient self-healing dielectric material, which will be conducive to reuse and sustainable development of the electronic packaging material in aqueous medium or wet environment.

Keywords: Diels-Alder bond; self-healing; dielectric properties; tensile strength; polyurethane

Low price and highly efficient energy-conversion semiconductor is urgently needed to meet the requirement of sustainable society. Micro-electronic materials, with the advantages of flexibility and wearability, have attracted widely attention in various fields including capacitors, chips, circuit board, sensors, and biomimetic robots [1–3]. However, the inevitable damage and cracks during their manufacture and/or repetitive use, results in worse insulation and safety issues. Self-healing dielectric materials may play an important role to protect those materials from broken [4–6]. Recently, different dielectric materials with high self-healing performance have been constructed. Among them, polymers are considered to be the most promising self-healing dielectric materials due to their easy processing, good compatibility, tunable dielectric constants and low cost [7,8]. Similar to organisms, self-healing polymer dielectric materials can independently repair the cracks and local damage to restore the original functions, such as conductivity, sensing, and corrosion resistance [9,10]. Therefore, it stimulates a wide research interest on the field of self-healing polymer dielectric materials with improved reliability and good service life.

Usually, hydrogen bonds, with the merits of outstanding reversibility and good directionality, have been widely introduced to assemble intrinsic self-healing polymer dielectric materials [11,12]. Nevertheless, the self-healing polymer materials with hydrogen bonds show high hydrophilicity due to the strong polarity and hydrophily of hydrogen bond, which largely restrict their application in the humid environment. Compared with hydrogen bond, the Diels-Alder (D-A) reaction is well known as a thermally reversible covalent bond reaction, furthermore, D-A reaction has mild reaction conditions and high yield. In general, D-A reaction can construct variety of chain structures, which has good biocompatibility with polymer materials [13–15]. More important, the reversible D-A bond in self-healing system shows appreciable self-healing rate and high efficiency along with low dielectric loss [16]. Particularly, polyurethane (PU), with strong molecular chain structure, presents good corrosion resistance, shock absorption, impact resistance, and water tolerance [17,18]. Thus, self-healing PU can be synthesized by introducing the D-A bond (PU-DA) as dielectric material. Nevertheless, due to the limited permittivity of self-healing PU-DA (dielectric constant ≤5), its application is impeded in electronic packaging material and micro- electronic field. As a result, it is significant to improve the dielectric properties of self-healing PU-DA in the practical application.

In general, high-permittivity nanofillers have the advantages of superior thermal conductivity, dielectric property and electric breakdown property, which make them become the promising candidates to enhance the dielectric properties of polymer composites [19–22]. Among those dielectric materials, barium titanate (BT) is considered as an ideal high dielectric filler due to its high permittivity and low dielectric loss, which has been widely used in polymer composites [22,23]. Nevertheless, this kind of filler in polymer composites limit their self-healing process [24,25]. In this regard, BT can be introduced into PU-DA to realize the self-healing PU composite with low dielectric loss in efficient semiconductor technology.

Herein, to solve the high hydrophilicity of self-healing polymer materials with hydrogen bonds, a thermally reversible covalent D-A reaction is introduced into polymer materials, we construct self-healing BT/PU-DA dielectric composites with different BT contents by adopting PU with D-A bond as matrix. The as-prepared composite exhibits superior self-healing ability. Dielectric constant of 10% BT/PU-DA composite can reach 9.3 at 1000 Hz, which is 2.4 times higher than that of PU-DA. Furthermore, its dielectric loss at 1000 Hz is only 0.04%, and 93% repair efficiency of tensile strength can be maintained. Experimental results suggest that the incorporation of BT nanoparticles and D-A bond contributes to the lower dielectric loss and superior tensile strength after healing. This strategy demonstrates a promising and facile strategy to develop high-performance dielectric material with improved self-healing ability and good dielectric properties after healing, which can stimulate the application of electronic packaging material in aqueous medium or wet environment.

Barium titanate nanoparticle with 100 nm, Polyether polyol (HK-310), Polypropylene glycol (PPG-2000), Isophorone diisocyanate (IPDI), Furan methylamine (DMF), N-N, dimethylformamide, Bismaleimide diphenylmethane (BMI), Dibutyltin dilaurate were supplied by Aladdin CO. All the chemicals were used without further purification.

2.2 Synthesis of Self-Repairing Polyurethane Prepolymer

30 g PPG-2000 (0.03 mol-OH) and 10 g polyether polyol HK-310 (0.03 mol-OH) were placed in a three-necked flask, and it was heated at 120°C in oil bath for 2 h. After the system cooled to 25°C, 13.3 g IPDI (0.12 mol-NCO) and 0.1 mL dibutyltin dilaurate were added into the above system. Then, the mixture was heated at 80°C for 2 h to obtain the isocyanate-terminated polyurethane prepolymer.

In addition, 5.83 g decylamine (0.06 mol-NH2) was dissolved in 10 g N, N-dimethylformamide (DMF), the solution was added dropwise to the obtained PU-NCO. Finally, the above solution was further heated at 60°C for 2 h to obtain the terminal furan ring-terminated polyurethane prepolymer.

2.3 Synthesis of Self-Repairing Polyurethane Composite

Different Nano-BT (5%, 10%, 15% and 20% mass ratio of polyurethane) was mixed with BMI and dissolved in DMF, and then ultrasonically dispersed until the BT was uniformly dispersed in the DMF solution. Then, dropped the prepolymer into the above solution, ultrasonically dispersed again for 15 min to mixed uniformly and poured into a polytetrafluoroethylene mold, heated at 60°C for 24 h, the obtained composite is denoted as BT/PU-DA.

To analyze the effect of D-A bond, BT/PU composites without D-A bond were prepared for comparison. Mixed different BT (5%, 10%, 15% and 20%) with polyurethane prepolymer, 1, 4-butanediol as a crosslinking agent, mixed uniformly and then ultrasonically dispersed for 15 min, the mixture was poured into a polytetrafluoroethylene mold, and heated at 50°C for 18 h, the obtained composite is denoted as BT/PU.

2.4 Material Characterizations

The morphology of various BT/PU-DA composites were observed with scanning electron microscopy (SEM, JSM-7600F, Japan). The repair of the cracks was observed under a metallographic microscope. The chemical structure of various composites was determined using Fourier transform infrared spectroscopy (FTIR Vertex 70, Germany). Thermal Gravimetric Analyzer (TGA, STA490PC) was adopted to analyze at a rate of 20 °C min−1 from 40°C to 700°C under the nitrogen atmosphere. Differential scanning calorimetry (DSC, TA Q-20) was used at a rate of 10°C min−1 from 20°C to 200°C under the nitrogen atmosphere. Dynamic mechanical analysis (DMA, DMAQ800) under tensile pattern at a temperature rate of 10 °C min−1 from −70°C to 100°C, the tested sample is 4 × 1 × 1 cm.

Dielectric data were derived from LCR dielectric spectrum frequency analyzer, both sides of the samples were sprayed with a layer of conductive silver paste, and put into oven at 50°C to dry. For the self-healing measurement, the prepared sample was cut into two pieces, then heated at 120°C for 20 min, and kept at 60°C for 12 h until the broken parts were completely connected. Similarly, a layer of conductive silver paste was coated on the surface and placed in oven at 50°C. The tensile test of samples was retested by universal testing machine (ICS-2000) at a stretch rate of 500 mm min−1.

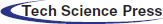

Figs. 1a, 1b show the synthesis route and chemical structure of PU-DA. Compared with the FTIR spectra of pure PU, PU-DA and BT/PU-DA samples exhibit an additional peak at 1775 cm−1 characteristic to D-A bond (Fig. 1c) [26]. Moreover, the peaks appearing at 1714 cm−1 and 1640 cm−1 respectively assigned to the C=O group, and N-H bending vibration [27]. The thermal transitions of PU-DA and BT/PU-DA are evaluated via the DSC, TGA and DTG analysis. Compared with PU-DA, the BT/PU-DA displays lower melt endotherm (138°C) (Fig. 1d). In general, BT nanoparticles can hinder the molecular cross-linking and induce less defects, which is beneficial for forming interface polarization area and lowering the temperature [22]. Furthermore, the composites with D-A bond show the lower weight loss, indicating the introduced D-A bond can enhance the strength of intermolecular interaction, resulting in improved thermal stability (Figs. 1e–1f) [16]. However, compared to the PU-DA, the maximum thermal weight loss of BT/PU-DA shows lower thermal weight loss at 360°C, and higher weight loss occurs at 410°C (Fig. 1f). These results are ascribed to BT nanoparticles with limited thermal conductivity, which can form a thermal conduction path, and transfer out part of the heat inside BT/PU-DA, resulting in its enhanced thermal stability.

Figure 1: (a)–(b) The chemical structure of PU-DA; (c) FTIR results of pure PU, PU-DA and BT/PU-DA; (d) DSC curves of PU-DA and BT/PU-DA; (e) TGA and (f) DTG curves of PU, BT/PU, PU-DA and BT/PU-DA

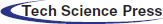

The SEM images show BT particles evenly disperse on the surface of sample with 10% ratio, nevertheless, the increasing of BT content causes the agglomeration of the BT nanoparticles in BT/PU-DA (Figs. 2a–2f). Due to BT nanoparticles with high surface energy, the higher content in PU cannot be effectively dispersed, which promotes BT nanoparticles to gather together.

Figure 2: SEM images of BT/PU-DA with different BT nanoparticles contents. (a) 0%, (b) 5%, (c) 10%, (d) enlarged image of 10%, (e) 15%, (f) 20%

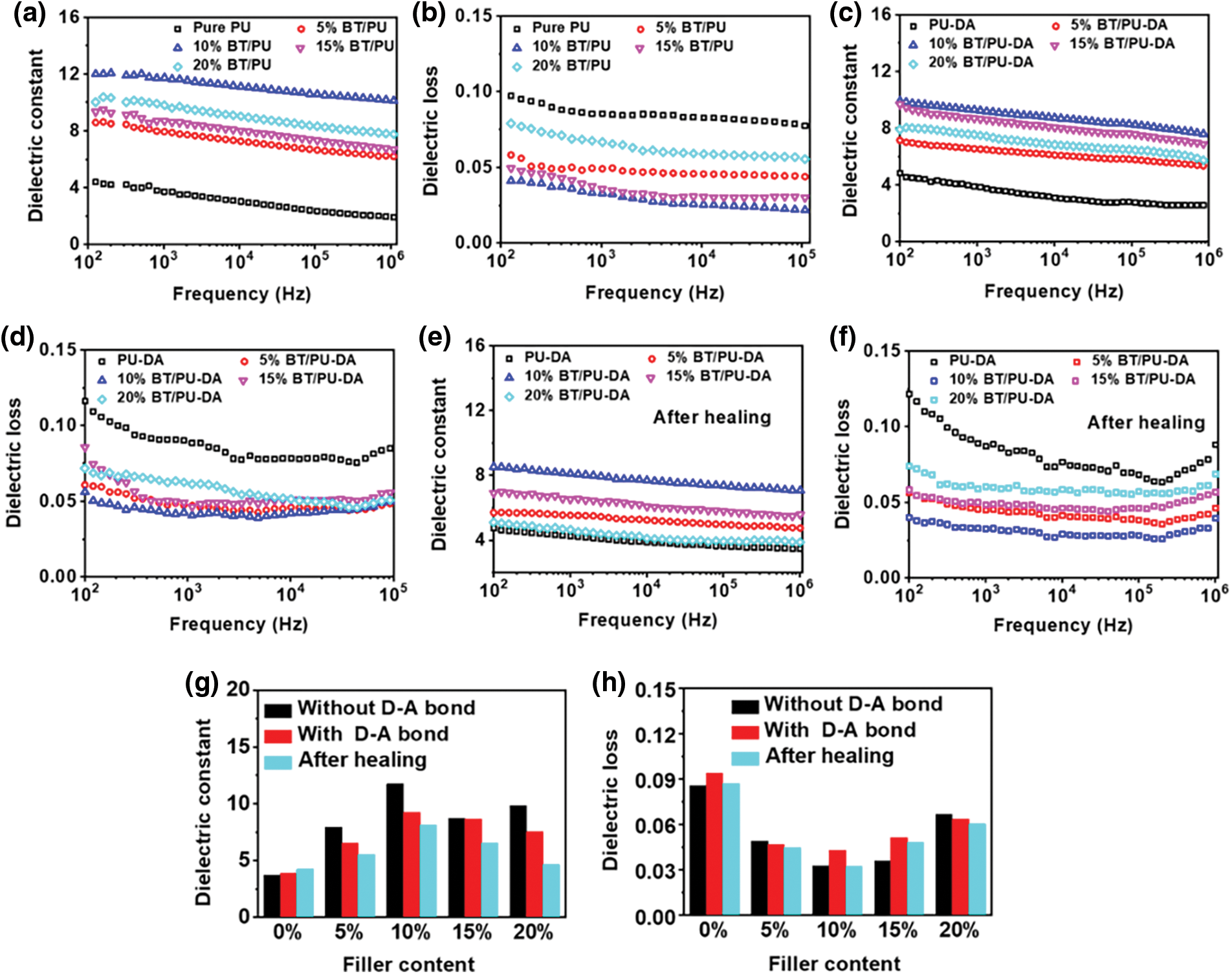

The dielectric properties of different composites are evaluated by their dielectric constants and dielectric loss (Figs. 3a–3d). The incorporation of BT nanoparticles in composites can significantly improve their dielectric constants and decrease their dielectric loss (Figs. 3a–3d), which can be ascribed to the enhanced interface polarization by integrating BT nanoparticles [28,29]. However, higher contents of BT induce their agglomeration, which causes an insufficient polarization and consequently leads to the decrease of dielectric constant [28]. Moreover, the introduced D-A bond in BT/PU-DA composites present more stable dielectric constant and dielectric loss in the entire frequency range. These results reveal the BT nanoparticles in BT/PU-DA composites contribute to enhance their dielectric constant and decrease dielectric loss, and the introduced D-A bond considerably participates in the improvement of their dielectric stability. More important, the self-healing ability of BT/PU-DA composites is crucial to dielectric performance. After being healed for 20 min at 120°C, the BT/PU-DA composites still show higher dielectric constant and lower dielectric loss than that of pure PU-DA (Figs. 3e–3f). In addition, the dielectric constants and dielectric loss of BT/PU-DA composites slightly decrease after healing (Figs. 3g–3h), notably, the 10% BT/PU-DA shows the lowest dielectric loss (0.04) among other composites (Fig. 3h), suggesting that BT/PU-DA dielectric composites have superior self-healing performance.

Figure 3: Dielectric constant (a) and dielectric loss (b) of BT/PU with different BT nanoparticles contents; dielectric constant (c, e) and dielectric loss (d, f) of BT/PU-DA with different BT nanoparticles contents before (c, d) and after healing (e, f); their comparison of (g) dielectric constant and (h) dielectric loss at 1000 Hz

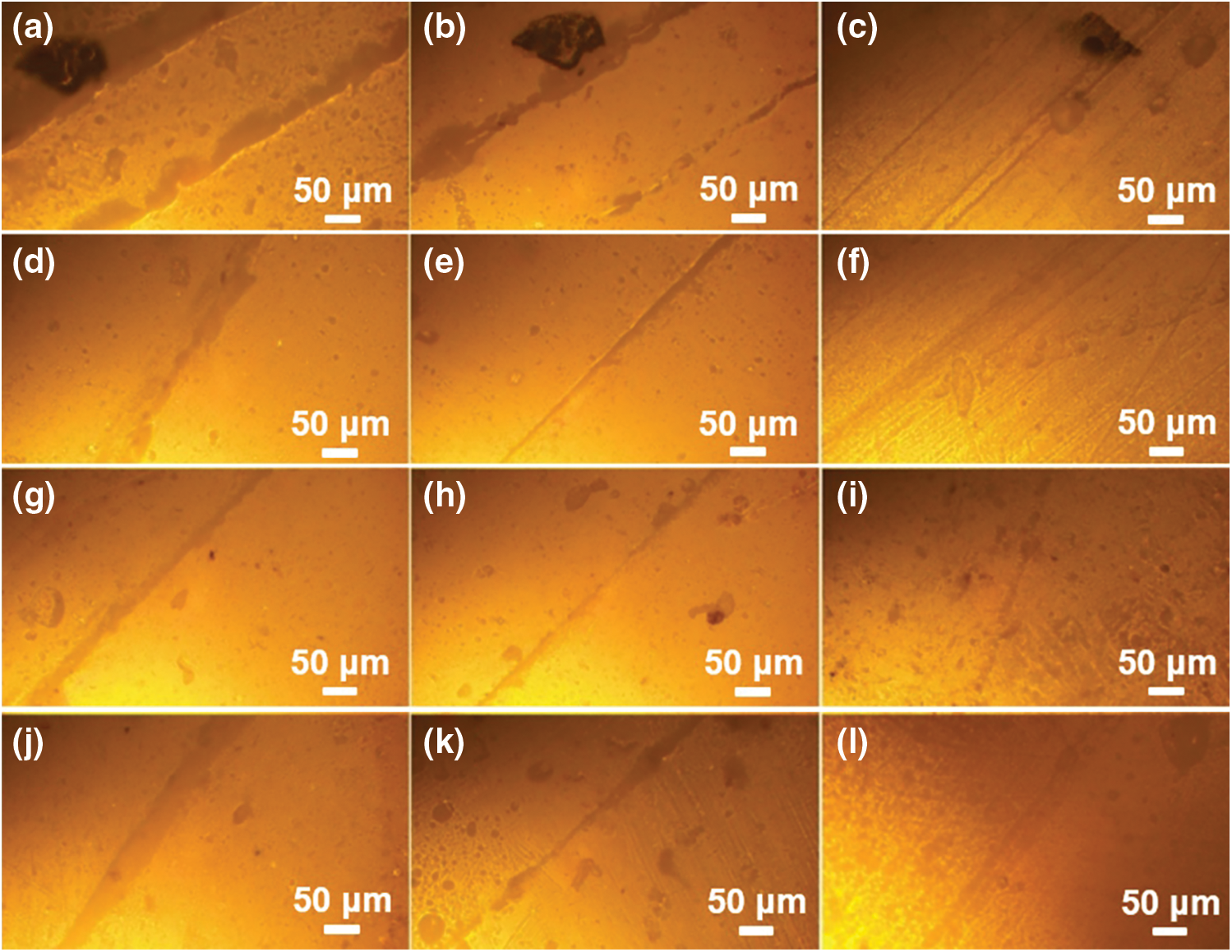

After healing, the metallographic microscope images of different BT/PU-DA composites show the cracks can be completely repaired (Fig. 4), indicating that the addition of BT nanoparticles have no effect on the breakage and reunion of D-A bond. Furthermore, the 10% BT/PU-DA composite with obvious cracks shows a smoother surface with some few random defects. This is mainly due to the reversibility of the D-A reaction, which endows the thermal healing property of the composite [30].

Figure 4: The self-healing behavior of BT/PU-DA composites with (a, b, c) 5% BT, (d, e, f) 10% BT, (g, h, i) 15% BT, (j, k, l) 20% BT under (a, d, g, j) 0 min, (b, e, h, k) 10 min, (c, f, i, l) 20 min at 120°C

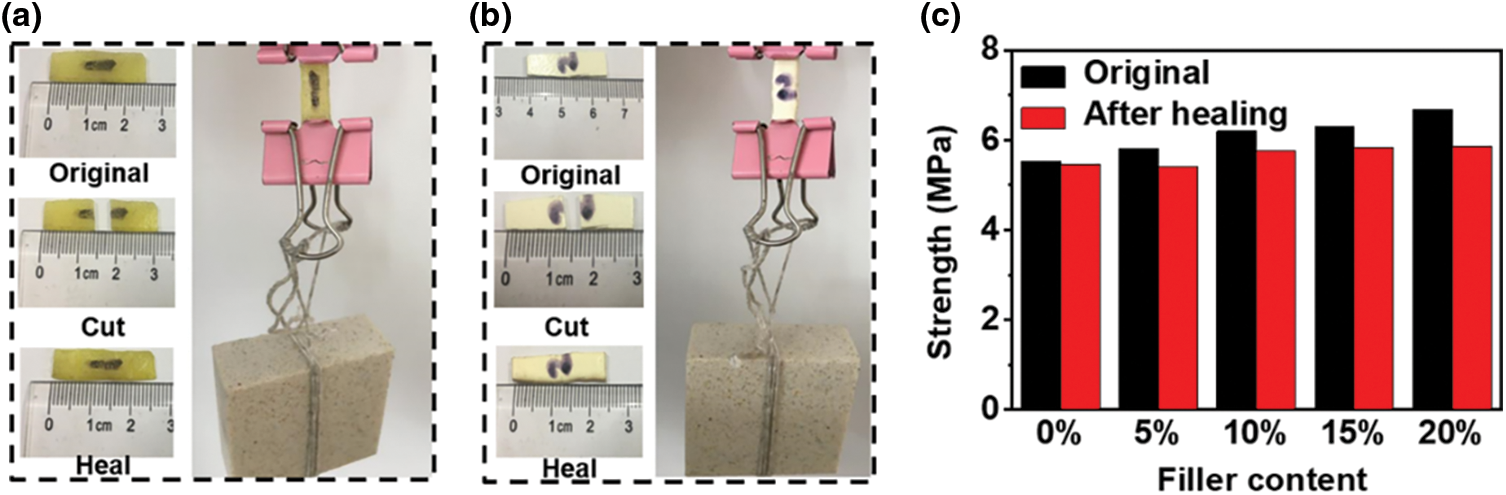

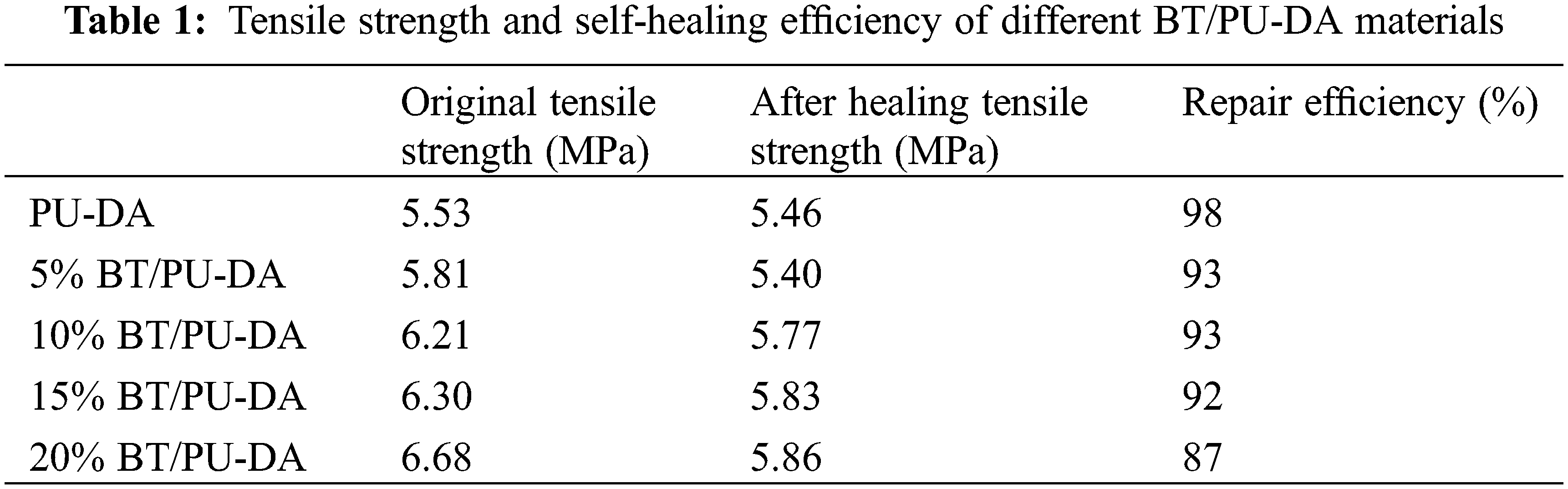

In order to analyze the effect of BT on the macro-properties of self-healing PU, both of the PU-DA and 10% BT/PU-DA materials are cut off and heated at 120°C for 20 min, then keep at 60°C for 30 min. Figs. 5a, 5b present the schematic diagrams of self-repairing process of PU-DA and BT/PU-DA composites. Hanging heavy objects under the PU-DA and 10% BT/PU-DA materials after healing are employed to visually show their healing efficiency. Interestingly, both samples exhibit excellent resistance to the hanging test and none of them appears to break, implying the samples have good self-healing performance. Furthermore, the tensile strength of samples is further conducted by universal testing machine, which can be adopted to verify their self-healing performance (Fig. 5c, Table 1). With the increment of BT content, the tensile strength of BT/CPU-DA materials increase, and the 10% BT/PU-DA material can reach 93% healing efficiency (Fig. 5c, Table 1). This may be ascribed to the enhanced strength of intermolecular interaction by introducing D-A bond (Figs. 1c, 1d) [31].

Figure 5: Schematic diagram of self-healing process of (a) PU-DA and (b) BT/PU-DA composites after healing, (c) their tensile strength before and after healing of BT/PU-DA composites with different BT contents

In summary, to solve the high hydrophilicity of self-healing polymer materials with hydrogen bonds, a thermally reversible covalent D-A reaction is introduced into polymer materials. This work reports the fabrication of BT/PU-DA composite by adopting polyurethane with D-A bond as matrix. The dielectric properties, self-healing performance as well as tensile strength of BT/PU-DA composite with different BT content are studied. The conclusions are as follows:

(1) BT/PU-DA composite with 10% BT particles can realize the evenly dispersion of sample. The as-prepared dielectric composite exhibits good dielectric properties. The dielectric constant of 10% BT/PU-DA composite ups to 9.3 at 1000 Hz, 2.4 times higher than that obtained by the PU-DA. These results reveal the BT nanoparticles in BT/PU-DA composites contribute to enhance their dielectric constant and decrease dielectric loss.

(2) Moreover, the BT/PU-DA composite presents superior self-healing ability. Its dielectric loss is only 0.04 at 1000 Hz. This may be ascribed to the enhanced strength of intermolecular interaction by introducing D-A bond, implying the introduced D-A covalent bond considerably enhances the thermostability and self-healing ability of BT/PU-DA composites.

(3) With the increment of BT content, the tensile strength of BT/CPU-DA materials increase, and the 10% BT/PU-DA material can reach 93% healing efficiency. The combination of BT nanoparticles and D-A bond contribute not only to the lower dielectric loss but also to the excellent tensile strength after healing. Thus, the reported strategy demonstrates a promising and facile approach to develop high-performance dielectric material with superior self-healing ability and good dielectric properties after healing, which can stimulate high interest in the reuse and sustainable development of the electronic packaging material.

Funding Statement: We acknowledge the support of the State Major Research Program of China (2020YFF0406126, Junlong Yao), the National Natural Science Foundation of China (22102125, Huan Yang), the Scientific Research Foundation of Wuhan Institute of Technology (K2021040, Huan Yang), the Innovation Foundation of Key Laboratory of Green Chemical Engineering Process of Ministry of Education (GCX202108, Huan Yang), and the Graduate Innovative Fund of Wuhan Institute of Technology (cx2021127, Wei Nie). The Analytical and Testing Center of Wuhan Institute of Technology for FTIR and SEM characterization are also acknowledged.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Arbabi, E., Arbabi, A., Kamali, S. M., Horie, Y., Faraji-Dana, M. et al. (2018). Mems-tunable dielectric metasurface lens. Nature Communications, 9(1), 812. DOI 10.1038/s41467-018-03155-6. [Google Scholar] [CrossRef]

2. Yang, C., Gao, X., Luo, Y. (2020). End-block-curing aba triblock copolymer towards dielectric elastomers with both high electro-mechanical performance and excellent mechanical properties. Chemical Engineering Journal, 382, 123037. DOI 10.1016/j.cej.2019.123037. [Google Scholar] [CrossRef]

3. Li, Q., Chen, L., Gadinski, M. R., Zhang, S., Zhang, G. et al. (2015). Flexible high-temperature dielectric materials from polymer nanocomposites. Nature, 523(7562), 576–579. DOI 10.1038/nature14647. [Google Scholar] [CrossRef]

4. Dünki, S. J., Ko, Y. S., Nüesch, F. A., Opris, D. M. (2015). Self-repairable, high permittivity dielectric elastomers with large actuation strains at low electric fields. Advanced Functional Materials, 25(16), 2467–2475. DOI 10.1002/adfm.201500077. [Google Scholar] [CrossRef]

5. Cao, Y., Morrissey, T. G., Acome, E., Allec, S. I., Wong, B. M. et al. (2017). A transparent, self-healing, highly stretchable ionic conductor. Advanced Materials, 29(10), 1605099. DOI 10.1002/adma.201605099. [Google Scholar] [CrossRef]

6. Zhou, W., Li, T., Yuan, M., Li, B., Zhong, S. et al. (2021). Decoupling of inter-particle polarization and intra-particle polarization in core-shell structured nanocomposites towards improved dielectric performance. Energy Storage Materials, 42, 1–11. DOI 10.1016/j.ensm.2021.07.014. [Google Scholar] [CrossRef]

7. Tiwari, N., Ho, F., Ankit., Mathews, N. (2018). A rapid low temperature self-healable polymeric composite for flexible electronic devices. Journal of Materials Chemistry A, 6(43), 21428–21434. DOI 10.1039/C8TA08328B. [Google Scholar] [CrossRef]

8. Ellingford, C., Zhang, R., Wemyss, A. M., Bowen, C., McNally, T. et al. (2018). Intrinsic tuning of poly(styrene-butadiene-styrene)-based self-healing dielectric elastomer actuators with enhanced electromechanical properties. ACS Applied Materials & Interfaces, 10(44), 38438–38448. DOI 10.1021/acsami.8b13785. [Google Scholar] [CrossRef]

9. Roy, N., Bruchmann, B., Lehn, J. M. (2015). Dynamers: Dynamic polymers as self-healing materials. Chemical Society Reviews, 44(11), 3786–3807. DOI 10.1039/C5CS00194C. [Google Scholar] [CrossRef]

10. Wang, S., Urban, W. M. (2020). Self-healing polymers. Nature Reviews Materials, 5(8), 562–583. DOI 10.1038/s41578-020-0202-4. [Google Scholar] [CrossRef]

11. Xu, J., Chen, J., Zhang, Y., Liu, T., Fu, J. (2021). A fast room-temperature self-healing glassy polyurethane. Angewandte Chemie International Edition, 60(14), 7947–7955. DOI 10.1002/anie.202017303. [Google Scholar] [CrossRef]

12. Du, R., Xu, Z., Zhu, C., Jiang, Y., Yan, H. et al. (2020). A highly stretchable and self-healing supramolecular elastomer based on sliding crosslinks and hydrogen bonds. Advanced Functional Materials, 30(7), 1907139. DOI 10.1002/adfm.201907139. [Google Scholar] [CrossRef]

13. Li, T., Hu, K., Ma, X., Zhang, W., Yin, J. et al. (2020). Hierarchical 3D patterns with dynamic wrinkles produced by a photocontrolled Diels-Alder reaction on the surface. Advanced Materials, 32 (7), 1906712. DOI 10.1002/adma.201906712. [Google Scholar] [CrossRef]

14. Hansmann, M. M. (2018). Synthesis of azaphosphinines by directed inverse-electron-demand hetero-Diels–Alder reactions with Na(OCP). Chemistry–A European Journal, 24 (45), 11573–11577. DOI 10.1002/chem.201802173. [Google Scholar] [CrossRef]

15. Beloqui, A., Mane, S. R., Langer, M., Glassner, M., Bauer, D. M. et al. (2020). Hetero-Diels-Alder cycloaddition with raft polymers as bioconjugation platform. Angewandte Chemie International Edition, 59(45), 19951–19955. DOI 10.1002/anie.202005747. [Google Scholar] [CrossRef]

16. Li, G., Xiao, P., Hou, S., Huang, Y. (2019). Rapid and efficient polymer/graphene based multichannel self-healing material via Diels-Alder reaction. Carbon, 147, 398–407. DOI 10.1016/j.carbon.2019.03.021. [Google Scholar] [CrossRef]

17. Yu, T., Halouane, F., Mathias, D., Barras, A., Wang, Z. et al. (2020). Preparation of magnetic, superhydrophobic/superoleophilic polyurethane sponge: Separation of oil/water mixture and demulsification. Chemical Engineering Journal, 384, 123339. DOI 10.1016/j.cej.2019.123339. [Google Scholar] [CrossRef]

18. Ding, H., Yang, X., Xu, L., Li, S., Xia, J. et al. (2020). Thermally reversible, self-healing polyurethane based on propyl gallate and polyurethane prepolymers with varied isocyanate content. Journal of Renewable Materials, 8(1), 1–11. DOI 10.32604/jrm.2020.08165. [Google Scholar] [CrossRef]

19. Dang, Z., Zheng, M., Zha, J. (2016). 1D/2D carbon nanomaterial-polymer dielectric composites with high permittivity for power energy storage applications. Small, 12(13), 1688–1701. DOI 10.1002/smll.201503193. [Google Scholar] [CrossRef]

20. Li, Y., Zhou, Y., Zhu, Y., Cheng, S., Yuan, C. et al. (2020). Polymer nanocomposites with high energy density and improved charge-discharge efficiency utilizing hierarchically-structured nanofillers. Journal of Materials Chemistry A, 8(14), 6576–6585. DOI 10.1039/D0TA01380C. [Google Scholar] [CrossRef]

21. Zhang, H., Marwat, M. A., Xie, B., Ashtar, M., Liu, K. et al. (2020). Polymer matrix nanocomposites with 1D ceramic nanofillers for energy storage capacitor applications. ACS Applied Materials & Interfaces, 12(1), 1–37. DOI 10.1021/acsami.9b15005. [Google Scholar] [CrossRef]

22. Prateek Bhunia, R., Siddiqui, S., Garg, A., Gupta, R. K. (2019). Significantly enhanced energy density by tailoring the interface in hierarchically structured TiO2-BaTiO3-TiO2 nanofillers in PVDF-based thin-film polymer nanocomposites. ACS Applied Materials & Interfaces, 11(15), 14329–14339. DOI 10.1021/acsami.9b01359. [Google Scholar] [CrossRef]

23. Saleem, M., Butt, M. S., Maqbool, A., Umer, M. A., Shahid, M. et al. (2020). Percolation phenomena of dielectric permittivity of a microwave-sintered batio3-ag nanocomposite for high energy capacitor. Journal of Alloys and Compounds, 822, 153525. DOI 10.1016/j.jallcom.2019.153525. [Google Scholar] [CrossRef]

24. Yang, Y., Gao, Z., Yang, M., Zheng, M. (2019). Enhanced energy conversion efficiency in the surface modified BaTiO3 nanoparticles/polyurethane nanocomposites for potential dielectric elastomer generators. Nano Energy, 59, 363–371. DOI 10.1016/j.nanoen.2019.02.065. [Google Scholar] [CrossRef]

25. Bi, M., Hao, Y., Zhang, J., Lei, M., Bi, K. (2017). Particle size effect of BaTiO3 nanofillers on the energy storage performance of polymer nanocomposites. Nanoscale, 9(42), 16386–16395. DOI 10.1039/C7NR05212J. [Google Scholar] [CrossRef]

26. Li, J., Zhang, G., Deng, L., Zhao, S., Gao, Y. et al. (2014). In situ polymerization of mechanically reinforced, thermally healable graphene oxide/polyurethane composites based on Diels-Alder chemistry. Journal of Materials Chemistry A, 2(48), 20642–20649. DOI 10.1039/C4TA04941A. [Google Scholar] [CrossRef]

27. Xu, J., Hadjichristidis, N. (2021). Well-defined poly(ester amide)-based homo- and block copolymers by one-pot organocatalytic anionic ring-opening copolymerization of n-sulfonyl aziridines and cyclic anhydrides. Angewandte Chemie International Edition, 60(13), 6949–6954. DOI 10.1002/anie.202015339. [Google Scholar] [CrossRef]

28. Bouharras, F. E., Raihane, M., Ameduri, B. (2020). Recent progress on core-shell structured BaTiO3@polymer/fluorinated polymers nanocomposites for high energy storage: Synthesis, dielectric properties and applications. Progress in Materials Science, 113, 100670. DOI 10.1016/j.pmatsci.2020.100670. [Google Scholar] [CrossRef]

29. Wang, Y., Yao, M., Ma, R., Yuan, Q., Yang, D. et al. (2020). Design strategy of barium titanate/polyvinylidene fluoride-based nanocomposite films for high energy storage. Journal of Materials Chemistry A, 8(3), 884–917. DOI 10.1039/C9TA11527G. [Google Scholar] [CrossRef]

30. Luo, S., Shen, Y., Yu, S., Wan, Y., Liao, W. et al. (2017). Construction of a 3D-BaTiO3 network leading to significantly enhanced dielectric permittivity and energy storage density of polymer composites. Energy & Environmental Science, 10(1), 137–144. DOI 10.1039/C6EE03190K. [Google Scholar] [CrossRef]

31. Oehlenschlaeger, K. K., Mueller, J. O., Brandt, J., Hilf, S., Lederer, A. et al. (2014). Adaptable hetero Diels-Alder networks for fast self-healing under mild conditions. Advanced Materials, 26(21), 3561–3566. DOI 10.1002/adma.201306258. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |