| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.018027

ARTICLE

Study on Microwave Pretreatment Technology to Improve the Effect of Shellac Impregnation of Fast-Growing Chinese Fir

1College of Material Engineering, Fujian Agriculture and Forestry University, Fuzhou, 350002, China

2Fujian Provincial Forestry Survey and Design Institute, Fuzhou, 350001, China

3Nanocellulose and Biocomposites Research Centre, College of Engineering, Design and Physical Sciences, Brunel University, London, UB8 3PH, UK

*Corresponding Authors: Qinzhi Zeng. Email: fjafuzqz@163.com; Weigang Zhao. Email: weigang-zhao@fafu.edu.cn

Received: 24 June 2021; Accepted: 11 August 2021

Abstract: To improve the mechanical properties of fast-growing Chinese fir (Cunnighamia lanceolate), expand its range of application, increase its value, and avoid the environmental pollution caused by impregnation with synthetic resin, Chinese fir was impregnated with a shellac solution. Since the shellac solution was difficult to penetrate into fast-growing Chinese fir, so microwave pretreatment was used to irradiate the wood to improve the permeability. This study investigated the effects of four factors, including the content of moisture in the wood before it was microwaved, the chamber pressure of microwave, the time of microwaving and the vacuum impregnation on the mechanical properties of Chinese fir wood. When the moisture content of wood before microwave was approximately 50%–60%, after microwaving and impregnation, the ultimate strength in static bending (modulus of rupture [MOR]) and strength in compression perpendicular to the grain (SCPG) of the wood increased significantly. A microwave time of 100 seconds was more effective at improving the MOR and SCPG of the wood. If the wood was microwaved for too short or long period of time, the microwave pretreatment was not effective. When the samples were immersed in shellac for a longer period, the MOR and SCPG of Chinese fir gradually increased, but when the wood was impregnated for more than 12 hours, the increases were not significant. After the shellac penetrated the Chinese fir wood, it spread on the inner wall surface of tracheid to form a shellac film and easily formed plug-like deposits in microcapillaries. The use of Fourier-transform infrared spectroscopy, scanning electron microscopy and scanning electron microscopy-energy dispersion x-ray indicated that the microwave pretreatment can destroy the pit membranes on tracheids and facilitate the ability of shellac to penetrate the channel.

Keywords: Fast-growing Chinese fir; Microwave pretreatment; Shellac; Impregnation; Mechanical properties

Chinese fir (Cunninghamia lanceolata) is an important species in the southern provinces of China [1,2]. Chinese fir wood that was harvested from natural forests has been widely used as furniture and building materials owing to its excellent characteristics, such as a straight texture, uniform structure, and ability to resist insects and wood-rot fungi [3]. However, because of its rapid growth and short maturity, fast-growing Chinese fir wood has some shortcomings, such as a low density, short fibers, and poor strength and stiffness among others [4]. These deficiencies result in wood that is easily deformed and damaged during use and rendered unsuitable for use as materials in furniture, floors, wooden structures and construction [5]. Therefore, to improve the properties of Chinese fir, expand its range of uses and increase the added value of its products, researchers have thoroughly studied modifications of the wood by impregnation with synthetic resin to increase its density and improve its physical and mechanical properties [6]. The synthetic resins that are commonly used to impregnate wood are urea formaldehyde resin [7], phenol formaldehyde resin [4], melamine-urea formaldehyde resin, phenol-melamine-urea formaldehyde resin [8], and unsaturated polyester resin [5] among others. However, the impregnation of synthetic resin can not only improve the physical and mechanical properties of Chinese fir but also introduce pollutants, such as formaldehyde, phenol and other chemicals, into the environment [9]. In order to reduce pollution, an environmentally friendly natural shellac solution was used to impregnate Chinese fir wood in this work. Shellac is a natural resin extracted from a resinous substance excreted by shellac insects (Laccifer lacca Kerr.) that parasitize on some trees [10]. Shellac consists of aleuritic acid (244–304 Da), terpenic acid (280–296 Da) and polyesters (470–1734 Da) connected composed of aleuritic acid and terpenic acid connected by ester bonds [11]. Despite molecular weight of shellac is relatively low, the shellac is still hard to penetrate into the wood through the pits and reduce the impregnation effect. This is because the radial and tangential infusion channel are blocked by the wood inclusions and the pit membranes. So some pretreatment methods were used to draw out the inclusions or destruct the pit membranes, which include mechanical, physical, chemical and biological treatment [12,13]. However, the chemical pretreatments will discharge waste water or gas, while mechanical or biological methods will reduce the mechanical properties of the wood [14]. An ideal pretreatment technology should possess several characteristics such as effectively improve the impregnation, low environmental impact, small decline in the physical and mechanical properties of the wood, and moderately low energy input. The Microwave pretreatment is a relatively new method, which can be applied to improve wood permeability [15]. When microwave irradiation, the water inside the wood absorbs the electromagnetic energy effectively, and vaporizes to generate a large internal vapor pressure within wood cells. The thin-walled cells and pit membranes will be ruptured by the vapor pressure, the radial and tangential permeability of the wood will be improved [16]. The moisture content of the wood before the microwave irradiation, the pressure of microwave chamber and the irradiation time have a greater impact on the improvement. How to control the conditions and parameters of microwave pretreatment to ensure the improvement of the permeability and the slight decrease of the mechanical properties is the purpose of the paper. Therefore, to improve the effect of shellac impregnation of macromolecular natural polymers and increase the bending strength and compression strength perpendicular to the grain of Chinese fir, the microwave pretreatment process was investigated in this article, which includes four factors, such as the content of moisture in the wood before it was microwaved, the chamber pressure of microwave, the time of microwaving and vacuum impregnation the content of moisture in the wood before it was microwaved, the chamber pressure of microwave, the time of microwaving and vacuum impregnation.

Fast-growing Chinese fir are 21 years old from Nanan City, Fujian, China. The logs are 5 meters in length and 320~400 mm in small head diameter. The air-dried density is around 0.36 g/cm3. The logs were sawn into some rift sawn lumbers with dimensions of 30 mm × 30 mm in square section. Bleached shellac was purchased from Yunnan Lvchun Shellac Co., Ltd., Yunnan, China. with an average molecular weight of about 765 Da. The Industrial alcohol (95%) was bought from Chongwen Guangzhou Chemical Co., Ltd., Guangzhou, China.

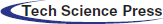

Using a single-side wood press planer the rift sawn lumbers were process into wooden bars with a cross-sectional size of 20 mm × 20 mm (the error is 0~1 mm). Then, defects such as cracks, knots, and rot were removed. The short samples with 300 mm length were cut from the wooden sticks. The short samples were marked in the form of ‘x-y’, where ‘x’ numbered wooden sticks, and ‘y’ was the serial number of the 300 mm long samples numbered in the order cut from same stick. Two samples cut from the longitudinally adjacent positions of a same Chinese fir stick were counted as a pair, and the serial numbers were marked y and y+1, where the former was the treatment specimen and the latter was the control specimen. The sample preparation and processing process is shown in Fig. 1.

The shellac was dissolved in ethanol at a liquid-solid ratio of 5:1, and 3000 mL of shellac solution was prepared each time, with a viscosity of about 37.2 mPa·s. Before impregnating, the shellac solution was stirred for about 3 minutes again.

Figure 1: Schematic of the test process

2.3 Effect of Moisture Content of Specimens before Microwave Pretreatment

Thirty-six pairs of Chinese fir samples were randomly selected, of which 36 odd-numbered samples were impregnated with the shellac solution, and 36 even-numbered samples were used as control samples. 36 treatment samples were soaked in water at room temperature (about 20°C to 25°C) for 24 h. After that, the samples were taken out of the water in 3 batches, 12 in each batch, labeled G1, G2 and G3, respectively. After taking out the G1 sample, firstly wipe the surface water with a filter paper, and then dried it in a 103 ± 2°C drying oven for 60 minutes. The moisture content of G1 samples was about 15%–25%, with an average of 19.16%. After taking out the G2 sample, firstly wipe the surface water with a filter paper, and then dried it in a 103 ± 2°C drying oven for 30 min. The moisture content of G2 samples was about 25%–35%, with an average of 29.06%. After taking out the G3 sample, only use filter paper to wipe the moisture on the sample surface without drying. Its average water content is 56.03%, and the water content ranges from 50% to 60%. After adjusting the moisture content through the above operation, the samples were processed in a microwave machine with microwave power of 4 kW and 2.45 GHz for 100 s. The sample was then placed in a drying oven at 103 ± 2°C for 5 h and then immersed in the shellac solution under vacuum conditions of −0.1 MPa for 3 hours. Remove from the shellac solution, clean the surface of the sample and store the sample at room temperature for 24 h. Finally, the immersed samples and 36 control samples were placed in a constant temperature and humidity chamber with relative humidity of 65% and temperature of 20°C for more than 48 hours.

2.4 Effect of Microwave Time under Atmospheric Pressure

The treatment samples were soaked in water for 24 h at room temperature. After taken out of the water and wiped with filter paper, the samples were treated in the microwave machine (microwave power 4 kW, 2.45 GHz) under atmospheric pressure for 40, 60, 80, 100, 120, 140, 160 or 180 s. The treatment samples were subsequently dried, impregnated, and conditioned according to the above methods.

2.5 Effect of Microwave Time under Vacuum

After being soaked in water for 24 h at room temperature, the treatment samples were put into the microwave machine. Closed the door of the microwave machine, turned on the vacuum pump, and reduced the cabin pressure of the microwave oven to −0.1 MPa. Then switched on the microwave magnetron (microwave power 4 kW, 2.45 GHz), the treatment samples were microwaved under vacuum of −0.1 MPa for 40, 60, 80, 100, 120, 140, 160 or 180 s. The treatment samples were then dried, impregnated, and conditioned according to the above methods.

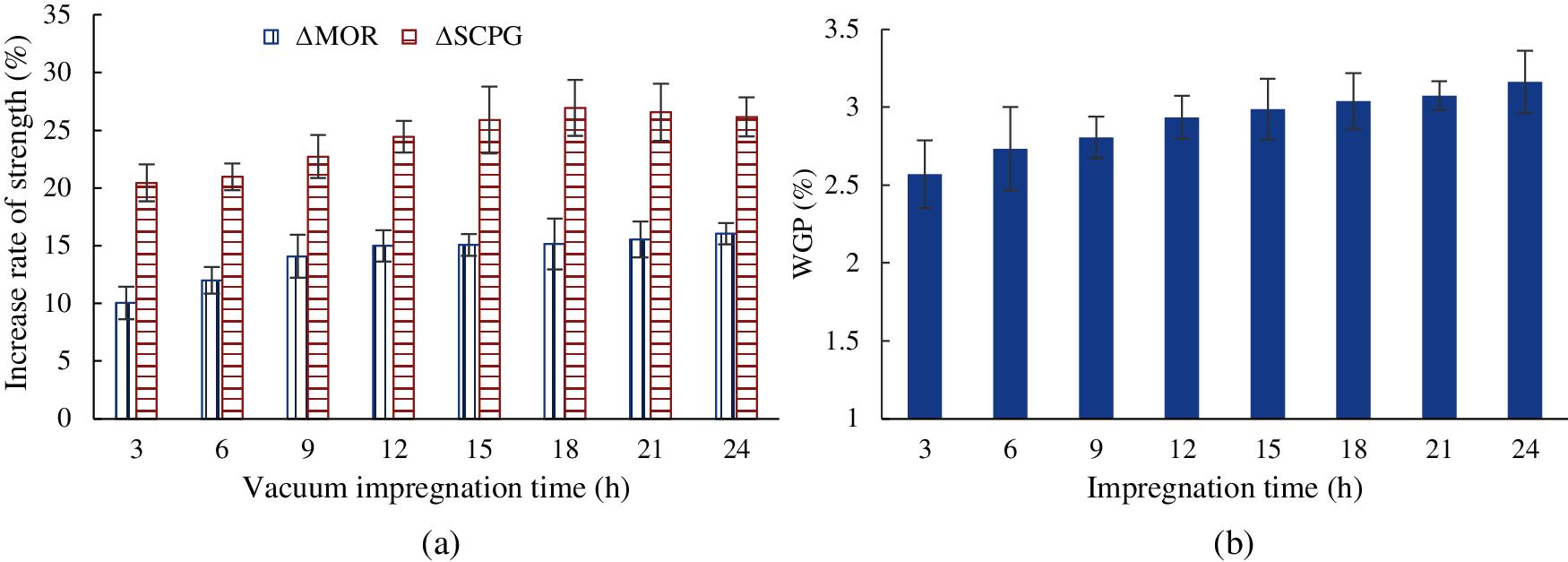

2.6 Effect of Vacuum Impregnation Time

The treatment samples were placed in water for 24 h, and the surface was wiped with a filter paper. The microwave time and cabin pressure of the microwave machine were set according above experience results. The impregnating time was set as 3, 6, 9, 12, 15, 18, 21 or 24 h under vacuum conditions of −0.1 MPa, respectively. The treatment samples were then dried and conditioned according to the above methods.

The electromechanical universal testing machine (E44.304, MTS systems Co., Ltd., Eden Prairie, USA) was used to determine the ultimate strength in static bending (MOR, modulus of rupture) according to ISO 13061-3:2014, and strength in compression perpendicular to grain (SCPG) according to ISO 13061-5:2020. For the case of MOR, the radius of the reaction support roller and curvature of load bearing block head were 30 mm, and the span was 240 mm, the loading speed was 10 mm/min. The loading direction was radial, that is, perpendicular to the annual rings. A pair of specimens were loaded in the same direction, either from the outside to the wood pith, or from the wood pith to the outside. For the case of SCPG, the loading direction also was radial, and the loading speed was 5 mm/min.

In order to compare the changes of MOR and SCPG of Chinese fir before and after microwave pretreatment and shellac solution immersion, MOR and SCPG of 12 pairs of samples were determine, and the increase rate of MOR and SCPG were calculated according to Eqs. (1) and (2), respectively. Finally, the average value of

where:

where:

The oven dry weight of samples before and after impregnation with shellac solution was determined and recorded as

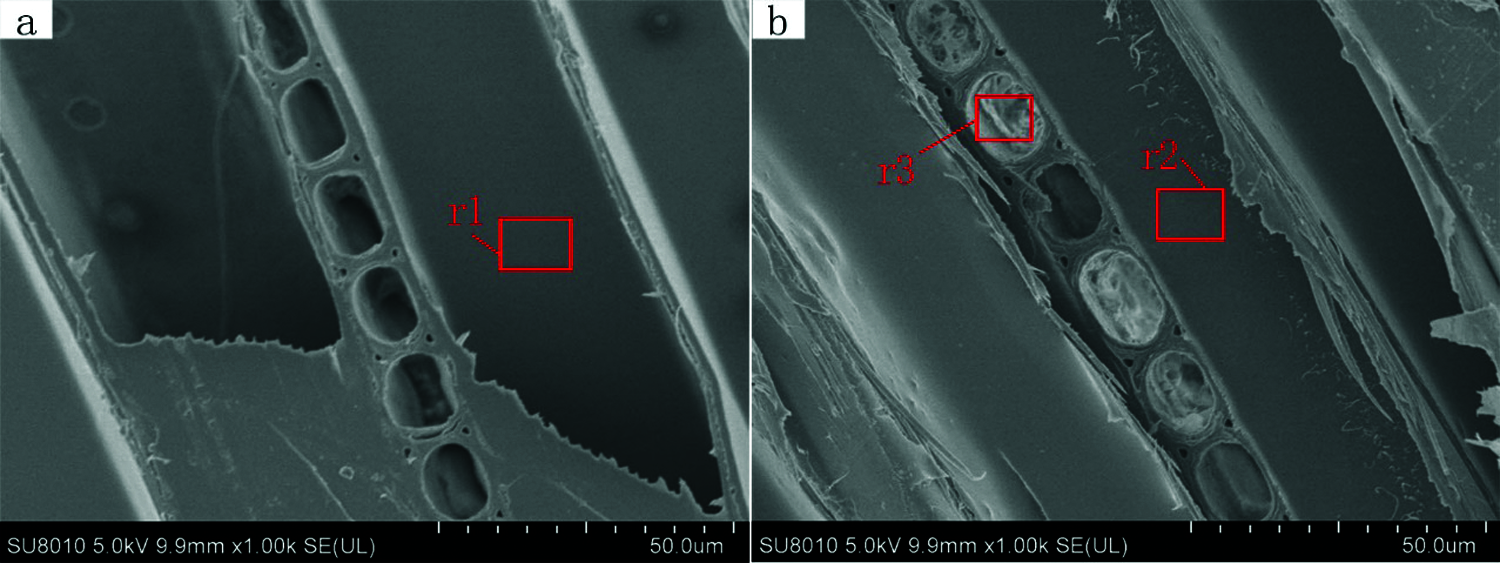

2.7.3 Scanning Electron Microscopy (SEM) and EDS Examination

A small part was sliced from Chinese fir samples and its surface was smoothed and cleaned. After drying for 5 hours in a drying oven at 103 ± 2°C, the specimens were sputter-coated with an ultra-thin Au layer. The microscopic morphology of the specimen surface was observed under a scanning electron microscope (SU8010, Hitachi Corp.) at a maximum voltage of 3.0 kV. In order to analyze the difference in atomic composition of the micro-regions specified under SEM, energy dispersive X-ray spectroscopy (EDS) was scanned at 10.0 kV.

The samples were grounded by a ball mill and passed through a 200 mesh sieve. And the samples were prepared by the KBr compression method. The FTIR spectra of samples were tested by a standard FTIR spectrometer (VERTEX 70, Bruker, Germany) with the resolution of 4 cm−1 in the range of 500–4000 cm−1.

3.1 Analysis of Mechanical Properties

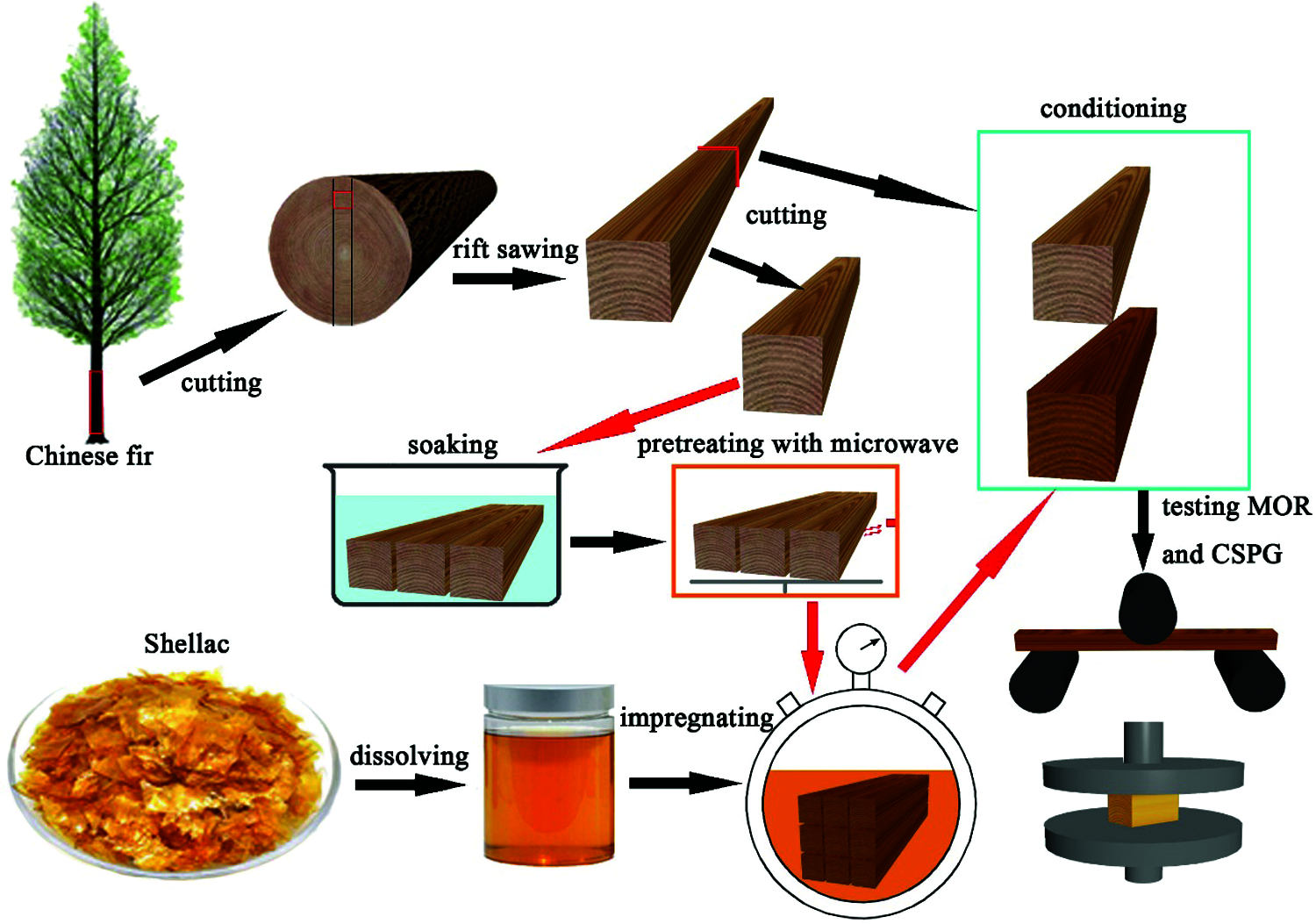

3.1.1 Effect of Moisture Content of the Wood Before Microwave Pretreatment

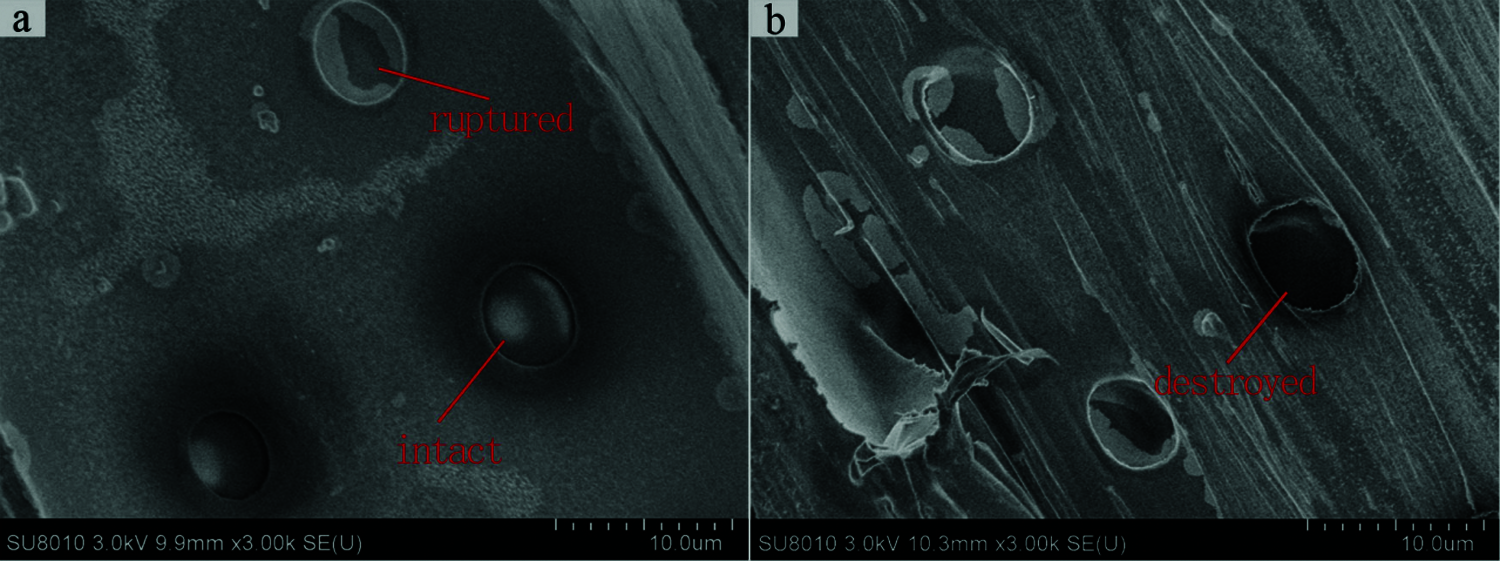

Fig. 2 shows the MOR and SCPG of Chinese fir that was impregnated with or without a solution of shellac to compare the effect of moisture on them before the microwave pretreatment. The MOR of the G1 samples increased by 10.91%, but their SCPG only increased by 1.28%. When the moisture content of wood is lower than the fiber saturation point (about 30%), there is hygroscopic water in the microcapillaries in the cell wall, and the wood cell cavity does not contain free water [17]. Therefore, the steam pressure generated by microwave heating is low, and it was not strong enough to destroy or rupture the pit membranes (Fig. 3a). The shellac solution did not easily enter the interior of the Chinese fir wood; the WGP was small, and the improvement in MOR and SCPG was minimal. In particular, the SCPG only increased by 1.28%.

Figure 2: The strength changes and weight gain percentage of the Chinese fir with different moisture content before microwave pretreatment (a) Increase in the rate of strength (b) Weight gain percentage

Figure 3: Damage of the wood pit membranes after microwave treatment: (a) microwave for 60 s; (b) microwave for 100 s

In the case of G2 samples, the moisture content of wood was close to its fiber saturation point. Although there was no free water in the cell cavity, the hygroscopic water in the cell wall was close to saturation [18]. More pit membranes of tracheids were fragmented by the vapor pressure generated by microwaving. This treatment provided an impregnation channel for the shellac solution and increased the WGP by 25.55% compared with that of the G1 samples. The MOR increased by 14.06%, and the SCPG increased significantly by 18.64%. The

The moisture content of wood in the G3 samples was higher than the fiber saturation point. Water is found in the cell wall in addition to that present hygroscopically. Therefore, there will be a large amount of free water in the cell cavity [19]. When the content of moisture is high, the water in Chinese fir will rapidly vaporize and generate a large amount of steam pressure during the microwave pretreatment, resulting in complete destruction of the pit membranes on cell wall of tracheids (Fig. 3b). This will increase the depth to which the shellac solution can impregnate the Chinese fir and effectively improve its mechanical properties, including the ultimate strength in static bending and SCPG to grain. The WGP of G3 samples increased by 98.90% compared with that of the G2 samples. The MOR and SCPG also improved. The MOR increased by 18.82%; the

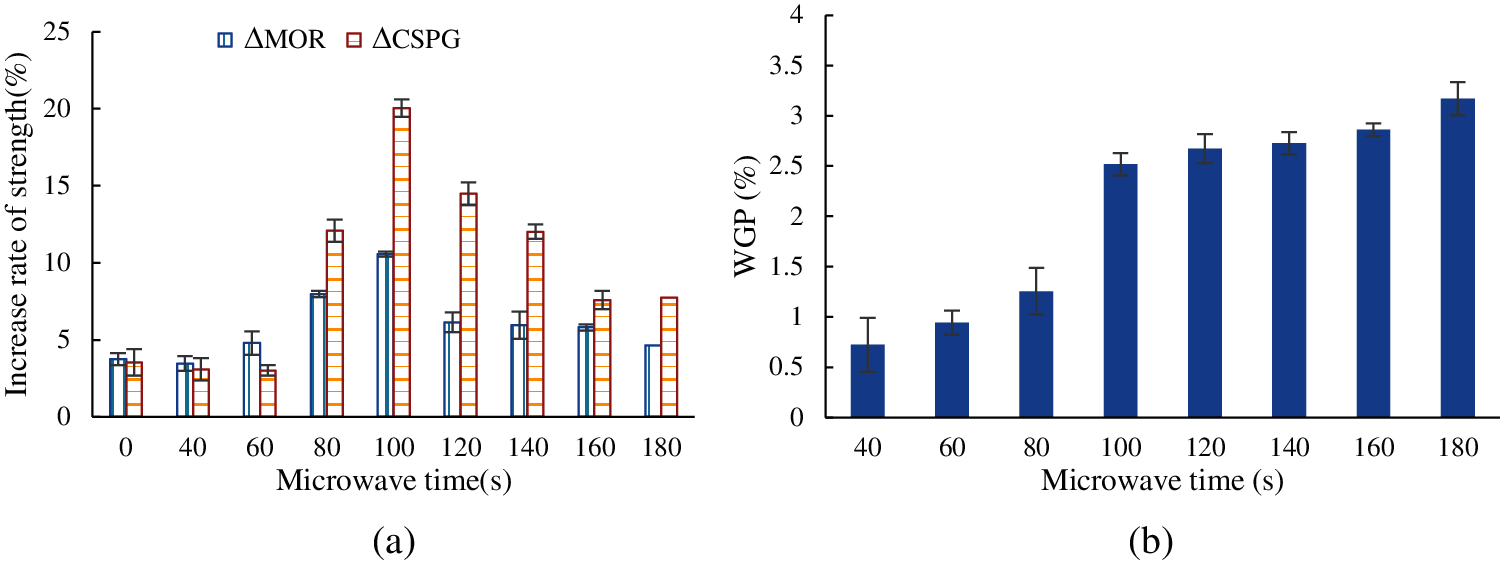

3.1.2 Effect of Microwaving Time under Atmospheric Pressure

After the Chinese fir samples were irradiated with microwaves for different times and impregnated with shellac solution, the changes in their MOR, SCPG are shown in Fig. 4. While the microwave time was short (40–60 seconds), the MOR and SCPG of the Chinese fir did not increase significantly, and both the

Figure 4: The MOR, SCPG and WGP of Chinese fir pretreated by microwaving for different time under air pressure (a) Increase in the rate of strength (b) Weight gain percentage. Note: The item in the figure where the microwave treatment time is 0 indicates the mechanical properties of the Chinese fir samples that had not been pretreated with microwaves before being immersed in the shellac solution

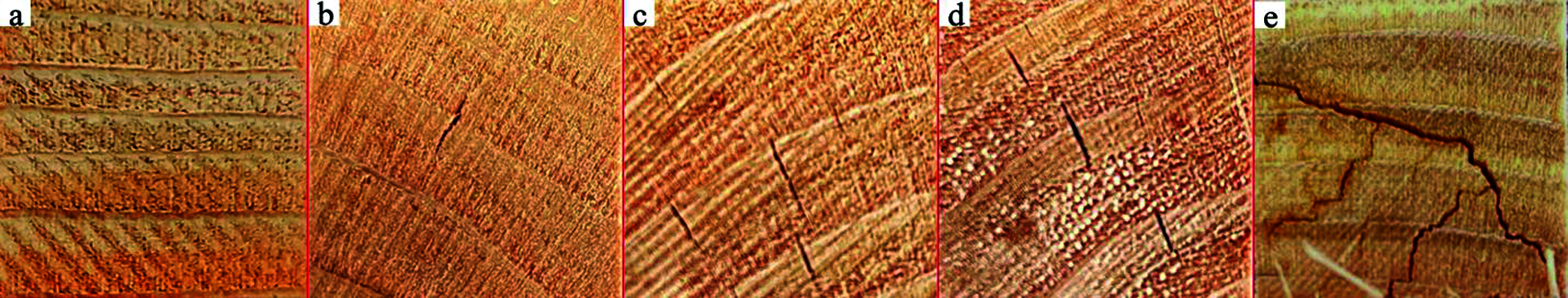

The water in tracheid was not adequately vaporized when the wood was microwaved for a short period of time. In addition, the amount of steam pressure generated was low. Thus, the pit membrane on the cell wall of tracheid could not be destroyed, and the impregnation channel could not be unblocked. Therefore, no increases in the MOR and SCPG of the Chinese fir after impregnation of shellac solution were apparent. With the increase in microwave time, the steam pressure generated by water vaporization effectively destroyed the pit membranes on the cell wall of tracheid. The number of pit membranes destroyed increased, and the effect of impregnation of shellac solution improved substantially. When the samples were microwaved for approximately 100 s, the pit membrane was destroyed, but the cell wall had no obvious damage. As microwave time was extended to > 100 seconds, the pressure generated by water vaporization increased further and damaged the cell wall and even caused cracks (Fig. 5) [20]. After microwave treatment for 120 s, cracks appeared in some of the Chinese fir samples (Fig. 5b). With the extension of the microwave time, the number and size of the cracks increased. In particular, after the wood had been microwaved for 180 s, all the samples had noticeable cracks (Fig. 5e). Although the shellac solution could easily penetrate the Chinese fir through the cracks, its mechanical properties were seriously reduced. As a result, the

Figure 5: Cracking of the sample after microwave treatment: (a) 100 s (b) 120 s (c) 140 s (d) 160 s (e) 180 s

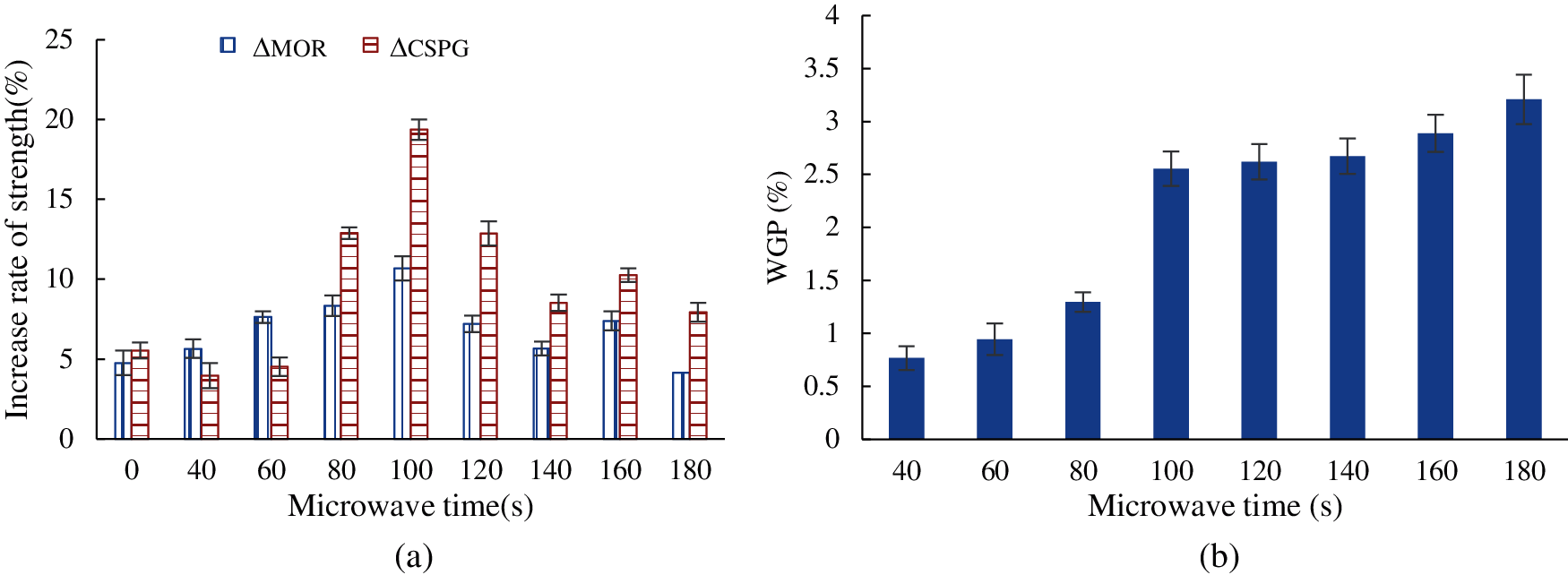

3.1.3 Effect of Microwave Time under Vacuum

After the Chinese fir samples were irradiated with microwaves under vacuum for different periods of time and impregnated with shellac solution, the changes in their MOR, SCPG are shown in Fig. 6.

Figure 6: The improvement of MOR and SCPG of Chinese fir pretreated by microwaves at different times under vacuum (a) Increase in the rate of strength (b) Weight gain percentage

After impregnation with the shellac solution, as the microwave time increased under vacuum, the changes in MOR and SCPG were similar to those of atmospheric microwaving, and the changes in WGP were also similar to that. When the samples were microwaved for 100 seconds,

When the samples were microwaved for a short period of time, although the steam pressure generated by the vaporization of water inside Chinese fir was low, the external environment was a vacuum. Therefore, the difference in pressure between the inside and outside was higher, which helped to destroy more pit membranes and improve the ability of shellac solution to impregnate the wood. However, during the process of reducing pressure with a vacuum pump, the free water inside the wood quickly moved outward, resulting in a decrease in the moisture content inside wood. The vapor pressure generated during the microwave treatment was not as high as that under normal pressure. Therefore, the effect of microwaving and impregnating the wood with a shellac solution did not change significantly.

3.1.4 Effect of the Vacuum Impregnation Time

After microwaving the wood at normal pressure for 100 s and immersing it in the shellac solution under vacuum for 3, 6, 9, 12, 15, 18, 21 or 24 h, the changes in MOR and SCPG of the Chinese fir are shown in Fig. 7. The results indicate that with the extension of the vacuum impregnation time, the MOR and SCPG of the Chinese fir noticeably improved, and the WGP gradually increased. Within 9 h, the increase in

Figure 7: The improvement of MOR and SCPG of Chinese fir with different vacuum impregnation times (a) Increase in the rate of strength (b) Weight gain percentage

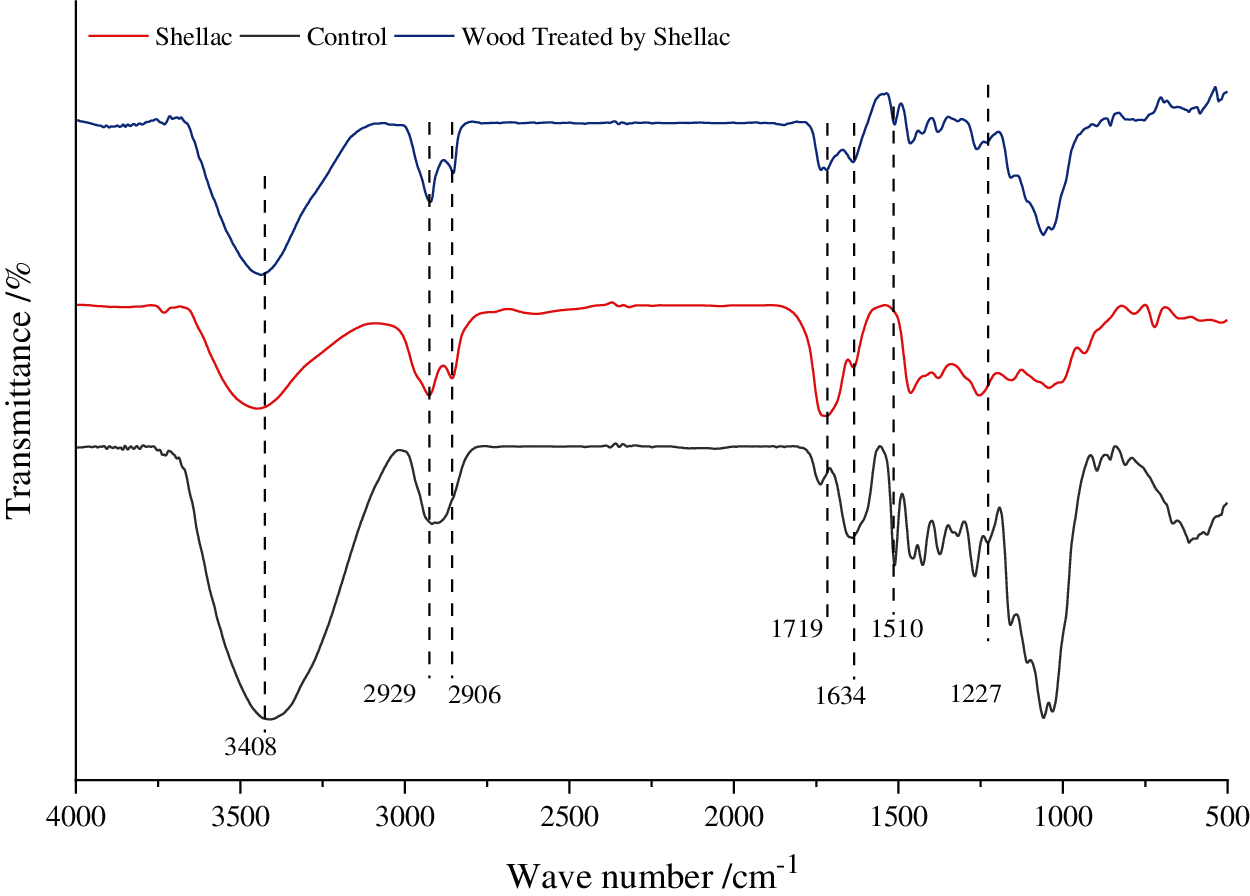

3.2 Analysis Using FTIR Spectroscopy

Fig. 8 presents the FTIR spectra for the impregnated Chinese fir, shellac, and control sample. The main difference between the FTIR spectra of shellac and Chinese fir lies in the three absorption peaks at 2906 cm−1, 1510 cm−1 and 1227 cm−1, which are the alkane C–H stretching vibration absorption peak at 2906 cm−1, the stretching vibration absorption peak of aromatic ring skeleton at 1510 cm−1 and the stretching vibration absorption peak of aromatic ring ether bond at 1227 cm−1, respectively [21,22]. Because the Chinese fir was immersed in a solution of shellac, the FTIR spectrum of the impregnated wood had an additional absorption peak at 2906 cm−1 and an enhanced C–O stretching vibration at 1719 cm−1. The –OH stretching vibration absorption peak at 3408 cm−1, the 1,634 cm−1 C=O stretching vibration absorption peak, the aromatic ring skeleton stretching vibration absorption peak at 1510 cm−1 and the aromatic ring ether bond stretching vibration absorption peak at 1227 cm−1 were all weakened significantly. These results indicate that the immersion of shellac brought in the alkane C–H, and reduced the relative number of –OH and C=O in the wood, while other chemical groups did not change.

Figure 8: FTIR spectra of the wood samples treated by shellac

SEM micrographs of the specimens in the impregnated sample and control sample are presented in Fig. 9. The tracheid cells and ray cells of Chinese fir are clean without any deposits (Fig. 9a). After being impregnated with shellac solution, some shellac was deposited in the microcapillaries, such as the wood ray cell cavity, but there was no obvious deposit in the tracheid cavity (Fig. 9b).

Figure 9: Photograph of wood sample under SEM: (a) control sample (b) wood impregnated with shellac solution

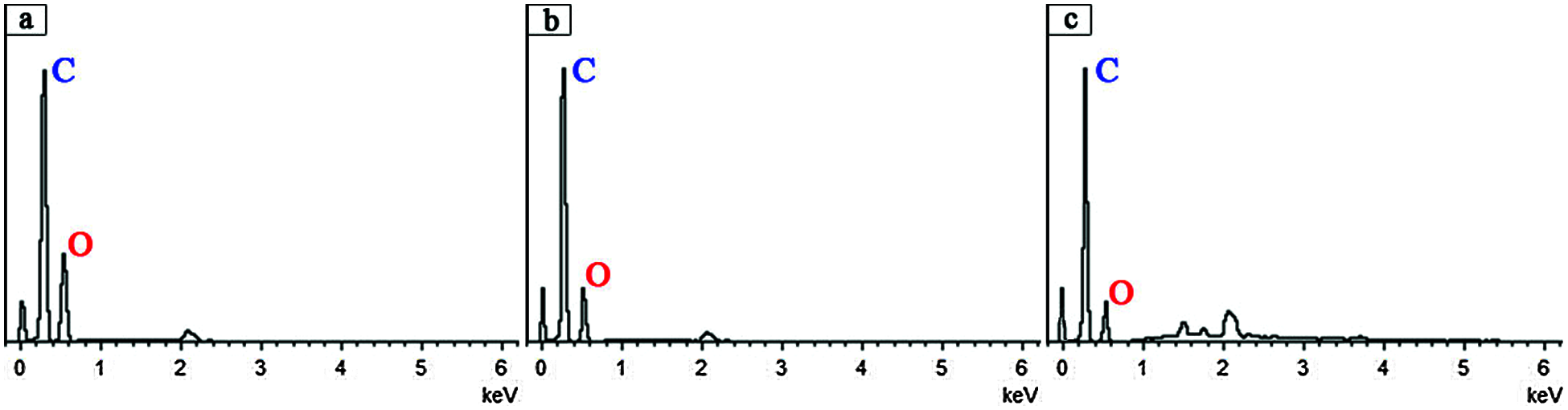

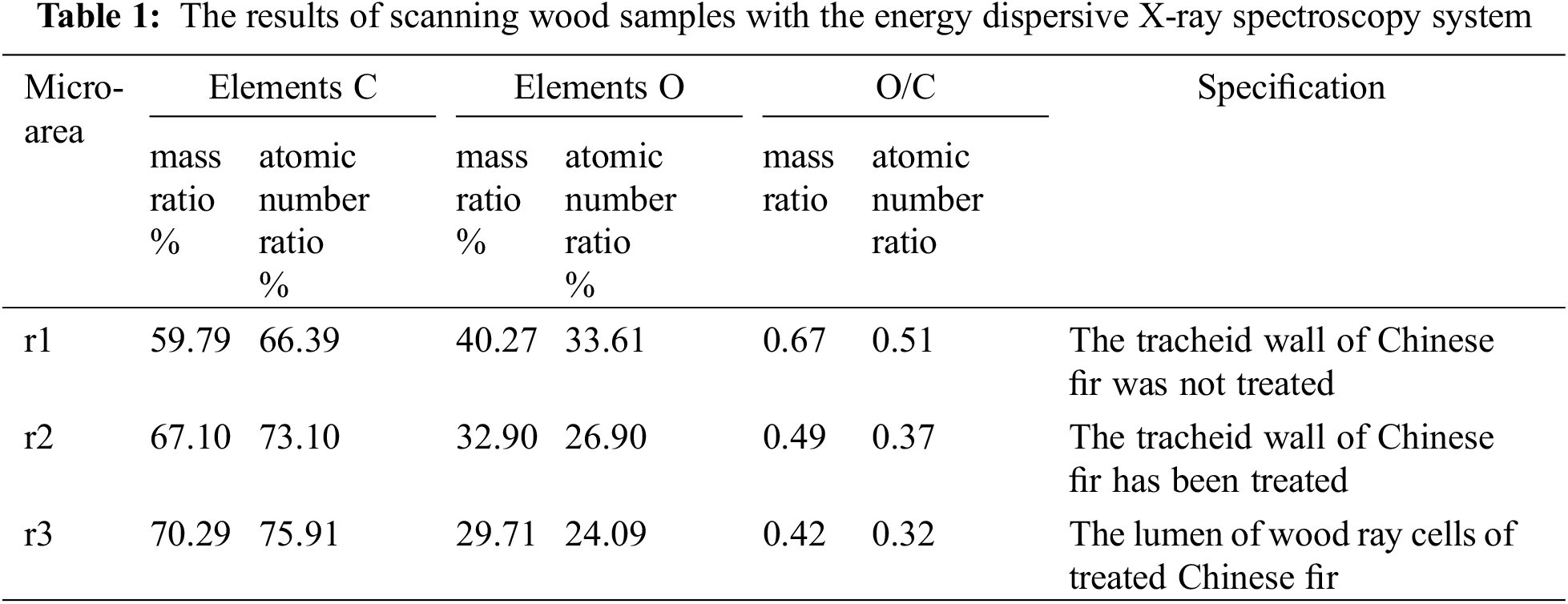

A micro area energy spectrum analysis was conducted using SEM with an energy dispersive X-ray spectroscopy (EDS) system. The tracheid wall of control sample (r1, Fig. 9a), tracheid wall of Chinese fir impregnated with shellac solution (r2, Fig. 9b) and the sediments in wood ray cell cavity (r3, Fig. 9b) were selected for an analysis of their energy spectrum scanning area. The energy dispersive X-ray spectra of three micro-areas are shown as Fig. 10. The main chemical components of wood are organic polymeric substances, such as cellulose, hemicellulose and lignin, which are composed of two elements, C and O.

Figure 10: The energy dispersive X-ray spectroscopy of (a) r1 (b) r2 and (c) r3

The analytical results in Table 1 indicate that the Chinese fir wood impregnated in the shellac solution had C and O as the main chemical components, but the ratio of O and C elements in the wood treated with shellac impregnation changed significantly. The mass fraction of C and O on the tracheid wall of Chinese fir was 59.79% and 40.27%, respectively, and the mass ratio of O/C was 0.67. After impregnation with the shellac solution, the mass fraction of C and O on the tracheid wall was 67.10% and 32.90%, respectively, and the mass ratio of O/C was 0.49. The mass fraction of C and O in the lumen sediments of the wood ray cell cavity was 70.29% and 29.71%, respectively, and the mass ratio of O/C was 0.42. Because shellac is a natural condensate formed by components, such as aleuritic acid and terpenic acid, the elements C, H and O are the main components [10]. Therefore, after impregnation in the shellac solution, the element C on the inner wall of the Chinese fir tracheid increased, and the O/C mass ratio decreased. That indicated that when the shellac entered the large capillaries, such as tracheids, the inner wall surface will be covered with a shellac film that is similar to that of a paint film [11]. Thus, the shellac film cannot be clearly observed under SEM. However, owing to the capillary tension, shellac tends to form plug-like deposits in small capillaries, such as the wood ray cell cavity.

To improve the effect of impregnating Chinese fir with a solution of shellac and enhance its MOR and SCPG, the wood samples were pretreated by microwaving before impregnation. In this study, the effects of four factors, including the moisture content of wood before microwaving, microwave chamber pressure, microwave time and vacuum impregnation time, on the increases of MOR and SCPG were investigated. The results showed that when the moisture content of wood is higher than the fiber saturation point, it is more likely to destroy the pit membranes and unblock the channel of shellac impregnation during the microwave progress, improving the effect of impregnation with shellac solution. When the moisture content of Chinese fir was 50%–60% after microwaving and impregnation, the MOR and SCPG of the Chinese fir increased significantly. The MOR increased by 18.82%, and the SCPG increased by 20.76%. When the samples were microwaved for a short period of time, the vacuum of the microwave chamber improved the effect of impregnation of the shellac solution. However, when the samples were microwaved for a long period of time, the microwave chamber pressure had no significant effect on the infiltration of shellac solution. When the microwave time was 100 s, the increases in the MOR and SCPG of Chinese fir were the most substantial. If the samples were microwaved for a short period of time, the microwave power was not enough to break the pit membranes. In addition, if the samples were microwaved for too long, the wood becomes damaged and cracked by the excessively high vapor pressure, and its mechanical properties were reduced. SEM enabled the observation that after the shellac penetrated the Chinese fir, it spread on the inner wall surface of tracheid to form a shellac film and tended to form plug-like deposits in microcapillaries, such as the wood ray cell cavity, and the result was proven using EDS and FTIR.

Funding Statement: This research was funded by the 2018 Forestry Science and Technology Research Project by Forestry Department of Fujian Province (No. 2018-26), Science and Technology Innovation Special Fund Project of Fujian Agriculture and Forestry University (CXZX2019111S), National Natural Science Foundation of China (31971593, 32071688), the Natural Science Foundation of Fujian Province Department of Science and Technology (2019J01386).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Bu, W. S., Gu, H. J., Zhang, C. C., Zhang, Y., Singh, A. N. et al. (2020). Mixed broadleaved tree species increases soil phosphorus availability but decreases the coniferous tree nutrient concentration in subtropical china. Forests, 11(4), 461. DOI 10.3390/f11040461. [Google Scholar] [CrossRef]

2. Wang, Z., Zhang, X. Q., Chhin, S., Zhang, J. G., Duan, A. G. (2021). Disentangling the effects of stand and climatic variables on forest productivity of Chinese fir plantations in subtropical China using a random forest algorithm. Agricultural and Forest Meteorology, 304–305(11), 108412. DOI 10.1016/j.agrformet.2021.108412. [Google Scholar] [CrossRef]

3. You, R., Zhu, N. H., Deng, X. W., Wang, J., Liu, F. (2021). Variation in wood physical properties and effects of climate for different geographic sources of Chinese fir in subtropical area of China. Scientific Reports, 11(1), 4664. DOI 10.1038/s41598-021-83500-w. [Google Scholar] [CrossRef]

4. Yue, K., Wu, J. H., Xu, L. Q., Tang, Z. Q., Chen, Z. J. et al. (2020). Use impregnation and densification to improve mechanical properties and combustion performance of Chinese fir. Construction and Building Materials, 241(8), 118101. DOI 10.1016/j.conbuildmat.2020.118101. [Google Scholar] [CrossRef]

5. Ma, Q., Zhao, Z. J., Yi, S. L., Wang, T. L. (2016). Modification of fast-growing Chinese Fir wood with unsaturated polyester resin: Impregnation technology and efficiency. Results in Physics, 6(4), 543–548. DOI 10.1016/j.rinp.2016.08.017. [Google Scholar] [CrossRef]

6. Li, P., Zhang, Y., Zuo, Y. F., Lu, J. X., Yuan, G. M. et al. (2020). Comparative study of organic and inorganic modification of chinese fir wood based on the respiratory impregnation method. Journal of Materials Research and Technology, 9(1), 1043–1053. DOI 10.1016/j.jmrt.2019.10.035. [Google Scholar] [CrossRef]

7. Khan, T. A., Gupta, A., Jamari, S. S., Nasir, M., Jang, S. et al. (2020). Synthesis of micro carbonaceous material by pyrolysis of rubber wood and its effect on properties of urea-formaldehyde (UF) resin. International Journal of Adhesion and Adhesives, 99(2), 102589. DOI 10.1016/j.ijadhadh.2020.102589. [Google Scholar] [CrossRef]

8. Wang, F., Liu, J. L., Lyu, W. H. (2019). Effect of boron compounds on properties of Chinese fir wood treated with PMUF resin. Journal of Bioresources and Bioproducts, 4(1), 60–66. DOI 10.21967/jbb.v4i1.182. [Google Scholar] [CrossRef]

9. Zhou, Y., Zhang, Y., Zuo, Y. F., Wu, Y. Q., Yuan, G. M. et al. (2020). Construction of a network structure in Chinese fir wood by Na2SiF6 crosslinked Na2SiO3. Journal of Materials Research and Technology, 9(6), 14190–14199. DOI 10.1016/j.jmrt.2020.10.033. [Google Scholar] [CrossRef]

10. Yuan, Y., He, N., Xue, Q. R., Guo, Q. Y., Dong, L. Y. et al. (2021). Shellac: A promising natural polymer in the food industry. Trends in Food Science & Technology, 109, 139–153. DOI 10.1016/j.tifs.2021.01.031. [Google Scholar] [CrossRef]

11. Bar, H., Bianco-Peled, H. (2021). The unique nanostructure of shellac films. Progress in Organic Coatings, 157, 106328. DOI 10.1016/j.porgcoat.2021.106328. [Google Scholar] [CrossRef]

12. Fu, F., Lin, L., Xu, E. (2017). 4-Functional pretreatments of natural raw materials. In: Fan, M., Fu, F. (Eds.Advanced high strength natural fibre composites in construction, pp. 87–114.Woodhead Publishing. DOI10.1016/B978-0-08-100411-1.00004-2. [Google Scholar] [CrossRef]

13. Xue, Z. H., Xie, Y. H., Zhu, H. Z. (2013). The effect of alkali treatment on wood crystalline structure and micro-structural model. Applied Mechanics and Materials, 423–426, 1339–1343. DOI 10.4028/www.scientific.net/AMM.423-426.1339. [Google Scholar] [CrossRef]

14. Zhao, Y. K., Zhao, X., Iida, I., Guo, J. (2019). Studies on pre-treatment by compression for wood impregnation II: The impregnation of wood compressed at different moisture content conditions. Journal of Wood Science, 65(1), 551. DOI 10.1186/s10086-019-1808-2. [Google Scholar] [CrossRef]

15. Hilton, A., Jeong, M., Hsu, J. H., Cao, F., Choi, W. et al. (2021). Thermal treatment using microwave irradiation for the phytosanitation of Xylella fastidiosa in pecan graftwood. PLoS One, 16(1), e0244758. DOI 10.1371/journal.pone.0244758. [Google Scholar] [CrossRef]

16. He, X., Xiong, X. Y., Xie, J., Li, Y. Y., Wei, Y. Q. et al. (2017). Effect of microwave pretreatment on permeability and drying properties of wood. BioResources, 12(2), 3850–3863. DOI 10.15376/biores.12.2.3850-3863. [Google Scholar] [CrossRef]

17. Almeida, G., Rémond, R., Perré, P. (2018). Hygroscopic behaviour of lignocellulosic materials: Dataset at oscillating relative humidity variations. Journal of Building Engineering, 19(2), 320–333. DOI 10.1016/j.jobe.2018.05.005. [Google Scholar] [CrossRef]

18. Autengruber, M., Lukacevic, M., Füssl, J. (2020). Finite-element-based moisture transport model for wood including free water above the fiber saturation point. International Journal of Heat and Mass Transfer, 161(9), 120228. DOI 10.1016/j.ijheatmasstransfer.2020.120228. [Google Scholar] [CrossRef]

19. Machmudah, S., Wicaksono, D. T., Happy, M., Winardi, S., Wahyudiono et al. (2020). Water removal from wood biomass by liquefied dimethyl ether for enhancing heating value. Energy Reports, 6(4), 824–831. DOI 10.1016/j.egyr.2020.04.006. [Google Scholar] [CrossRef]

20. Hansson, L., Antti, A. L. (2003). The effect of microwave drying on Norway spruce woods strength: A comparison with conventional drying. Journal of Materials Processing Technology, 141(1), 41–50. DOI 10.1016/S0924-0136(02)01102-0. [Google Scholar] [CrossRef]

21. Khairuddin, Pramono, E., Utomo, S. B., Wulandari, V., Zahrotul, W. A. et al. (2016). FTIR studies on the effect of concentration of polyethylene glycol on polimerization of Shellac. Journal of Physics: Conference Series, 776, 012053. DOI 10.1088/1742-6596/776/1/012053. [Google Scholar] [CrossRef]

22. Bar, H., Bianco-Peled, H. (2020). Modification of shellac coating using Jeffamine® for enhanced mechanical properties and stability. Progress in Organic Coatings, 141, 105559. DOI 10.1016/j.porgcoat.2020.105559. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |