| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.019834

ARTICLE

Preparation and Characterization of Sandwich Structured Materials with Interesting Insulation and Fire Resistance

1Yunnan Provincial Key Laboratory of Wood Adhesives and Glued Products, Southwest Forestry University, Kunming, 650224, China

2Department of Polymers and Pigments, National Research Centre, Cairo, 12622, Egypt

*Corresponding Authors: Hisham Essawy. Email: hishamessawy@yahoo.com; Xiaojian Zhou. Email: xiaojianzhou@swfu.edu.cn

#Haizhu Wu and Jinxin Li contributed equally to this work

Received: 19 October 2021; Accepted: 16 November 2021

Abstract: A cellular material in the form of 3-layered sandwich structure material was prepared via sole use of mechanical stirring without any use of a foaming agent, while Tween-80 was employed as a foam stabilizer via a developed in-situ mold casting. The resulting structure displayed a good appearance with no visual defects. The 3-layered composition of the sandwish structure, “nonporous resin layer-porous foam layer-nonporous resin layer”, was examined in terms of the microstructure, density & density distribution, pulverization ratio, mechanical strength, insulation and flame retardant performance. It was indicated from the results that the bonding between the resin layer and foam layer was tight, while the tensile rupture always occurred in the porous layer. Also, the density of the sandwich structure material was symmetrical with “saddle” distribution, and a uniform density for any given layer. The increase in the density at the interface layer provided a good interpretation for the tensile rupture never occurred at the interface. The brittleness resistance of the developed material was significantly improved, and the pulverization ratio was sharply decreased from 9.93% to 0.31%. The material acquired a thermal conductivity and limiting oxygen index (LOI) of 0.0241 W/m ⋅ K and 29.92%, respectively, indicating potential use of such materials broadly in fields of insulation and flame retardancy.

Keywords: Building materials; tannin resin; sandwich structure; insulation; fire resistance

Tannins are extensively abundant in the bast or xylem of wood resources, and they are divided into two main categories: condensed and hydrolyzable [1]. Condensed tannins account for more than 90% of the tannin world production, with an annual production of more than 200,000 tons. This posed a great motivation to replace phenolic compounds with tannins in a wide range of applications [1–6]. Recent studies have conducted successful preparations of tannin resin-based adhesives [7], foam materials [8], abrasion-resistive grinding wheel materials, film materials [9] and impregnated adhesives for papers and fibers [10,11].

Tannin foam was made from tannin and furfuryl alcohol as the main raw materials. The foaming and molding processes have been conducted in presence of a catalyst, a crosslinking agent and a foaming agent [12,13], in which a foam with a black color, uniform pore size and reasonable properties was obtained. The produced foam received a great attention due to its lightweight, excellent thermal insulation, flame retardancy, and agreeable strength [8,14]. Some recent reports showed that tannin-based foams can be realized through “mechanical stirring” process, which gives up the dependence on foaming agent and reduces environmental pollution [15,16].

Similar to phenolic foam, tannin foam has a high pulverization ratio, which prevents its excellent flame retardancy and thermal insulation from being used in the field of building materials. It was reported that the use of a toughening agent can decrease the pulverization ratio of phenolic foam, nevertheless the addition of toughening agent affected its flame retardancy [17]. The slag dropping of tannin foam can be improved by preparing a sandwich structure, but there are still some problems, such as foaming process, cannot be given up from the foaming agent and tedious steps [18,19].

A porous/non-porous foam structure had been prepared via “in-situ one-step” method using tannin resin, which helped fundamentally to solve the foam slagging problem [15]. The current study is dedicated to investigate the impact of in-situ casting on the molding and curing rate of a sandwich structure material comprising 3 layers, namely; “non-porous resin layer, porous foam layer, and non-porous resin layer”.

Liquefaction product of Bayberry bark (Myrica esculenta Buch.-Ham.) was provided by Guangxi Wuming Tannin Extract Factory (China) in the form of 32% solution with about 65%–70% tannin content. Furfuryl alcohol, p-toluenesulfonic acid (p-TSA), formaldehyde and Tween-80 are analytical grade products, purchased from Sinopharm Chemical Reagent Co, Ltd., Shanghai, China. Other equipment used are conventional instruments and equipment in the laboratory. The pouring mold for sandwich structural materials was self-made in the laboratory.

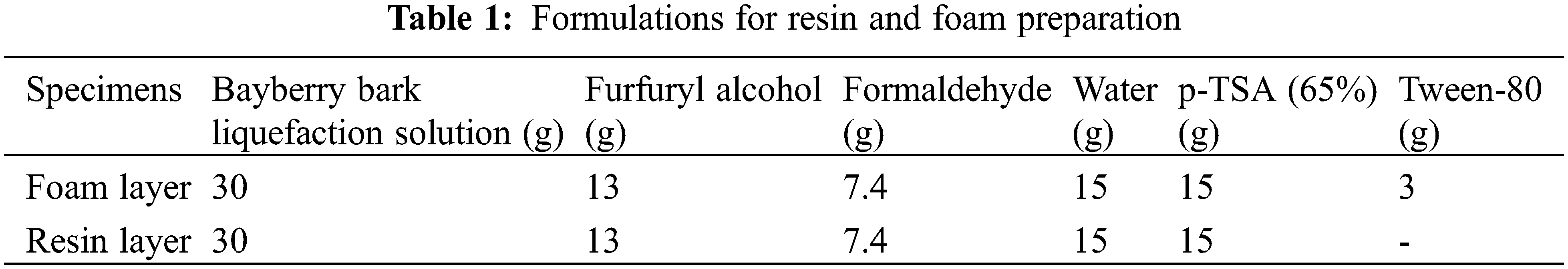

2.2.1 Resin Preparation for Sandwich Structural Materials

The employed formula for resin synthesis is shown in Table 1. Firstly, Bayberry bark liquefaction solution (30 g), furfuryl alcohol (13 g) and water (15 g) were mixed and stirred for 3–5 min using a stirrer at a steady rate of 500 r/min. Then, formaldehyde (7.4 g) as crosslinking agent, and a solution (65% in water) of p-TSA as a catalyst (15 g) were added. Stirring was continued for a while until homogenous mixture of tannin resin was obtained and this was identified as a base for foam preparation.

2.2.2 Foam Preparation of Sandwich Structure Materials

Tween-80 (3 g) was added to the prepared tannin resin as a foam stabilizer and the mixture was stirred vigorously for 8–10 min at a rate of 1000–1500 r/min until the liquid resin solution became wrapped through air admixture and converted completely into a foam. Next, the foam was transferred to an oven for curing at 75°C. This was followed by drying and aging for 10 h and finally the sample was cut and kept aside.

2.2.3 Preparation of Sandwich Structural Materials

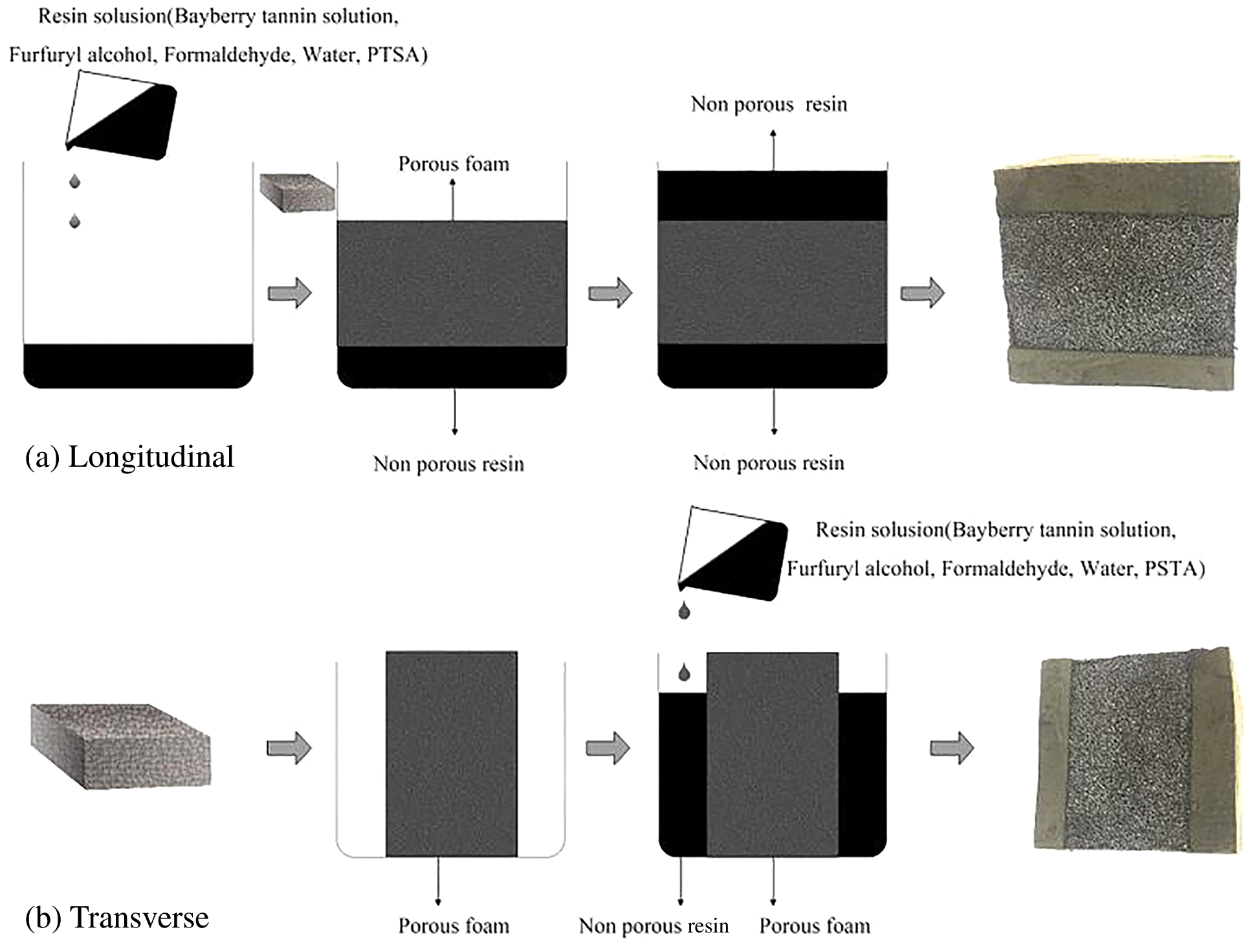

Sandwich structure material is defined as a material that comprises a non-porous resin layer-porous foam layer-non-porous resin layer composite. Two different routes, symbolized as longitudinal and transverse, were adopted in the current study for formation of the sandwich structural materials (as shown in Fig. 1) in order to consider the effect of the non-porous resin layer on the foam layer under pressure during molding and development of the sandwich structure.

Figure 1: Preparation of sandwich structure materials via: (a) longitudinal and; (b) transverse routes

Longitudinal preparation: The tannin resin solution prepared according to Section 2.2.1 was first poured into the bottom of the mold and left for 2 h to pre-cure until the resin solution layer was no longer flowing, then the prepared foam according to Section 2.2.2 was slowly moved to the mold, and then a layer of the tannin resin was poured slowly from the upper part to constitute a top layer. Then, transferred to an oven set at 75°C for curing, drying and aging over 10 h. Finally, a longitudinally sandwich structure material was obtained.

Transverse preparation: Firstly, the porous foam layer prepared in Section 2.2.2 was discharged in the middle of the mold in a vertical manner and fixed with rubber bands. The tannin resin solution prepared in Section 2.2.1 was slowly poured along the inner wall of the mold to the same height as for the foam and left to pre-cure for 2 h at room temperature until the resin solution was no longer flowing, and the formed sandwich structure was transferred to an oven set at 75°C for complete curing and drying, followed by aging for 10 h. Eventually, a transverse sandwich structure material was obtained.

The size of sandwich structure material can be adjusted arbitrarily, and the thickness of the porous foam layer as well as the non-porous resin layer can be controlled by changing the mold dimensions. In order to investigate the experimental effects, the work was also extended to immerse the foam prepared according to Section 2.2.2 into the tannin resin for 30 min to make the tannin resin fully wrapping around the foam material, then removed, and dried to obtain the tannin resin wrapped foam material.

2.3.1 Macro/Micro Structural Analysis

The macroscopic and microscopic properties of the materials were examined using visual observation and photographic imaging as well as scanning electron microscopy (SEM) according to a previous report [13].

2.3.2 Density Measurement of Non-Porous Resin Layer and Porous Foam Layer

The non-porous resin layer and porous foam layer were cut with a sharp knife, and their apparent density was tested by referring to the national standard GB/T 6342-2009 and a well-established method [13]. Further, the density distribution of the sandwich structure material was examined using X-ray profiling densitometer [11] on samples with a size of 50 × 50 × 30 mm3.

The porosity (ø) was calculated from the equation as follows:

where ρb is the bulk density of the cellular foam, and ρs is the skeletal density of the non-porous tannin resin layer.

2.3.4 Pulverization Ratio Test

The pulverization ratio of the material was expressed by the slagging rate, which was tested separately for the porous foam layers and sandwich structure materials as described elsewhere [15].

Mf is pulverization ratio (%), m1 is original mass of the sample (g), m0 is the mass of the sample after test.

The samples were cut into rectangular specimens with dimensions of (80 ± 5) mm × (10 ± 5) mm × (10 ± 5) mm, and their oxygen index was determined according to the method of national standard GB/T 2406.2-2009, and the average value was used as the limiting oxygen index (LOI) to measure the flame retardant performance of the material after testing a minimum of 10 specimens for each group. The combustion test was then performed according to the method mentioned in reference [20].

The sandwich structure material was made into a cubic piece of 50 mm × 50 mm × 50 mm, in which the overall thickness of the non-porous resin layer and the porous foam layer in the longitudinal direction was 50 mm = 10 mm + 30 mm + 10 mm, and the test performed by referring to reference [15].

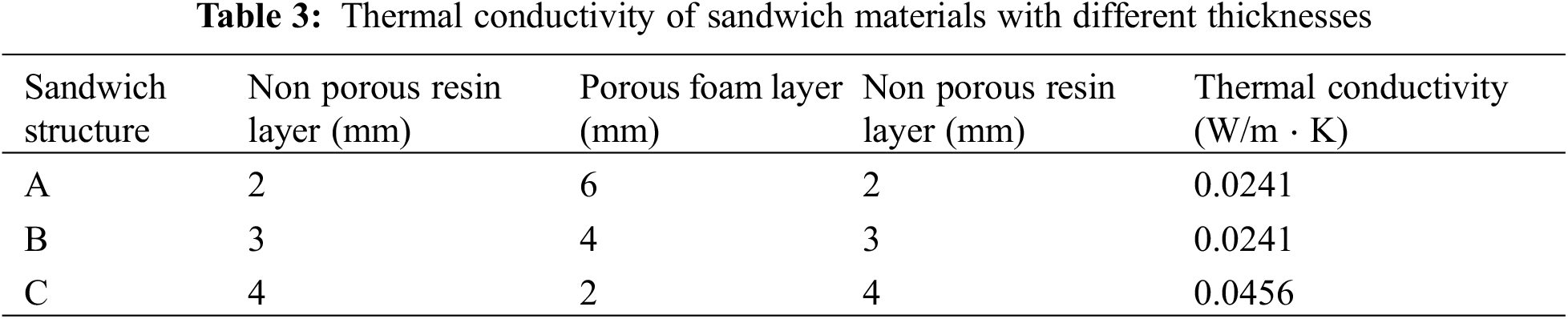

2.3.7 Evaluation of Thermal Insulation

The thermal insulation performance of the sandwich structural materials was evaluated by measuring the thermal conductivity following the method presented in reference [15]. In order to distinguish the influence of the thickness ratio of the nonporous resin layer and the porous foam layer on the thermal insulation performance of the material, three groups of porous foam layers and non-porous resin layers with different thickness ratios were prepared for the thermal conductivity test, while the total thickness of the sandwich structure material was fixed at 10 mm. Details on the thickness of each layer can be shown in Table 3.

3.1 Macro/Micro Structural Analysis

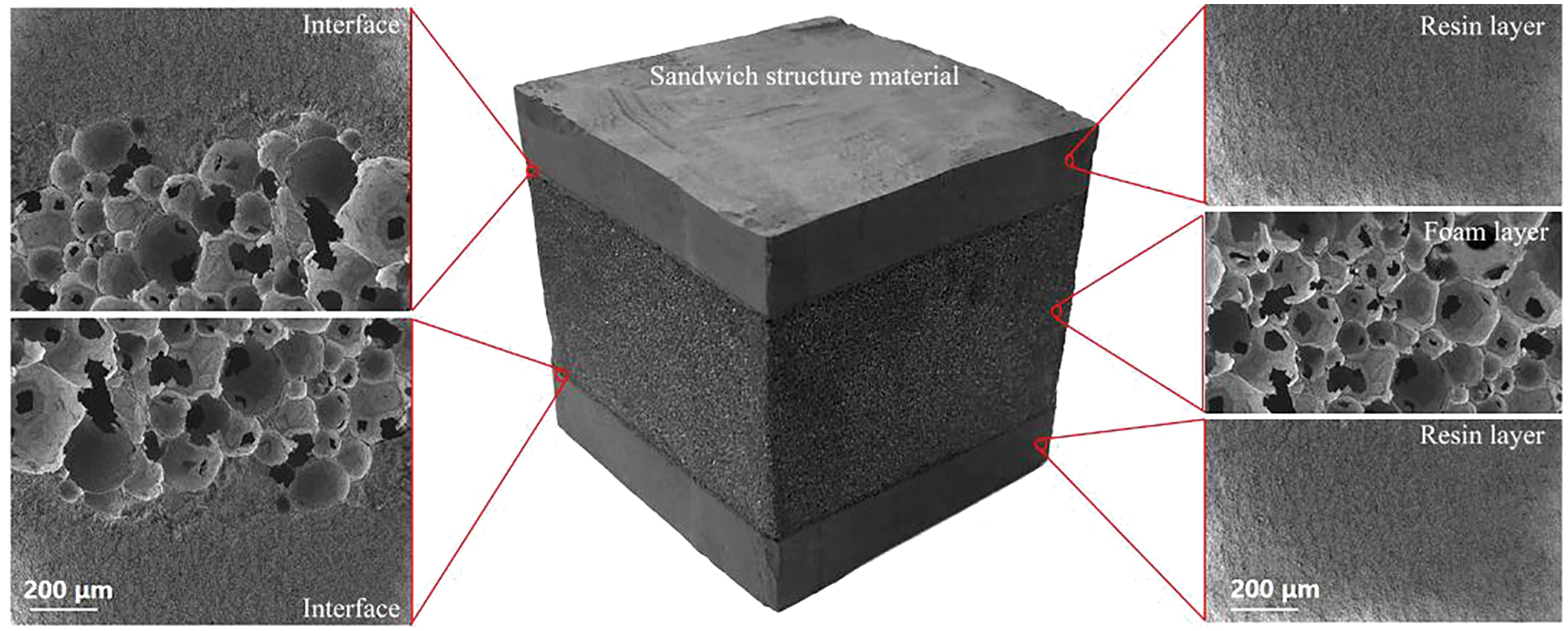

A preliminary visual check did not indicate any significant difference between the sandwich structural materials prepared either longitudinally or transversely (check the right side images in Fig. 1). Therefore, the transversely prepared sandwich structure materials will be addressed as shown in Fig. 2. The structure has a clear, smooth surface with clear visual perception of two non-porous resin layers (upper and lower surfaces) and a porous foam layer (core layer). The SEM images on the right side of Fig. 2 exposed clearly that the resin and foam layers were significantly different. The porous foam layer had uniform pore size with domination of closed cells, whilst the nonporous resin layers were absolutely flat without any holes that could be found. It is apparent from the left diagram of Fig. 2 that the interface between the non-porous resin layer and the porous foam layer is intact with a tight connection. Further, a gradual transition from the non-porous layer to the porous one is noticed and this will be more correlated in next sections by means of profile density measurements as well as evaluation of mechanical properties.

Figure 2: Sandwich structure material

3.2 Density, Profile Density and Porosity

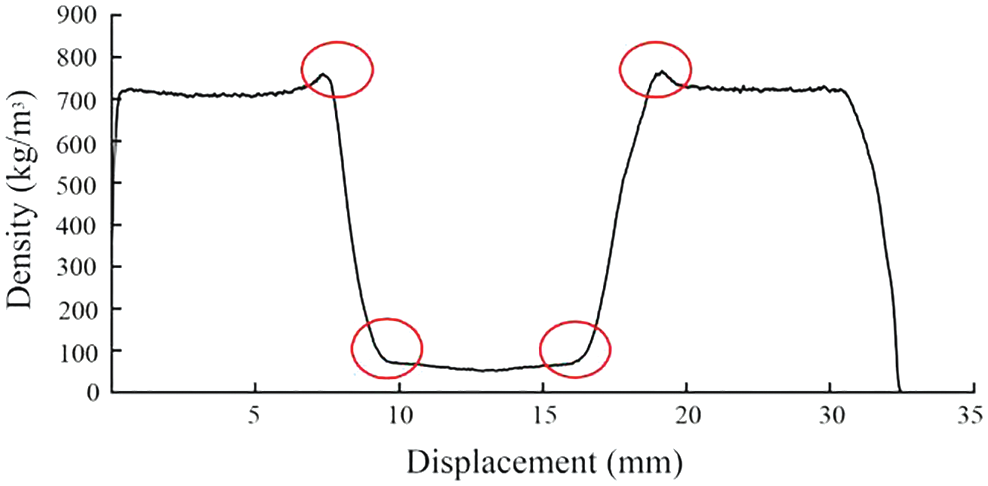

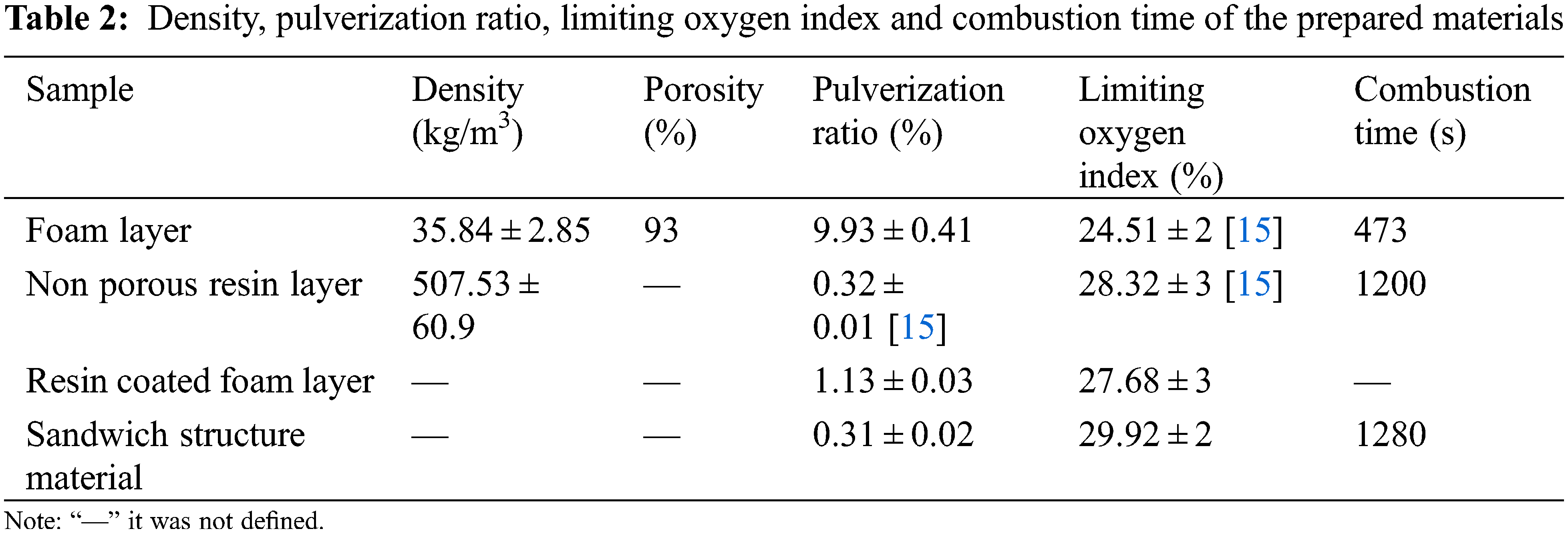

Table 2 displays the apparent density of the porous foam layer and the non-porous resin layer, which are about 36 and 761 kg/m3, respectively. This large difference in the density may reflect a supposition for a large difference in the properties of both layers. From the profile density curve of the sandwich structure material (Fig. 3), a steady, gradual transition can be realized at the interface where the non-porous resin layer and the porous foam layer are bonded (marked by a red circle in the figure). The density distribution curve is symmetrical “saddle” type. It is relatively uniform either for the non-porous resin layer or the porous foam layer, which signifies that the profile density curve of each layer was straight. The slightly elevated density at two points in the transition zone between the porous foam layer and the nonporous resin layer was due to the formation of resin buildup at the interface layers of the porous foam after the resin interpenetration into the foam voids under the penetration pressure. This can rationalize the density increases in this region. It is thereby assumed that the increased density at the interfacial layer would result in a significant upgrading of the adhesion strength of the material, which had been confirmed in similar previous studies [11] and absence of any damage at the interface layer following tensile strength testing as will be shown in Section 3.5. There was no significant difference in the density and its distribution between the longitudinally and transversely prepared sandwich structures. The average porosity for the cellular foam was 93% and this porosity range is lower than that of other similar foams [8] which have been explained in our previous work [15]. In current work, more water was added, thus lower density was obtained, leading to a higher porosity because of the water influence.

Figure 3: Profile density curve of the sandwich structure material

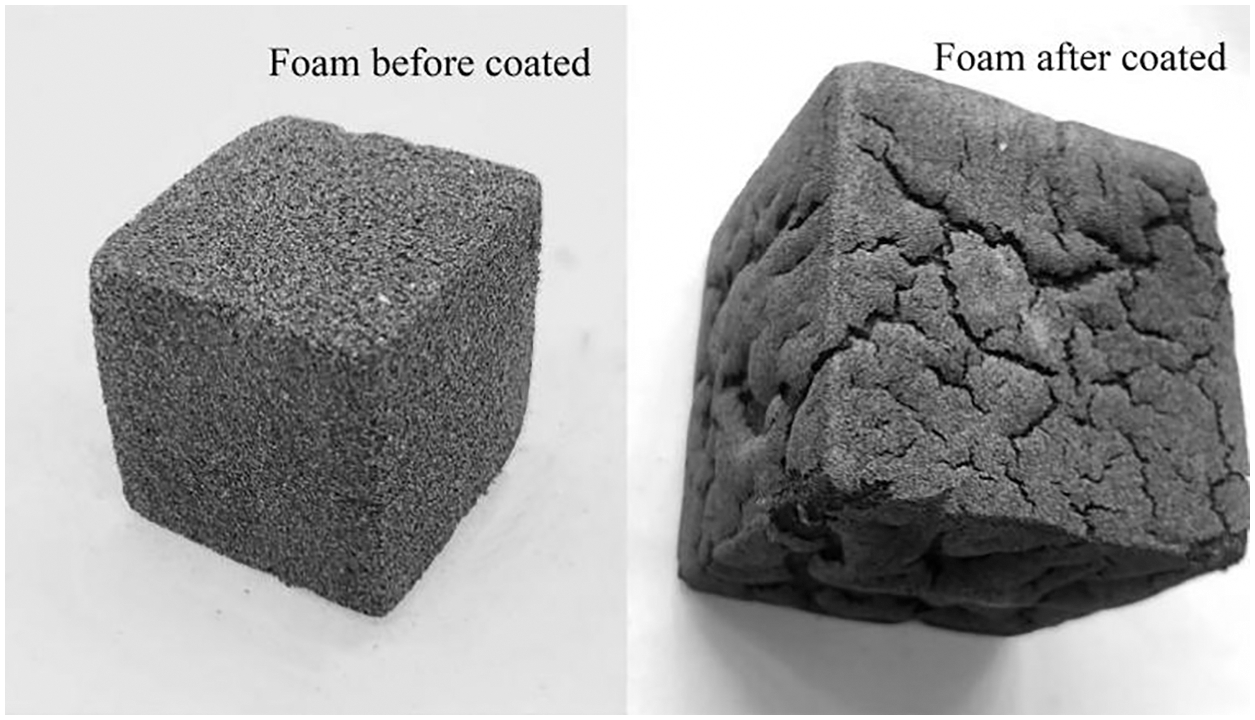

A high pulverization ratio was found to render this material very brittle, and easy to slag even with touch or contact, leading to difficulty of its application. Therefore, it was extremely necessary to reduce the pulverization ratio of the material. This was considered firstly by coating with a thin layer of tannin resin by impregnation process (as prepared in Section 2.2.1) so that the foam material was wrapped by the resin. This strategy proceeded well and the degree of pulverization of the foam was greatly improved. Thus, a pronounced decrease in the pulverization ratio from 9.93% to 1.13% was encountered (Table 2). However, with the elapse of time, the encapsulated foam material by the tannin resin showed cracking due to the stress distribution unbalance between the porous foam layer and non-porous resin layer, which affect the aesthetics and application fatally (Fig. 4).

Figure 4: Macroscopic contrast images of the foam before and after coating with resin

It was concluded that the degree of pulverization was mainly influenced by the surface material. When the thickness of the resin layer was further increased whereas the sandwich structure material was prepared using the in-situ casting method, the cracking problem could be disappeared because of stress balance. Interestingly, when the pulverization ratio was further reduced to 0.31%, the pulverization and slagging shortcomings were improved entirely and the limitations of the material were solved. A comparison between the sandwich structural materials derived from both the longitudinal and transverse routes did not show any significant difference in the degree of pulverization.

Table 2 shows that the wrapping strategy of the foam material by the tannin resin (sandwich structure material) can effectively improve the flame retardant properties of the foam material and slow down the burning rate of the material. In particular, the limiting oxygen index of the sandwich structure material reached 29.92% (>27%, that is required for classification as flame retardant material). Thus, the developed sandwich structure can be categorized as a refractory material with excellent flame retardant action. Moreover, it has the same flame retardant performance as for the tannin/furanic resin-based foam, prepared using ether as a foaming agent [8,12].

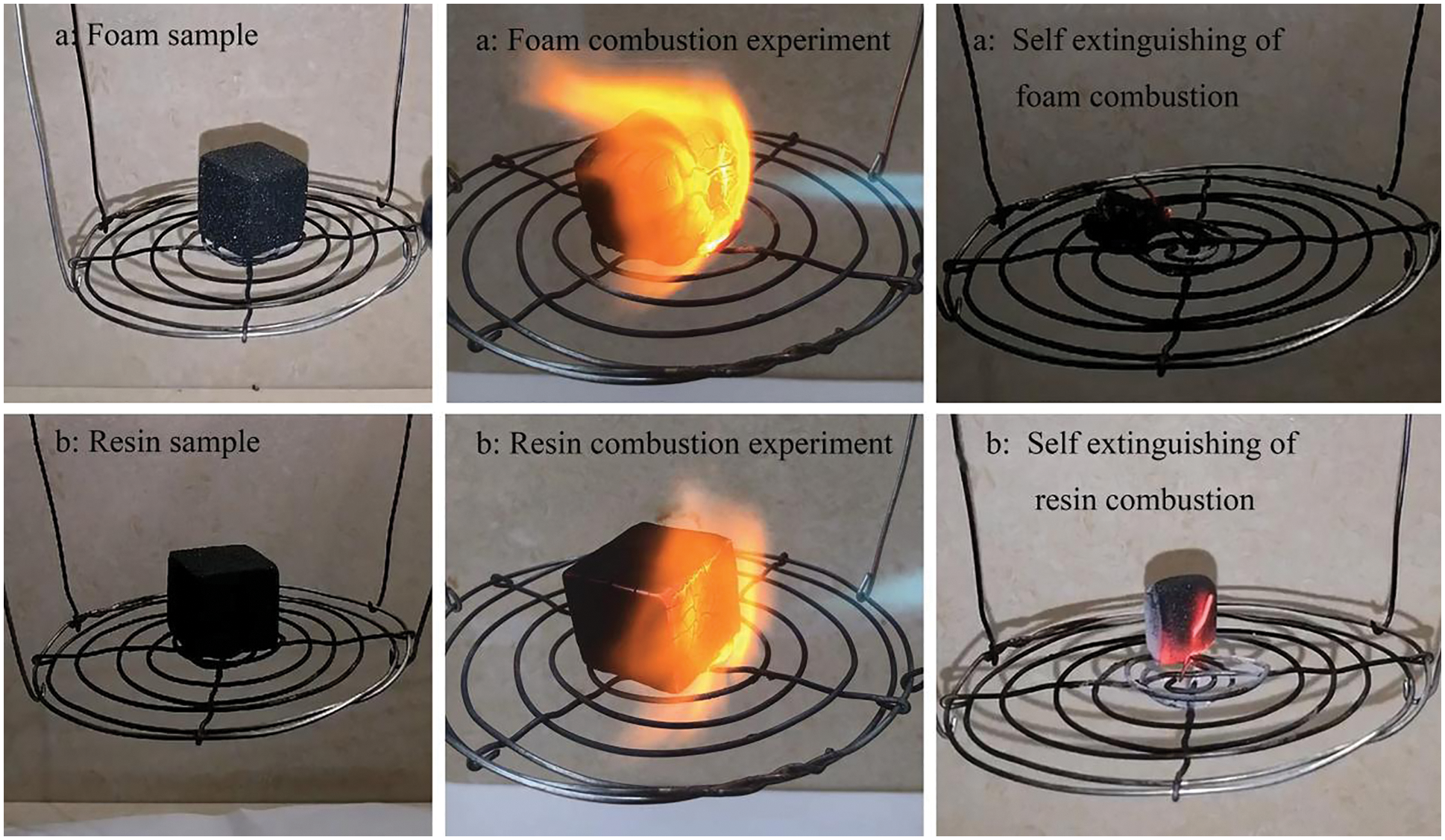

The experiments were conducted simultaneously using a Bunsen burner to record the burning time and evaluate the fire resistance of the samples (Fig. 5). As can be demonstrated from Table 2, the sample needed 473 s for the porous foam to burn completely (counted from the beginning of ignition), whilst 1200 s for the non-porous resin layer to burn completely. It is worthy to mention that neither burning drips nor odor were produced during the combustion process. In addition, both the porous foam material and the non-porous resin material could be burned out, with only very tiny amount of ash remained. The interesting fire resistance of the sandwich structure material can be accounted for by the covering of the intermediary porous layer with resin layers. The additional advantage that was also observed both the porous foam and non-porous resin materials showed “self-extinguishing” deposition in few seconds when they were moved away from the Bunsen burner during the fire process.

Figure 5: Ignition and combustion experiments of porous foam and non-porous resin

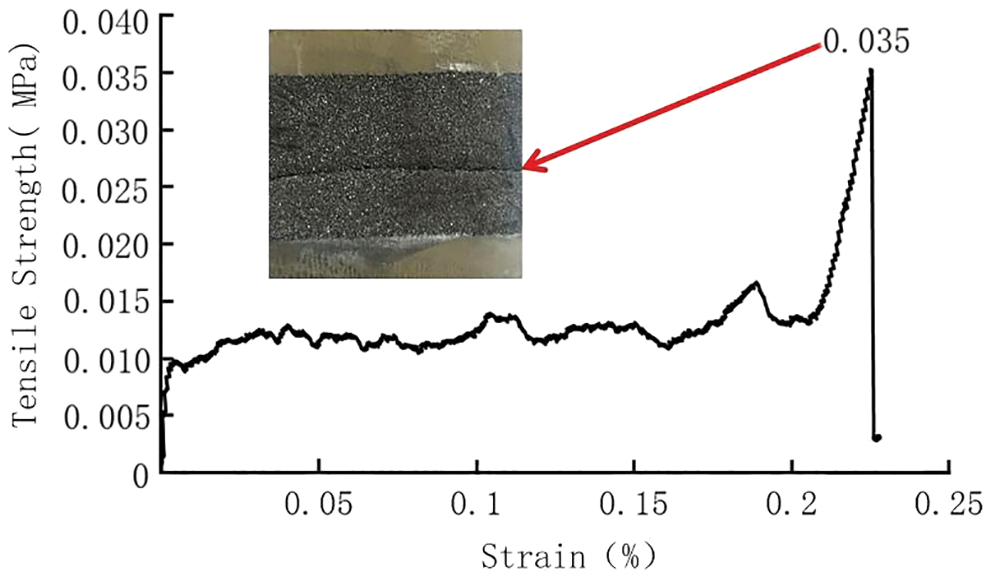

The stress-strain profile of the sandwich structure material is depicted in Fig. 6. The stress at rupture occurred at 0.035 MPa for a foam density of 35.8 kg/m3, which is consistent with the profile density data in Section 3.2, indicating that the non-porous resin layer acted as would have been glued after casting and bonded firmly with the porous foam layer yielding an interface that is much stronger compared with internal bond strength of the foam layer [15]. Consequently, it was found that the weakest part of the sandwich structure material, either prepared by the longitudinal or transverse casting approach, always located at the porous foam layer and never appeared in the non-porous resin layer or at the interface, so it is the foam layer that influences the tensile strength of the sandwich structure material.

Figure 6: Stress-strain curve of the sandwich structure material

3.6 Thermal Insulation Performance

The thermal conductivity of a material can directly reflect to which extent its potential application as thermal insulator. It was presented in one of our previous work that the overall thermal insulation of a similarly prepared foam structure was not affected by other factors given that the thickness of the porous foam layer was greater than 4 mm [15]. It was implied from previous studies that the tannin foam had very low thermal conductivity and thus can be considered as an excellent thermal insulator, while the resin material although exhibited slightly higher thermal conductivity, but still in an ideal range. Despite that, it still possessed some advantages compared to other building materials used for insulation [15]. Likewise, Table 3 shows that for the current work. When the thickness of the porous foam layer of the sandwich structure material was 6 mm (Sample A) or 4 mm (Sample B), the thermal conductivity of material did not deviate from 0.0241 W/m · K, whereas it is realized that thermal conductivity of the sandwich structure material increased to 0.0456 W/m · K when the thickness of the porous foam layer was reduced to 2 mm (Sample C) and would present an adverse effect on the applicability as thermal insulation insulator. The thermal conductivity of the sandwich structure material prepared longitudinally was no different from that of transverse structure, and their thermal insulation was equivalent.

A 3-layered sandwich structure comprising “non-porous resin-porous foam–non-porous resin” layers can be prepared by a developed molding approach via in-situ casting method with the use of Tween-80 as foam stabilizer. The molding can be accomplished either transversely or longitudinally, where no difference could be found between them in terms of the mechanical, thermal insulation, flame retardancy, density distribution, and pulverization properties. However, the transverse option is much easier from the preparation point of view. Beside the good appearance and absence of defects, the adhesion between the layers at the interface was significantly higher than the internal bond strength of the foam layer, and consequently the tensile failure occurred always in the porous foam layer. A symmetric “saddle” type distribution was found for the density of the sandwich structure material with a uniform distribution for a given layer, whereas there was a bump at the transition zone between the non-porous resin layer and porous foam layer interface, due to the density increase, which provides a reasonable explanation for the enhancement of strength. The new developed approach can also contribute very efficiently to solve the traditional problems of foam materials such as brittleness and facile slag dropping. As such, this is correlated with the drop in pulverization ratio from 9.93% to 0.31% for such sandwich structure materials. Furthermore, maintaining a thickness not less than 4 mm for porous foam layer can ensure a thermal conductivity as low as 0.0241 W/m · K for the material. An ultimate oxygen index of 29.92% was acquired by the prepared sandwich structure material with self-extinguishing character, which rendered these materials a strong candidate for expanded applications requiring flame retardancy and as thermal insulators.

Funding Statement: This work was supported by National Natural Science Foundation of China (NSFC 31760187, 31971595), Yunnan Provincial Natural Science Foundation (2017FB060), the “Ten-thousand Program”–Youth Talent Support Program and Yunnan Provincial Reserve Talents for Middle & Young Academic and Technical Leaders (2019HB026), and the 111 Project (D21027).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Pizzi, A. (2019). Tannins: Prospectives and actual industrial applications. Biomolecules, 9(8), 344. DOI 10.3390/biom9080344. [Google Scholar] [CrossRef]

2. Tondi, G., Wieland, S., Wimmer, T., Thevenon, M. F., Pizzi, A. et al. (2012). Tannin-boron preservatives for wood buildings: Mechanical and fire properties. European Journal of Wood and Wood Products, 120(5), 689–696. DOI 10.1007/s00107-012-0603-1. [Google Scholar] [CrossRef]

3. Tondi, G., Johansson, M., Leijonmarck, S., Trey, S. (2015). Tannin based foams modified to be semi-conductive: Synthesis and characterization. Progress in Organic Coatings, 78, 488–493. DOI 10.1016/j.porgcoat.2014.06.013. [Google Scholar] [CrossRef]

4. Tondi, G., Oo, C. W., Pizzi, A., Trosa, A., Thevenon, M. F. (2009). Metal adsorption of tannin based rigid foams. Industrial Crops & Products, 29(2–3), 336–340. DOI 10.1016/j.indcrop.2008.06.006. [Google Scholar] [CrossRef]

5. Lagel, M. C., Hai, L., Pizzi, A., Basso, M. C., Delmotte, L. et al. (2016). Automotive brake pads made with a bioresin matrix. Industrial Crops & Products, 85, 372–381. DOI 10.1016/j.indcrop.2015.12.090. [Google Scholar] [CrossRef]

6. Li, X., Pizzi, A., Cangemi, M., Navarrete, P., Segovia, C. et al. (2012). Insulation rigid and elastic foams based on albumin. Industrial Crops & Products, 37(1), 149–154. DOI 10.1016/j.indcrop.2011.11.030. [Google Scholar] [CrossRef]

7. Comyn, J. (1985). Wood adhesives: Chemistry and Technology: Edited by: A. Pizzi Marcel Dekker Incorporated, 1984 (SFr 174). Elsevier, USA. [Google Scholar]

8. Pizzi, A. (2019). Tannin-based biofoams–A review. Journal of Renewable Materials, 7(5), 477–492. DOI 10.32604/jrm.2019.06511. [Google Scholar] [CrossRef]

9. Liao, J., Li, J., Wang, H., Zhu, Y., Essawy, H. et al. (2022). Development of antioxidant packaging film based on Chinese bayberry tannin extract and polyvinyl alcohol. Journal of Renewable Materials, 10(1), 19–31. DOI 10.32604/jrm.2021.016152. [Google Scholar] [CrossRef]

10. Abdullah, U. H., Pizzi, A., Rode, K., Delmotte, L., Zhou, X. et al. (2013). Mimosa tannin resins for impregnated paper overlays. European Journal of Wood and Wood Products, 71(2), 153–162. DOI 10.1007/s00107-012-0652-5. [Google Scholar] [CrossRef]

11. Zhou, X., Segovia, C., Abdullah, U. H., Pizzi, A., Du, G. (2017). A novel fiber-veneer-laminated composite based on tannin resin. The Journal of Adhesion, 93(6), 461–467. DOI 10.1080/00218464.2015.1084233. [Google Scholar] [CrossRef]

12. Tondi, G., Pizzi, A. (2009). Tannin-based rigid foams: Characterization and modification. Industrial Crops & Products, 29(2–3), 356–363. DOI 10.1016/j.indcrop.2008.07.003. [Google Scholar] [CrossRef]

13. Zhao, W., Fierro, V., Pizzi, A., Du, G., Celzard, A. (2010). Effect of composition and processing parameters on the characteristics of tannin-based rigid foams. Part II: Physical Properties. Materials Chemistry & Physics, 123(1), 210–217. DOI 10.1016/j.matchemphys.2010.03.084. [Google Scholar] [CrossRef]

14. Chen, X., Li, J., Pizzi, A., Fredon, E., Gerardin, C. et al. (2021). Tannin-furanic foams modified by soybean protein isolate (SPI) and industrial lignin substituting formaldehyde addition. Industrial Crops & Products, 168, 113607. DOI 10.1016/J.indcrop.2021.113607. [Google Scholar] [CrossRef]

15. Li, J., Liao, J., Essawy, H., Zhang, J., Zhou, X. (2021). Preparation and characterization of novel cellular/nonporous foam structures derived from tannin furanic resin. Industrial Crops and Products, 162(1), 113–264. DOI 10.1016/J.indcrop.2021.113264. [Google Scholar] [CrossRef]

16. Li, J., Liao, J., Zhang, J., Zhou, X., Du, G. (2020). Effect of post-added water amount on pre-concentrated bark foaming materials by mechanical stirring. Journal of Renewable Materials, 8(12), 1607–1616. DOI 10.32604/jrm.2020.013976. [Google Scholar] [CrossRef]

17. Hu, X. M., Wang, D. M., Cheng, W. M., Zhou, G. (2014). Effect of polyethylene glycol on the mechanical property, microstructure, thermal stability, and flame resistance of phenol–urea–formaldehyde foams. Journal of Materials Science, 49(4), 1556–1565. DOI 10.1007/s10853-013-7838-z. [Google Scholar] [CrossRef]

18. Tondi, G., Pizzi, A., Olives, R. (2008). Natural tannin-based rigid foams as insulation for doors and wall panels. Maderas Ciencia Y Tecnología, 10(3), 219–227. DOI 10.4067/S0718-221X2008000300005. [Google Scholar] [CrossRef]

19. Rangel, G., Chapuis, H., Basso, M. C., Pizzi, A., Gerardin-Charbonnier, C. (2016). Improving water repellence and friability of tannin-furanic foams by oil-grafted flavonoid tannins. Bioresources, 11(3), 7754–7768. DOI 10.15376/biores.11.3.7754-7768. [Google Scholar] [CrossRef]

20. Xi, X., Pizzi, A., Gerardin, C., Lei, H., Amirou, S. (2019). Preparation and evaluation of glucose based non-isocyanate polyurethane self-blowing rigid foams. Polymers, 11(11), 1802. DOI 10.3390/polym11111802. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |