| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.019726

ARTICLE

Evaluating Simultaneous Impact of Slag and Tire Rubber Powder on Mechanical Characteristics and Durability of Concrete

1Department of Civil Engineering, Science and Research Branch, Islamic Azad University, Tehran, Iran

2Structural and Earthquake Research Center (SERC), Amirkabir University of Technology (Tehran Polytechnic), Tehran, Iran

3Department of Civil Engineering, Monash University, Melbourne, Australia

*Corresponding Author: Farzad Hatami. Email: Hatami@aut.ac.ir

Received: 11 October 2021; Accepted: 01 December 2021

Abstract: In this experimental study, the impact of Portland cement replacement by ground granulated blast furnace slag (GGBFS) and micronized rubber powder (MRP) on the compressive, flexural, tensile strengths, and rapid chloride migration test (RCMT) of concrete were assessed. In this study, samples with different binder content and water to binder ratios, including the MRP with the substitution levels of 0%, 2.5% and 5%, and the GGBFS with the substitution ratios of 0%, 20% and 40% by weight of Portland cement were made. According to the results, in the samples containing slag and rubber powder in the early ages, on average, a 12.2% decrease in the mechanical characteristics of concrete was observed, nonetheless with raising the age of the samples, the impact of slag on reducing the porosity of concrete lowered the negative impact of rubber powder. Regarding durability characteristics, the RCMT results of the samples were enhanced by using rubber powder because of its insulation impact. Moreover, adding slag into the MRP-included mixtures results in a 23% reduction in the migration rate of the chloride ion averagely. At last, four mathematical statements were derived for the mechanical and durability of concrete containing the MRP and GGBFS utilizing the genetic programming method.

Keywords: Micronized rubber powder; ground granulated blast furnace slag; waste materials; mechanical properties; durability

Nowadays, sustainable development is highly valued in construction projects. One of the most significant factors contributing to this criterion is the use of substitutes for Portland cement. Cement production requires a high amount of energy and contributes significantly to higher environmental pollution and the emission of greenhouse gases. A reduction in cement consumption is recommended as a solution to protect the environment. Incorporating ground granulated blast furnace slag (GGBFS) and micronized rubber powder (MRP) as waste materials in concrete mixtures not only eliminate the negative repercussions of the burial of such hazardous industrial wastes but also, there will be lower greenhouse gases produced as a result of lower cement production [1].

Ground granulated blast furnace slag is one of the by-products of the steel plant that does not react if water is added to it. Unlike pozzolans, which react with and consume calcium hydroxide from cement hydration, they use calcium hydroxide only as a catalyst and have a cement-like reaction in the presence of water. GGBFS is often delivered in crystalline shape and is used as coarse aggregate in road construction. The other utilization of slag is within the generation of slag wool for isolating purposes within the building industry and as components of lightweight concrete [2].

Slag possesses hydraulic characteristics, and its hydration procedure is the same as cement [3,4]. The literature in this field suggested that GGFBS containing concrete has a better performance than ordinary concrete [5]. Slag-containing concrete is less penetrable toward the water than a naturally hardened concrete mix [6]. Considering the negative impact of slag on compressive strength and resistance to chloride ion migration and carbonization, cement must not be replaced in high proportions [7,8]. Some research has been conducted on the replacement of Portland cement by ground granulated blast furnace slag (GGBFS), up to 70% of the cement replacement [9–11]. Khatib et al. [12] substituted up to 70% of Portland cement by GGBFS. The optimal output was derived in the replacement of 60%. After 28 and 91 days of curing, the mechanical properties were enhanced. However, by raising the replacement percentage to 80%, test results were dwindled 25.4%, on average. San-José et al. studied the efficiency of the hardened GGBFS containing concrete mixes and suggested that these samples yield a concrete with a 35% increase in compressive strength and a 24% decrease in permeability compared with normal concrete [13]. Yao et al. [14] also reported that replacing cement with higher than 50% of steel slag in the concrete results in concrete with a high alkaline level. In another research [15] evaluate consumption of slag as an aggregate replacement. According to the results, incorporating 50% of steel slag increased the mechanical properties of pervious concrete compared to reference control.

Regarding the effect of GGBFS on the durability of concrete, Teng et al. [16] assessed the effect of incorporating slag in concrete samples on compressive and flexural strength, RCMT, and electrical resistivity. In general, the experiment results demonstrated that slag-included concrete has higher characteristics such as higher early mechanical properties, lower permeation, and enhanced durability at three days. In another study, Wang et al. [17] evaluated the impact of GGBFS on the mechanical properties and rapid chloride migration test. In this series of studies, W/C and 28 days compressive strength were determined the same for all mixtures. According to the data, raising the percentage of the slag substitution leads to dwindling the early-age strength and increasing the permeability. The adverse impact of GGBFS on the durability characteristics is higher at lower W/C ratios.

Nowadays, the automobile industry development has increased tire consumption. This growth has produced huge stockpiles of the used tire. Scrap tires are composed of compounds that are not inseparable in natural conditions, and lots of environmental damages were incurred by these waste materials. One of the methods to optimize scrap tires is to use them in the construction industry. According to national statistics of Iran, nearly 26 million tires will be produced in 2020 [18], and it was estimated that about 13 million time-worn tires would be collected in Iran annually. That is why numerous research attempts have been focused in recent years on the optimal and functional use of tire waste in the construction industry [19].

Many studies have been done on waste tire crumbs. Researchers have found that mixing crumb rubber as a replacement to natural aggregate in concrete increases the ductility and durability of concrete specimens [20–22]. Scientists expressed various outputs by substituting different proportions of crumb tires in concrete mixtures and declared that the optimum incorporation of crumb rubber is 10% [23]. The compressive strength was reduced significantly by using the waste rubber crumb with a replacement percentage of 25% [24]. The weakness of the interfacial transition area in the middle of the rubber and cement paste can be the reason for reducing compressive strength [25].

About utilizing micronized rubber powder, Al-Tayeb et al. [26] assessed the impact of the cement replacement by MRP on the concrete compressive strength. Concrete samples were made, including 2.5%, 5%, and 10% waste rubber as a substitution for cement. The compressive strength declined by 19%, 32%, and 53% by replacing 2.5%, 5%, and 10% Portland cement by MRP. Liu et al. [27] assessed the influence of these particles on the mechanical characteristics of concrete samples. The result of the experiments revealed a reduction of 15% in the compressive and flexural strength of the concrete. It was expressed that this decrement is related to the softness of rubber powder in concrete structures. The impact of MRP on mechanical characteristics of the lightweight samples was the aim of research done by Mehrani et al. [28]. The finding of this examination revealed that MRP increased the mechanical strength in the sample included 5% of this waste materials. Gupta et al. [29] investigated utilizing tire fibers and MRP in concrete mixtures. The output of this experimental evaluation depicted that the mechanical properties of concrete decreased, although the flexural strength of concrete was raised. On the other hand, by synergic usage of the fibers and rubber, the permeability of the concrete specimens was enhanced.

The durability of the MRP-included concrete samples was evaluated in a few studies. Guneyisi et al. [30] declared an increment in RCMT results by increasing waste tire replacement percentage for pozzolan-included samples. By Raising the MRP substitution percentage from 0 to 25, the permeation of the chloride ion increased 27%–59% in comparison to the reference sample. Concerning the impact of MRP on the RCMT output of the samples, Na et al. [31] expressed lower results in rubber-included mixtures. In this examination, it was deduced that the migration rate of mixtures was less than reference samples because of the blockage properties of MRP that can hinder connection among the pores of the cement paste.

There are few papers about the synergic influence of waste tires and slag. Long et al. [32] evaluated the consumption of recycled tire waste in steel slag-containing concrete. They declared that higher replacement of tire waste for cement would decrease the durability and mechanical characteristics of the concrete, including slag. The compressive strength of steel slag concrete will generally decrease due to adding to the tire content. Besides, it has been shown that cement substitution by steel slag and rubber powder will bring about positive environmental and economic impacts.

According to the preceding literature, simultaneous incorporating of rubber powder and slag and evaluating the mechanical and durability characteristics were chosen as one of the main aims of this research. In addition, deriving mathematical formulas for estimating properties of the waste-materials-included concrete based on primary data of reference samples is one of the novelties of this study.

The chemical composition and characteristics of the cementitious materials are demonstrated in Table 1. The binders incorporated are Portland cement and GGBFS. CEM I-32.5 R cement in agreement with the specifications of ASTM C 150 [33] was utilized in this analysis. Micronized rubber powder (MRP) was generated by incineration of worn-out tires under 850 centigrade for 72 h. The size range of this powder is the size range of 0.0635 mm and 0.65 mm, seen in Fig. 1, with a density of 1.191 g/cm3. Also, the chemical substances of the MRP are shown in Table 2.

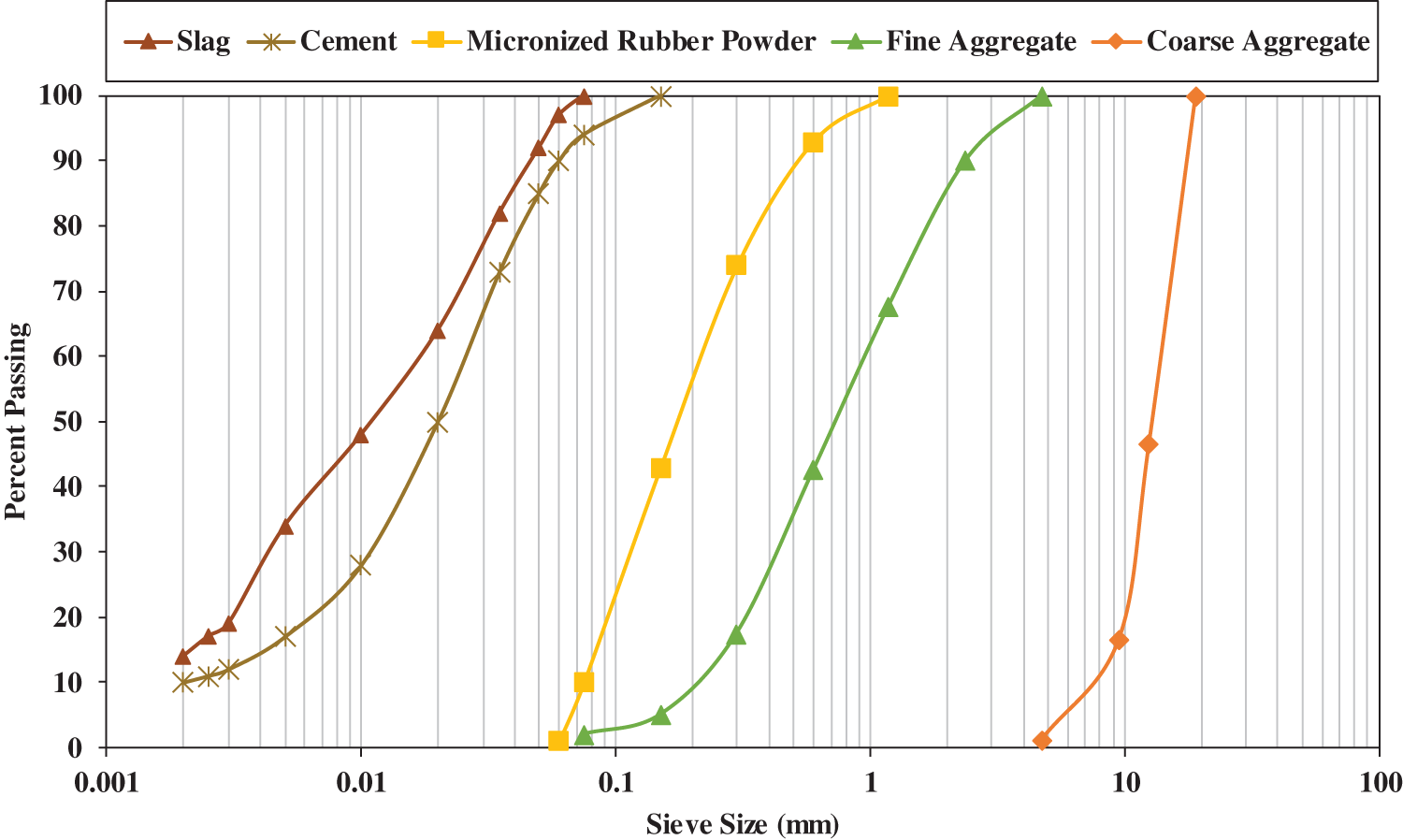

This experiment used gravel with a density of 2.55, a 19 mm of maximum size aggregate, an absorption of water of 1.9 percent, and fine river aggregate with a specific gravity of 2.45 and water absorption of 3.2 percent from Shahriyar mine in Iran. The gravel and sand all meet ASTM C33 [34] specifications and are consistent with the C19 curve originating from the national concrete mix methods of Iran. Fig. 2 shows the size range of cement, GGBFS, MRP, gravel, and sand.

Figure 1: The MRP utilized this examination

Figure 2: The size range of cement, slag, MRP, gravel, and sand

The Poly-carboxylate superplasticizer used as chemical admixture with a density of 1.12 g/cm3 according to the ASTM C494 Type F requirements [35].

The impact of GGBFS and Slag on the properties of concrete samples was investigated using an experimental design. Concrete mixtures were prepared with binder (cement, MRP, and slag) content of 325, 375, and 425 kg/m3 and W/B of 0.35, 0.40, and 0.45. The MRP substitution percentage were 0%, 2.5%, and 5% of binder content on preceding research [26]. GGBFS substitution percentages were 20% and 40% of binder content. A total of 81 concrete mixtures were prepared with 18 samples for MRP-included type, 18 samples for slag-added type, and 36 concrete samples containing both materials simultaneously. Aside from that, nine mixtures were prepared as control samples. For each mixture proportion, three samples were made.

Slump value was kept in the range of 80 and 100 mm by using a Poly-carboxylate superplasticizer in the concrete mixtures. Flow chart of experimental and mix design is presented in Fig. 3. The mixture proportions of the designed concrete samples are listed in Table 3.

Figure 3: Flow chart of experimental and mix design

2.3 Sample Preparation and Testing

The mixer’s inner surface was wetted to prevent absorbing concrete water. Fine and coarse aggregate was then blended for 1 min before applying 25% of the water and three-quarters of the HRWRA and blending for 2 min. The remaining mixing water, binder (cement, MRP, and slag) were then applied to the samples and blended for three minutes. At the final mixing phase, the superplasticizer was applied to the sample. Following the concrete mixing phase, tests on workability were done. The specimens were stored one day at 24 ± 2°C, and cured in water.

ASTM C39 [36] was applied to assess the compressive strengths of the samples. For this experiment, concrete was poured into 200 × 100 mm cylindrical molds. The non-uniform surface of cylindrical specimens was leveled based on ASTM C1231 [37] for the compressive strength test. 150 × 300 mm cylindrical concrete specimens were made based on ASTM C496 [38] for the tensile strength test. The flexural strength of concrete samples was examined using 450 × 100 × 100 mm prism specimens conforming to ASTM C293 [39]. The rapid chloride migration test (RCMT), based on AASHTO TP64-03 [40], was also done to investigate the resistance of the concrete sample against chloride-ion penetration. The cylindrical specimens with the size of 200 × 100 mm were applied in this examination. In order to assess the samples, microstructure, scanning electron microscopy (SEM) was utilized at the 28 days of curing by Philips XL30 apparatus. In this test, some fragments of each concrete sample were obtained by breaking tested concrete. Some of the pieces were covered with a gold ultra-thin layer to avoid electrical charges accumulation on the surfaces. It was observed that for each measurement, three concrete specimens were tested, and the output was described in this investigation based on the average of results.

Three formulas were proposed to derive a value for estimating the mechanical strength of the waste material-included mixtures according to the data achieved from ordinary concrete as a mechanical factor (MF). Thus, genetic programming (GP) software was used for finding the best-fitted relationship based on outputs.

Furthermore, the factor of durability (DF) was measured by dividing the migration rate of waste-materials samples to the RCMT results of the reference samples to estimate the durability of concrete, including MRP and slag. The rubber powder percentage, slag replacement level, W/B ratio, binder content, and curing age of the concrete were used as the vital specification regarding the data achieved from the experimental examination.

The variables of genetic programming were fixed in order to obtain precise and straightforward formulas. The program of experimentation yielded 243 distinct records, of which approximately 70% (164 outputs) were chosen at random for formula development the (training stage), and the remainder (79 outputs) were used to validate the acquired equation (testing phase).

The MAPE (average absolute percentage error), R (Pearson correlation coefficient), and RMSE (root mean squared error) of the numerical evaluations implemented to guesstimate the efficiency of the acquired formulas, listed in the following:

In which N,

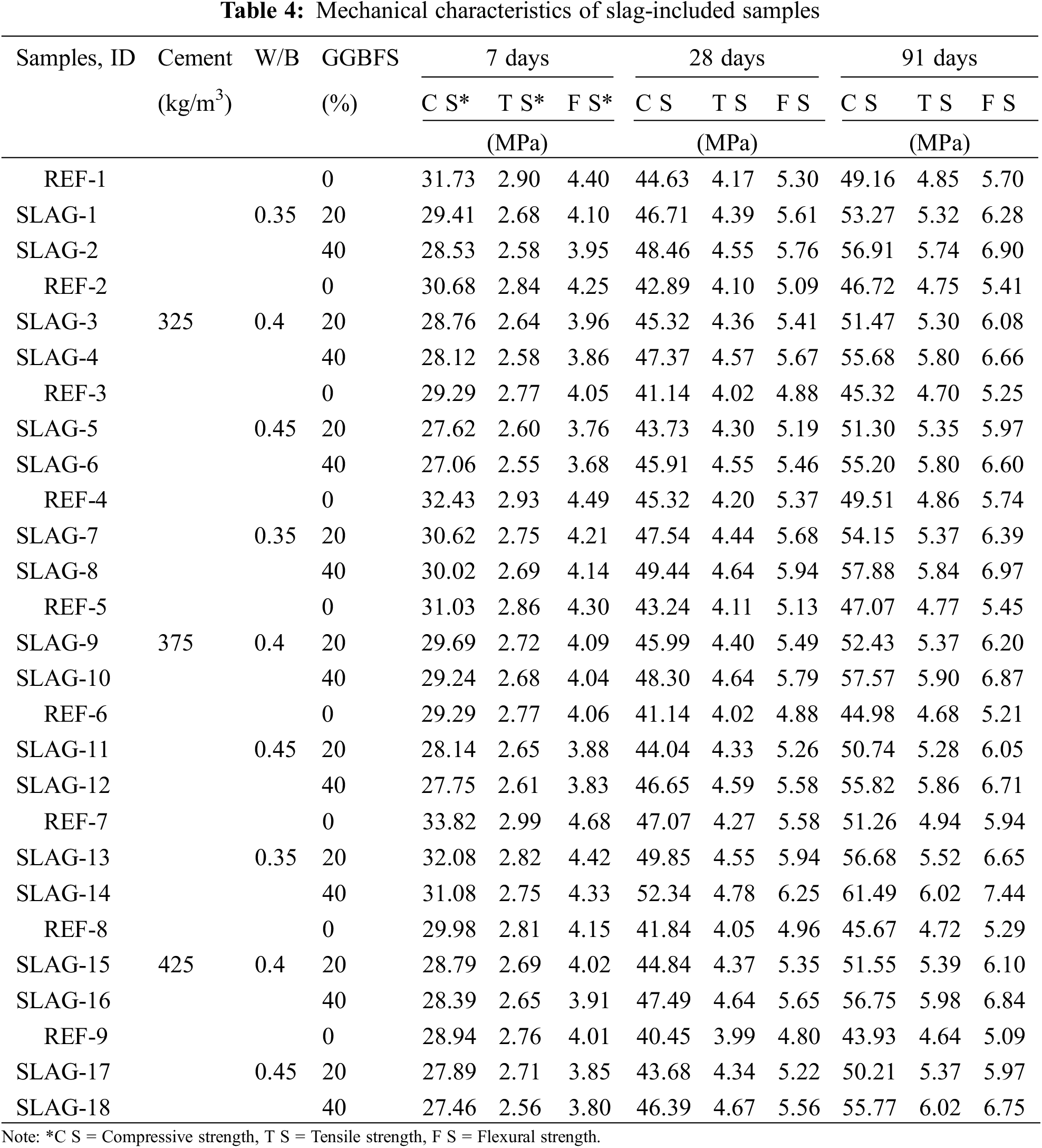

3.1.1 Slag–Included Concrete Samples

The mechanical characteristics of concrete samples, including GGBFS with substitution ratios of 20% and 40% for different curing ages, are demonstrated in Table 4. Regarding the results of the samples, compressive strength (CS), it can be obtained at the age of 7 days in samples containing 325 kg/m3 of cement and with a W/B of 0.35, the use of slag at a rate of 40% by weight of Portland cement results in a reduction of CS of concrete by 10.5% compared to reference concrete, averagely.

The negative effect of slag at an early age decreases by growing W/B so that this reduction for samples with a W/B of 0.45 is on average 8.6% for compressive strength. The main reason for the negative effect of slag at an early age can be considered the lack of production of hydration products such as Portlandite. In the presence of Portlandite, hydration of slag and water occurs, and this procedure of hydration with cement hydration products differs from that of other pozzolans. The Portlandite produced during the cement hydration affects the hydration of GGBFS. There are not any hydration products in the mixture of slag and water when Ca(OH)2 is not enough for the hydration procedure at seven days of curing.

As the age of the samples increases, the slag influence on the mechanical properties is positively evaluated so that the compressive strength of samples including 20% slag at 28 and 91 days is on average 11.3 and 17.7% higher than the 7-day samples. By doubling the replacement percentage, this betterment increases to an average of 18.9 and 28.3.

Concerning the impact of water to cement ratio, by examining the results, it can be derived that the improvement rate of samples with 20% replacement of slag compared to the reference specimens at 28 days for the samples including 325 kg/m3 of cement and W/B ratios of 0.35, 0.4 and 0.45 is 4.7, 5.7 and 6.3 percent, respectively. By increasing slag replacement up to 40%, compressive strength enhancement is 8.6, 10.4, and 11.6% compared with control samples. According to the outputs, it can be acquired that by lowering the ratio of water to cement, the effectiveness of slag on compressive strength dwindles. By decreasing the water to binder ratio, the substances produced during hydration become a more homogeneous shape and include a lower amount of Portlandite. This occurrence results in a lower hydration reaction of GGBFS and water in lime and reduces the enhancement level.

On the effect of cement content, this can be seen that increasing the cement amount results in an increase in the positive effect of slag in the long run so that increasing the amount of cement from 325 kg/m3 of concrete to 375 and 425 kg/m3 leads to an improvement of 3.4% and 7.9% in the samples containing 40% of GGBFS, in the order given.

The flexural and tensile strength results show that the effect of slag on enhancing this characteristic in the long term compared to compressive strength results at 28 and 91 days is 3.8% and 5.1% for all samples, respectively. This rise is possibly attributed to the more substantial ITZ (interfacial transition zone) in the cement paste containing slag and aggregate due to the morphology of the slag particles.

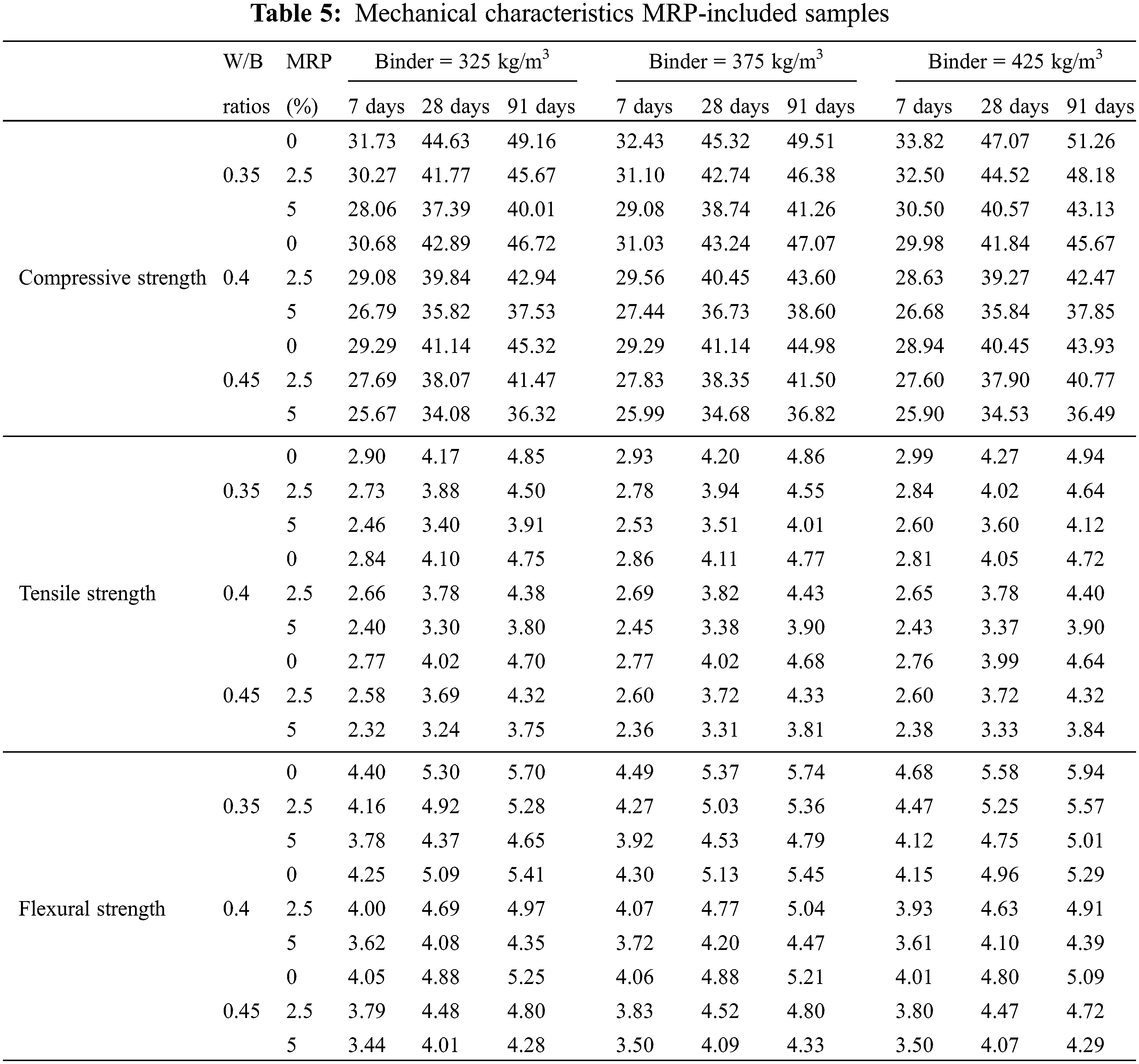

3.1.2 MRP-Included Concrete Mixtures

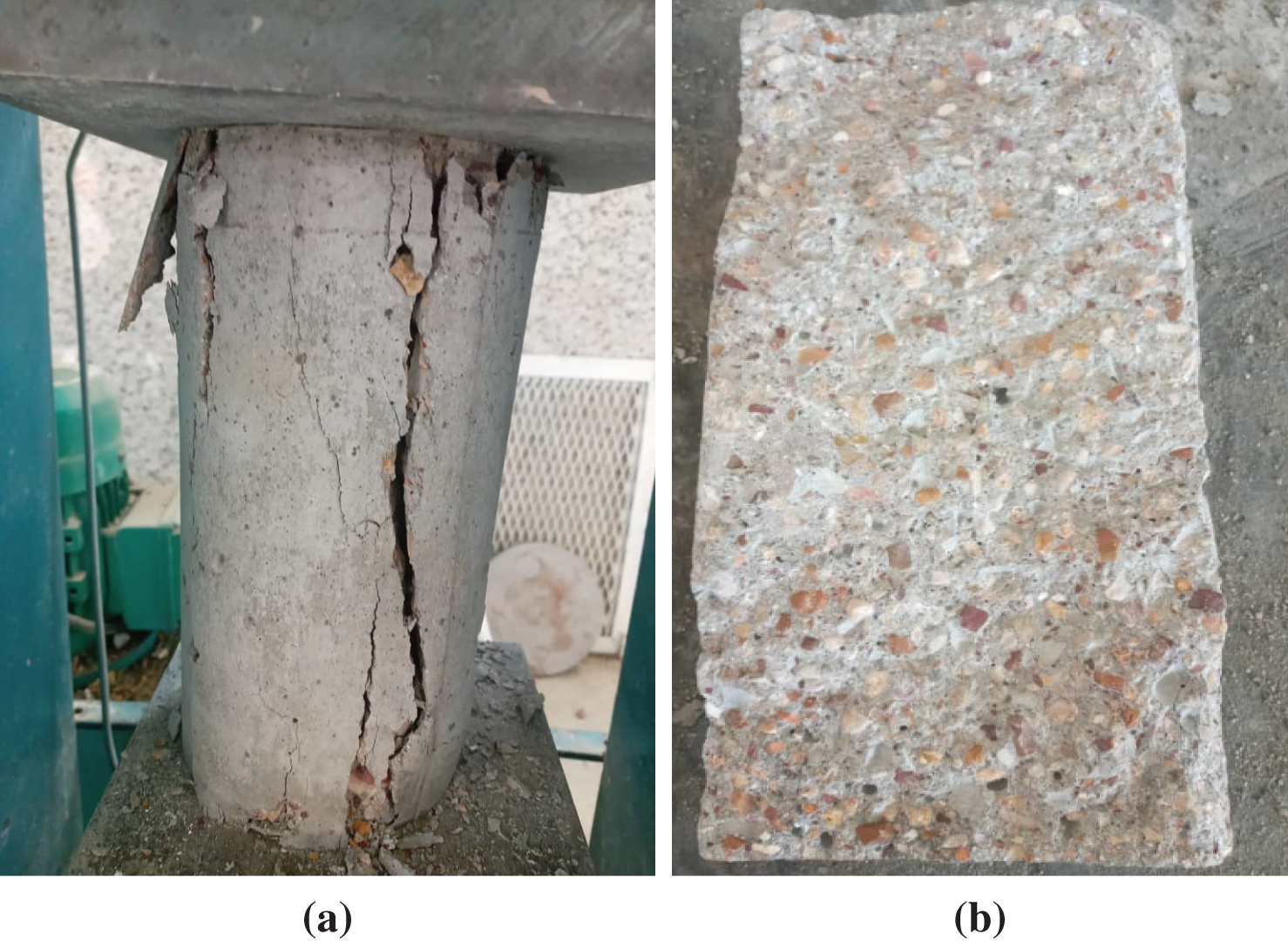

Table 5 demonstrates the outputs of mechanical characteristics experiments. Moreover, the actual photos of the specimen and the images when loading are presented in Fig. 4.

Figure 4: Rubber-powder-included mixture (a) under loading, and (b) after loading (broken sample)

Regarding the compressive strength of samples, including rubber powder, the compressive strength declines by increasing the replacement percentage of MRP. By replacing 2.5% of cement with WRP, the compressive strength of the samples reduced, averagely for all W/B ratios and cement contents, 4.7%, 6.4%, and 7.3% at the curing ages of 7, 28, and 91 days, in comparison to the control specimens, in the order given. By elevating the replacement percentage to 5%, the compressive strength of samples reduced 11.2%, 15.3%, and 17.9% at various age of curing, averagely, compared to the samples without adding waste materials. It can be interpreted that the compressive strength declined more intensely by increasing the MRP ratios in the concrete samples.

About the impact of cement content, for the cement of 325 and 425 kg/m3 of concrete, the reduction percentage of compressive strength compared with the reference sample by replacing cement with 2.5% of MRP is 6.7% and 5.7% for the content of 325 and 425 kg/m3, in the order given. Concerning the MRP of 5%, the amount of reduction was changed to 16.1% and 13.8% for 325 and 425 kg/m3 of cement. Therefore, MRP’s negative influence on the strength decreases by raising the volume of the cement in the concrete mixtures.

About the W/B ratio, the mean reduction of strength outputs with a WRP of 2.5% is 5.5% and 6.6%, respectively, with the W/B ratios of 0.35 and 0.45. The average decrement for concrete samples` compressive strength with a W/B ratio of 0.35 and 0.45 in comparison to the control specimen is equivalent to 14.2% and 15.2% for the mixtures containing MRP of 5%. While any essential discrepancies were not found among the compressive strength of specimens with different water to the binder, the unfavorable influence of rubber powder on the compressive strength is slightly higher for higher water to binder ratios.

For tensile properties, the finding is in line with the compressive strength outputs. Increased substitution of MRP decreases the TS relative to reference specimens. In the order given, the decrement of tensile strength for the samples containing 2.5% and 5% of MRP is 7% and 17.6% at 28 days of curing.

Besides, elevating the W/B from 0.35 to 0.45 does not significantly impact the tensile strength. However, the TS negative effect for the mixtures, including 2.5% and 5% of MRP, increases 1.1% and 2.7% by raising Portland cement content between 325 kg/m3 to 425 kg/m3.

On the effect of adding 2.5% and 5% of MRP on FS of the specimens, the average outputs demonstrate that strength reduction in these samples is 6.6% and 15.9%, respectively. Increasing the amount of cement from 325 kg/m3 to 425 kg/m3 leads to a decrement of 2.4% in flexural strength of the samples containing 5% of rubber powder replaced the Portland cement.

The removal of high-strength content by mixing cement with MRP is one of the fundamental causes of mechanical properties of concrete deterioration. Furthermore, the weakness of the ITZ between the rubber powder’s surface and cement paste structure can be another reason for declining mechanical characteristics. This finding is in line with Bisht et al. [41] research. Moreover, agglomeration of the powder, which hinders the appropriate dispersion in concrete, can be deduced as another reason for the mechanical properties degradation of MRP-added mixtures.

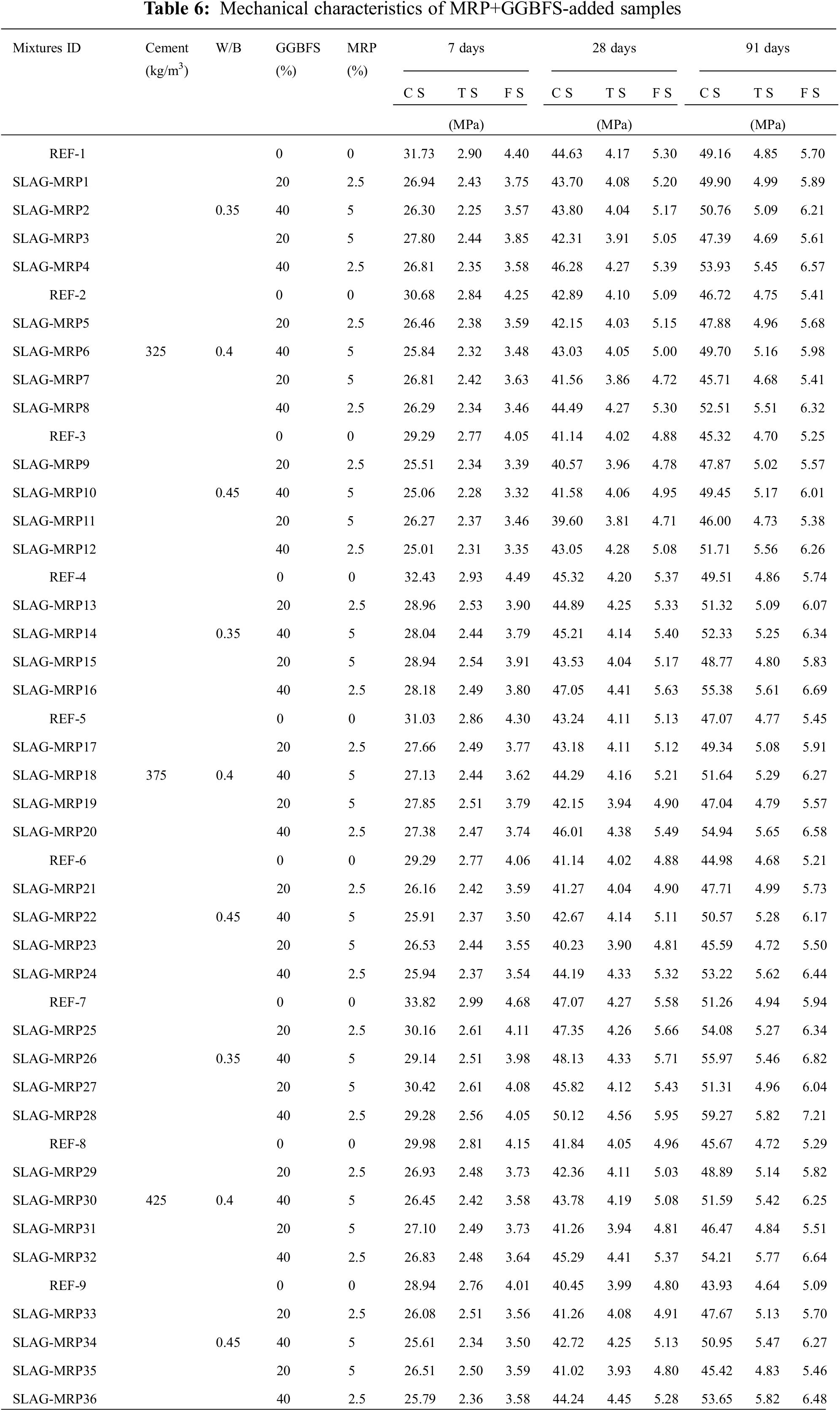

3.1.3 Synergic Impact of Rubber Powder and GGBFS

The characteristics of concrete samples including MRP (2.5% and 5%) and slag (20% and 40%) were examined at 7, 28, and 91 days as depicted in Table 6. Generally, GGBFS, except for early ages, moderates the negative effects of rubber powder by increasing the hydration products and improving the quality of these substances.

At the 7 days curing, the CS of the concrete samples with GGBFS+MRP replacement of 20% + 2.5%, 40% + 5%, 20% + 5%, and 40% + 2.5% reduced 15.1%, 17.1%, 12.4%, and 15.5% compared to control samples which are without waste materials. As samples curing increased to 28 days, the CS increased by 17.2%, 19%, 17.6%, and 11.8% in comparison to the seventh days of curing for the samples containing 20% + 2.5%, 40% + 5%, 20% + 5%, and 40% + 2.5%, respectively. In the 91 days of curing, the negative impact was removed due to the appropriate performance of the GGBFS at that age. In samples containing 5% of MRP, 325 kg/m3 of Portland cement, and water to binder of 0.45, replacing cement by 40% of slag results in 17.8% higher compressive strength than the slag-free sample.

Related patterns can be found in the FS and TS of concrete. The negative effect of waste material has dwindled as the W/B ratio increased, and this impact is amplified as the amount of MRP and GGBFS rose. The impact of cement content on the characteristics of concrete is minimal. In other words, the variations in reduction in properties between samples of 325 kg/m3 and 425 kg/m3 binder contents are lower than 1%.

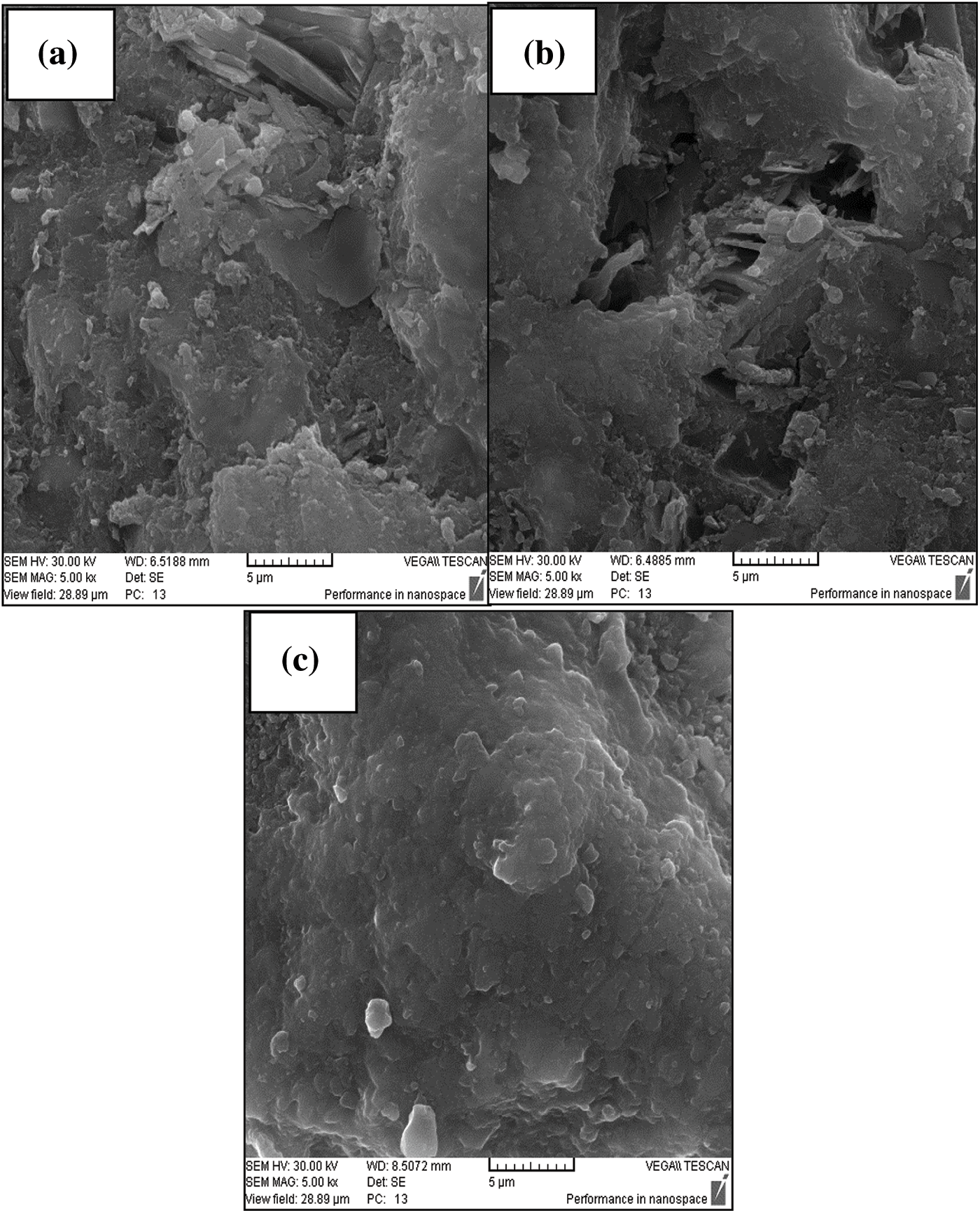

To assess the synergic impact of samples containing slag and rubber powder on the microstructure of the samples and its repercussion on mechanical characteristics, Scanning Electron Microscope (SEM) pictures were incorporated.

Fig. 5 depicted the morphological characteristics of the paste microstructures in three different types of samples, to better compare the waste materials effect. The Fig. 5a depicts the Ref-9 sample (with water to cement ratio = 0.45, cement content = 425 kg/m3). The Fig. 5b represents the MRP-18 sample (with water to cement ratio = 0.45, cement content = 425 kg/m3, MRP = 5%). The Fig. 5c demonstrates the simultaneous impact of MRP and slag in SLAG-MRP-34 sample (with water to cement ratio = 0.45, cement content = 425 kg/m3, MRP = 5%, and GGBFS = 50%).

As derived from Fig. 5b, porosity in the concrete that can be linked to the MRP substitution. Thus, in MRP-added concrete mixtures, unfavorable capillary pores in the paste are elevated. The fundamental explanation for the rise in porosity and permeation of concrete paste is the substitution of MRP with cement, leading to a higher W/B and previous research [42], higher porosity in paste microstructure. Furthermore, due to the hydrophobic properties of rubber powder, on the surface, it repulses water and collects air. As a result, it leads to the increasing porosity of the concrete paste. As seen in Fig. 5b, the surface morphology of the control samples (without adding waste materials) is denser than the rubber powder-included mixtures due to the advantages of higher hydration level and minor W/B due to the higher mass of cement. Due to the presence of Portlandite and calcium-silicate-hydrate (CSH) products of the same shape, the chemical structure of the samples does not change.

Figure 5: SEM images of the concrete paste for (a) Reference concrete, (b) MRP-added sample, and (c) Slag-MRP-added sample

To evaluate the impact of slag on negative properties of rubber powder, the SEM image taken from the SLAG-MRP-34 sample (Fig. 5c) was investigated and compared with Fig. 5a. Based on the outputs, at 28 days of curing, the hydration compounds produced by the slag were able to adequately fill the pores created in the samples, including rubber powder. Also, compared with the reference sample, the SLAG-MRP-34 sample has a more compacted structure. By comparing the compressive strength results of these samples, this was derived that in the sample containing slag and rubber powder, the compressive strength has increased by 5.6% in comparison to the control specimens, while in the MRP-18 sample, the MRP reduced the CS by 14.6%. The reason for the improvement due to the slag replacement can be considered the hydration of slag beside Ca(OH)2.

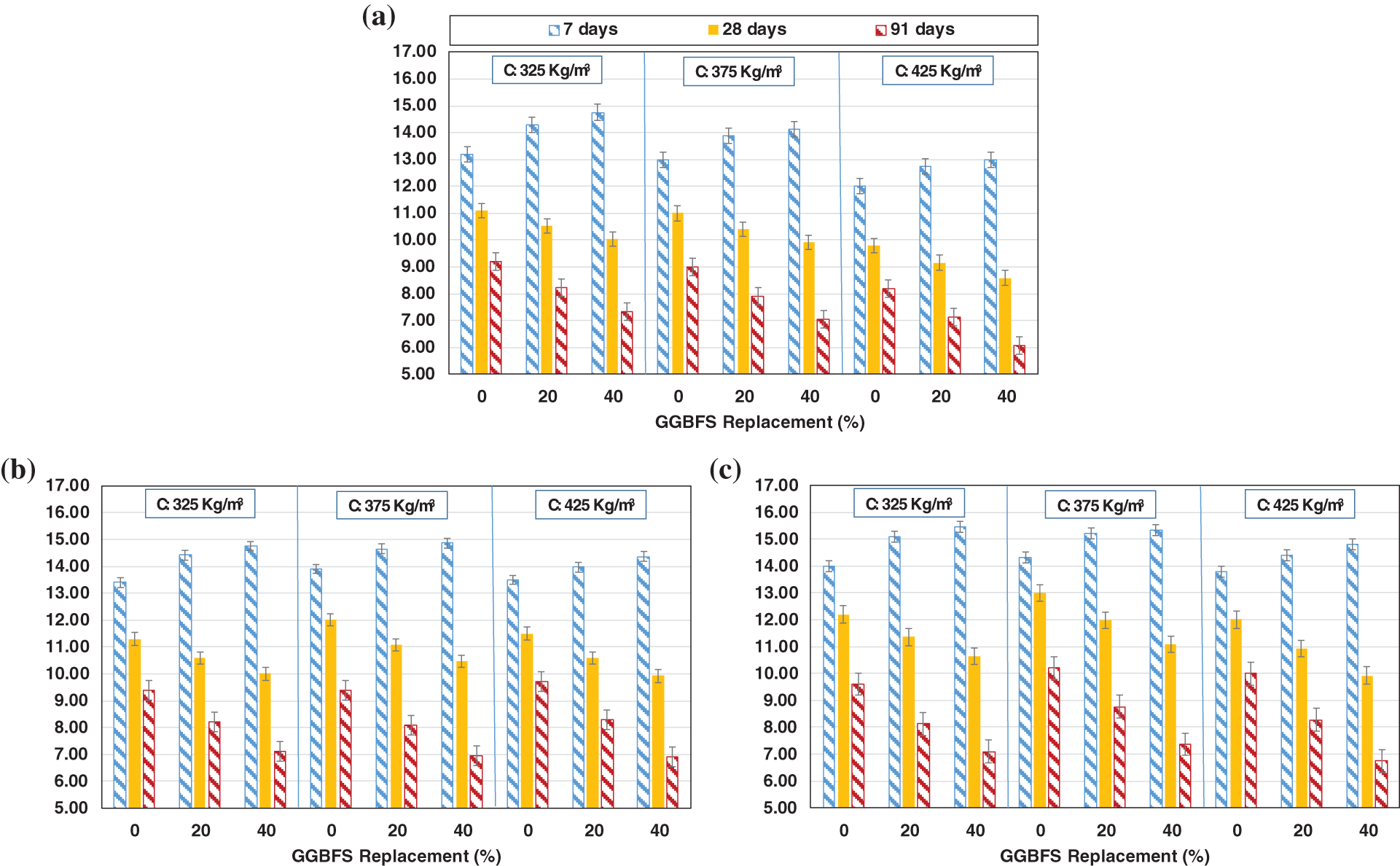

3.2.1 Slag Added Concrete Samples

Fig. 6 presents the RMCT results of samples containing 20% and 40% slag for different W/B ratios and different amounts of cement at various curing times. According to the data, specimens including GGBFS at 28-day of curing increased the average durability of concrete for 20% and 40% replacements by 9.2% and 12.4%, respectively. At 91 days, durability properties enhancement has increased compared to the reference sample and elevated to 14.5% and 26.3% for replacement percentages of 20% and 40%.

Regarding the W/C ratio effect, on 28 days on average, the betterment of 40%-slag incorporation for W/C of 0.35 was 9.9%. However, this improvement for W/C of 0.45 was 14.7. These outputs indicate the more significant impact of GGBFS on concrete’s durability in upper W/B. On the effect of slag in short-term ages, the outputs of mixtures at seven days show a negative effect, which on average in the replacement ratio of 40%, the durability of concrete is 7.9% lower than the reference sample.

Figure 6: The rapid chloride migration test results of the slag-included samples (a) W/B = 0.35, (b) W/B = 0.40, and (c) W/B = 0.45

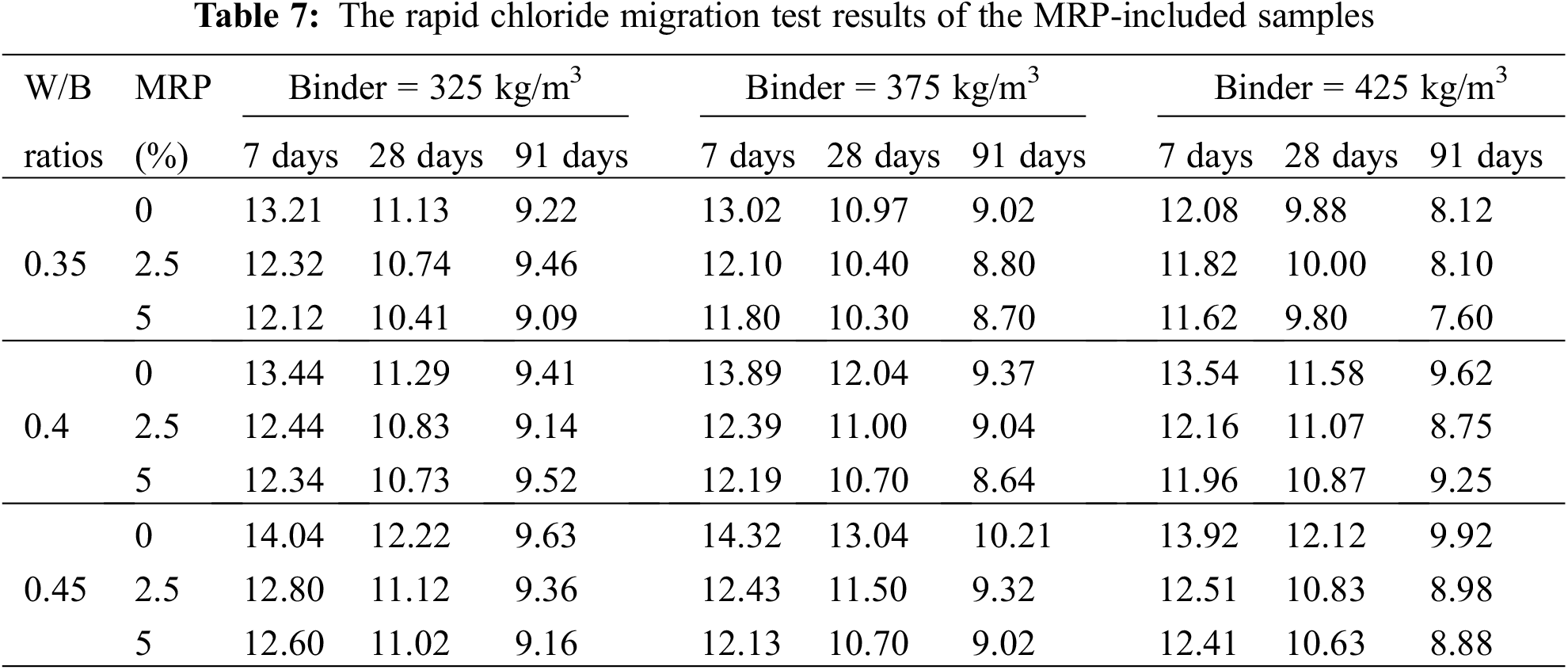

Table 7 shows the RCMT concrete’s outcomes, including MRP with different cement contents. Since micro-sized MRP is an applied electrical insulating material, which can block the relation of the pores in the concrete system, raising the rubber powder level decreases the RCMT results in concrete. These data are in line with observations of Na et al. [31]. The insulation that occurred by incorporating rubber powder balances its negative effect on increasing the porosity of samples.

In comparison to the control mixtures with the 0.45 of water to binder ratio and cement of 325 kg/m3, the migration rates of chloride with the rubber powder replacement of 2.5 percent and 5% rise 8.8% and 9.7%, sequentially, at the concrete curing age of 28 days. When the W/B ratio was reduced to 0.35, and cement was increased to 425 kg/m3, the specimens migrating included 2.5% and 5% rubber powder reduced to 0 percent and 2.0 percent, respectively. It shows that binder material and the W/B ratio were influential on the migration rate.

For specimens included rubber powder of 0%, 2.5%, and 5%, raising the concrete age of curing of 7 to 91 decreases the overall migrating pace by 30.8 percent, 27.2 percent, and 26.8 percent, in the order given.

3.2.3 Synergic Impact of the Rubber Powder and Slag

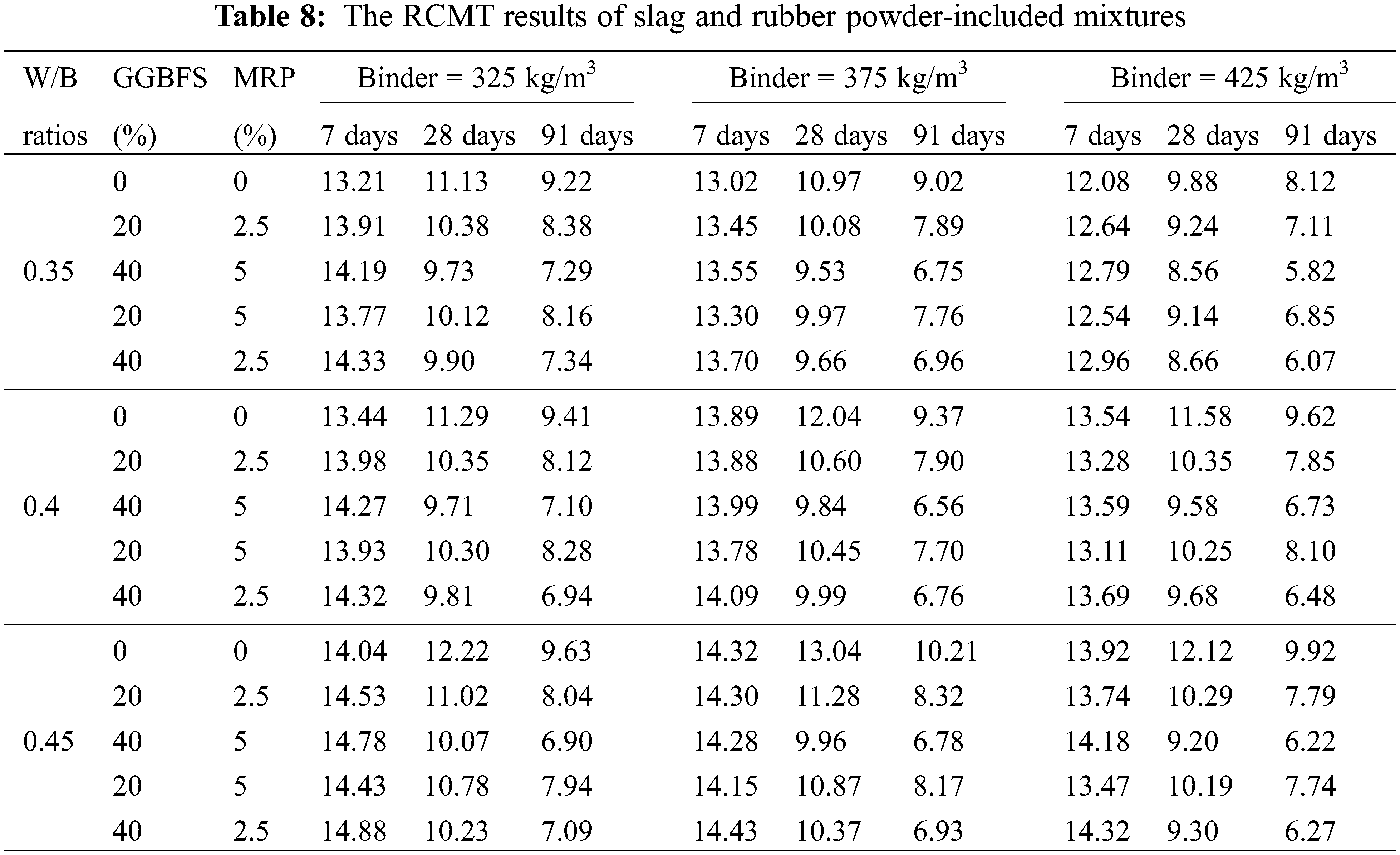

Concrete samples were made with four combinations of the various percentage of rubber powder and slag to explore the simultaneous impact of the consumed waste particles on durability, and Table 8 shows the results.

In general, replacing cement with rubber powder and slag at the ages of 28 and 91 days has led to the improved pore structure of concrete and more excellent resistance to chloride ion penetration. At 28-day, this amount for samples with GGBFS+MRP replacement of 40% + 5% is 17.5% lower than reference samples, on average. This output for the samples with half of this replacement percentage is 10.7%.

At 91 days, this result for concrete specimens with GGBFS+MRP replacement of 40% + 5% is 25.5% lower than reference samples, on average. The samples with GGBFS+MRP replacement of 20% + 2.5% is 19.6% which has a higher impact on reducing migration rate than the specimens with GGBFS+MRP replacement of 40% + 5%, at 28 days of curing.

Regarding the comparison of waste materials’ effect, the general outputs at long ages show a more significant effect of slag in reducing the migration rate of chloride ion compared to rubber powder. At the 28 days of curing, by comparing the migration rate of the samples with GGBFS+MRP replacement of 20% + 5% and 40% + 2.5%, it can be derived that the impact of the first type of samples on reducing RCMT results is 3.8% higher than the second type which has 5% of rubber powder and 20% of slag.

3.3 Estimation of the Waste Material-Included Mixtures Properties

The MFc, MFt, MFf as the mechanical factor for mechanical properties, and DFr as the factor of durability for RCMT of concrete including rubber powder and slag were determined using the equations below:

wherein

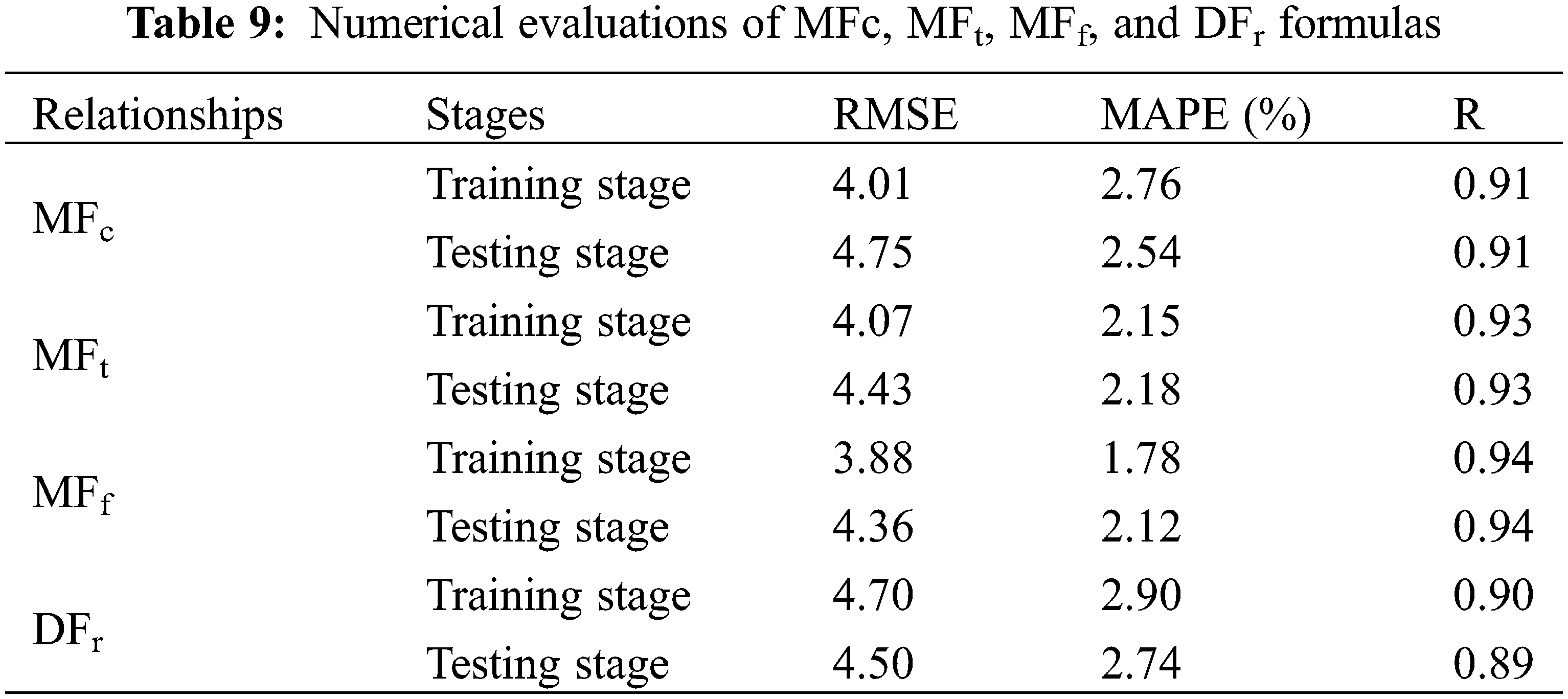

Table 9 displays the predictive measurements of the obtained equations for calculating the MFc, MFt, and MFf for both the training and testing stages. For both the training and testing stages, the MAPEs of the equations are lower than 3%. Furthermore, the experimental and expected strength data are highly correlated.

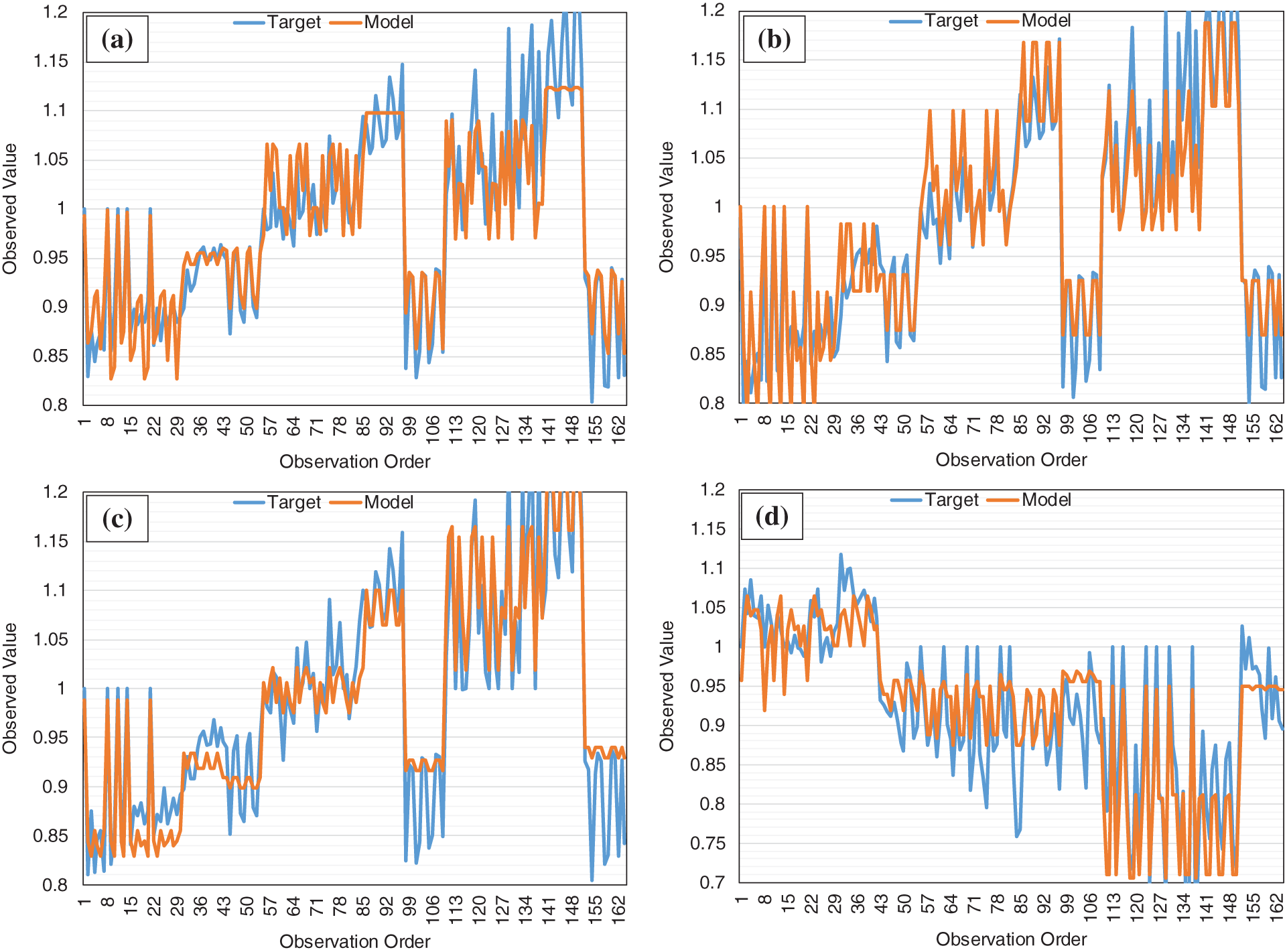

The experimental and expected values for estimating the mechanical properties and durability are shown in Fig. 7. This illustration shows a slight variation between the expected and experimental values, suggesting that the proposed equations are correct.

Figure 7: Predicted and experimented with values for the strength and durability estimation factor of (a) CS, (b) TS, (c) FS, and (d) durability of mixtures

Conclusions were deduced as follows:

• Regarding the compressive strength of samples, including rubber powder, the CS declines by rising the replacement percentage of MRP.

• Except for early ages, slag results in the negative impact of MRP reduction.

• By decreasing the ratio of water to cement, the effectiveness of slag on compressive strength dwindles.

• Generally, GGBFS, except for early ages, moderates the negative effects of rubber powder by increasing the hydration products and improving the quality of these substances.

• In general, replacing cement with rubber powder and slag at the ages of 28 and 91 days has led to the improved pore structure of concrete and more excellent durability.

• Regarding the comparison of waste materials’ effect, the general outputs at long curing time of 28 days and 91 days show a more significant effect of slag in reducing the migration rate of chloride ion compared to rubber powder.

• Four formulas were proposed to derive a value to estimate the various properties of the waste-material-included mixtures.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Sivakrishna, A., Adesina, A., Awoyera, P., Kumar, K. R. (2020). Green concrete: A review of recent developments. Materials Today: Proceedings, 27, 54–58. DOI 10.1016/j.matpr.2019.08.202. [Google Scholar] [CrossRef]

2. Ramezanianpour, A. A. (2014). Cement replacement materials. Springer Geochemistry/Mineralogy, 10, 978–973. DOI 10.1007/978-3-642-36721-2. [Google Scholar] [CrossRef]

3. Li, J., Yu, Q., Wei, J., Zhang, T. (2011). Structural characteristics and hydration kinetics of modified steel slag. Cement and Concrete Research, 41(3), 324–329. DOI 10.1016/j.cemconres.2010.11.018. [Google Scholar] [CrossRef]

4. Liu, S., Li, Q., Xie, G., Li, L., Xiao, H. (2016). Effect of grinding time on the particle characteristics of glass powder. Powder Technology, 295(2), 133–141. DOI 10.1016/j.powtec.2016.03.030. [Google Scholar] [CrossRef]

5. Peng, Y. C., Hwang, C. L. (2010). Carbon steel slag as cementitious material for self-consolidating concrete. Journal of Zhejiang University–Science A, 11(7), 488–494. DOI 10.1631/jzus.A0900635. [Google Scholar] [CrossRef]

6. Wang, Q., Yang, J., Yan, P. (2013). Cementitious properties of super-fine steel slag. Powder Technology, 245(8–9), 35–39. DOI 10.1016/j.powtec.2013.04.016. [Google Scholar] [CrossRef]

7. Hu, J. (2017). Comparison between the effects of superfine steel slag and superfine phosphorus slag on the long-term performances and durability of concrete. Journal of Thermal Analysis and Calorimetry, 128(3), 1251–1263. DOI 10.1007/s10973-017-6107-9. [Google Scholar] [CrossRef]

8. Zhang, T., Yu, Q., Wei, J., Li, J. (2012). Investigation on mechanical properties, durability and micro-structural development of steel slag blended cements. Journal of Thermal Analysis and Calorimetry, 110(2), 633–639. DOI 10.1007/s10973-011-1853-6. [Google Scholar] [CrossRef]

9. Sun, J., Lin, S., Zhang, G., Sun, Y., Zhang, J. et al. (2021). The effect of graphite and slag on electrical and mechanical properties of electrically conductive cementitious composites. Construction and Building Materials, 281(6), 122606. DOI 10.1016/j.conbuildmat.2021.122606. [Google Scholar] [CrossRef]

10. Perez-Garcia, F., Rubio-Cintas, M. D., Parron-Rubio, M. E., Garcia-Manrique, J. M. (2020). Advances in the analysis of properties behaviour of cement-based grouts with high substitution of cement with blast furnace slags. Materials, 13(3), 561. DOI 10.3390/ma13030561. [Google Scholar] [CrossRef]

11. Maharishi, A., Singh, S., Gupta, L. K. (2021). Strength and durability studies on slag cement concrete made with copper slag as fine aggregates. Materials Today: Proceedings, 38, 2639–2648. [Google Scholar]

12. Khatib, J., Hibbert, J. (2005). Selected engineering properties of concrete incorporating slag and metakaolin. Construction and Building Materials, 19(6), 460–472. DOI 10.1016/j.conbuildmat.2004.07.017. [Google Scholar] [CrossRef]

13. San-José, J. T., Vegas, I., Arribas, I., Marcos, I. (2014). The performance of steel-making slag concretes in the hardened state. Materials & Design, 60(6), 612–619. DOI 10.1016/j.matdes.2014.04.030. [Google Scholar] [CrossRef]

14. Yao, X., Yang, T., Zhang, Z. (2016). Compressive strength development and shrinkage of alkali-activated fly ash-slag blends associated with efflorescence. Materials and Structures, 49(7), 2907–2918. DOI 10.1617/s11527-015-0694-3. [Google Scholar] [CrossRef]

15. Adilah, A. N., Mohammed, S. A., Ramadhansyah, P., Rokiah, O., Hainin, M. R. (2020). The influence of steel slag as alternative aggregate in permeable concrete pavement. IOP Conference Series: Materials Science and Engineering. DOI 10.1088/1757-899X/712/1/012011. [Google Scholar] [CrossRef]

16. Teng, S., Lim, T. Y. D., Divsholi, B. S. (2013). Durability and mechanical properties of high strength concrete incorporating ultra fine ground granulated blast-furnace slag. Construction and Building Materials, 40(7), 875–881. DOI 10.1016/j.conbuildmat.2012.11.052. [Google Scholar] [CrossRef]

17. Wang, Q., Yan, P., Yang, J., Zhang, B. (2013). Influence of steel slag on mechanical properties and durability of concrete. Construction and Building Materials, 47(3), 1414–1420. DOI 10.1016/j.conbuildmat.2013.06.044. [Google Scholar] [CrossRef]

18. Iranian Information Centre of Industries and Mines (2020). Iran’s Economic Year in Review. Ministry of Industries and Mines Publication, Tehran, Iran. [Google Scholar]

19. Etefa, G., Mosisa, A. (2020). Waste rubber tires: A partial replacement for coarse aggregate in concrete floor tile production. American Journal of Civil Engineering, 8(3), 57–63. DOI 10.11648/j.ajce.20200803.12. [Google Scholar] [CrossRef]

20. Kaloush, K. E., Way, G. B., Zhu, H. (2005). Properties of crumb rubber concrete. Transportation Research Record, 1914(1), 8–14. DOI 10.1177/0361198105191400102. [Google Scholar] [CrossRef]

21. Si, R., Wang, J., Guo, S., Dai, Q., Han, S. (2018). Evaluation of laboratory performance of self-consolidating concrete with recycled tire rubber. Journal of Cleaner Production, 180(7), 823–831. DOI 10.1016/j.jclepro.2018.01.180. [Google Scholar] [CrossRef]

22. Ganjian, E., Khorami, M., Maghsoudi, A. A. (2009). Scrap-tyre-rubber replacement for aggregate and filler in concrete. Construction and Building Materials, 23(5), 1828–1836. DOI 10.1016/j.conbuildmat.2008.09.020. [Google Scholar] [CrossRef]

23. Al-Tayeb, M. M., Bakar, B. A., Ismail, H., Akil, H. M. (2012). Impact resistance of concrete with partial replacements of sand and cement by waste rubber. Polymer-Plastics Technology and Engineering, 51(12), 1230–1236. DOI 10.1080/03602559.2012.696767. [Google Scholar] [CrossRef]

24. Gupta, T., Sharma, R. K., Chaudhary, S. (2015). Impact resistance of concrete containing waste rubber fiber and silica fume. International Journal of Impact Engineering, 83(2), 76–87. DOI 10.1016/j.ijimpeng.2015.05.002. [Google Scholar] [CrossRef]

25. Najim, K. B., Hall, M. R. (2012). Mechanical and dynamic properties of self-compacting crumb rubber modified concrete. Construction and Building Materials, 27(1), 521–530. DOI 10.1016/j.conbuildmat.2011.07.013. [Google Scholar] [CrossRef]

26. Al-Tayeb, M. M., Abu Bakar, B., Akil, H. M., Ismail, H. (2012). Effect of partial replacements of sand and cement by waste rubber on the fracture characteristics of concrete. Polymer-Plastics Technology and Engineering, 51(6), 583–589. DOI 10.1080/03602559.2012.659307. [Google Scholar] [CrossRef]

27. Liu, R., Zhang, L. (2015). Utilization of waste tire rubber powder in concrete. Composite Interfaces, 22(9), 823–835. DOI 10.1080/09276440.2015.1065619. [Google Scholar] [CrossRef]

28. Mehrani, S. A., Bhatti, I. A., Bhatti, N. B., Jhatial, A. A., Lohar, M. A. (2019). Utilization of rubber powder of waste tyres in foam concrete. Journal of Applied Engineering Sciences, 9(1), 87–90. DOI 10.2478/jaes-2019-0011. [Google Scholar] [CrossRef]

29. Gupta, T., Chaudhary, S., Sharma, R. K. (2014). Assessment of mechanical and durability properties of concrete containing waste rubber tire as fine aggregate. Construction and Building Materials, 73(10), 562–574. DOI 10.1016/j.conbuildmat.2014.09.102. [Google Scholar] [CrossRef]

30. Gesoğlu, M., Güneyisi, E. (2007). Strength development and chloride penetration in rubberized concretes with and without silica fume. Materials and Structures, 40(9), 953–964. DOI 10.1617/s11527-007-9279-0. [Google Scholar] [CrossRef]

31. Na, O., Xi, Y. (2017). Mechanical and durability properties of insulation mortar with rubber powder from waste tires. Journal of Material Cycles and Waste Management, 19(2), 763–773. DOI 10.1007/s10163-016-0475-2. [Google Scholar] [CrossRef]

32. Long, W. J., Li, H. D., Wei, J. J., Xing, F., Han, N. (2018). Sustainable use of recycled crumb rubbers in eco-friendly alkali activated slag mortar: Dynamic mechanical properties. Journal of Cleaner Production, 204(7), 1004–1015. DOI 10.1016/j.jclepro.2018.08.306. [Google Scholar] [CrossRef]

33. ASTM, C 150 (2017). Standard specification for portland cement. ASTM International. ICS Code: 91.100.10. DOI 10.1520/C0150_C0150M-17. [Google Scholar] [CrossRef]

34. ASTM, C 33-97 (1997). Standard specification for concrete aggregates. Annual Book of ASTM Standards. ICS Code: 91.100.30. DOI 10.1520/C0033-01. [Google Scholar] [CrossRef]

35. ASTM, C494 (2005). Standard specification for chemical admixtures for concrete. PA, USA: ASTM West Conshohocken. [Google Scholar]

36. ASTM, C39M-99 (1999). Standard test method for compressive strength of cylindrical concrete specimens. ASTM International West Conshohocken. ICS Code: 91.100.30. DOI 10.1520/C0039_C0039M-09. [Google Scholar] [CrossRef]

37. ASTM, C1231M-10a (2010). Standard practice for use of unbonded caps in determination of compressive strength of hardened concrete cylinders. ASTM Philadelphia. ICS Code: 91.100.30. DOI 10.1520/C1231_C1231M-09. [Google Scholar] [CrossRef]

38. ASTM, C496 (1996). Standard test method for splitting tensile strength of cylindrical concrete specimens. ASTM International West Conshohocken. ICS Code: 91.100.30. DOI 10.1520/C0496-96. [Google Scholar] [CrossRef]

39. ASTM, C293M-16 (2008). Standard test method for flexural strength of concrete, using simple beam with center-point loading. ICS Code: 91.100.30. DOI 10.1520/C0293_C0293M-16. [Google Scholar] [CrossRef]

40. AASHT, T 64-03 (2003). Standard method of test for prediction of chloride penetration in hydraulic cement concrete by the rapid migration procedure. Washington: American Association of State Highway and Transportation Officials. [Google Scholar]

41. Bisht, K., Ramana, P. (2017). Evaluation of mechanical and durability properties of crumb rubber concrete. Construction and Building Materials, 155(8), 811–817. DOI 10.1016/j.conbuildmat.2017.08.131. [Google Scholar] [CrossRef]

42. Nikbin, I., Beygi, M., Kazemi, M., Amiri, J. V., Rabbanifar, S. et al. (2014). A comprehensive investigation into the effect of water to cement ratio and powder content on mechanical properties of self-compacting concrete. Construction and Building Materials, 57(284), 69–80. DOI 10.1016/j.conbuildmat.2014.01.098. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |