| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.018908

ARTICLE

Research of Mechanical and Thermal Properties of Composite Material Based on Gypsum and Straw

Faculty of Civil Engineering, VSB–Technical University of Ostrava, Ostrava, 70800, Czech Republic

*Corresponding Author: Nikola Vavřínová. Email: nikola.vavrinova@vsb.cz

Received: 24 August 2021; Accepted: 10 December 2021

Abstract: This article is focused on the investigation of the mechanical and thermal properties of composite material that could be used for the production of plaster or plasterboards. This composite material is made of gypsum and reinforcing natural fibers. The article verifies whether this natural reinforcement can improve the investigated properties compared to conventional plasters and gypsum plasterboards made of pure gypsum. From this composite material, high-strength plasterboards could then be produced, which meet the higher demands of users than conventional gypsum plasterboards. For their production, natural waste materials would be used efficiently. As part of the development of new building materials, it is necessary to specify essential characteristics for their later use in civil engineering. Crushed wheat straw and three gypsum classes with strengths G2 (2 MPa)—gypsum Class I., G5 (5 MPa)—gypsum Class II. and G16 (16 MPa)—gypsum Class III. were used to create the test samples. Samples were made with different ratios of the two ingredients, with the percentages of straw being 0%, 2.5%, and 5% for each gypsum grade. The first part of the article describes how the increasing proportion of straw affects the composite’s mechanical properties (flexural strength and compressive strength). The second part of the article focuses on the change of thermal properties (thermal conductivity and specific heat capacity). The last part of the article mentions the verification of the fire properties (single-flame source fire test and gross heat of combustion) of this composite material. The research has shown that the increasing proportion of straw reinforcement caused a deterioration in the flexural strength (up to 56.49% in the 3. series of gypsum Class II.) and compressive strength (up to 80.27% in the 3. series of gypsum Class III.) and an improvement in the specific heat capacity and thermal conductivity (up to 31.40% in the 3. series). This composite material is thus not suitable for the production of high-strength plasterboards, but its reduced mechanical properties do not prevent its use for interior plasters. Based on the performed fire tests, it can be said that this composite material can be classified as a non-flammable material of reaction to fire Classes A1 or A2. From an ecological point of view, it is advantageous to use a composite material with a higher straw content.

Keywords: Composite material; gypsum; plasterboard; crushed straw; flexural strength; compressive strength; thermal conductivity; specific heat capacity; ignitability; gross heat of combustion

Gypsum and products made from gypsum are standard building materials and there are many ways of using them in civil engineering [1]. Gypsum is the base raw material for the production of many types of building materials. Typical examples are interior plasters and gypsum plasterboards. Gypsum plasterboards are often used to create interior partitions, ceiling soffits, or pitched roofs. Gypsum has good properties in response to fire, so gypsum products are well suited as protective cladding structures for other flammable materials. Their use slows the spread of fire and increases the fire resistance of the structure. One of the typical examples is roofs, whose bearing structure consists of wooden beams. The gypsum cladding plasterboards here are not only a visual cladding, but also temporary fire protection of the roof against collapse, at least during evacuation of people. Another suitable use of gypsum plasterboards is as cladding, for example, of a ceiling with wooden beams or a ceiling with thermal insulation made of polystyrene, which melts and drips quickly in the event of a fire. This property of gypsum plasterboards is undoubtedly important and desired, so it should also be met in the case of the composite material discussed in this research. In contrast, the disadvantages of gypsum plasterboards are their strength and water absorption [2]. The problem is their use in environments with higher mechanical demands. A possible solution to this problem is to improve the strength of gypsum plasterboards by adding reinforcing fibers to the gypsum binder. The most commonly used are cellulosic fibers or synthetic fibers. With regard to the economic and especially ecological burden in the production of synthetic fibers, it is possible to use natural materials, which would otherwise be disposed of without use as natural waste. Rice [3,4], wheat [5–9], barley [10,11], wood fiber [11], flax, jute, hemp [12,13], corn fibers [14], etc., [15–17] can be used. In history, the use of natural materials was due to their availability, knowledge, and low economic difficulty.

Natural crushed wheat straw, without chemical additives, was chosen for this research. One of the advantages of using straw as a building material is the reduction of energy consumption from the environmental point of view. These fibers are usually agricultural waste, so they consume less energy in production. They also offer good thermal properties due to their porous nature, which leads to reduced energy consumption in the operation of buildings [18]. According to [19], the addition of straw to the gypsum-based composite reduces the thermal conductivity of the samples. Ismail et al. [7] successfully tried to further improve the thermal properties of a biocomposite based on cereal straw and mineral binders using hemoglobin, casein and gelatin. The treated composite is even suitable for use in building insulation. Thus, straw as a nature material can compete with synthetic fibers in a variety of engineering applications.

The question is how adding natural fibers to the composite will affect its mechanical properties. Yang et al. [19] presented the verification of the properties of gypsum-based composite wall materials. They investigated the effect of cement, inorganic wastes, and straw fiber on the mechanical and water resistance properties of flue gas desulfurization (FGD) gypsum. The results indicate that the properties of the gypsum-based composites improved with the addition of cement and waste due to the synergistic effect between them and the addition of 3 wt% of sorghum straw fiber (SSF) significantly improved the flexural strength and decreased the apparent density of the samples. In contrast, Antunes et al. [3] found in the study of rice husk-earth-based composites that increasing the rice husk content decreases the flexural strength. Ashour et al. [11] even added wheat and barley straw to the composition of unfired earth bricks. In contrast to the research mentioned above, this paper examines the properties of a composite material made of gypsum and straw using different classes of gypsum strength. This will be used to determine the applicability of the composite material in the case of requirements for its higher strength.

The disadvantage of straw reinforcement may be its smooth surface, which reduces the cohesion with the binder. This was the subject of research in which straw fibers were modified by treatment with acrylic acid coating and the mechanical properties of straw fiber-reinforced gypsum composite were investigated. The results of this research showed that by the treatment with acrylic acid coating, the roughness of the straw fibers increased markedly, and the dry flexural strength and the dry compressive strength of the gypsum composite increased respectively by 71.3% and 52.4% [20]. The disadvantage of this treatment is the work with acid, which introduces a safety risk into the production process. Acid is a flammable caustic that is dangerous to the environment. Another disadvantage of using straw could be a deterioration in the fire resistance of the composite because gypsum is a non-flammable material, but straw is very flammable [5]. According to [21], samples with untreated straw fibers also met the ignitability requirement. However, composites with treated straw fibers have better fire resistance.

The aim of this research is to verify whether these natural fibers can increase the strength of the plasterboards as well as synthetic fibers. These would be used indoors just like common gypsum plasterboards, but would also meet higher mechanical user requirements. Due to the reinforcing fibers, they could be stronger and have a higher load-bearing capacity. These composite plasterboards differ from commonly available high-strength plasterboards precisely in that they are not reinforced with synthetic fibers but effectively use natural fibrous materials. The straw was mixed with gypsum in various proportions. The percentage amount of straw and the class of gypsum that influence the mechanical and thermal properties investigated can also affect the ignitability of composite materials. This research focuses on investigating the basic properties of a new composite material made of gypsum and straw, which can be further used for the production of interior plasters and gypsum plasterboards.

This paper first describes the production of composite material and methods to test the individual properties of this composite. Specifically, this research is focused on the determination of the following characteristics: flexural strength Pt (N·mm−2), the compressive strength Rc (N·mm−2), the thermal conductivity λ (W·m−1·K−1), the specific heat capacity c (J·kg−1·K−1), the ignitability, and the gross heat of combustion QPCS (MJ·kg−1) of the composite material created. Finally, all results are presented and compared with each other, and the causes of the obtained values of these properties are discussed.

For the production of the test samples, gypsum was selected as the binder. It is a powder mixture of hemihydrate of calcium sulfate (CaSO4·1/2 H2O). For research, three types of gypsum with strengths G2 (2 MPa)—gypsum Class I., G5 (5 MPa)—gypsum Class II. and G16 (16 MPa)—gypsum Class III. were tested [22].

The variant of crushed wheat straw as reinforcing fiber was chosen due to its relatively high tensile strength [23]. Crushed straw is produced by cutting and grinding straw stalks into small pieces. The crushed straw is produced using a straw chopper. It is easily available, inexpensive, and fully recyclable. For research, crushed straw stalks in the length of 0.5–1.5 cm were used. The crushed straw used in the research is shown in Fig. 1. The straw used in this research was purchased as bedding for horses. The name of the straw producer is MIKÓ STROH (Hungary).

Figure 1: Crushed straw used in the research

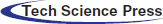

For experimental testing, three series of samples were prepared. The series and numbers of test samples produced are described in Table 1. To test mechanical and thermal properties, test samples measuring 40 mm × 40 mm × 160 mm [24] were made in steel moulds to test the mechanical properties of mortar and cement materials. For the single-flame source fire test, test samples (gypsum-straw plates) with dimensions 250 mm × 90 mm × 15 mm were made. First, plywood forms were made. These forms were filled with the fresh gypsum-straw mixture (Fig. 2). The percentage content of straw in the test samples was 0%, 2.5% and 5.0%. After filling, the surface of the test samples was smoothed with a steel trowel. After curing, the test samples were removed from the forms. Since the material of the test samples was not degraded in any way during the fire test, it could be used to determine the gross heat of combustion (calorific value). The material for this fire test was crushed with a hand crusher.

The samples were created in a technical laboratory adapted to this. The ingredients of each series were weighed in proportion and amount and the test samples were made in the number according to Table 1.

After weighing and mixing the dry ingredients, a powdery mixture was formed and mixed with water for 1 min [24]. Fig. 2 shows the mixture of gypsum with crushed straw stalks.

Figure 2: Mixture of gypsum with straw stalks

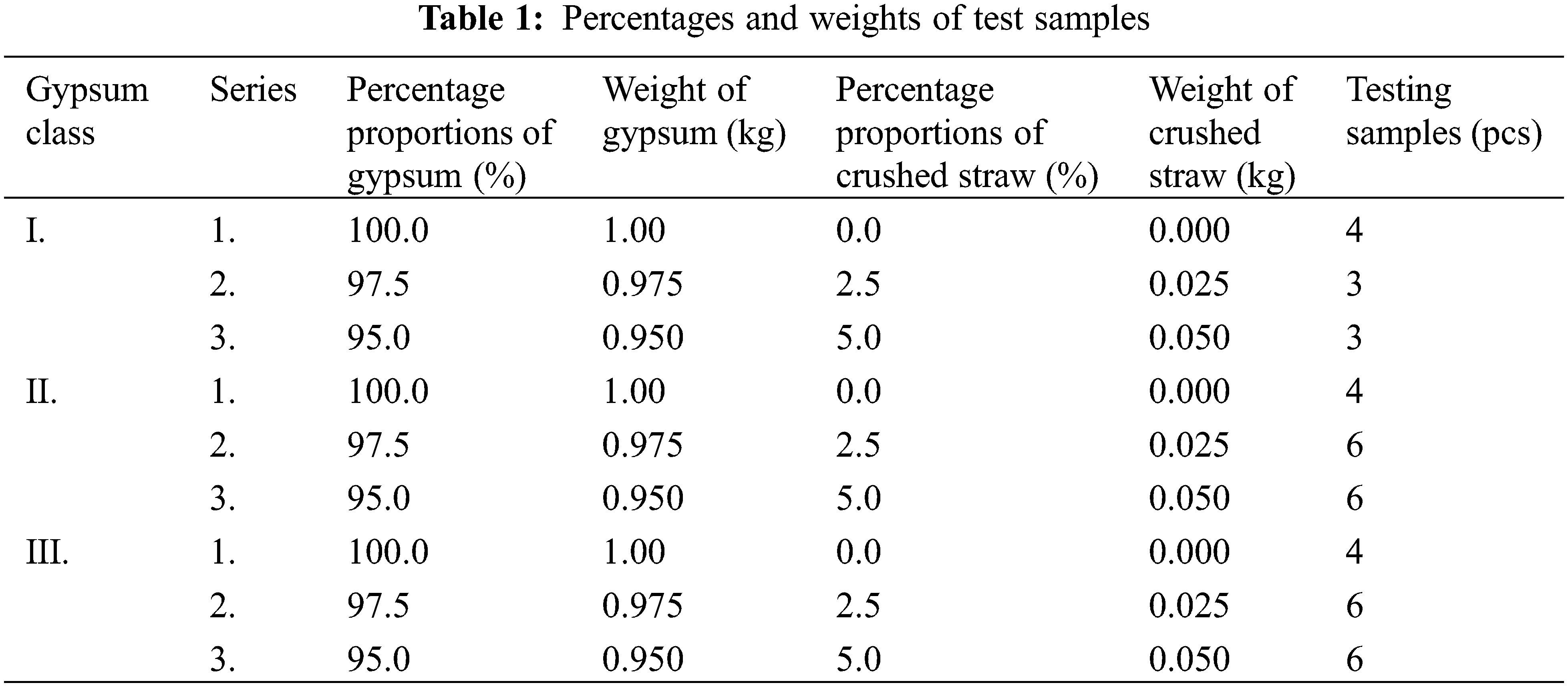

The resulting mixture filled the prepared steel moulds, which were vibrated on the vibrating table for one min. to achieve complete filling of the mould. After 24 h, the samples were removed from the moulds, dried at 40°C to steady weight, and then stored for seven days in the test environment (temperature (23 ± 2)°C and relative air humidity (50 ± 5)%) [24]. Fig. 3 shows the test samples in the test mould.

Figure 3: Test samples in the test mould (Gypsum Class II.; Percentage proportion of 100% gypsum, 0% straw)

Samples twenty-eight days old were weighed and the dimensions of each sample were measured. The bulk density of the measured composite material was determined as the arithmetic mean of the weight of the test samples of each series divided by the volume of the test samples. Samples of the I. gypsum class were tested in thermal conductivity and specific heat capacity tests. After these tests, the flexural strength measurement was performed on each sample. The compressive strength values were then measured in the individual halves of the samples. The indoor air temperature and relative humidity during the sample testing were 21.9°C and 55.0%. Ignitability and gross heat of combustion were determined in the samples for fire properties tests.

The main purpose of this test was to measure the force needed to break the test samples.

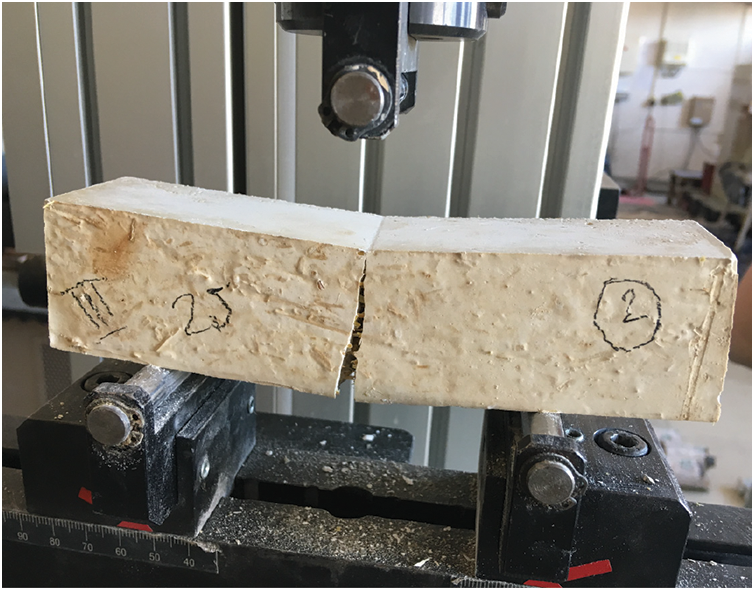

The samples were placed in the FormTest press and oriented so that their horizontal axis was perpendicular to the supports of the test press machine. Therefore, the load was perpendicular to the direction of filling the test moulds. The load roller transferred the load perpendicular to the opposite surface of the test sample. The load velocity was set to 10 N/s for all samples. The load was evenly increased until the sample broke [24], see Fig. 4.

Figure 4: Broken test sample after the flexural strength test

The measured values of the maximum applied load P of the individual test samples were recorded. According to Eq. (1), the values of the flexural strength Pt were calculated. Then, the average values of the flexural strength Pt of each series were calculated.

Calculation of flexural strength [24]:

where: Pt Flexural strength (N·mm−2)

P Maximum applied load (N).

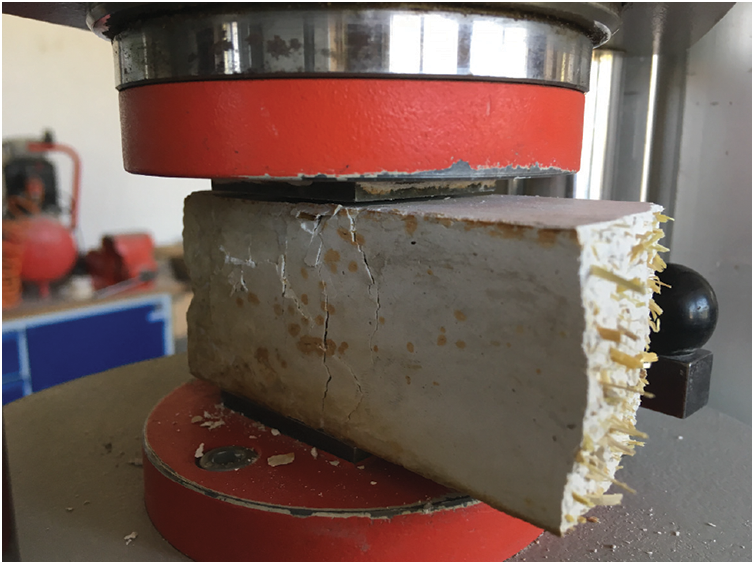

Half of the samples were created by the flexural strength test of each original sample and were marked by the proportion of straw content. Immediately after this test, these new samples were tested for compression strength. The samples were placed in the FormTest press so that the load was perpendicular to the direction of filling; the samples were centered in relation to the load boards. The area of the load boards is 40 mm × 40 mm, so the entire area of the load board was in contact with the sample. The load velocity was set to 50 N/s for all samples. The load was evenly increased until the damage of the sample [24] (Fig. 5).

Figure 5: Damage of the test sample after the compressive strength test

The measured values of the maximum applied load Fc of the individual test samples were recorded. According to Eq. (2), the values of the compressive strength Rc were calculated. Then the average values of compressive strength Rc of each series were calculated.

Calculation of compressive strength [24]:

where: Rc Compressive strength (N·mm−2)

Fc Maximum applied load (N)

1600 40 mm × 40 mm is the area of load boards (mm2).

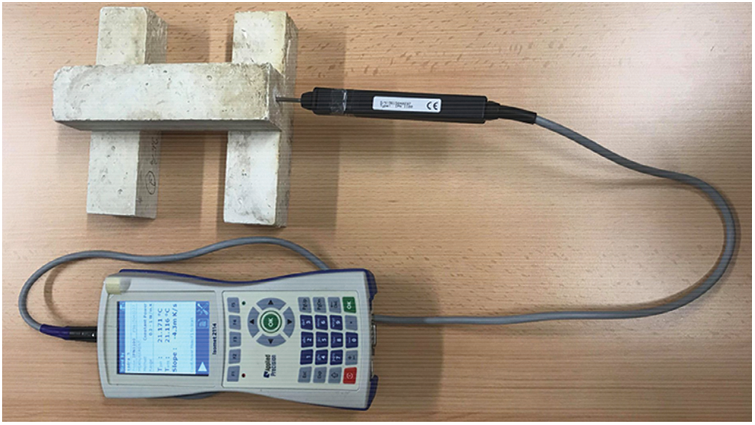

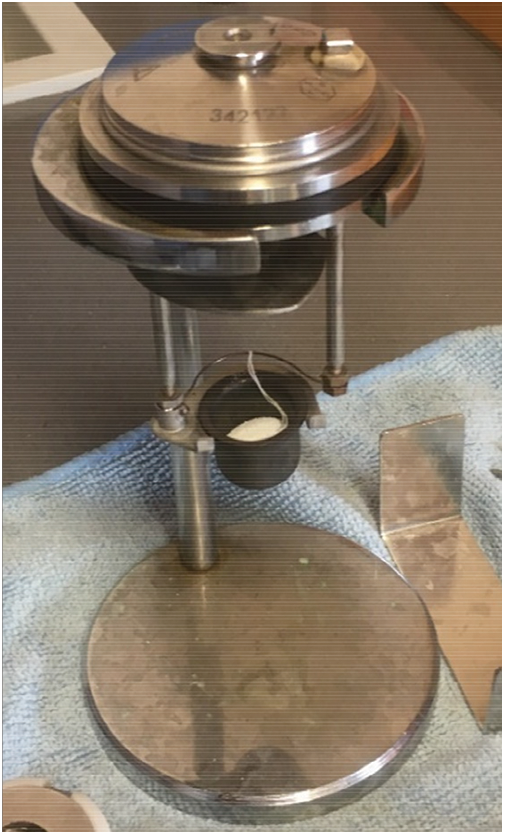

The measurement was performed on only one set of samples. Samples containing gypsum class G2 (I.) were selected to measure thermal properties using the ISOMET 2114 device. This device can determine the value of thermal conductivity λ (W·m−1·K−1) and volumetric heat capacity Cρ (J·m−3·K−1) [25]. The ISOMET device was equipped with a needle sensor [25], which was inserted into a predrilled hole in the test sample filled with thermal conductive silicone gel (Fig. 6). This sensor uses a non-stationary hot wire method for measurement. The principle of the hot wire method is based on the measurement of temperature rise at a defined distance from a linear heat source, which is a hot wire. Increasing the temperature of the hot wire is provided by electrical energy. It heats a thin wire that is placed in the test sample and is a source of heat. The device records the rise and fall of temperatures and calculates the thermal conductivity according to Eq. (3) [26]:

where: λ Thermal conductivity (W·m−1·K−1)

Q Power per unit length (W·m−1)

T1, T2 Temperatures (K)

t1, t2 Times (s).

Another quantity that the ISOMET device can measure is the volumetric heat capacity Cρ (J·m−3·K−1). The ISOMET device measures how much heat is needed to heat one m3 of the tested material. Then it is necessary to calculate the specific heat capacity c (J·kg−1·K−1) from the measured values of the volumetric heat capacity Cρ. To calculate the specific heat capacity, it is necessary to determine the bulk density of the measured material. From the measured volumetric heat capacity and bulk density, the specific heat capacity of each series of the test samples was calculated according to Eqs. (4) and (5) [26]:

where: Cρ Volumetric heat capacity (J·m−3·K−1)

c Specific heat capacity (J·kg−1·K−1)

Q Amount of heat per unit volume (J·m−3)

T Temperature (K)

ρ Bulk density (kg·m−3).

For measurements, the test samples were placed in a test chamber where the temperature (23°C) and air humidity (50%) were constant. The results of each measurement were recorded.

Figure 6: ISOMET device with needle sensor inserted into the test sample

3.4 Fire Properties–Reaction to Fire

In this research framework, the ignitability and gross heat of combustion were measured. The single-flame source fire test of composite material made of gypsum and reinforced with natural fibers has been performed [27]. These tests were carried out to verify whether the straw added to the gypsum would significantly impair the fire resistance of the resulting composite materials. These tests were based on previously implemented research, focusing on the fire properties of crushed straw [28].

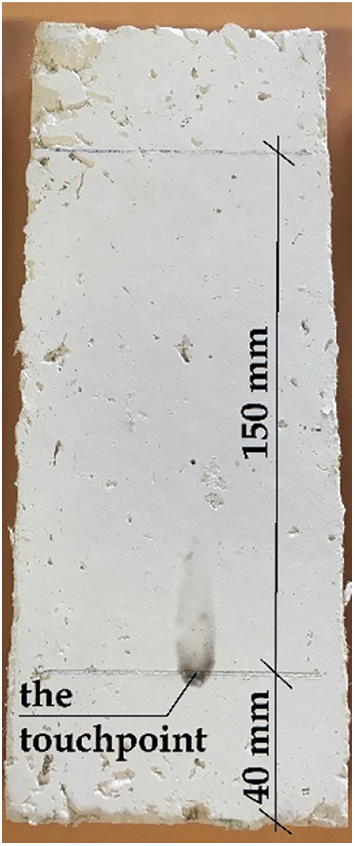

The single-flame source fire test was carried out on three test samples to test fire properties. On the exposed surface of the samples, two horizontal axes were marked. The first was 40 mm above the bottom edge of the testing sample, and the second was 150 mm above the first axis, as shown in Fig. 7. The first axis shows the touchpoint where the gas burner with a small normative flame [29] touches the surface of the tested material. The burner’s angle is 45°, and the length of the flame must be measured by a special meter. The time at which the flame is allowed to act on the test material began to be measured. The time of the fire test (flame effect) was 30 s. During the fire test, two criteria are checked: if the flame ignites the sample’s surface and if the flame spreads from the first horizontal ax (touchdown point) to the second horizontal ax 150 mm above the touchdown point. If the flame spreads to the second horizontal ax, the tested material does not meet the fire test requirements. The time before the flame touches the second horizontal ax (Burning time track 150 mm criteria) is measured.

Figure 7: Description of the sample surface exposed to the flame, marked by two horizontal axes

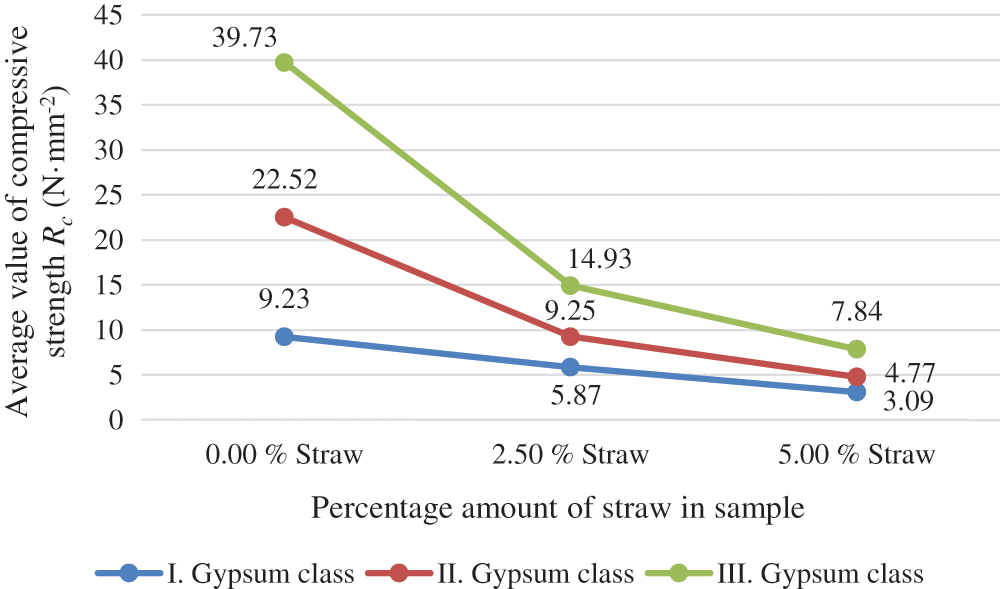

The test to determine the gross heat of combustion (calorific value) QPCS (MJ·kg−1) was performed in an oxygen bomb calorimeter IKA C 200 under standardized conditions, at constant volume and in an atmosphere of oxygen. The gross heat of combustion is calculated on the basis of the observed temperature rise, taking account of heat loss and the latent heat of vaporization of water. The crucible method was used with 0.5 g of crushed straw (Fig. 8) according to [30]. The device measured the gross heat of combustion of the crushed straw itself. Since gypsum is a non-flammable material, the gross heat of combustion of the composite material was calculated from the measured value based on the percentage of straw in the composite.

Figure 8: Measured sample in the crucible of the bomb calorimeter

4.1 Bulk Density, Flexural Strength, Compressive Strength

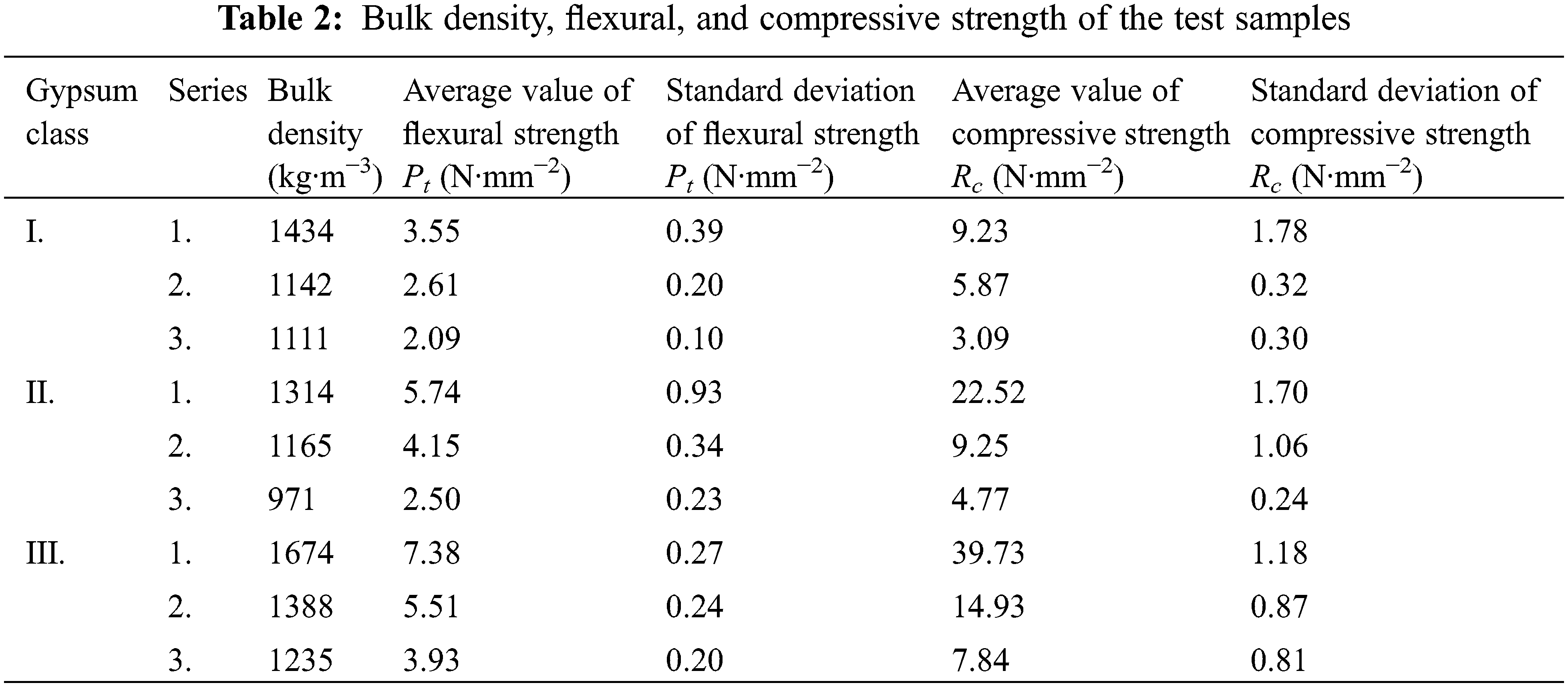

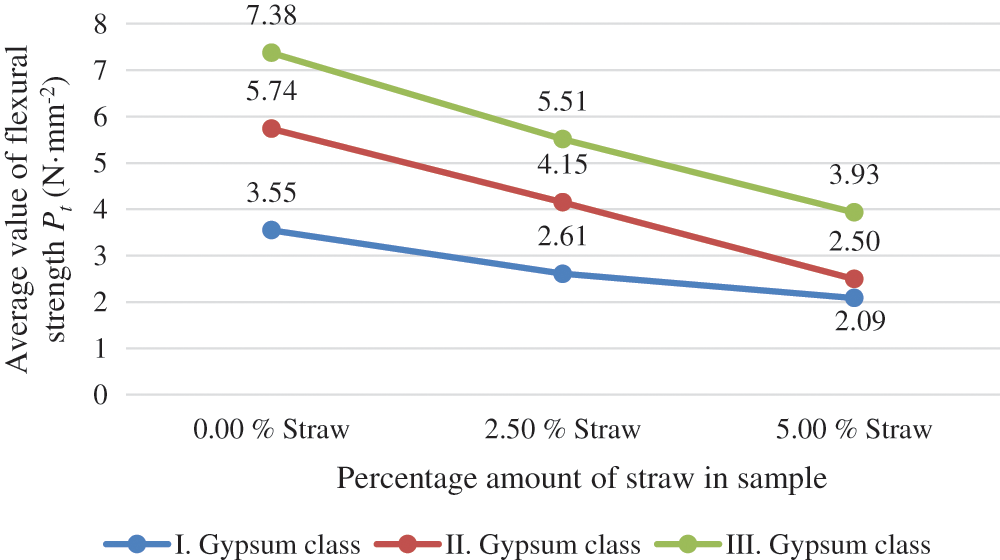

Table 2 shows the average values of the measured bulk density, flexural strength, and compressive strength of the test samples. Standard deviations were also calculated and recorded.

Figs. 9 and 10 show the dependence of the average value of flexural strength Pt and compressive strength Rc on the percentage amount of straw in the sample. Different colors present different classes of gypsum. It is clear that with an increasing percentage of straw in the sample, the flexural strength and the compressive strength decrease. The largest decrease in flexural strength occurred in the sample with 5% crushed straw (3. series) of gypsum Class II. when the average value decreased by 56.49%. And the largest decrease in compressive strength occurred in the sample with 5% crushed straw (3. series) of gypsum Class III. when the average value decreased by 80.27%. On the other hand, it can be said that the smallest decrease in these mechanical properties occurred in samples with 2.5% crushed straw (2. series). When the gypsum Class III. sample with this percentage of straw achieved the smallest decrease in the values of the flexural strength, namely 25.2%, and the smallest decrease in the compressive strength was achieved by a gypsum Class I. sample, which decreased by 36.4%. The sample of gypsum Class I. with 2.5% crushed straw achieved the smallest decreases both in flexural strength (by 26.5%) and also in compressive strength (by 36.4%). So, the results showed that the most suitable ratio of gypsum and straw was achieved by 2. series (97.5% gypsum and 2.5% crushed straw).

Figure 9: Comparison of the average values of the flexural strength Pt for the measured samples

Figure 10: Comparison of the average values of the compressive strength Rc for the measured samples

The smooth surface of the individual stalks of crushed straw can be the reason for the decrease in flexural and compressive strength. According to Bouasker et al. [10], this property has an adverse effect on the mechanical strength of the final straw fiber materials, especially on the pull-out resistance of the fibers, and therefore, the higher roughness of the fiber is required to contribute to better adhesion to gypsum. The reduction in strength has also been demonstrated by other research, whose low strength values obtained do not qualify their composites for use as structural materials [3,7,14–16].

On the contrary, Yang et al. [19] have shown an improvement in flexural strength; they used untreated sorghum straw fiber (SSF) and SSF only treated with compound pretreatment (successively treated with alkali, enzyme and waterproofing agent), which further improved the overall properties of the composite wall materials based on gypsum. The flexural strength of the composites with compound pretreated SSF was 13.4% higher than the strength of the composites with untreated SSF. The disadvantage of this pre-treatment is the use of chemicals for treatment, which worsens the impact on the environment and increases the financial cost of production. The increasing strength results are also achieved [4,9,13]. Interestingly, the mechanical properties of straw composites also depend on the straw fragmentation method described by Masłowski et al. [8].

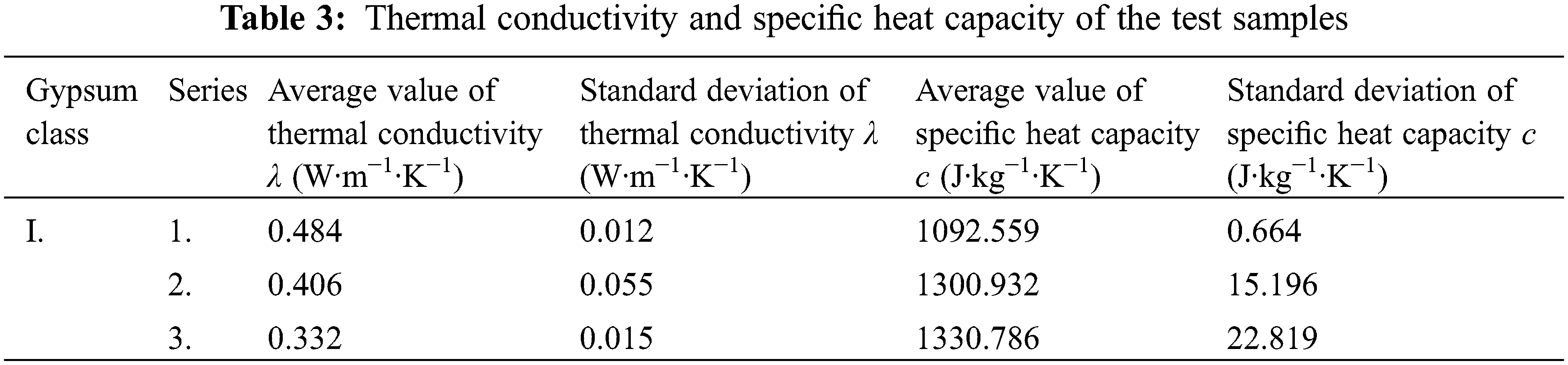

Table 3 shows the average values of the thermal conductivity λ of each series and the standard deviation. In the composite material measurement, the volumetric heat capacity Cρ (J·m−3·K−1) of the individual test samples was measured. According to Eq. (5), the specific heat capacity was calculated based on the bulk density of the individual samples. The results of the volumetric heat capacity measurements and the value of the specific heat capacity c were recorded. The average values of the specific heat capacity c and the standard deviation are given in Table 3.

It is clear from Table 3 that with an increasing percentage of straw in the sample, the thermal conductivity decreases and the specific heat capacity increases. The thermal conductivity coefficient decreased by 31.40% for the sample with 5% crushed straw (3. series). Further research on composites with natural fibers has also shown that the thermal properties will improve with increasing amounts of straw [3,7,13,11,15,18].

It is worth mentioning that the thermal conductivity λ of a material is affected by humidity. As explained by El Fgaier et al. [31], an increase in the water content causes a higher amount of water in the porosity of the sample, which replaces air. Water has a higher thermal conductivity than air; therefore, the thermal conductivity of the sample increases. Bouasker et al. [10] proved that straw has a high water absorption coefficient compared to other vegetable fibers. At 20°C, the straw absorbs the average weight of water three times higher than its own weight. There were significant differences between the straw varieties (barley and wheat), as this value was measured four times higher for barley straw.

Fig. 11 shows the test samples after the single-flame source fire test. The results have shown that this composite material has very good flame resistance. During the single-flame source fire test, the surface of all test samples did not ignite and there was no fire propagation or release of smoke and odor during this test. Therefore, for all test samples, the requirements of ignitability were met by a single-flame source fire, and this composite can be classified as better than Class E.

Figure 11: The test samples after the single-flame source fire test

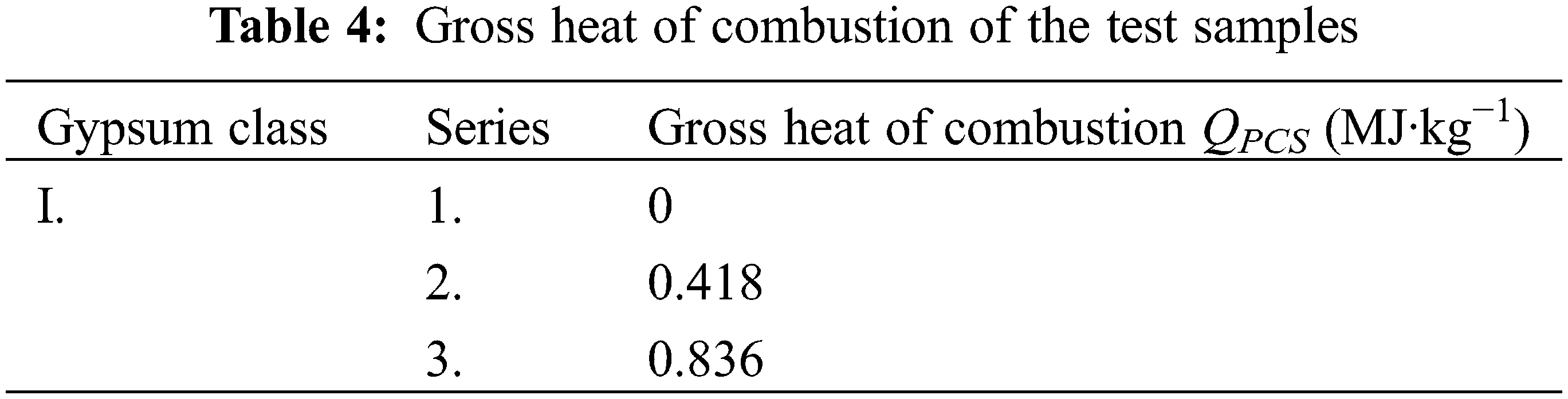

The next step in the research of fire properties was to verify whether the composite material can be classified as a non-flammable material. Thus, into the reaction to fire A1 or A2 class. Whether this composite material meets the requirements for classification as a non-flammable material was verified by the gross heat of combustion (calorific value) fire test [30]. The criteria for classification in reaction to fire for non-flammable (Classes A1 and A2) on the basis of the gross heat of combustion fire test are given in [32]. The measurement showed that the gross heat of combustion of the crushed straw is 16.712 MJ·kg−1. Since gypsum is a non-flammable, the gross heat of combustion was calculated for each series of composite materials according to their percentage content of crushed straw. The values of gross heat of combustion of individual test samples are given in Table 4.

Based on the fire tests performed, it can be said that the composite material is non-flammable (Classes A1, A2 according to its reaction to fire). The single-flame source test excluded Classes E and F for the composite material. Depending on the behavior of the material during this fire test, it can be assumed that the SBI (Single Burning Item) fire test would also exclude Classes B, C, and D. The SBI fire test is used in practice to classify building materials into Classes A2 to D [33]. This test will be performed only on gypsum-straw plasterboards in the following phases of research. The gross heat of combustion fire test confirmed that the material is non-flammable. The gross heat of combustion QPCS of the composite material is 0.418 and 0.836 MJ·kg−1 (Table 4). These calculated values are lower than the maximum values of gross heat of combustion specified in [32] for non-flammable materials (Classes A1 and A2).

Moreover, Yue et al. [5] and Antunes et al. [3] achieved comparable fire resistance of their composites in the fire test as this research. According to Bouasker et al. [10], wheat and barley straw exhibit the same reaction to fire. To further retard the flame spread and prevent the composite degradation, the treatment with linseed oil and boiled water has a significant effect [21]. Linseed oil and boiled water reduce their water absorption and increase their compatibility and adhesion to the binder. Jami et al. [12] found that their hemp concrete satisfies the requirements of European fire tests, but its resistance to fire needs to be further studied and validated against the fire resistance standards of other countries.

The research contains basic information on the mechanical, thermal, and fire-resistant properties of the composite material made of gypsum and natural fibers. It is evident from the measurements made that with an increasing proportion of straw reinforcement, the flexural strength, the compressive strength, and the thermal conductivity decrease. On the contrary, the specific heat capacity increases with the increasing proportion of straw. The fire resistance of the composite material does not deteriorate.

Thus, this research has shown that adding reinforcing straw fibers to the gypsum binder does not improve its mechanical properties and therefore this composite material cannot be used as high-strength plasterboards. The largest decrease in flexural strength (by 56.49%) occurred in the sample with 5% crushed straw (3. series) of gypsum Class II., and the largest decrease in compressive strength (by 80.27%) occurred in the sample with 5% crushed straw (3. series) of gypsum Class III. The reason for the decrease in strength can be that with an increasing proportion of straw, the intergranular porosity increases, and the amount of binder decreases. Another reason may be the smooth surface of the individual stalks of crushed straw. This composite material should be used primarily for the production of cladding plasterboards or plasters, because research has shown that the added straw fibers improve its thermal properties and do not worsen fire resistance. Their thermal insulation properties were better, but not as much as insulation boards that would replace other insulations. Surprisingly, even with 5% crushed straw, the composite material is still non-flammable (reaction to fire Classes A1, A2).

In any case, we consider the use of straw stalks, rice, corn or other natural fibers with various binders to be beneficial in areas where they are readily accessible because it could allow a reduction in the manufacturing costs of conventional products by using inexpensive and renewable natural fillers. This is advantageous in terms of economic, environmental and life-cycle analysis using different impact assessment indicators.

Availability of Data and Materials: Any additional data not presented in this article is available upon request to the corresponding author.

Acknowledgement: The authors would like to thank the staff of the laboratories of the Department of Building Materials and Diagnostics of Structures, Faculty of Civil Engineering, VSB–Technical University of Ostrava.

Funding Statement: This article was financed from the budget of the Student Grant Competition VSB-TUO (Registration No. SGS SP2020/135). This article has been elaborated in the framework of scholarship of the City of Ostrava (RRC/2806/2019) and in the framework of the grant programme “Support for Science and Research in the Moravia-Silesia Region 2018” (RRC/10/2018), financed from the budget of the Moravian-Silesian Region.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. CEN (2009). EN 13279-1: Gypsum binders and gypsum plasters–Part 1: Definitions and requirements. [Google Scholar]

2. USG Corporation (2009). The gypsum construction handbook. Kingston, MA: R.S. Means Company, Inc. [Google Scholar]

3. Antunes, A., Faria, P., Silva, V., Brás, A. (2019). Rice husk-earth based composites: A novel bio-based panel for buildings refurbishment. Construction and Building Materials, 221(4), 99–108. DOI 10.1016/j.conbuildmat.2019.06.074. [Google Scholar] [CrossRef]

4. Chen, X., Shi, X., Zhou, J., Yu, Z., Huang, P. (2020). Determination of mechanical, flowability, and microstructural properties of cemented tailings backfill containing rice straw. Construction and Building Materials, 246(7), 118520. DOI 10.1016/j.conbuildmat.2020.118520. [Google Scholar] [CrossRef]

5. Yue, K., Li, M., Liu, J., Wang, L., Liu, W. et al. (2019). Mechanical properties and fire resistance of gypsum-based composites with wheat straw. Transactions of the Chinese Society of Agricultural Engineering, 35, 308–316. DOI 10.11975/j.issn.1002-6819.2019.18.037.2019. [Google Scholar] [CrossRef]

6. Qudoos, A., Ullah, Z., Baloch, Z. (2019). Performance evaluation of the fiber-reinforced cement composites blended with wheat straw ash. Advances in Materials Science and Engineering, 2019(5), 1–8. DOI 10.1155/2019/1835764. [Google Scholar] [CrossRef]

7. Ismail, B., Belayachi, N., Hoxha, D. (2020). Optimizing performance of insulation materials based on wheat straw, lime and gypsum plaster composites using natural additives. Construction and Building Materials, 254, 118959. DOI 10.1016/j.conbuildmat.2020.118959. [Google Scholar] [CrossRef]

8. Masłowski, M., Miedzianowska, J., Strzelec, K. (2018). Influence of wheat, rye, and triticale straw on the properties of natural rubber composites. Advances in Polymer Technology, 37(8), 2866–2878. DOI 10.1002/adv.21958. [Google Scholar] [CrossRef]

9. Zhang, X., Wang, Z., Cong, L., Nie, S., Li, J. (2020). Effects of fiber content and size on the mechanical properties of wheat straw/recycled polyethylene composites. Journal of Polymers and the Environment, 28(7), 1833–1840. DOI 10.1007/s10924-020-01733-8. [Google Scholar] [CrossRef]

10. Bouasker, M., Belayachi, N., Hoxha, D., Al-Mukhtar, M. (2014). Physical characterization of natural straw fibers as aggregates for construction materials applications. Materials, 7(4), 3034–3048. DOI 10.3390/ma7043034. [Google Scholar] [CrossRef]

11. Ashour, T., Korjenic, A., Korjenic, S., Wu, W. (2015). Thermal conductivity of unfired earth bricks reinforced by agricultural wastes with cement and gypsum. Energy and Buildings, 104(5), 139–146. DOI 10.1016/j.enbuild.2015.07.016. [Google Scholar] [CrossRef]

12. Jami, T., Karade, S. R., Singh, L. P. (2019). A review of the properties of hemp concrete for green building applications. Journal of Cleaner Production, 239(1), 117852. DOI 10.1016/j.jclepro.2019.117852. [Google Scholar] [CrossRef]

13. Suresh Babu, K., Ratman, C. (2021). Mechanical and thermophysical behavior of hemp fiber reinforced gypsum composites. Materials Today: Proceedings, 44, 2245–2219. DOI 10.1016/j.matpr.2020.12.363.2021. [Google Scholar] [CrossRef]

14. Aladejana, J. T., Wu, Z., Fan, M., Xie, Y. (2020). Key advances in development of straw fibre bio-composite boards: An overview. Materials Research Express, 7(1), 012005. DOI 10.1088/2053-1591/ab66ec. [Google Scholar] [CrossRef]

15. Brouard, Y., Belayachi, N., Hoxha, D., Ranganathan, N., Méo, S. (2018). Mechanical and hygrothermal behavior of clay–Sunflower (Helianthus annuus) and rape straw (Brassica napus) plaster bio-composites for building insulation. Construction and Building Materials, 161(4), 196–207. DOI 10.1016/j.conbuildmat.2017.11.140. [Google Scholar] [CrossRef]

16. Wei, J., Meyer, C. (2014). Degradation rate of natural fiber in cement composites exposed to various accelerated aging environment conditions. Corrosion Science, 88, 118–132. DOI 10.1016/j.corsci.2014.07.029. [Google Scholar] [CrossRef]

17. Liu, J., Li, Z., Chen, H., Guan, B., Liu, K. (2020). Investigation of cotton straw fibers for asphalt mixtures. Journal of Materials in Civil Engineering, 32(5), 04020105. DOI 10.1061/(ASCE)MT.1943-5533.0003181. [Google Scholar] [CrossRef]

18. Belayachi, N., Hoxha, D., Slaimia, M. (2016). Impact of accelerated climatic aging on the behavior of gypsum plaster-straw material for building thermal insulation. Construction and Building Materials, 125, 912–918. DOI 10.1016/j.conbuildmat.2016.08.120. [Google Scholar] [CrossRef]

19. Yang, L., Jing, M., Lu, L., Zhu, X., Zhao, P. et al. (2020). Effects of modified materials prepared from wastes on the performance of flue gas desulfurization gypsum-based composite wall materials. Construction and Building Materials, 257(1), 119519. DOI 10.1016/j.conbuildmat.2020.119519. [Google Scholar] [CrossRef]

20. Gao, Z., Li, G. (2011). Effect of straw fiber modification on performance of gypsum composite. Advanced Materials Research, 168–170, 1455–1458. DOI 10.4028/www.scientific.net/AMR.168-170.1455. [Google Scholar] [CrossRef]

21. Belayachi, N., Hoxha, D., Ismail, B. (2017). Impact of fiber treatment on the fire reaction and thermal degradation of building insulation straw composite. Energy Procedia, 139, 544–549. DOI 10.1016/j.egypro.2017.11.251. [Google Scholar] [CrossRef]

22. ČNI Praha (1980). ČSN 72 2301: Plaster binders. Classification. Common technical requirements. Testing methods. Including Change A: Changes Z2 and Changes Z3. [Google Scholar]

23. Teslík, J., Kurečka, P., Zdražilová, N. (2016). Determination of thermal conductivity coefficient of crushed straw using cool box. 16th International Multidisciplinary Scientific GeoConference: SGEM 2016: Nano, Bio and Green-Technologies for a Sustainable Future, pp. 413–420. Albena, BulgariaII. [Google Scholar]

24. CEN (2014). EN 13279-2: Gypsum binders and gypsum plasters–Part 2: Test methods. [Google Scholar]

25. Applied Precision, Ltd. ISOMET 2114 Thermal properties analyzer User’s Guide. Version 1.46. https://www.appliedp.com/download/catalog/isomet_pc_en.pdf. [Google Scholar]

26. Lee, S. J., Choi, J. C., Baek, S., Kwon, T. H., Ryu, H. H. et al. (2016). Use of a pre-drilled hole for implementing thermal needle probe method for soils and rocks. Energies, 9(846), 1–10. DOI 10.3390/en9100846. [Google Scholar] [CrossRef]

27. Teslík, J., Hošťálková, M., Vavřínová, N. (2019). Ignitability small attack flame fire test of gypsum composite reinforced with natural fibres. International Review of Applied Sciences and Engineering, 10(1), 57–61. DOI 10.1556/1848.2019.0009. [Google Scholar] [CrossRef]

28. Teslík, J., Vodičková, M., Kutilová, K. (2015). The assessment of reaction to fire of crushed straw. Applied Mechanics and Materials, 824, 148–155. DOI 10.4028/www.scientific.net/AMM.824.148. [Google Scholar] [CrossRef]

29. CEN (2020). EN ISO 11925-2: Reaction to fire tests—Ignitability of products subjected to direct impingement of flame–Part 2: Single-flame source test. [Google Scholar]

30. CEN (2018). EN ISO 1716: Reaction to fire tests for products—Determination of the gross heat of combustion (calorific value). [Google Scholar]

31. El Fgaier, F., Lafhaj, Z., Chapiseau, C., Antczak, E. (2016). Effect of sorption capacity on thermo-mechanical properties of unfired clay bricks. Journal of Building Engineering, 6(4), 86–92. DOI 10.1016/j.jobe.2016.02.011. [Google Scholar] [CrossRef]

32. CEN (2019). EN 13501-1: Fire classification of construction products and building elements–Part 1: Classification using test data from reaction to fire tests. [Google Scholar]

33. CEN (2020). EN 13823: Reaction to fire tests for building products-Building products excluding floorings exposed to the thermal attack by a single burning item. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |