| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.016025

ARTICLE

Effects of Planting Density of Rubber Tree Clone (RRIM 2020 Clone and RRIM 2025 Clone) Wood to Particleboard Properties

1Institute of Tropical Forestry and Forest Products (INTROP), Universiti Putra Malaysia (UPM), Serdang, 43400, Malaysia

2Faculty of Technology Management and Business, Universiti Tun Hussein Onn Malaysia (UTHM), Parit Raja, 86400, Malaysia

3Department of Wood Industry, Faculty of Applied Sciences, Universiti Teknologi MARA (UiTM), Bandar Tun Abdul Razak, Jengka, Pahang, 26400, Malaysia

4School of Chemical and Energy, Faculty of Engineering, Universiti Teknologi Malaysia, Johor Bahru, 81310, Malaysia

5Centre for Advanced Composite Materials, Universiti Teknologi Malaysia, Johor Bahru, 81310, Malaysia

*Corresponding Authors: Syeed SaifulAzry Osman Al-Edrus. Email: saifulazry@upm.edu.my; Seng Hua Lee. Email: lee_seng@upm.edu.my

Received: 01 February 2021; Accepted: 27 November 2021

Abstract: The depletion of log resources encourages research into alternative ways to sustain the wood supply. Therefore, the 4-year-old Rubber Research Institute of Malaysia (RRIM) clones series, RRIM 2020 and RRIM 2025, were chosen as potential raw materials for particleboard in this study. The purpose of this study was to assess the effects of planting density and rubber tree clones on the mechanical and physical properties of single-layer particleboard. The planting densities used were low, moderate-low, moderate-high, and high, representing 500, 1000, 1500, and 2000 trees/ha, respectively. Prior to manufacturing, the RRIM 2000 series clone trees were harvested, cut, chipped, flaked, and screened. The mechanical and physical properties were evaluated in accordance with the Japanese Industrial Standard (JIS A 5908-2003). The findings revealed that both planting density and clone had a significant impact on the mechanical and physical properties of particleboard with a thickness of 10 mm and a density of 700 kg/m3. RRIM 2020 specimens with low planting density had superior modulus of elasticity (MOE), modulus of rupture (MOR), and internal bonding (IB) values of 2415, 19, and 1.7 MPa, respectively. Furthermore, moderate-low planting density demonstrated the lowest thickness swelling (TS) and water absorption (WA) values and was comparable to control particleboard from commercial clone Prang Besar (PB), PB260. In terms of rubber clones, RRIM 2020 particleboard met the minimum requirements of the JIS standard for mechanical properties and outperformed RRIM 2025. This study recommended a low planting density of 500 trees/ha and the RRIM 2020 clone as a suitable raw material for particleboard manufacturing with a ten percent urea formaldehyde resin content.

Keywords: Rubberwood; RRIM 2020; RRIM 2025; mechanical; physical; urea formaldehyde

For several decades, rubberwood has been recognised as a major timber in the production of wood-based products. Rubberwood PB 260 clone is the most well-established, widely planted, and widely used in commercial plantations. According to a recent Fitch [1] report, rubberwood has become the most preferred material in Malaysia for the production of particleboard and medium density fibreboard (MDF), with the highest export of both occurring in 2007 with a value of USD500 million. Aside from that, rubberwood is the most common material used in Malaysian wooden furniture. For many years, the availability of rubberwood supply drove the success of the wood industries in Malaysia and Thailand [2,3]. Rubberwood logs are harvested 25 to 30 years after planting in Malaysian plantations. Over the years, the Malaysia Rubber Board (MRB), formerly known as the Rubber Research Institute of Malaysia (RRIM), has consistently provided new improvements to the rubber industry in order to improve latex yield, particularly in breeding and selection of rubber clones. The RRIM 2000 series clones have been identified as rubber clones with high wood volume due to their branching habits, as well as an outstanding latex yield of over 2000 kg/ha/year [4].

RRIM 2020 is one of eight clones of the first selection clones in the RRIM 2000 series, which was introduced in 1995. Meanwhile, RRIM 2025 is a clone from the second selection of the RRIM 2000 series, which was introduced in 1998 [5]. RRIM 2020 and RRIM 2025 are both classified as ‘latex timber clones’ with the goal of producing high latex and timber yield [5]. Both RRIM 2020 and RRIM 2025 have roughly the same girth and annual girth increment. However, the timber yield varies significantly between these two clones. According to Ramli et al. [6], a 14-year-old RRIM 2025 tree can produce 1.87 m3/tree of total wood volume, compared to 1.00 m3/tree for RRIM 2020. According to Paridah et al. [7], both RRIM 2020 and RRIM 2025, which are four years old, are suitable for the production of particleboard that meets the JIS A 5908 standard. The resulting particleboard exhibits comparable performance to that of mature PB260 clone particleboard. Apart from rubberwood, two other fast-growing tree species, kelempayan and petai belalang, have been successfully used to manufacture particleboard [8]. Consumption of fast-growing trees benefit the industry by increasing wood supply in a short period of time rather than over a normal harvesting period of time.

The performance of particleboard is well known to be highly dependent on the density of the wood [7]. The number of wood particles required to achieve a fixed density decreases as the density of the wood particles increases. This inevitably has a detrimental effect on the compaction ratio of the resultant particleboard. Generally, boards with a lower compaction ratio exhibit inferior properties. As Mitlin [9] suggests, the particleboard produced should be at least 5% denser than the natural wood density to achieve a desired level of performance. Saffian et al. [10] found that the planting density of rubber trees has a significant effect on the wood properties. For example, a low planting density of 4 m × 4 m trees with a total of 625 trees/ha or fewer resulted in rubber trees suitable for solid wood production. Nonetheless, higher planting densities of 1110 to 1666 trees/ha are appropriate for composites, such as particleboard and MDF, where harvesting can occur earlier. Melo et al. [11] concluded that a lower initial planting density (312 trees/ha) of wood would be appropriate for more homogeneous timber production. Prior research has generally confirmed that planting at varying densities can affect the wood’s basic density. According to Rocha et al. [12], Eucalyptus trees planted at low density had a higher wood density than those planted at high density. However, another study conducted by Lim et al. [13] found that as planting spacing increased, the density of the wood decreased by 4%. In their study, the mean density of clone PB 235 decreased from 622 kg/m3 (2.2 m × 2.4 m spacing) to 575 kg/m3 (3.7 m × 3.7 m spacing), and that of clone PB 260 decreased from 599 kg/m3 (2.2 m × 2.4 m spacing) to 546 kg/m3 (3.7 m × 3.7 m spacing). As a result, the purpose of this study is to investigate the effects of four planting densities of RRIM 2000 series clones (RRIM 2020 and RRIM 2025) on the mechanical and physical properties of particleboard.

This study utilised three clones. Two rubber tree clones, RRIM 2020 and RRIM 2025, were harvested from the RRIM station in Tok Dor Besut, Terengganu, Malaysia, when they were four years old. Both rubber tree clones were planted at four different planting densities (PD): 500 (low), 1000 (moderate-low), 1500 (moderate-high), and 2000 (high) trees/ha with an average diameter of 15 cm. Meanwhile, a commercial PB 260 clone (age > 25 years old and planted at 450 trees/ha) chip obtained from a local manufacturer was used as a control.

2.2 Procurement of Rubberwood Particles

The RRIM 2000 series clone trees (RRIM 2020 and RRIM 2025 clones) were felt and cut into billet size, with a total of 80 trees and 10 trees representing each clone’s variable. The samples were debarked and chipped using Pallman chipper and air-dried for 24 h before being flaked in a Pallman flaker machine. PB 260 chips were flaked with the same equipment. The particles were then screened using a screener vibrator, and only particles with a length of 0.5–2.0 cm were used. The particles were oven-dried at 103 ± 2°C to less than 6% moisture content.

2.3 Manufacture of Particleboard

There were nine different types of boards produced, a total of 27 boards with dimensions of 340 mm × 340 mm × 10 mm. These nine boards included PB 260 as a control, RRIM 2020 at 500 PD, RRIM 2020 at 1000 PD, RRIM 2020 at 1500 PD, RRIM 2020 at 2000 PD, RRIM 2025 at 500 PD, RRIM 2025 at 1000 PD, RRIM 2025 at 1500 PD, and RRIM 2025 at 2000 PD. From each board type, three replicates of particleboard with a density of 700 kg/m3 were made. The rubberwood particles were blended and sprayed with Urea Formaldehyde (solids 65%) at a resin content of 10%. Ammonium chloride was used as a hardener at 1% resin and 1% wax content. The sprayed particles were formed into a homogeneous mat and cold-pressed for 5 min. The formed mats were pressed for 7 min at 170°C with a pressing pressure of 4 MPa in a Tahei oil heated hydraulic press, and two rectangular steel bars with dimension of 10 mm × 10 mm × 400 mm were placed at both mat edges to achieve 10 mm thickness. Three days prior to cutting the test specimens, the boards were placed in the conditioning room.

2.4 Evaluation of Particleboard Performance

Trimming and conditioning the boards for three days at a temperature of 23°C and a relative humidity of 50% were performed. The boards were then cut into specimen sizes and tested for density, bending (modulus of elasticity (MOE) and modulus of rupture (MOR)), internal bonding (IB), thickness swelling (TS), and water absorption (WA) properties in accordance with the Japanese Industrial Standard (JIS), JIS A 5908-2003. By dividing the mass of test specimens by their volume, the density was determined. While the Instron Universal Testing Machine Model 4204 was used to perform the bending and internal bond performance tests on particleboard. The loading rates for bending and internal bonding tests are approximately 10 and 2 mm/min, respectively. Meanwhile, the TS and WA specimens were immersed in water at 20 ± 1°C horizontally about 3 cm below the water surface for 24 h prior to the thickness and weight measurements. Three specimens are taken for each board to determine the mechanical and physical properties of the particleboard.

The results of each test were analysed using Analysis of Variance (ANOVA) to determine whether there were any significant differences between the planting density and rubber clone variables used in this study. The effects were then further examined using the Least Significant Difference (LSD) method at p ≤ 0.05. For the mean separation, the LSD method was used to determine the effect of planting density and rubber clone on the mechanical and physical properties of the boards.

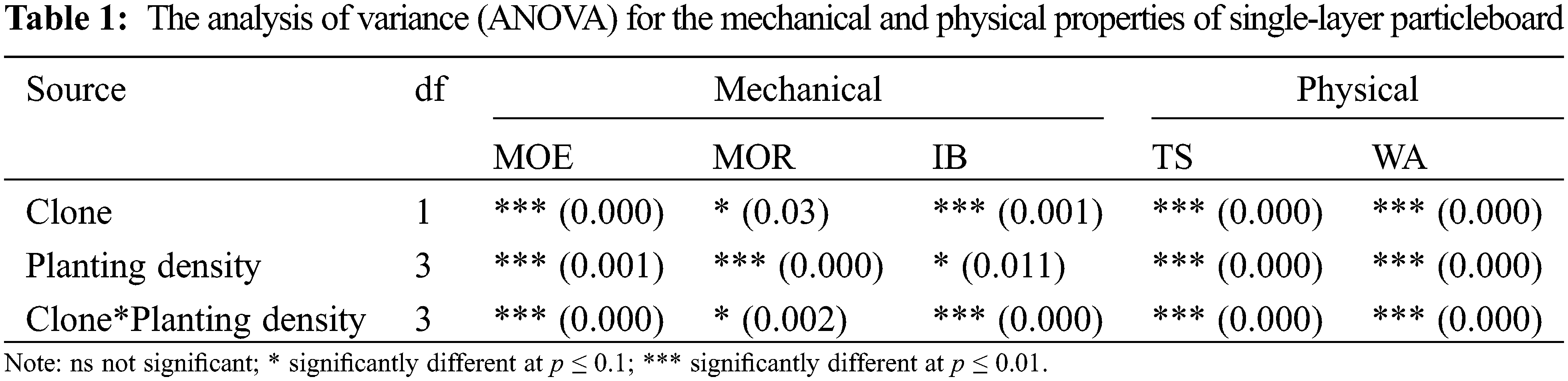

Table 1 summarises the ANOVA results for the effects of planting density and rubber clone on the mechanical and physical properties of particleboard. The interaction between planting density and rubber clone had a significant influence on the MOE, IB, TS, and WA properties. MOR, on the other hand, showed less interaction effects. All of the properties studied were found to be significantly affected by both planting density and rubber clone. Clone, on the other hand, has a smaller effect on MOR while planting density has a smaller effect on IB.

3.1 Effect of Planting Density and Rubber Clone on the Mechanical Properties of Particleboards

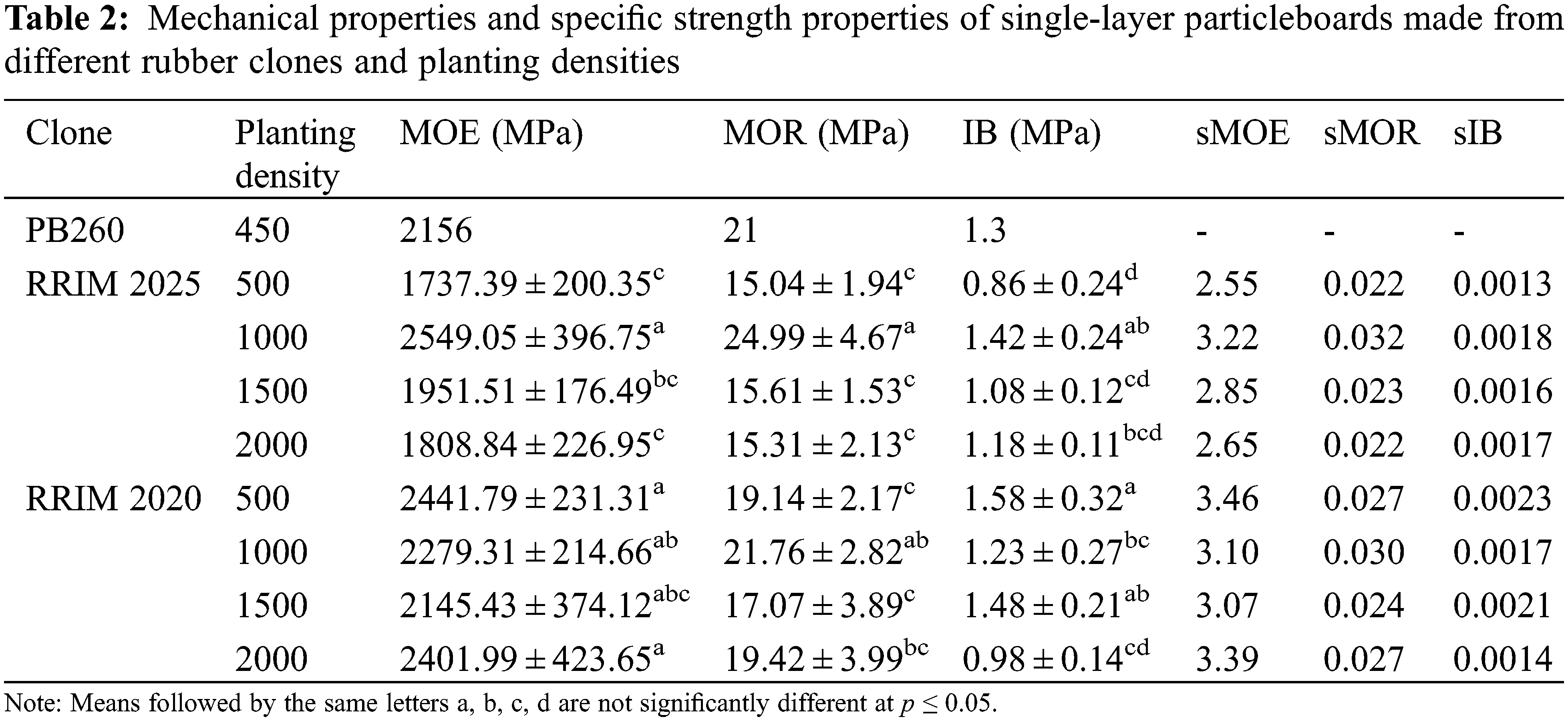

The mechanical performances of particleboards made from 4-year-old RRIM 2020 and RRIM 2025 series clones planted at various planting densities were compared to that of particleboards made from 25-year-old PB260 planted at 450 trees/ha (control/commercial planting density) in this study. Prior to the data normalisation, the average densities of PB260, RRIM 2020-500 PD, RRIM 2020-1000 PD, RRIM 2020-1500 PD, RRIM 2020-2000 PD, RRIM 2025-500 PD, RRIM 2025-1000 PD, RRIM 2025-1500 PD and RRIM 2025-2000 PD were 754, 642, 771, 666, 672, 686, 721, 662, and 683 kg/m3, respectively. As shown in Table 2, the highest MOE value was recorded in the boards produced with RRIM 2025 planted at 1000 trees/ha (RRIM 2025-1000 PD). However, the density of the particleboard obtained in this study varied greatly. To eliminate the effect of density, specific strength was calculated by dividing the strength properties by density [14]. After dividing by density, the RRIM 2020-500 PD board had the highest specific (sMOE). Wood density and compaction ratio are two factors that influence particleboard performance. The high MOE value of the control board could be attributed to the high density of mature wood. There was no discernible relationship between the sMOE and planting density. However, the high sMOE value of RRIM 2020-500 PD could be attributed to a combination of low density and a higher compaction ratio, as low density frequently resulted in a higher compaction ratio. Although the compaction ratio increased, it appears that wood density had a greater influence on particleboard MOE. While the RRIM 2025-500 PD boards had the lowest sMOE value. Low stiffness values, particularly those obtained from RRIM 2025, could be attributed to the juvenile wood properties. According to previous research, juvenile wood has a slightly lower MOE and MOR than matured wood [15,16].

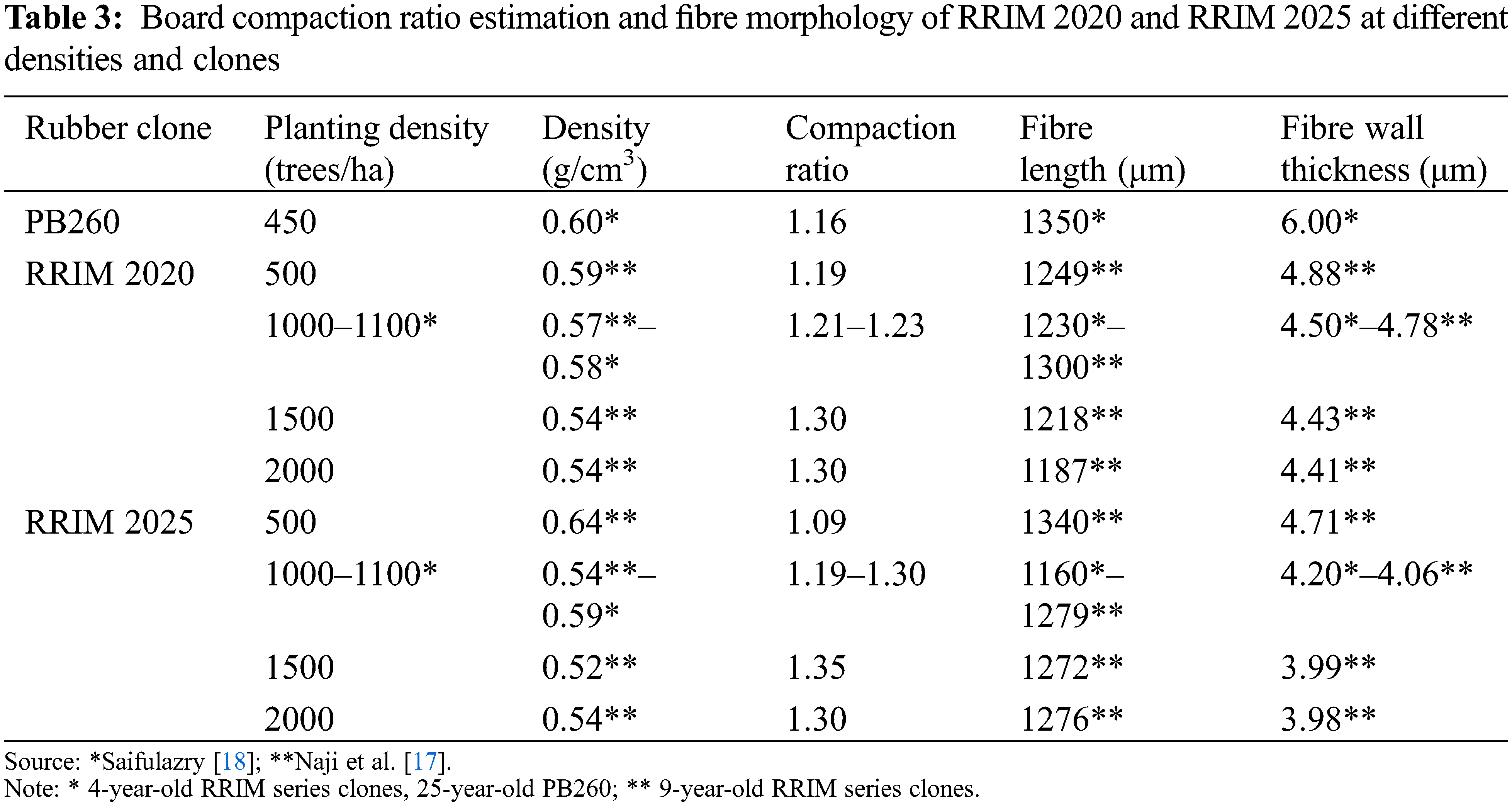

According to the observations, the planting density of both clones had different trends in terms of board stiffness (Table 2). The planting densities were classified as low, moderate-low, moderate-high, and high. For the RRIM 2020 clone, the lowest (500 trees/ha) and highest planting densities (2000 trees/ha) were significantly better in terms of stiffness than both moderate planting densities (1000 and 1500 trees/ha). Meanwhile, the stiffness of the RRIM 2025 clone’s moderate-high planting density (1500 trees/ha) was significantly higher than that of other planting densities. The variation in MOE values was most likely influenced by wood density and anatomical characteristics of the fibres in relation to planting density. Melo et al. [11] agreed that planting density had a significant impact on fibre length, wall thickness, and ray height. In their study, low planting density (312 trees/ha) had significantly longer fibre length and thicker wall thickness than high planting density (624 trees/ha). Naji et al. [17] discovered a similar result, in that the fibre length and wall thickness of 9-year-old rubberwood planted at a low density (500 trees/ha) were significantly greater than those planted at a high density (2000 trees/ha). Since the stresses were transferred from one particle to another as the load was applied to the board surface, longer fibres were able to withstand greater stress [7].

In terms of rubber clones, the current study discovered that the RRIM 2020 clone had superior stiffness properties and met the minimum MOE requirement of the JIS A 5908-2003 standard for Type 8, which is 2000 N/mm2. A significant difference between RRIM 2020 and RRIM 2025 could be attributed to the fibre length, diameter, wall thickness, and lumen diameter characteristics. According to Saifulazry [18], four-year-old RRIM 2025 planted at moderate-low planting density (1100 trees/ha) had shorter, smaller, and thinner cell wall fibres than RRIM 2020. Even though RRIM 2025 has a slightly higher wood density (0.589 g/m3) than RRIM 2020 (0.580 g/m3), it has lower fibre quality at the age of four. Furthermore, Naji et al. [17] reported that the wood density of 9-year-old rubberwood taken from low to moderate planting density (500–1000 trees/ha) had significant differences in both clones RRIM 2020 and RRIM 2025, but no significant differences were observed in high planting density. As a result, specimens made from RRIM 2020 at any planting density had a higher MOE value.

Aside from the fibre morphology, the compaction ratio had most likely influenced board performance. The compaction ratio is the relationship between wood and board densities. According to Dias et al. [19], a high compaction ratio can be obtained using low-density wood, resulting in a higher contact surface between the particles than with high-density wood. In their study, increasing the compaction ratio of particleboard increased the MOE and MOR while also stabilising the dimensional stability. Prior research backs up the belief that the compaction ratio of typical particleboard must be at least 1.30 to ensure the densification required for board formation [20]. As shown in Table 3, appropriate compaction ratios were observed, particularly at moderate-low, moderate-high, and high planting densities. Due to the high compaction ratios of both the clones studied, it was expected that both would have relatively high mechanical properties. While this behaviour was evident in RRIM 2020, it was not observed in RRIM 2025. This could be a result of RRIM 2020’s superior fibre morphology and high compaction ratio.

Similar to the MOE, no discernible trend in planting density was observed for either clone. The minimum bending strength requirement for JIS A 5908-2003 standards is 8.0 MPa. According to the test results, all of the specimens exceeded the JIS requirements. As seen in Table 2, higher MOR values were observed in particleboard made from rubberwood planted at 1000 trees/ha planting densities. After removing the effect of density, the highest sMOR value was obtained from both RRIM 2025 and RRIM 2020 at planting densities of 1000 trees/ha. Meanwhile, there were no significant differences in planting densities in the RRIM 2025 clone, with the exception of moderate-low planting density. The MOR values of particleboard specimens showed a descending trend at higher planting densities (i.e., 1500 and 2000 trees/ha) of RRIM 2020 and RRIM 2025 [17]. Wood density was moderately related to planting density in their study, and they stated that low planting density wood was harder to bend than high planting density wood. Rocha et al. [12] claimed that wider spacing between trees resulted in denser wood. In their study, the wood of clones planted with spacings ranging from 4.5 to 9.0 m2 had a significantly higher density than clones planted with a 1.5 m2 spacing. The variation in wood densities as a function of plant density could be due to competition between trees for light, water, and nutrients.

Even though low planting density resulted in good fibre morphology, it had little effect on board strength, notably in RRIM 2025. The decrease in mechanical properties of wood could be attributed to complex features consequence [21]. They claimed that these characteristics could be attributed to the effect of low wood density as well as low anatomical property values.

In terms of rubber clones, specimens taken from RRIM 2020 had a significantly higher MOR than specimens taken from RRIM 2025. This significant difference is most likely due to RRIM 2020’s superior fibre length, fibre diameter, wall thickness, and lumen diameter characteristics. The rubber tree modifies its anatomical structure during growth, changing the size and frequency of the vessels to maximise hydraulic conductivity, thereby minimising xylem vulnerability and ensuring mechanical security [22,23]. Aside from that, previous research has shown that the relationship between stiffness and strength with wood density is heavily influenced by fibre wall thickness [17,24,25]. As shown in Table 3, RRIM 2020 had a thicker fibre wall than RRIM 2025. The higher strength values of RRIM 2020 specimens may help clarify this situation.

Table 2 represents the average results of IB strength. Apparently, the IB followed a different pattern than MOE and MOR. In general, no distinct trend was observed in terms of planting density and rubber clone effects. The IB measures the tensile strength of the specimen when a force perpendicular to the surface is applied to particleboard or fibreboard. In solid wood, however, shear strength is used to calculate tensile strength in the direction of the grain. Previous research found that shear strength parallels grain tracked changes in wood density in planting densities [17,26]. Thus, low and moderate-low planting densities for both clones were expected to have slightly improved internal bonding properties as a result of their high densities (Table 2). This performance was evident in the low-and moderate-high planting densities of RRIM 2020 and the moderate-low planting densities of the RRIM 2025 clone, but not in the moderate-low or low planting densities of RRIM 2020 or RRIM 2025.

RRIM 2020-500 PD specimens had the highest IB, followed by RRIM 2020-1500 PD. Remarkably, when compared to control specimens, these specimens have significantly higher internal bonding. PB260 specimens, for example, have longer fibres and thicker cell walls than those made from mature wood [10,27]. Young wood, on the other hand, has short fibres and thin cell walls, as evidenced by RRIM series clones (Table 3). Regardless of planting density or rubber clone, most young wood specimens exhibited comparable properties to control boards. This is most likely due to the lower compaction ratio of PB260, which results in less surface contact among the particles. At a planting density of 1100 trees/ha, particleboard made from RRIM 2020 had a lower IB value than particleboard made from RRIM 2025 [7], and a similar trend was found in the current study for moderate-low planting density (1000 trees/ha) specimens.

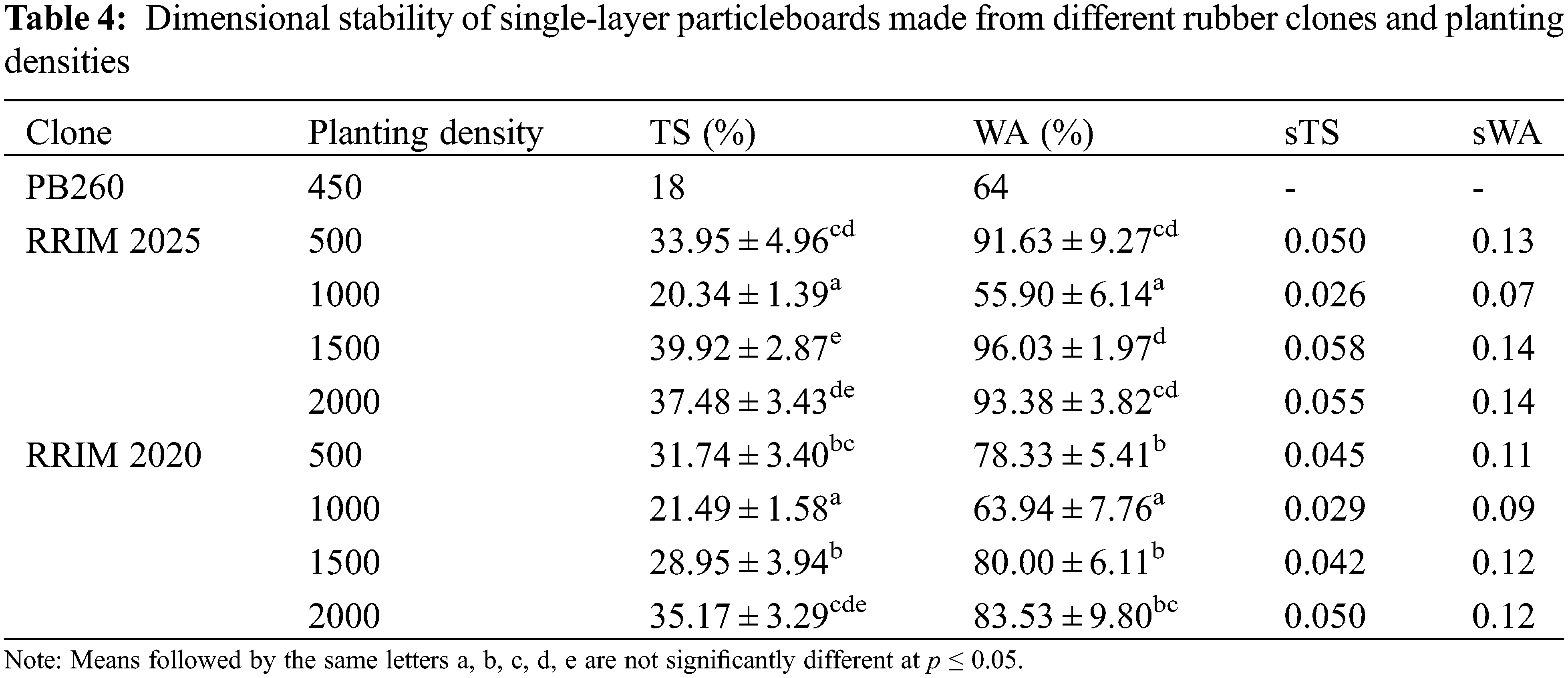

3.2 Effect of Planting Density and Rubber Clone on the Physical Properties of Particleboards

Table 4 lists the physical properties of single-layer particleboards. A similar trend was observed for both TS and WA, with the specimens made from moderate-low yielding the lowest values, followed by moderate-high, low, and high for the RRIM 2020 clone. Meanwhile, for the RRIM 2025 clone, the lowest TS and WA values were obtained from moderate-low specimens, followed by low, high, and moderate-high specimens. Observations show that control specimens have superior dimensional stability when compared to the RRIM clones series. The average TS of RRIM series clone specimens ranged from 20% to 43%, and the WA ranged from 66% to 94%. The TS and WA, after removing the density effects, followed a similar pattern. The JIS standard requires specimens to have a maximum TS value of 12% after 24 h of immersion. This meant that all types of particleboards, including control specimens, failed to meet the TS minimum requirement of the JIS standard. Despite having a lower IB, specimens made from moderate-to-low planting density wood had dimensional stability comparable to that of a control board. A low IB value indicated that the particles’ bonding strength was weak. As demonstrated in RRIM 2025 particleboard, low IB encourages water uptake, causing baulking and swelling of the specimens, resulting in high TS and WA. The high TS and WA values found in RRIM 2025 particleboard are most likely due to the material’s high volume, which is influenced by its low density and high compaction ratio. After 24 h in cold water, specimens made of moderate-high and high planting density wood swelled and absorbed more water. RRIM 2020 was significantly more stable than RRIM 2025 among both rubber clones.

Earlier research indicated that particleboards with a high compaction ratio generally had higher TS and WA values [19,28]. The average values of TS and WA in Eucalyptus wood and coffee parchment particleboard decreased as the compaction ratio increased [28]. As a result, Klímek et al. [29] proposed standardising the compaction ratio in order to reduce specimen springback. However, no evidence of such behaviour was found in the current study. For example, specimens constructed using a high planting density and a high compaction ratio had the highest TS and WA. Inadequate adhesive and wax content may impart low stability. According to Lee et al. [30,31], particleboard with a high compaction ratio contains a small amount of adhesive per particle due to the large particle volume. As a consequence, the manufacturing of the RRIM series clone particleboards may require additional resin and wax.

Particleboard was constructed using rubberwood clones (RRIM 2020 and RRIM 2025) planted at varying densities. In general, particleboard made from RRIM 2020 exhibits superior mechanical properties to particleboard made from RRIM 2025. According to the findings, both planting density and rubber clones had a significant effect on the mechanical and physical properties of the RRIM clones’ series particleboard. Particleboard made from wood with a low planting density (500 and 1000 trees/ha) exhibited improved bending and internal bonding properties, particularly for the RRIM 2020 clone. The RRIM 2020 clone produced particleboard with the lowest TS and WA, as well as the highest MOR value, when planted at a density of 1000 trees per ha. In the case of RRIM 2025 clones, the particleboard made from rubberwood planted at a planting density of 1000 trees/ha had the highest MOR and IB. The resulting particleboard had the lowest TS and WA values at this planting density. Meanwhile, moderate-low planting density was found to be the most effective for both clones with low TS and WA values. Due to the low dimensional stability, higher levels of resin content and the use of waterproof resin, namely Melamine Urea Formaldehyde (MUF), were proposed to improve the physical properties of the RRIM series clone’s particleboard.

Acknowledgement: The authors would also like to thank Malaysian Adhesive Chemicals, the Forest Research Institute of Malaysia, and the Malaysian Rubber Board for their assistance with the studies by providing materials, facilities, and advice.

Availability of Data and Materials: The data and materials will be made available upon request.

Funding Statement: The authors would like to thank the Ministry of Science, Technology, and Innovation and Ministry of Higher Education as well as the Institute of Tropical Forestry and Forest Products, Universiti Putra Malaysia, for providing the fund INTROP HICOE-(6369115).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Fitch, P. (2019). The amazing success story of rubberwood. MMMA Newsletter for PF Asia. [Google Scholar]

2. Shigematsu, A., Mizoue, N., Kajisa, T., Yoshida, S. (2011). Importance of rubberwood in wood export of Malaysia and Thailand. New Forests, 41(2), 179–189. DOI 10.1007/s11056-010-9219-7. [Google Scholar] [CrossRef]

3. Ioras, F., Ratnasingam, J., Ramasamy, G., Kaner, J., Wenming, L. (2012). Production potential of rubberwood in Malaysia: Its economic challenges. Notulae Botanicae Horti Agrobotanici Cluj-Napoca, 40(2), 317–322. DOI 10.15835/nbha4028006. [Google Scholar] [CrossRef]

4. Wei, O. C., Shamsul Bahri, A. R. (2014). The introduction of rubber planting recommendations by the rubber research Institute of Malaysia since 1925. Journal of Biology, Agriculture and Healthcare, 4(11), 49–53. [Google Scholar]

5. Hoong, C. W., Siang, T. K., San, O. T. (2003). Early growth and secondary characteristics of RRIM 2000 series clones in a large plantation group. Planter, 79(926), 295–310. [Google Scholar]

6. Ramli, O., Najib, L. A., Ong, S. H., Masahuling, B., Mohd Ghouse, W. et al. (1995). Potential hevea genotypes for timber production. Proceedings of RRIM Rubber Growers’ Conference, pp. 340–360. Kuala Lumpur. [Google Scholar]

7. Paridah, M. T., Saifulazry, S. O., Jalaluddin, H., Zaidon, A., Rahim, S. (2010). Mechanical and physical properties of particleboard made from 4-year-old rubberwood of RRIM 2000 series clones. Journal Tropical Forest Science, 22(4), 440–447. [Google Scholar]

8. Nur Nadira, U. (2019). Properties of particleboard from petai belalang and kelempayan (Bachelor of Science Thesis). Universiti Teknologi MARA, Shah Alam, Selangor. [Google Scholar]

9. Mitlin, L. (1969). Particleboard manufacture and application. Pressmedia, Ltd., Kent. [Google Scholar]

10. Saffian, H. A., Tahir, P. M., Harun, J., Jawaid, M., Hakeem, K. R. (2014). Influence of planting density on the fiber morphology and chemical composition of a new latex-timber clone tree of rubberwood (Hevea brasiliensis Muell. Arg.). BioResources, 9(2), 2593–2608. [Google Scholar]

11. Melo, L. E., Silva, C. D., Protásio, T. D., Mota, G. D., Santos, I. S. et al. (2018). Planting density effect on some properties of Schizolobium parahyba wood. MADERAS: Ciencia y Tecnología, 20(3), 381–394. DOI 10.4067/S0718-221X2018005003901. [Google Scholar] [CrossRef]

12. Rocha, M. F., Vital, B. R., de Carneiro, A. C., Carvalho, A. M., Cardoso, M. T. et al. (2016). Effects of plant spacing on the physical, chemical and energy properties of Eucalyptus wood and bark. Journal Tropical Forest Science, 28(3), 243–248. [Google Scholar]

13. Lim, S. C., Fujiwara, T. (1997). Wood density variation in two clones of rubber trees planted at three different spacings. Journal of Tropical Forest Products, 3(2), 151–157. [Google Scholar]

14. Aizat, G., Zaidon, A., Lee, S. H., Edi, S. B., Paiman, B. (2017). A comparison between the properties of low and medium molecular weight phenol formaldehyde resin-treated laminated compreg oil palm wood. International Forestry Review, 19(S3), 1–11. DOI 10.1505/146554817828562305. [Google Scholar] [CrossRef]

15. Pazdrowski, W., Spława-Neyman, S. (2003). Stage growth of trees and its effect on selected properties of Norway spruce wood (Picea abies (L.) Karst.). Electronic Journal of Polish Agricultural Universities, 6(2), 1–7. [Google Scholar]

16. Bao, F. C., Jiang, Z. H., Jiang, X. M., Lu, X. X., Luo, X. Q. et al. (2001). Differences in wood properties between juvenile wood and mature wood in 10 species grown in China. Wood Science and Technology, 35(4), 363–375. DOI 10.1007/s002260100099. [Google Scholar] [CrossRef]

17. Naji, H. R., Bakar, E. S., Sahri, M. H., Soltani, M., Hamid, H. A. et al. (2014). Variation in mechanical properties of two rubberwood clones in relation to planting density. Journal Tropical Forest Science, 26(4), 503–512. [Google Scholar]

18. Saifulazry, S. O. A. (2007). Evaluation of the properties of 4-year-old rubberwood clone RRIM 2000 series for particleboard manufacture, Universiti Putra Malaysia, Serdang. [Google Scholar]

19. Dias, F. M., Nascimento, M. F., Martinez-Espinosa, M., Lahr, F. A., Valarelli, I. D. (2005). Relation between the compaction rate and physical and mechanical properties of particleboards. Materials Research, 8(3), 329–333. DOI 10.1590/S1516-14392005000300018. [Google Scholar] [CrossRef]

20. Maloney, T. M. (1993). Modern particleboard and dry-process fiberboard manufacturing (2nd ed)São Francisco: Miller Freeman. [Google Scholar]

21. Lasserre, J. P., Mason, E. G., Watt, M. S. (2005). The effects of genotype and spacing on Pinus radiata [D. Don] corewood stiffness in an 11-year old experiment. Forest Ecology and Management, 205(1–3), 375–583. DOI 10.1016/j.foreco.2004.10.037. [Google Scholar] [CrossRef]

22. Schuldt, B., Leuschner, C., Brock, N., Horna, V. (2013). Changes in wood density, wood anatomy and hydraulic properties of the xylem along the root-to-shoot flow path in tropical rainforest trees. Tree Physiology, 33(2), 161–174. DOI 10.1093/treephys/tps122. [Google Scholar] [CrossRef]

23. Zhao, X. (2016). Spatial variation of vessel grouping in the xylem of Betula platyphylla Roth. Journal of Plant Research, 129(1), 29–37. DOI 10.1007/s10265-015-0768-x. [Google Scholar] [CrossRef]

24. Sass, U., Eckstein, D. (1995). The variability of vessel size in beech (Fagus sylvatica L.) and its ecophysiological interpretation. Trees, 9(5), 247–252. DOI 10.1007/BF00202014. [Google Scholar] [CrossRef]

25. Zobel, B. J., Van Buijtenen, J. P. (1989). Wood variation: Its causes and control. Berlin: Springer-Verlag. [Google Scholar]

26. Rokeya, U. K., Hossain, M. A., Ali, M. R., Paul, S. P. (2010). Physical and mechanical properties of (Acacia auriculiformis x A mangium) hybrid Acacia. Journal of Bangladesh Academy of Sciences, 34(2), 181–187. DOI 10.3329/jbas.v34i2.6864. [Google Scholar] [CrossRef]

27. Zobel, B. J., Kellison, R. C. (1972). Short rotation forestry in the Southeastern United States. TAPPI, 55(8), 1205–1208. [Google Scholar]

28. Scatolino, M. V., Costa, A. D., Guimarães Júnior, J. B., Protásio, T. D., Mendes, R. F. et al. (2017). Eucalyptus wood and coffee parchment for particleboard production: Physical and mechanical properties. Ciência e Agrotecnologia, 41(2), 139–146. DOI 10.1590/1413-70542017412038616. [Google Scholar] [CrossRef]

29. Klímek, P., Wimmer, R., Meinlschmidt, P., Kúdela, J. (2018). Utilizing Miscanthus stalks as raw material for particleboards. Industrial Crops and Products, 111(111), 270–276. DOI 10.1016/j.indcrop.20. [Google Scholar] [CrossRef]

30. Lee, S. H., H’ng, P. S., Lum, W. C., Zaidon, A., Bakar, E. S. et al. (2014). Mechanical and physical properties of oil palm trunk core particleboard bonded with different UF resins. Journal of Oil Palm Research, 26(2), 163–169. [Google Scholar]

31. Lee, S. H., Ashaari, Z., Chen, L. W., San, H. P., Tan, L. P. et al. (2015). Properties of particleboard with oil palm trunk as core layer in comparison to three-layer rubberwood particleboard. Journal of Oil Palm Research, 27(1), 67–74. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |