Open Access

Open Access

ARTICLE

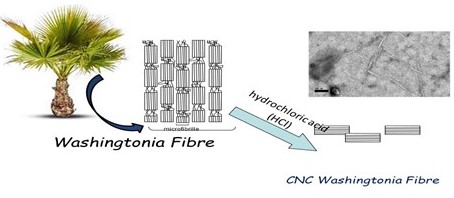

Cellulose Nanocrystal from Washingtonia Fibre and Its Characterization

1 Laboratory of Biocomposite Technology, Institute of Tropical Forestry and Forest Products (INTROP), Universiti Putra Malaysia, Selangor, Malaysia 2 Applied Medical Science Department, Community College, King Saud University, Riyadh, Saudi Arabia 3 CNRS, University of Grenoble Alpes, Grenoble, France 4 Department of Textile, Higher Institute of Technological Studies of Ksar Hellal, Ksar Hellal, Tunisia 5 University of Monastir, Laboratory of Environmental Chemistry and Cleaner Process (LCE2P-LR21ES04), Monastir, Tunisia 6 Chemical Engineering Department, College of Engineering, King Saud University, Riyadh, Saudi Arabia 7 Dental Health Department, College of Applied Medical Sciences, King Saud University, Riyadh, Saudi Arabia

* Corresponding Author: Ramzi Khiari. Email:

Journal of Renewable Materials 2022, 10(6), 1459-1470. https://doi.org/10.32604/jrm.2022.018415

Received 23 July 2021; Accepted 17 August 2021; Issue published 20 January 2022

Abstract

Cellulose nanocrystal (CNC) is a biomaterial derived from plant lignocellulosic components, widely applied in various industrial fields. Concurrently, with the growth of awareness in developing green nanomaterial, the explored Washingtonia fibre could be alternative biomass for obtaining CNC products. In the present work, different acid concentrations of 5%, 15%, and 25% hydrochloric solutions were employed to produce CNCs from Washingtonia fibre. With the chemical treatments, the yield of the CNC product was successfully retained at 21.6%−25.1%. Individually separated and needle-shaped CNC particles could be observed under the microscopic viewing with the increased acid concentrations. From elemental analysis, a relatively pure cellulose compartment was produced for all CNC samples. The zeta potential values between −10 to −16 mV proved that each nanoparticle sample possessed dispersion ability within an aqueous solution. Meanwhile, the degree of crystallinity and the thermal behavior of CNCs were enhanced with the increased acidic concentrations. Hence, the isolated CNCs (with 15%) from Washingtonia fibre lead a CNC with the highest aspect ratio (30). This parameter is so important that these structures show empowering points of view as nanomaterials for reinforced polymer composites, and it could be a reliable nano-filler for the composite fabrication process in the future.Graphic Abstract

Keywords

Cite This Article

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools