Open Access

Open Access

ARTICLE

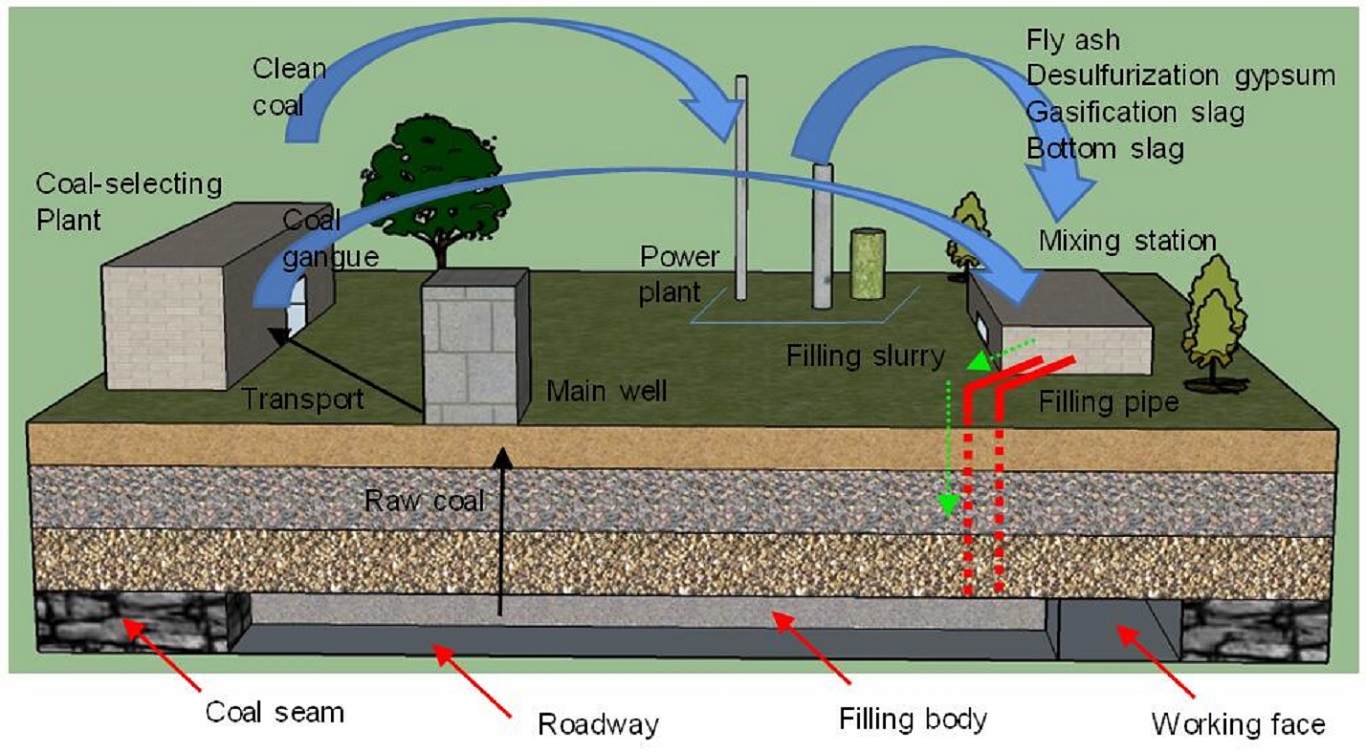

Fluidity Influencing Factor Analysis and Ratio Optimization of New Filling Slurry Based on the Response Surface Method

State Key Laboratory of Mining Response and Disaster Prevention and Control in Deep Coal Mines, Anhui University of Science and Technology, Huainan, 232001, China

* Corresponding Author: Xinzhu Hua. Email:

(This article belongs to the Special Issue: New Trends in Sustainable Materials for Energy Conversion, CO2 Capture and Pollution Control)

Journal of Renewable Materials 2022, 10(5), 1439-1458. https://doi.org/10.32604/jrm.2022.018607

Received 05 August 2021; Accepted 19 August 2021; Issue published 22 December 2021

Abstract

The filling mining method is important in realizing the green mining of mineral resources. Aiming at the problems of land resource occupation, environmental pollution, and rational utilization of coal-based solid wastes such as coal gangue, fly ash, and desulfurization gypsum, a new paste filling material was developed with coal gangue, fly ash, and desulfurization gypsum as raw materials. The microstructure of the raw materials was analyzed by XRD and SEM. Combined with the Box-Behnken experimental design, the effect of each component on the fluidity of the filling slurry was analyzed through the response surface analysis. The significance of each component on its bleeding and fluidity was determined, and the optimal ratio of the filling slurry was obtained. Experimental results show that the microcosmic morphology of coal gangue, desulfurization gypsum, and gasification slag presents an irregular block and rough particle surface; the microcosmic morphology of fly ash and bottom slag presents first out spherical or quasi spherical particles. Moreover, obvious sintering traces exist on the surface of the bottom slag. The main crystal mineral of coal gangue and fly ash is SiO2, the desulfurization gypsum is composed of Ca(SO4) (H2O) and Ca(CO3) crystal minerals, the gasification slag is composed of carbon and nitrogen compounds, and the main crystal mineral components in the bottom slag sample are SiO2 and AlxSiyOz compounds. The order of significance of each key factor on slurry fluidity is as follows: C (desulfurization gypsum) > D (gasification slag and bottom slag 1:1) > A (coal gangue) > B (fly ash). The order of the significance of each key factor on slurry bleeding is as follows: B (fly ash) > C (desulfurization gypsum) > D (gasification slag and bottom slag 1:1) > A (coal gangue). Considering the material preparation, field application, and other conditions, the mass percentage of each factor content of the new paste filling material is as follows: 49.5% coal gangue, 8.3% fly ash, 4.1% desulfurization gypsum, 6.2% gasification slag, and 6.2% bottom slag.Graphic Abstract

Keywords

Cite This Article

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools