| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.018255

ARTICLE

An Investigation on the Visible Characteristics of Four Caesalpiniaceae Wood Species in Gabon

1College of Materials Science and Engineering, Central South University of Forestry and Technology, Changsha, 410004, China

2Hunan Taohuajiang Bamboo Science & Technology Co., Ltd., Yiyang, 413400, China

3Yihua Lifestyle Technology Co., Ltd., Shantou, 515834, China

4Guangxi Gaofeng State Owered Forest Farm, Nanning, 530022, China

*Corresponding Authors: Jinbo Hu. Email: hjb1999@hotmail.com; Yuan Liu. Email: liuyuan601220@163.com

Received: 10 July 2021; Accepted: 27 August 2021

Abstract: Color, whiteness and glossiness of four caesalpiniaceae wood species were characterized by quantitative measurements and image analysis, i.e., which were respectively Berlinia bracteosa Benth., Monopetalanthus heitzii Pellegr., Distemonanthus benthamianus and Erythrophleum ivorense A. Chev. The color of four wood species was evaluated to be consistent by the CIELab and CIE1931 color system. The boards of B. bracteosa, M. heitzii and E. ivorense was divided into dark color. The wood color of B. bracteosa had the highest red to green hue, while the wood appearance of D. benthamianus had the brightest and yellowest color within the four wood species. The whiteness of D. benthamianus was significantly higher than the other three wood species, namely tangential section 21.9% and radial section 22.2%. Hence, the color of the four species varied significantly, which was closely related to internal constituents of wood materials. M. heitzii wood had the highest surface glossiness on both tangential and radial section surfaces. The surface glossiness was highly related to the wood microstructure, especially with the pore and groove structure. This study of the visible characteristics provided the indicated knowledge for the application of the four wood species in wood industry.

Keywords: Caesalpiniaceae; visible characteristic; wood color; glossiness; whiteness

The visible characteristics of wood, such as color, which differ widely among species [1], are of quite importance in the commercialization process of wood production. The visible characteristics of wood are not only the ones of the physical quantity of the wood surface, but also the important indicators for evaluating the quality of wood bulk and determining the value of wood products [2]. Besides, the visible characteristics are also one of the quality attributes that influence the customer’s perception of wood products. The visible characteristics of wood can be influenced by multiple factors. Reinprecht et al. [3] found significant effects of natural and artificial weathering on the color of seven tropical wood species. Also, they could be affected by other factors such as drying [4], natural light irradiation [5], soil condition [6], and genetic variation [7], etc. Matsuo et al. [8] demonstrated that natural aging process of wood was primarily a slow and gentle oxidation process, resulting in changes in the color of wood. In addition, color changes in wood can occur not only under natural conditions, but also by means of artificial treatments, such as thermal treatment [9,10], light radiation [11], etc. Kubovský et al. [12] investigated changes in color and major wood constituents of limewood by using CO2 laser beam irradiation. Colorimetry was a good method for obtaining objective information on the color of wood, the most widely used of which was the CIELab color system. Pastore et al. [13] characterized the color modifications caused by exposure to artificial UV radiation of four tropical hardwoods from various Amazonian regions according to the CIELab system. Using the same color system, Liu et al. [14] investigated and compared the behavior of four wood species originating from Europe and China in temperature induced artificial ageing. Gurleyen et al. [15] measured the surface glossiness, color and roughness to investigate the surface properties of Scots pine laminated parquet with UV varnish application.

A variety of caesalpiniaceae wood from tropical African forests are generally high-quality materials for solid wood flooring due to their generally excellent mechanical properties and beautiful appearance. Berlinia bracteosa Mpossa, Monopetalanthus heitzii Pellegr, Distemonanthus benthamianus and Erythrophleum ivorense A. Chev are widely distributed in Africa. These caesalpiniaceae species have the characteristics of large diameter, fine texture and beautiful color, which are high quality raw materials for solid wood floors or furniture. However, there is few information about their visible characteristics, especially lack of physical sensations about their attractive colors and textures.

The visible characteristics of wood mainly include physical quantity parameters such as wood color, whiteness, glossiness, etc. In this paper, the wood color, whiteness and glossiness were discussed for the four kinds of caesalpiniaceae wood grown in Gabon. The results of this investigation can help to expand the wood color database in the world, and provide insights into the application of the four caesalpiniaceae wood species from Gabon. This will prompt the application of African hardwood in the wood product industry.

In this study, wood samples were taken from B. bracteosa, M. heitzii, D. benthamianus and E. ivorense, which were harvested in the tree farm of Yihua Lifestyle Technology Co., Ltd., in Gabon. Table 1 shows the related information about collecting the four tree samples in Gabon.

The heartwood samples of the four wood species (Table 1) were investigated in this research. The collected wood samples were produced into heartwood boards with the size of 200 × 120 × 15 mm3 (Longitudinal × Tangential × Radial). Each wood species had ten heartwood samples, half of them with tangential sections and other half with radial sections. The heartwood samples were sanded to create fresh and smooth surfaces by the 320P sandpaper. After that, they were placed in a climatic chamber at a temperature of 20 ± 2°C and a relative humidity of 65 ± 5% for more than 3 months to achieve color stability. Besides, the heartwood samples of the four wood species were cut into small pieces of around 5 × 5 × 5 mm3 (L × T × R), which were used for microscopic observation in the tangential and radial sections.

The surface images (as shown in Fig. S1) of the boards from the four wood species were created with a Digital Single Lens Reflex (DSLR) camera (Nikon D5, Japan) under sunny outdoor conditions (temperature 27°C, relative humidity 60%). There was no direct sunlight on the surfaces when photographing, and the natural color and grain of the board surfaces could be exhibited on the images to the greatest extent possible. Adjusted the focal length while using a tripod to fixed the position of the DSLR camera. Took away each board immediately after taking photos, and then put the next sample in the same position for photographing, ensuring that the position of the samples and camera remain unchanged during the photographing process. At the same time, tried to complete the photo process quickly, which ensured the consistency of the natural daylight environment and reduces the influence of the surrounding environment. No artificial light sources such as incandescent lamps were used to avoid affecting the surface color of the wood.

The surface color of the heartwood samples was measured by using a portable chromatimeter (CS-200, Hangzhou, China) with an illumination area of 8 mm in diameter, illuminant D65, an observer of 10°. The surface color was qualitatively characterized based on the CIE1931xy chromaticity coordinates (CIE1931) and CIE1976 L*a*b* color system (CIELab). CIE1931 was a color model proposed by Commission Internationale de l’Éclairage (CIE) organization in 1931, which displayed color coordinates in a two-dimensional model [17]. The measured x and y value were the horizontal and vertical coordinates in the CIE 1931 chromaticity diagram, respectively. The color system CIELab consists of three mutually perpendicular axes: L* represents lightness on the black-white axis (0 for black and 100 for white), a* represents the red–green axis (+100 values for red, −100 values for green), b* represents the yellow–blue axis (+100 values for yellow, −100 values for blue). The color saturation (C*) and hue angle (H*) of the surface color were calculated by (1, 2) [18].

where a* is the red–green axis and b* is the yellow–blue axis.

The whiteness is the degree of white color on the surface of a substance, and it is expressed as a percentage of white content. The whiteness of the heartwood samples was measured by using the desktop whiteness meter (YQ-Z-48B, China). Wood whiteness was defined by the R457 whiteness value (%). The glossiness of the heartwood samples was determined by a surface glossiness meter (KGZ-1A, China). Meanwhile, a 45° angle was used to measured surface glossiness of the heartwood wood samples. The measurement of the surface glossiness was performed when the light source was incident parallel to the wood grain direction, and the data was recorded as GZL. Conversely, the glossiness measured was GZT when the light source was perpendicular to the wood grain. To investigate the effect of wood surface pore structure on surface glossiness. 10-μm-thick sections were cut with a sliding microtome (G.S.L.1, Switzerland), stained with safranin O (AR, Ourchem), and dehydrated in a graded series of ethanol solutions (30%, 50%, 70%, 90%, 95%, 100%, 5 min each). Finally, observed under an optical microscope (H550S, Nikon, Japan). And then, the percentage of grooves of tangential and radial sections were measured using image analysis software (Image-Pro Plus 6.0) to evaluate the relationship between groove structure and glossiness.

Total 32 locations were selected on a surface of each sample for measurement of the color, whiteness and glossiness. Marks were made once the measurement was done at a location to ensure that each parameter was measured at the same position for each sample. The color measurement was performed at the location without knots or other defects for each samples.

The standard deviation and coefficients of variation were calculated to evaluate the reliability of the experimental results. In the CIE1931 color system, the values of x and y were used as the horizontal and vertical coordinates of the chromaticity diagram to trace the points in the rectangular coordinates, and the relative position in the chromaticity diagram indicates the shade of the colors.

Pearson’s correlation coefficient was applied to investigate the correlation relationship among the color, whiteness and glossiness of each wood species. The two tailed significance tests were carried out at levels of 0.05 and 0.01. Correlation coefficients between the measured surface characteristics were calculated. Statistical analysis and graphing were implemented by using Origin 2016 and IBM SPSS Statistics software.

3.1 Differences in Wood Color Parameters among Species

First of all, the visible characteristics of four African species were defined by the three chromaticity coordinates in CIELab color system. Wood color parameters on the tangential and radial section surfaces of the four wood species samples were measured according to the CIELab system. The results were shown in Table 2. Parameters L*, a* and b* had almost no statistically difference between tangential and radial section surface in one species, showing that there was no significant color difference between tangential and radial section surface of the same species.

Combined the values of wood color parameters in CIELab color system (Table 2) and wood surfaces images (Fig. S1). Differences in lightness, red–green and yellow–blue hues of heartwood were observed among these four species of caesalpiniaceae. In general, wood was darker colored (lower value for parameters L*) in B. bracteosa and E. ivorense, redder (higher value for parameters a*) in B. bracteosa, and yellower (higher value for parameters b*) in D. benthamianus, compared with the other species (Table 2). The parameter a* corresponds to the red to green axis was found to be highest in the heartwood of B. bracteosa (Table 2). D. benthamianus had the greatest lightness L* and the highest b* values (Table 2). Compared with the other three species, B. bracteosa appeared to be more reddish (higher a*, Table 2), varying from different shades between reddish brown and deep reddish brown. Dark purple or brown stripes were shown on the surface of B. bracteosa (as shown in Fig. S1). D. benthamianus appeared to be light yellow or yellowish brown (higher b*, Table 2). Furthermore, the color of E. ivorense was reddish brown to pale yellowish brown, with dark stripes (Fig. S1). M. heitzii appeared to be less yellowish (lower b*, Table 2), light brown to pink brown with fine and uniform structure. B. bracteosa and D. benthamianus had higher purity of wood color (higher C*, Table 2), showing brighter colors compared with the other species (Table 2). In conclusion, B. bracteosa, M. heitzii and E. ivorense were classified as dark color. While D. benthamianus was distinctly light color and yellow.

In Fig. 1, the color of four species wood samples was plotted according to the CIE1931 chromaticity coordinates [19] chromaticity diagram. As shown in Fig. 1, the color values of four species wood were mainly concentrated in a small area in the center of the rectangular coordinates system (x-value was between 0.387 and 0.420, y-value was between 0.362 and 0.391), which mainly in the lighter reddish and lighter yellowish areas. In the CIE1931 color system as shown in Fig. 1, the most central point of the graph was pure white. The process of moving a color point from the center to the boundary was the process of gradually deepening the color from pure white. Moreover, B. bracteosa was closer to the reddish areas in the lower right corner (Fig. 1), which was consistent with observation that the B. bracteosa had a significant redder hue than the other three species wood (Fig. S1).

Figure 1: Wood color in CIE1931 color coordinates of (a) B. bracteosa, (b) M. heitzii, (c) D. benthamianus, (d) E. ivorense. T = tangential sections, R = radial sections

3.2 Differences in Wood Whiteness Parameters among Species

The whiteness results were presented in Fig. 2. It showed broad variation of four wood species whiteness from caesalpiniaceae that ranged from 12.1% to 22.2% (Fig. 2). In general, it could be seen intuitively that there was no significant difference in the whiteness of tangential and radial section surface of the same species. For one species, the whiteness of radial section was higher than the tangential section. The whiteness of D. benthamianus was significantly higher than the other three species, with tangential section whiteness 21.9% and radial section 22.2%. And B. bracteosa had the lowest whiteness, with tangential section whiteness 12.1% and radial section 12.9%. The tangential whiteness value of D. benthamianus was 81.0% higher and radial whiteness value was 72.0% higher than that of B. bracteosa. In combination with surface images of the wood (Fig. S1), it was easy to found that the higher the wood whiteness value, the lighter the surface color of the wood. Lower whiteness value means darker colors of the wood. In summary, it was a feasible method to use the wood whiteness value to initially determine the darkness of wood color.

Figure 2: Comparison of whiteness values of four species wood in the tangential and radial section. Species: Bb = B. bracteosa, Mh = M. heitzii, Db = D. benthamianus, Ei = E. ivorense; T = tangential sections, R = radial sections

Particularly, combined with Fig. 1 above, it was found that the closer the wood coordinate was to the center in the CIE1931 chromaticity coordinates, the higher was the whiteness value, which meant the center of CIE1931 chromaticity coordinates had the highest whiteness.

3.3 Differences in Wood Surface Glossiness Parameters among Species

Glossiness was a performance indicator of the ability of wood surface to reflect light. Usually, glossy wood provided a sense of visual beauty. The surface glossiness results of four species were shown in Fig. 3.

Figure 3: Mean glossiness value of four species samples in tangential section (a) and radial section (b). Species: Bb = B. bracteosa, Mh = M. heitzii, Db = D. benthamianus, Ei = E. ivorense. GZL means surface glossiness parallel to the wood grain, GZT means surface glossiness perpendicular to the wood grain

In general, there was almost no difference in GZL between tangential and radial sections of the same species, and it was the same for GZT. For the tangential sections of four species, M. heitzii had the highest gloss value (with 5.5% for GZL and 4.7% for GZT), and glossiness value for E. ivorense was lower than the other species (with 3.7% for GZL and 3.1% for GZT). When it came to radial section, values of GZL were ranged from 3.6% (E. ivorense) to 5.3% (D. benthamianus), and GZT was ranged from 3.1% (E. ivorense) to 4.4% (M. heitzii).

Particularly, for one species, surface glossiness values parallel to the wood grain direction were generally higher than those perpendicular to grain. The main reason for these results was its unique structural characteristics, mainly from the anisotropic structure of wood [20,21]. The longitudinal surface of the wood after smooth shaving was observed to have numerous narrow cell lumens with many indentations formed. When light emitted along the wood grain, the light entered the cell cavity could be refracted directly along the long axis of the cell with little energy loss. And yet, since the width diameter of the cell was much smaller than its length, when light was transmitted perpendicular to the direction of the cell length, the light entering cell cavity was blocked by the inner cell wall. Therefore, the intensity of the reflected light was even weaker, and the value of surface glossiness parallel to the grain direction was higher than that of perpendicular to grain.

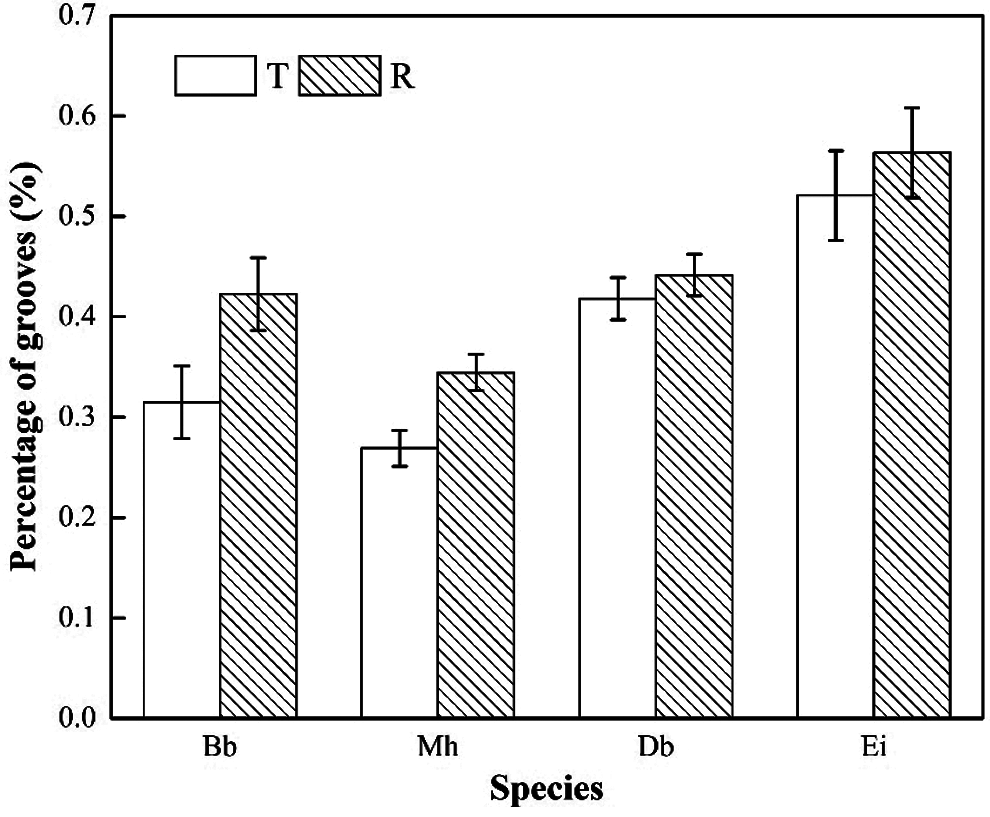

Microscopic structure of tangential and radial sections of four wood species samples were shown in Fig. S2. Fibers, vessels and wood rays were mainly observed on the two longitudinal sections. Wood fibers were tightly arranged with elongated spindle-shaped cells. D. benthamianus had storied rays, while the other three species were non-storied rays. There were many grooves on the surface of tangential and radial section, which were mainly composed of cell lumen of wood fibers and vessels, followed by cell lumen of wood rays and parenchyma (Fig. S2). Different glossiness values (Fig. 3) revealed the impact of the individual wood structure on the surface glossiness [22].

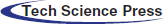

The groove percentages of four species wood in tangential and radial sections were shown in Fig. 4. For each wood species, the groove percentage in the radial section was higher than that in the tangential section. It was presumed that there were many ray cells dissected longitudinally on the radial section of the wood, forming a large number of grooves, and their pore ratio was larger compared with the ray cell lumen on the tangential section. Therefore, the grooves percentage of the radial section was higher than that of the tangential section. Among the four wood species (Fig. 4), E. ivorense showed the highest grooves percentage of grooves, with 52.08% for tangential section and 56.32% for radial section, and followed by D. benthamianus, with 41.80% for tangential section and 44.15% for radial section. B. bracteosa was the third, with 31.49% for tangential section and 42.27% for radial section, while M. heitzii showed the lowest groove ratio, with 27.34% for tangential section and 34.45% for radial section.

Figure 4: Percentage of grooves of four species samples in tangential sections (T) and radial sections (R). Species: Bb = B. bracteosa, Mh = M. heitzii, Db = D. benthamianus, Ei = E. ivorense

By comparing the percentage of grooves (Fig. 4) and surface glossiness (Fig. 3), the mechanism which glossiness was influenced by the surface structure of the wood was explored. Results showed that M. heitzii had the highest glossiness value both for tangential and radial sections, owing to its minimum surface groove ratio. While E. ivorense had the lowest glossiness value, which had the highest percentage of grooves on their tangential and radial sections. Therefore, it could be presumed that the larger the wood surface groove ratio means that there were more cutting pores and grooves on the surface of the wood, and the wood surface glossiness would be lower. Presumably for the following reasons, when light was directed into the wood, the inner wall of the numerous grooves caused much refraction and irregular reflection of the light, thus weakening the intensity of the reflected light. This explanation just verified the above speculation was reasonable. The surface glossiness of wood was generally lower than other materials, like glass, metal, cement and tile, etc. [23,24]. In other words, wood had softer surface glossiness than other materials. When strong sunlight hit a building with white tiles, it was hard to blink under the strong light reflection because the white tiles completely formed a directional reflection of light. It was probably the reason why people preferred to decorate their surroundings with wood materials.

3.4 Correlations among Wood Color Variables

Results of correlations among the wood color variables were shown in Tables 3 and 4. There were some similarities but also significant differences in correlations among wood color parameters of the four wood species. For tangential section, lighter colored wood tended to be lower redness (negative correlation between parameters L* and a*: M. heitzii, D. benthamianus and E. ivorense), and yellower (positive correlation between parameters L* and b*: B. bracteosa and E. ivorense). There was almost no correlation between parameters a* and b* in all the wood species. Meanwhile, lighter colored wood tended to had higher whiteness, with positive correlation between parameters L* and W both for tangential and radial sections, which indicated a close relationship between wood brightness and whiteness. Both for tangential and radial sections, Lighter colored wood tended to be higher surface glossiness both for tangential and radial sections, based on the positive correlation between parameters L* and GZL, GZT. The higher the brightness of wood, the stronger the ability of wood surface to reflect light and the higher the glossiness of the wood. In addition, the correlation coefficients between wood whiteness and glossiness were mainly ranged 0.4 to 0.6, indicating a moderate positive correlation between them. Furthermore, there were significant positive correlation between GZL and GZT both for the tangential and radial sections of all the wood species.

The inhomogeneity of wood’s color and glossiness was one of its most beautiful natural characteristics of wood, with the color hue between red and yellow showing a distinctive warm and pleasant aesthetic effect [11]. Results from the measurement of the color showed that D. benthamianus had the greatest lightness L*, the highest b* and whiteness values, tended to give people a sense of warmth and softness [25]. In other words, D. benthamianus showed a bright yellow color with clear and beautiful narrow grains of wood, which was suitable for interior decoration for created a warm and relaxing atmosphere. Meanwhile, the unique yellow color and grain structure of D. benthamianus was an important feature for its identifying. The results of the color variables analysis were consistent with the visual observation sensations shown in Fig. S1. The clear texture and dark red color of B. bracteosa tended to give people a feeling of elegance, nobility and luxury [26], which made it a good choice for high-grade furniture (Fig. S1). Therefore, it was recommended to use radial planning during processing to form beautiful and advanced patterns formed by their unique color and grain variation. In addition, B. bracteosa had distinct dark stripes and was generally evenly spaced, which could be used as a unique decorative material and also provided a simple and effective way to identify this species.

Previous research mainly focused on the colors but ignored the saturation [27]. Studies had shown that objects with low saturation colors could draw attention to their global abstract features while those with highly saturated colors could draw people’s attention to local detailed features [28]. B. bracteosa and D. benthamianus tended to give a sense of warmth and heaviness, which could helped increase the friendliness of the furniture to people due to their highly saturation. Thus, furniture made of B. bracteosa and D. benthamianus gave an intimate, natural feeling, and showed the natural detailed grain characteristics of the wood more clearly.

According to the above results, the whiteness and glossiness of E. ivorense were relatively lower than other species, with reddish brown to pale yellowish brown. Their pores and parenchyma tissue formed the pattern that resembled the shape of a school of fish in the deep sea, which showed a natural sense of rhythm that was spectacular and fascinating [29]. It was often used for high-grade furniture and solid wood flooring in China, and becoming more and more popular nowadays. M. heitzii appeared to be less yellowish (lower b*, Table 2), with high glossiness (Fig. 3). Furniture or interior decoration made of M. heitzii showed light brown to pink brown with fine and uniform structure, which gave people a traditional and natural feeling [30].

Briefly speaking, different colors and textures of wood bring different intuitive feelings. B. bracteosa, M. heitzii and E. ivorense were good choice for people who want to pursue wood products with a sense of heaviness, nobility or luxury; If people put a high value on warm and energetic feelings, lighter colored wood materials, D. benthamianus was an appropriate choice. In summary, although the color of wood varied significantly between different species, wood materials could always create a soft, natural and comfortable atmosphere [31]. The reason for this was closely related to their unique natural visible characteristics. The wood cells had a substantial amount of their interfaces aligned parallel to the grain, and such interface patterns contribute to the appeal of wood as a material [32].

In this study, wood color, whiteness and glossiness of four caesalpiniaceae wood species were investigated. These results showed that the lightness L* of D. benthamianus was 67.24 on the tangential section surface and 67.11 on the radial section surface, and its yellow to blue hue, b*, was 33.82 on the tangential section surface and 32.95 on the radial section surface. It was brightest and yellowest within the four wood species. B. bracteosa had the highest red to green hue, a*, 23.44 on the tangential section surface and 22.57 on the radial section surface. The whiteness of D. benthamianus was significantly higher than the other three wood species. For the same species, the values of the surface glossiness parallel to the wood grain direction were generally higher than those perpendicular to the grain direction. M. heitzii had the highest surface glossiness on both tangential and radial section surfaces. In general, B. bracteosa, M. heitzii and E. ivorense were darker in color while D. benthamianus was lighter, and M. heitzii was more lustrous. The distinctive colors and wood grain of each species could create different atmospheres of furniture and interior decoration styles, and provided a basis for wood identification as well [33]. This study contributed to a deeper understanding of the visible characteristics of the four caesalpiniaceae wood species. It was helpful to expanding the global market for high-quality wood products from these African caesalpiniaceae species.

Acknowledgement: We thank the Yihua Lifestyle Technology Co., Ltd., for providing the wood material for this study. We thank Dongnian Xu for his help in wood microsection, and we thank Professor Xiaodong(Alice) Wang for her help for checking thegrammar of the paper.

Authors’ Contributions: Conceived and designed the experiments: Zhaoyang Yu, Jinbo Hu; performed the experiment: Zhaoyang Yu, Ting Li, Qiongtao Huang, Jianying Yuan; supervised the work: Jinbo Hu, Yuan Liu; wrote the paper: Zhaoyang Yu, Shanshan Chang, Jinbo Hu; revised the paper: Zhaoyang Yu, Jinbo Hu, Yuan Liu, Gonggang Liu.

Funding Statement: This work was financially supported by the Hunan Provincial Natural Science Foundation of China (2020JJ2058), Scientific Research Foundation of Hunan Provincial Education Department (18A159), Technology Innovation Project of Yihua Lifestyle Technology Co., Ltd. (YH-JS-JSKF-201708006).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Moya, R., Calvo-Alvarado, J. (2012). Variation of wood color parameters of tectona grandis and its relationship with physical environmental factors. Annals of Forest Science, 69(8), 947–959. DOI 10.1007/s13595-012-0217-0. [Google Scholar] [CrossRef]

2. Rosu, D., Teaca, C. A., Bodirlau, R., Rosu, L. (2010). FTIR and color change of the modified wood as a result of artificial light irradiation. Journal of Photochemistry and Photobiology B: Biology, 99(3), 144–149. DOI 10.1016/j.jphotobiol.2010.03.010. [Google Scholar] [CrossRef]

3. Reinprecht, L., Mamoňová, M., Pánek, M., Kačík, F. (2018). The impact of natural and artificial weathering on the visual, colour and structural changes of seven tropical woods. European Journal of Wood and Wood Products, 76(1), 175–190. DOI 10.1007/s00107-017-1228-1. [Google Scholar] [CrossRef]

4. Sandoval-Torres, S., Jomaa, W., Marc, F., Puiggali, J. R. (2010). Causes of color changes in wood during drying. Forestry Studies in China, 12(4), 167–175. DOI 10.1007/s11632-010-0404-8. [Google Scholar] [CrossRef]

5. Živković, V., Arnold, M., Radmanović, K., Richter, K., Turkulin, H. (2014). Spectral sensitivity in the photodegradation of fir wood (Abies alba Mill.) surfaces: Colour changes in natural weathering. Wood Science and Technology, 48(2), 239–252. DOI 10.1007/s00226-013-0601-4. [Google Scholar] [CrossRef]

6. Sotelo Montes, C., Weber, J. C., Silva, D. A., Andrade, C., Muñiz, G. I. B. et al. (2012). Effects of region, soil, land use, and terrain type on fuelwood properties of five tree/shrub species in the sahelian and sudanian ecozones of Mali. Annals of Forest Science, 69(6), 747–756. DOI 10.1007/s13595-012-0195-2. [Google Scholar] [CrossRef]

7. Sotelo Montes, C., Hernández, R. E., Beaulieu, J., Weber, J. C. (2008). Genetic variation in wood color and its correlations with tree growth and wood density of calycophyllum spruceanum at an early age in the Peruvian Amazon. New Forests, 35(1), 57–73. DOI 10.1007/s11056-007-9060-9. [Google Scholar] [CrossRef]

8. Matsuo, M., Yokoyama, M., Umemura, K., Sugiyama, J., Kawai, S. et al. (2011). Aging of wood: Analysis of color changes during natural aging and heat treatment. Holzforschung, 65(3), 361–368. DOI 10.1515/hf.2011.040. [Google Scholar] [CrossRef]

9. Li, R., Chen, J., Wang, X. A. (2020). Prediction of the color variation of moso bamboo during CO2 laser thermal modification. Bioresources, 15(3), 5049–5057. DOI 10.15376/biores.15.3.5049-5057. [Google Scholar] [CrossRef]

10. Li, R., He, C., Chen, Y., Wang, X. (2021). Effects of laser parameters on the width of color change area of poplar wood surface during a single irradiation. European Journal of Wood and Wood Products, 79(5), 1109–1116. DOI 10.1007/s00107-021-01706-1. [Google Scholar] [CrossRef]

11. Tolvaj, L., Mitsui, K. (2010). Correlation between hue angle and lightness of light irradiated wood. Polymer Degradation and Stability, 95(4), 638–642. DOI 10.1016/j.polymdegradstab.2009.12.004. [Google Scholar] [CrossRef]

12. Kubovský, I., Kačík, F. (2014). Colour and chemical changes of the lime wood surface due to CO2 laser thermal modification. Applied Surface Science, 321(1), 261–267. DOI 10.1016/j.apsusc.2014.09.124. [Google Scholar] [CrossRef]

13. Pastore, T. C., Santos, K. O., Rubim, J. C. (2004). A spectrocolorimetric study on the effect of ultraviolet irradiation of four tropical hardwoods. Bioresource Technology, 93(1), 37–42. DOI 10.1016/j.biortech.2003.10.035. [Google Scholar] [CrossRef]

14. Liu, X. Y., Timar, M. C., Varodi, A. M., Sawyer, G. (2016). An investigation of accelerated temperature-induced ageing of four wood species: Colour and FTIR. Wood Science and Technology, 51(2), 357–378. DOI 10.1007/s00226-016-0867-4. [Google Scholar] [CrossRef]

15. Gurleyen, L., Ayata, U., Esteves, B., Cakicier, N. (2017). Effects of heat treatment on the adhesion strength, pendulum hardness, surface roughness, color and glossiness of Scots pine laminated parquet with two different types of UV varnish application. Maderas. Ciencia y Tecnología, 19(2), 213–224. DOI 10.4067/s0718-221x2017005000019. [Google Scholar] [CrossRef]

16. Jiang, Z. (2013). Wood properties of the global important tree species, Beijing: China Science Publishing & Media Ltd. [Google Scholar]

17. Wang, H., Wang, X., Yan, C., Zhao, H., Zhang, J. et al. (2017). Full color generation using silver tandem nanodisks. ACS Nano, 11(5), 4419–4427. DOI 10.1021/acsnano.6b08465. [Google Scholar] [CrossRef]

18. Klement, I., Vilkovská, T. (2019). Color characteristics of Red false heartwood and mature wood of beech (Fagus sylvatica L.) determining by different chromacity coordinates. Sustainability, 11(3), 1–9. DOI 10.3390/su11030690. [Google Scholar] [CrossRef]

19. Mortimer, R. J., Sialvi, M. Z., Varley, T. S., Wilcox, G. D. (2014). An in situ colorimetric measurement study of electrochromism in the thin-film nickel hydroxide/oxyhydroxide system. Journal of Solid State Electrochemistry, 18(12), 3359–3367. DOI 10.1007/s10008-014-2618-5. [Google Scholar] [CrossRef]

20. Bonarski, J. T., Kifetew, G., Olek, W. (2015). Effects of cell wall ultrastructure on the transverse shrinkage anisotropy of scots pine wood. Holzforschung, 69(4), 501–507. DOI 10.1515/hf-2014-0075. [Google Scholar] [CrossRef]

21. Mihajlovski, N., Bahchevandjiev, K. (2017). Transverse anisotropy and dimensional stability of thermal treated beech red heartwood. TEM Journal, 6(1), 126–131. DOI 10.18421/TEM61-18. [Google Scholar] [CrossRef]

22. Meints, T., Teischinger, A., Stingl, R., Hansmann, C. (2017). Wood colour of central european wood species: CIELAB characterisation and colour intensification. European Journal of Wood and Wood Products, 75(4), 499–509. DOI 10.1007/s00107-016-1108-0. [Google Scholar] [CrossRef]

23. Menne-Happ, U., Ilie, N. (2013). Effect of gloss and heat on the mechanical behaviour of a glass carbomer cement. Journal of Dentistry, 41(3), 223–230. DOI 10.1016/j.jdent.2012.11.005. [Google Scholar] [CrossRef]

24. Yavuz, H., Ozkahraman, T., Demirdag, S. (2011). Polishing experiments on surface quality of building stone tiles. Construction and Building Materials, 25(4), 1707–1711. DOI 10.1016/j.conbuildmat.2010.10.016. [Google Scholar] [CrossRef]

25. Oh, S., Kwak, Y. (2019). Hue and warm-cool feeling as the visual resemblance criteria for iso-CCT judgment. Color Research & Application, 44(2), 176–183. DOI 10.1002/col.22324. [Google Scholar] [CrossRef]

26. Ou, L. C., Luo, M. R., Woodcock, A. E., Wright, A. (2004). A study of colour emotion and colour preference. Part II: Colour emotions for two-colour combinations. Color Research & Application, 29(4), 292–298. DOI 10.1002/col.20024. [Google Scholar] [CrossRef]

27. Hagtvedt, H., Adam Brasel, S. (2017). Color saturation increases perceived product size. Journal of Consumer Research, 44(2), 396–413. DOI 10.1093/jcr/ucx039. [Google Scholar] [CrossRef]

28. Lee, H., Deng, X., Unnava, H. R., Fujita, K. (2014). Monochrome forests and colorful trees: The effect of black-and-white versus color imagery on construal level. Journal of Consumer Research, 41(4), 1015–1032. DOI 10.1086/678392. [Google Scholar] [CrossRef]

29. Chang, L. (2015). The application of wood in modern interior design. Open Construction & Building Technology Journal, 9(1), 103–107. DOI 10.2174/1874836801509010103. [Google Scholar] [CrossRef]

30. Ramananantoandro, T., Ramanakoto, M. F., Rajemison, A. H., Eyma, F. (2013). Relationship between density and aesthetic attributes of wood and preference of Malagasy consumers. Annals of Forest Science, 70(6), 649–658. DOI 10.1007/s13595-013-0299-3. [Google Scholar] [CrossRef]

31. Nyrud, A. Q., Roos, A., Rdbotten, M. (2008). Product attributes affecting consumer preference for residential deck materials. Canadian Journal of Forest Research, 38(6), 1385–1396. DOI 10.1139/X07-188. [Google Scholar] [CrossRef]

32. Wan, Q., Li, X. H., Zhang, Y. C., Song, S. S., Ke, Q. (2021). Visual perception of different wood surfaces: An event-related potentials study. Annals of Forest Science, 78(2), 1–18. DOI 10.1007/s13595-021-01026-7. [Google Scholar] [CrossRef]

33. Ruffinatto, F., Crivellaro, A., Wiedenhoeft, A. C. (2015). Review of macroscopic features for hardwood and softwood identification and a proposal for a New character list. IAWA Journal, 36(2), 208–241. DOI 10.1163/22941932-00000096. [Google Scholar] [CrossRef]

Supporting Information

Figure S1: Wood surface images of tangential sections (T) and radial sections (R) of Berlinia bracteosa Mpossa. (a), Monopetalanthus heitzii Pellegr. (b), Distemonanthus benthamianus (c), Erythrophleum ivorense A. Chev. (d)

Figure S2: Microscopic structure of tangential sections (T) and radial sections (R) of Berlinia bracteosa Mpossa. (a), Monopetalanthus heitzii Pellegr. (b), Distemonanthus benthamianus (c), Erythrophleum ivorense A. Chev. (d)

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |