| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.018082

ARTICLE

Concurrent Material Selection of Natural Fibre Filament for Fused Deposition Modeling Using Integration of Analytic Hierarchy Process/Analytic Network Process

1Fakulti Teknologi Kejuruteraan Mekanikal dan Pembuatan, Universiti Teknikal Malaysia Melaka, Melaka, 76100, Malaysia

2Fakulti Kejuruteraan Mekanikal, Universiti Teknikal Malaysia Melaka, Melaka, 76100, Malaysia

*Corresponding Author: M. T. Mastura. Email: mastura.taha@utem.edu.my

Received: 28 June 2021; Accepted: 07 August 2021

Abstract: The employment of natural fibres in fused deposition modeling has raised much attention from researchers in finding a suitable formulation for the natural fibre composite filaments. Moreover, selection of suitable natural fibres for fused deposition modeling should be performed before the development of the composites. It could not be performed without identifying selection criteria that comprehend both materials and fused deposition modeling process requirements. Therefore, in this study, integration of the Analytic Hierarchy Process (AHP)/Analytic Network Process (ANP) has been introduced in selecting the natural fibres based in different clusters of selection concurrently. The selection process has been performed based on the interdependency among the selection criteria. Pairwise comparison matrices are constructed based on AHP’s hierarchical model and super matrices are constructed based on the ANP’s network model. As a result, flax fibre has ranked at the top of the selection by scored 19.5% from the overall evaluation. Flax fibre has excellent material properties and been found in various natural fibre composite applications. Further investigation is needed to study the compatibility of this fibre to be reinforced with a thermoplastic polymer matrix to develop a resultant natural fibre composite filament for fused deposition modeling.

Keywords: Material selection; natural fibre composites; fused deposition modeling; analytic hierarchy process; analytic network process

Nowadays, the employment of natural fibre composites in any type of application has become common and popular to achieve sustainability goals. Generally, natural fibre composites are classified into three resources which are plants, animals, and minerals. Among these three groups of natural fibre, plant-based natural fibres have been majorly found in various product design applications as reinforced materials for polymer-based products due to their availability and simple extraction processing. Research on plant-based natural fibre was conducted a long time ago, and its properties have been proven comparable with synthetic fibre [1]. The advantages of employing natural fibres in product design are environmentally friendly, improving the material properties, low cost, lightweight and biodegradable. Mansor et al. [2] in their study have shown that employment of natural fibre composites in product design could reduce the carbon footprint and energy consumption during the product’s whole life cycle. Ishak et al.’s [3] study has shown that the addition of natural fibre in polymer materials increased the materials’ tensile strength. Moreover, natural fibres composites have become a popular choice in material selection for cheaper and lightweight criteria [4]. All these studies show the potential of natural fibres to be applied in various product types and reduce the dependency of polymer materials in product design. Therefore, many manufacturers are looking for the potential of natural fibres to be employed in their products such as automotive components, medical tools, food packaging, and others. Audi has developed natural fibre composites seat back, side, and back door panel, boot lining and hat rack for model A2, A3, A4, A4 Avant, A6, A8, Roadstar, and Coupe [5]. Danso et al. [6] had studied soil building blocks made of fibre reinforced composite, which are sugarcane bagasse, oil palm fruit, and coconut husk. Moreover, to reduce the waste from the food industry, Universal Biopack has commercialized bamboo/cassava food containers to cut down on trash issues in Thailand [7]. Many researchers have studied natural fibers for their manufacturability in different techniques of the manufacturing process. As reinforced materials for polymer, natural fibres have a similar manufacturing process principle with polymer-based materials and are more likely into additive manufacturing techniques. The process includes extraction of the fibres from the origin, producing the desired form such as yarn, particles and mat, blending with the matrix, and finally forming the desired shapes and products [8]. Before blending method, the fibres will be treated or clean up to removes impurities to ensure good adhesive bonding with the polymer matrix. Consequently, the properties of the fibre composites would be improved by proper fibre treatment either by alkaline, silane or sea water concentration. However, improper treatment process would lead to degradation of the fibres [9].

Generally, Fused Deposition Modeling (FDM) is a process where the thermoplastic filament is extruded through a hot nozzle head onto a flat platform to build a 3D object layer by layer [10]. The quality of the 3D printed object majorly depends on the quality of the filament. Before the printing process, the filament is prepared through the kneading or extrusion process. Various filament materials are developed for FDM, such as ceramics, biopolymers, and natural fibre composites [11]. For natural fibre composites to be employed for FDM, it includes mixing and extruding the composites to produce the feedstock. Stoof et al. [12] fed polymer and fibre granules into a twin-screw extruder to fabricate fibre reinforced recycled polypropylene filament. In another way, initially, Kariz et al. [13] compounded the wood particles and polylactide (PLA) granules and pelletized them to extrude the 1.75 mm filament using a single screw filament extruder. When the filament is ready to be used in the FDM 3D printer, the engineer needs to optimize the printing process parameter concerning material properties. As mentioned previously, the filaments’ quality is necessary before the filament is ready to be used for the 3D printer. The properties of the filament materials are greatly influencing the process parameter set up during the printing process. Consequently, the process parameter could influence the quality of the final 3D printed object. Jiang et al. [14] had shown a study of the effect of printing process parameters on the quality of the 3D printed object. Most of the process parameters significantly affect the mechanical properties of the 3D printed object. Determination of the raster angle and layer thickness would affect the interlayer properties. A raster angle that less than 45° would contribute to interlayer fracture mode, and smaller layer thickness is preferable to strengthen the interlayer bonding strength. A study from Attoye et al. [15] had showed that 45° printing angle is not recommended as it exhibits the weakest mechanical properties of printed object. Sheoran et al. [16] stated that printed objects with 0° of raster angle would have a higher tensile strength as the fibres are parallel to applied tensile load. Interlayer bonding strength of the printed object is influenced by the layer thickness set up and influenced by the properties of the morphological of the filament materials. Less void is desirable where it would strengthen the bonding. However, voids in the composite filament would significantly appear when the fibre volume fraction is increasing. Besides, the water absorption behaviour of the fibres could contribute to void occurrence in the composite morphology [17]. Moreover, good interfacial bonding strength of the composites could avoid agglomeration in the nozzle during the printing process [18]. Therefore, it is important to select the most suitable material that could comprehend process parameters. As the principle of FDM includes thermal extrusion process, filament material is heated with elevated temperature inside a nozzle. It is necessary to employ filament material with suitable working temperature ranges and melt flow properties. A suitable material with the desirable thermal and physical properties should be selected prior to printing process to ensure the molten filament could be extruded. For natural fibre composite, thermal degradation behaviour of the composite should be observed as the fibre could affect the amorphous and semi-crystalline properties of the thermoplastic materials. Moreover, it is suggested to increase fill rate of the printing process as it would decrease the air gap in the material. Therefore, the printing process parameter such as fill rate and nozzle temperature are greatly affected by the thermal and physical properties of the filament materials. Printing angle and layer thickness would influence the mechanical properties of the filament material.

The variety of natural fibre has become an issue in selecting which type is the most suitable for a particular application. Material selection of natural fibres has been performed by many researchers for different applications such as automotive components [19], food industry [20], medical instruments [21], construction [22,23], defence technology [24], and manufacturing process [25]. In selecting the most suitable natural fibre, the engineer must be aware of the material characteristics that should be aligned with the selection requirements. For manufacturing process application, the candidate of materials should satisfy the essential process parameters to ensure the processability and compatibility of the material as the feedstock. Therefore, in selecting natural fibre for FDM, it is vital to understand the unique characteristics of the natural fibres that comprehend the process parameters. A structured and systematic decision making is required to avoid any mistakes and a biased decision that can lead to damages on cost, time, and materials. In addition, the material selection process could take most of the time in the product development process. The selection requirements that are grouped in different elements should be evaluated in detail. The selection criteria have to be prioritized before selecting the natural fibre to avoid misleading judgment and bias. Moreover, the relationship among the criteria should be considered, and it could influence the judgement during the selection. Consequently, this process requires more time and will delay the development process. A concurrent engineering approach is introduced by several researchers [26–28] in selecting materials that could reduce the time of decision making. Hence, in this study, selecting the most suitable natural fibres for FDM is performed using an integrated decision-making tool. The selection process will be performed under principle of concurrent engineering approach where all the selection criteria from different categories will be evaluated in parallel.

2 Selection of Natural Fibre Filament for Fused Deposition Modeling

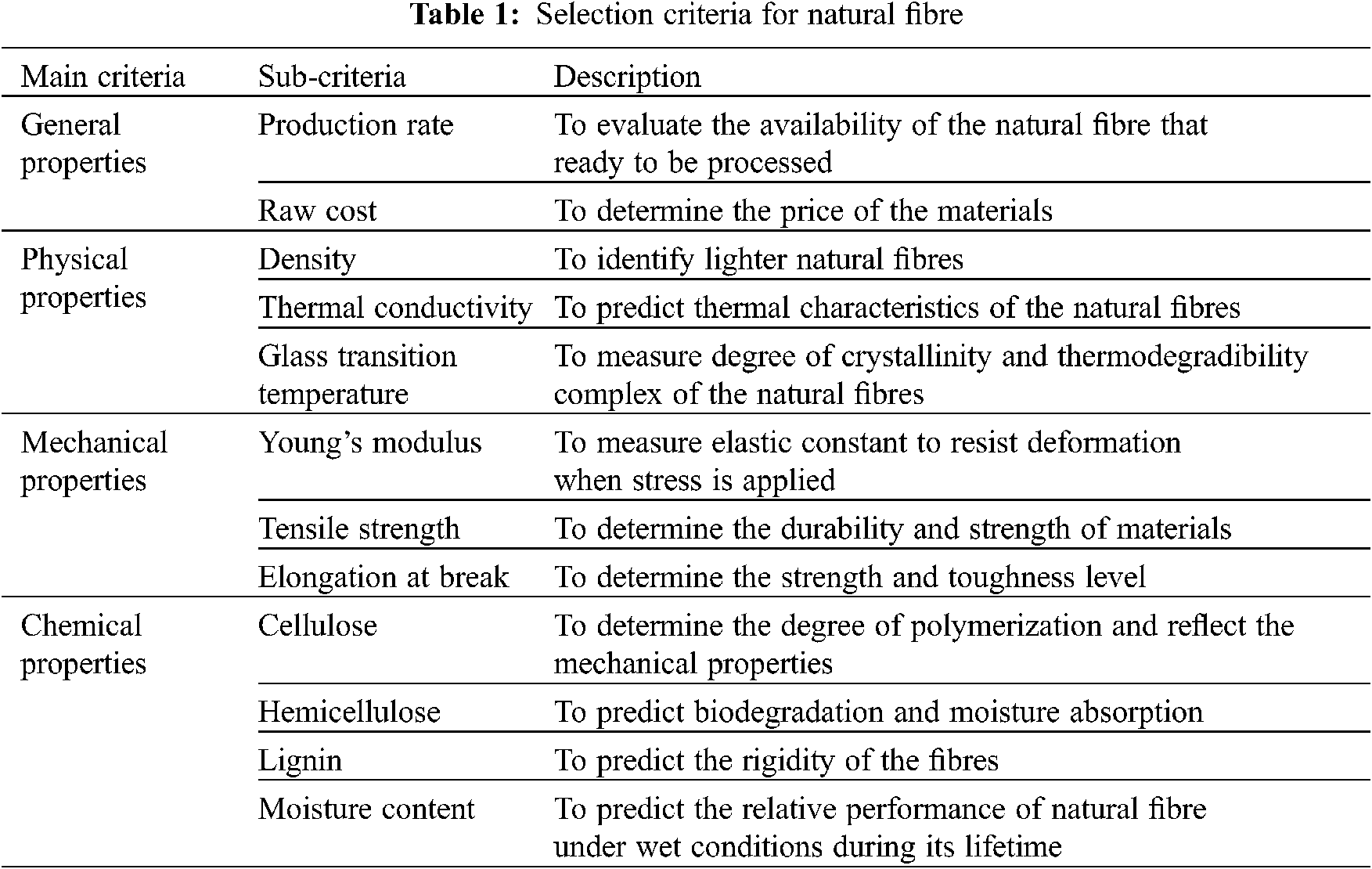

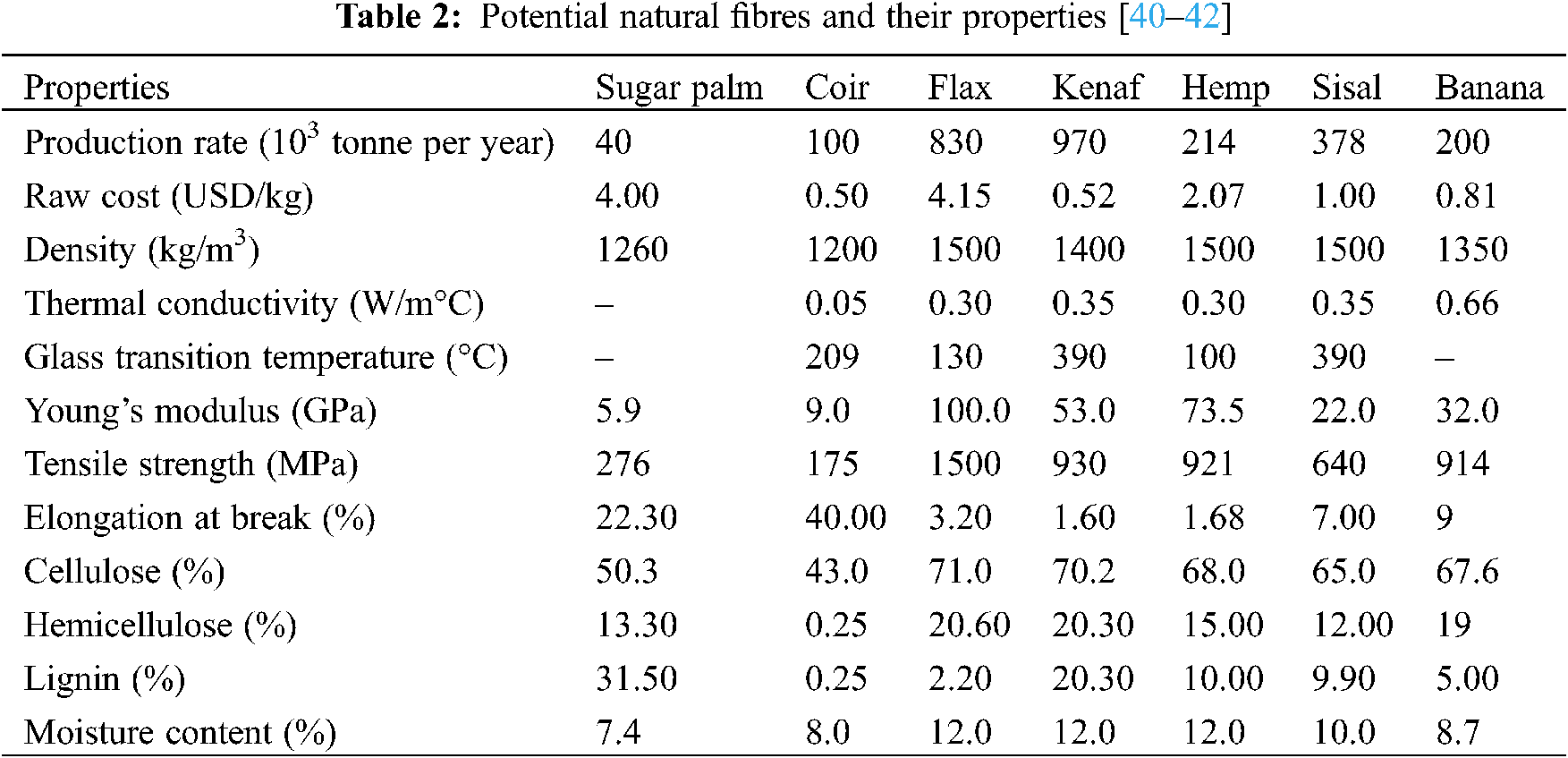

The selection of natural fibres is determined from critical criteria studied through past literature. The criteria are based on material characteristics that should comply with the process parameter of FDM. It could be categorized into four main categories: general properties, physical properties, mechanical properties, and chemical properties. As summarized in Table 1, each of the criteria is described. According to the table, the general properties included in the selection criteria are the natural fibers’ production rate and raw cost. These two sub-criteria are vital as they would exhibit the potential and readiness of the natural fibres to be processed using FDM techniques as an alternative to 100% polymer filaments. The three sub-criteria; density, thermal conductivity, and glass transition temperature, are important for the physical properties. These criteria would predict the natural fibers’ behaviour under certain heat conditions during the thermal extrusion in the FDM process. Besides, these properties would predict the behaviour of the natural fibre-based filaments that are supposed to solidify immediately after extrusion from a nozzle [29]. Glass transition temperature of the materials is highly related to printing temperature (nozzle and platform temperature) where the operator must know at which level of temperature that the filament material able to change its phase from crystalline to liquid state without damaging its integrity. Undesirable material characteristics would lead to the set up of thermal processing parameters mistakenly. Consequently, the mechanical and physical properties of the fabricated object will get affected. Moreover, inappropriate set up of printing temperatures that do not match the properties of filament materials would cause deformation such as warping or shrinkage [30]. Mechanical properties are usually required in any design and process condition to ensure the performance of the final parts would not be affected or degraded. Young’s modulus, tensile strength, and elongation at break would measure the reliability of the materials to resist stress and show the material’s strength. In FDM, the feeding mechanism involved mechanically pushing a filament held between two-counter rotating gears. The filament is subjected to compression, and if the filament material is too brittle, it tends to fracture and discontinue. Consequently, the fractured filament blocks the nozzle orifice. Similarly, if the filament material is too ductile, it will deform inside the nozzle and block the nozzle orifice. Therefore, before the printing process, the operator needs to understand the mechanical behaviour of the filament materials to determine their printability [31]. For natural fibre, chemical properties are important and should be considered as they contribute to the behaviour of natural fibre composites. Four important chemical properties were chosen as sub-criteria: cellulose, hemicellulose, lignin, and moisture content. These properties are related to other properties such as physical and mechanical properties. They also would exhibit the behaviour of the natural fibres in facing challenges in FDM in terms of the rheological and interfacial bonding strength with a polymer matrix. These chemical properties significantly cause the fibre’s hydrophilic behaviour, affecting the resin compatibility and surface adhesion. This behaviour exhibits the stiffness and rigidity of the fibres. Moreover, cellulose in natural fibre acts as a thermal barrier would exhibit the thermal stability of the composites. The FDM technology is mainly using the thermal extrusion process principle, and therefore the feedstock materials must have good thermal stability. Selection of the desirable properties of the filament materials should considered all these behaviours of natural fibre to ensure the printability of the resultant composite. Therefore, all these criteria and their sub-criteria are considered in selecting natural fibres for FDM in this study.

The potential of natural fibres to be reinforced in a polymer matrix to produce filament for FDM is selected based on past studies. In Table 2, the potential natural fibres are listed together with their properties for unbiased judgement. Sugar palm, hemp, kenaf, coir, flax, and banana are shortlisted as the potential natural fibres to be employed for the FDM process. Hemp, kenaf, coir, flax, sisal, and banana fibres are already being studied by past researcher [32] for their ability as a reinforced element in polymer filaments except for sugar palm. In this study, sugar palm is considered to evaluate the potential of this local natural fibre in the additive manufacturing industry. Sugar palm or “ijuk” is well planted in the south area of Peninsular Malaysia and has the potential to be applied in various industries. Consequently, it would improve the rural community financially and support the sustainability campaign nationally and globally. Natural fibres like hemp and flax with good mechanical properties regarding modulus and strength are most likely to be found in any application, including FDM [33]. Hemp and flax fibre reinforced composites filaments are already being developed and commercialized [34]. In addition, sisal, banana, coir, kenaf and sugar palm are found as reinforced natural fibres for poly-lactic acid (PLA) or acrylonitrile butadiene styrene (ABS) composites. PLA and ABS polymers are the most common polymer filaments that applied for FDM. Wang et al. [35] have studied the potential of sisal to be reinforced with PLA. Their study shows that sisal fibres can nucleate and transcrystallize in the PLA matrix, which is the desired behaviour of materials for FDM. Hybrid banana/sisal reinforced PLA composites also exhibit better mechanical properties in a study shown by Asaithambi et al. [36]. Šafka et al. [37] show a study on coir/ABS composites for FDM and concluded that adding natural fibres such as coir in ABS could decrease its strength. Dong et al. [38] suggested fibre treatment to improve the properties of the polymer matrix. A study on kenaf as filler in the ABS polymer matrix also has been studied by other researchers. Dunne et al. [39] characterized hybrid kenaf/sisal reinforced ABS matrix to determine their mechanical properties. Adding natural fibres for polymer composites FDM would enhance the performance and add elements of environmentally friendly.

Selection of the most suitable natural fibre for composites FDM should be performed to avoid any mistakes after the decision has been made. The selection process should consider all the requirements concurrently and prioritize without biased judgement. Concurrent engineering for natural fibres selection is an approach where all the requirements from different criteria are evaluated together by correlating them in the judgement. Besides, this approach has been widely applied in decision-making by many researchers. Hambali et al. [27] used a concurrent engineering approach to select design concepts and material at the conceptual design stage. Both decisions comply with each other in conceptual design development. Sapuan et al. [43] reported that Sapuan [44] and Sapuan et al. [45] had developed an expert system for material selection that satisfied mechanical, chemical, physical, economic, and manufacturing requirements in a concurrent engineering manner. Furthermore, to satisfy the requirements of the product design, Voice of Customers and Voice of Environment should be applied concurrently in material selection. Hence, a concurrent material selection process has been applied and approved for its effectiveness in making a decision. This technique complied with integrated decision-making tools that will be explained in the next section.

3 Integration of AHP/ANP method

Analytic Hierarchy Process (AHP) was developed by Saaty [46] to derive the scale of relative importance for alternatives and criteria. This method has been used since it effectively computes the weighting value to deal with complex decision-making problems. The weighting values obtained from this method are acceptable in objective or subjective evaluation by using pairwise comparisons that can derive accurate ratio and scale priorities [47]. AHP has been employed widely in deciding on suitable materials for a particular application. As mentioned in Noryani et al. [48] study, AHP has been applied by many researchers in determining the most suitable materials that could meet the product design specification. Sapuan et al. [49] determined the most appropriate natural fibre composite for the automotive dashboard panel by considering the main criteria and sub-criteria in the hierarchy model developed through AHP. Salwa et al. [50] employed AHP to determine suitable natural fibres in food packaging applications. Regarding the simple operation of decision-making through AHP, some researchers integrate AHP with other decision-making tools. Salwa et al. [51] integrated AHP with Quality Functional Deployment for Environment (QFDE) to rank the choices of materials based on the customer needs for take-out food container application. In another study, Shaharuzaman et al. [52] found that integration of AHP with Vlse Kriterijumska Optimizacija Kompromisno Resenje (VIKOR) would provide systematic comparison and material selection method especially for automotive product development that involves hybrid natural fibre composites. Bakhoum et al. [53] proposed a hybrid approach that combined AHP with other decision-making tools which are TOPSIS and the concept of entropy that present an objective, systematic and comprehensive method for the sustainable ranking of materials. This approach would assist design engineer to select sustainable materials for structural element design. With regards to all advantages and flexibility of AHP, this tool will be employed in this study to evaluate all the criteria in selecting the most appropriate natural fibres for FDM. There is another tool that also has been used in the decision-making process is the Analytic Network Process (ANP). Saaty [54] has mentioned in his book that ANP is proposed to solve the interactions among criteria that could deal with all kinds of dependences systematically to evaluate the decision criteria. Therefore, some researchers would prefer to use ANP to select materials and solve the interaction between the criteria and alternatives. Milani et al. [55] showed a concept of ANP for a material selection process based on network problems as opposed to a conventional hierarchical decision-making process in their study. Mahmoudkelaye et al. [22] applied ANP to assist constructionists in selecting materials that could reduce the environmental footprint. Similarly, ANP has been integrated with other decision-making tools to improve the judgement and reliability of the final score. Liu et al. [56] integrated ANP with other decision-making tools, which are Decision Making Trail and Evaluation Laboratory (DEMATEL) and modified Vlse Kriterijumska Optimizacija Kompromisno Resenje (VIKOR) to solve the material selection problems of multiple dimensions and interdependent criteria. Govindan et al. [23] have employed ANP and other decision-making tools; DEMATEL and TOPSIS to evaluate the best sustainable construction material based on sustainable indicators. Zhang et al. [57] have proposed a hybrid approach that integrates four types of decision-making tools: DEMATEL, ANP, Grey Relational Analysis (GRA), and TOPSIS. This approach would help the design engineer to select the most suitable green material for sustainability based on the product’s requirements. Moreover, there is another study performed by Sharma et al. [58]. They have selected the priority parameter for manufacturing material for motorcycle axle using an integration of AHP and ANP.

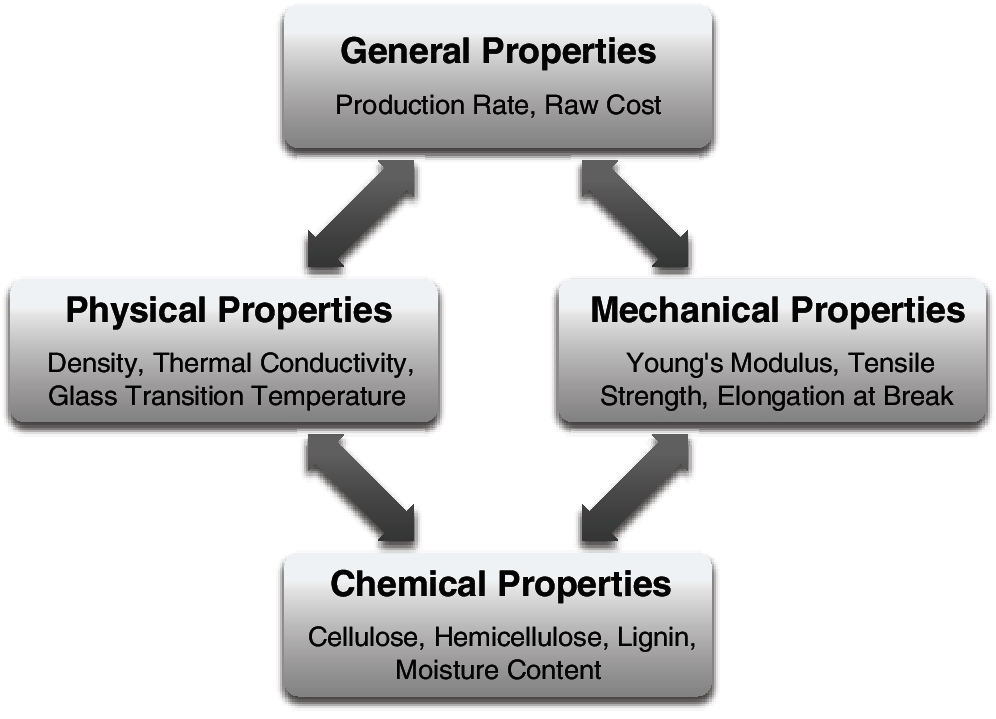

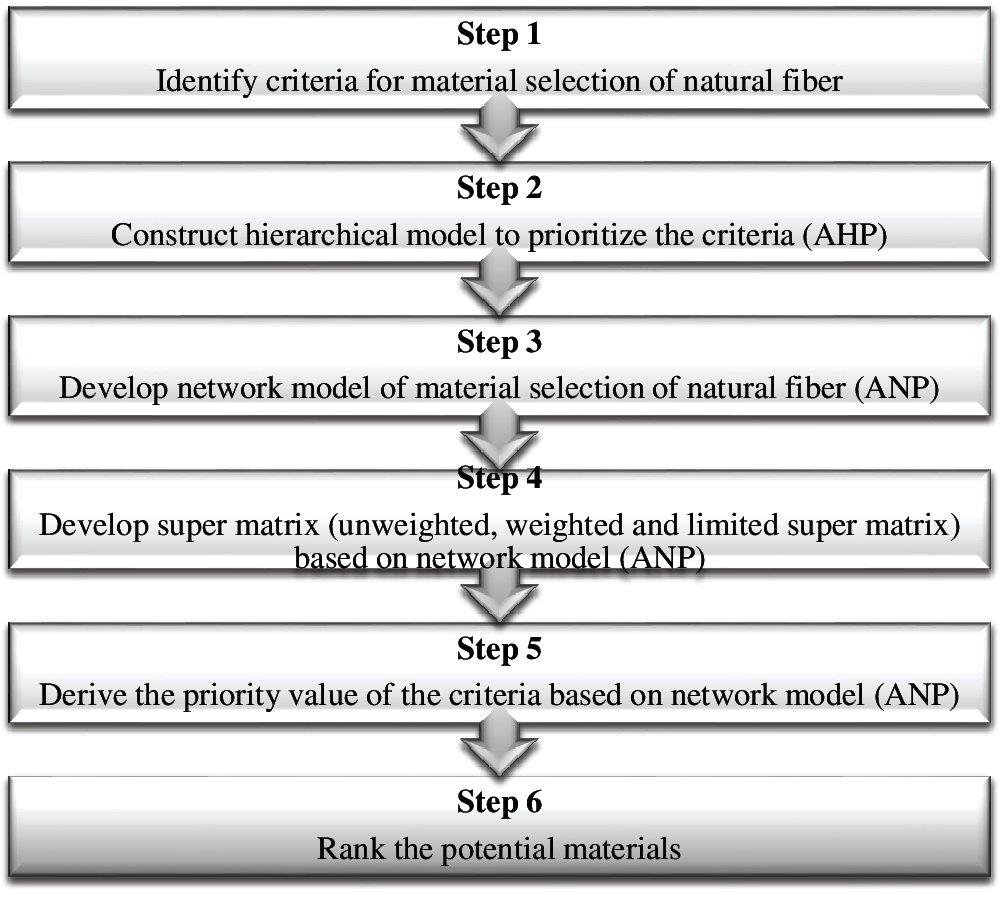

Selecting natural fibres with regards to the application should consider all the material constraints, and dependency among them should be considered during the selection process. Therefore, integration of AHP and ANP is employed in this study. It was proven as an alternative method in making a decision, especially for selecting materials for a particular application. Integration method in decision making is preferable to overcome the deficiency of single method approach. As conducted in previous study [59], a single method of AHP cannot evaluate the inner dependency among the selection criteria, which is necessarily performed to avoid biasness and misjudgement in final score calculation. Decision-making in AHP includes linear relationships among the criteria in single-direction judgement. In this study, it is clearly explained in the previous section that the selection of suitable natural fibre for FDM is based on the material characteristics that comply with the printability requirements for FDM. Therefore, the integration approach of AHP and ANP is more desirable where the ANP could assess the interrelationship between the criteria, and two-way direction judgement is more reliable and valid. The concept of a pairwise comparison matrix from AHP is implemented and embedded in the supermatrix of the ANP approach. Hence, the complex material selection of natural fibre is possibly achieved by integrating AHP/ANP where the selection criterion is evaluated concurrently considering interrelationship among them. In material selection for filament FDM, there are four clusters of main selection criteria regarding the process parameter set up for fibre reinforced FDM, as mentioned previously. The four clusters are general properties, physical properties, mechanical properties and chemical properties. These four clusters include criteria for the selection, as shown in Fig. 1. All the criteria are arranged based on a related cluster. Candidate of natural fibres is selected as suggested in the literature review of material for FDM as in Table 2.

Figure 1: Four main clusters for selection of natural fibres

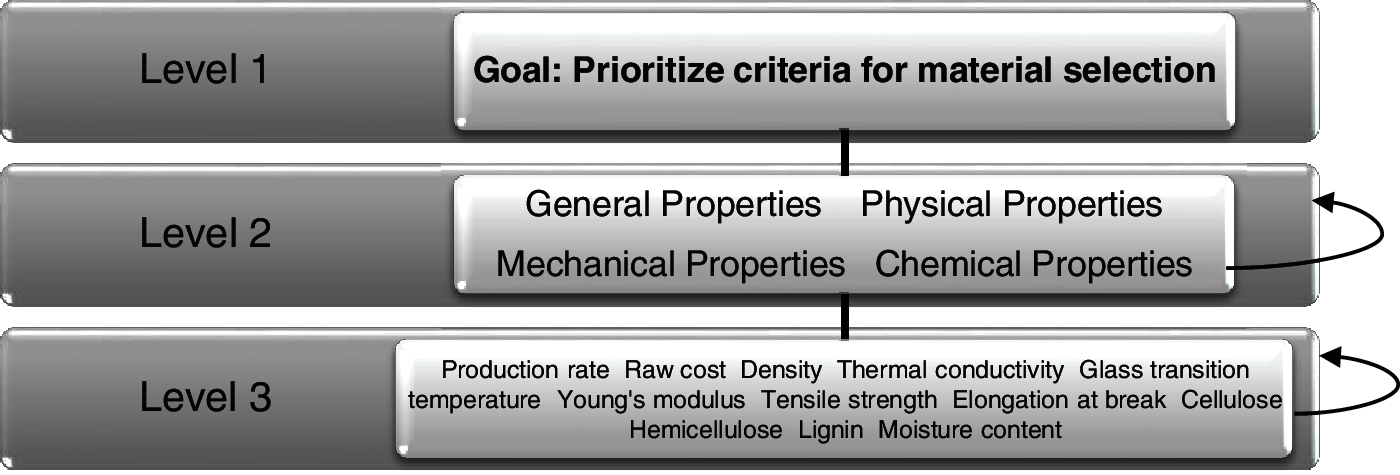

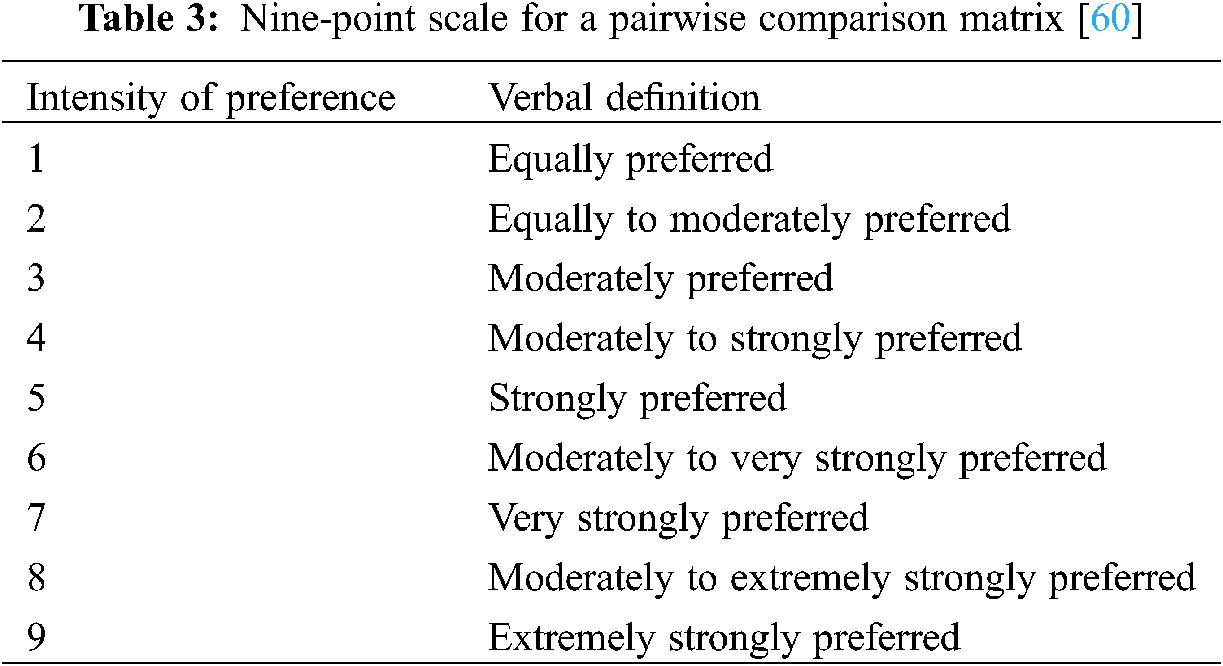

Initially, the hierarchical model is constructed based on the goal, cluster, and criteria to perform a pairwise comparison matrix as practised in AHP, as shown in Fig. 2. The goal is to prioritize criteria for material selection that are set at Level 1. The four main clusters are set at Level 2, and the criteria are set at Level 3, which need to be prioritised. Loops are drawn at the side of the model to indicate the inner dependence of the elements which implied the network model. Next, a pairwise comparison matrix is conducted based on the importance rate for each cluster and criteria over one and another using a nine-point scale as explained in Table 3. Based on the literature reviews, the scoring criterion is determined. The pairwise comparison matrices are constructed by answering questions like how much tensile strength (criteria) is more important than cellulose (criteria) concerning mechanical properties. Priority values are obtained by calculating the eigenvector of the comparison matrix. The eigenvalue of the comparison matrix would be used to calculate the consistency index and consistency ratio of the judgments in a pairwise comparison. The consistency ratio will be considered, and it should be less than 10% to validate the judgement in the pairwise comparison matrix. All the calculations of eigenvector, eigenvalue, and consistency ratio are automatically generated from the Expert Choice® software.

Figure 2: Hierarchical and network model for selection of natural fibres

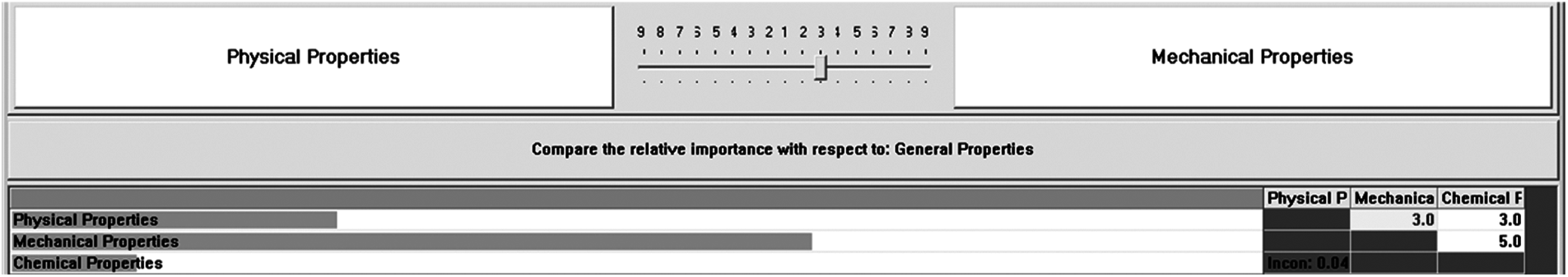

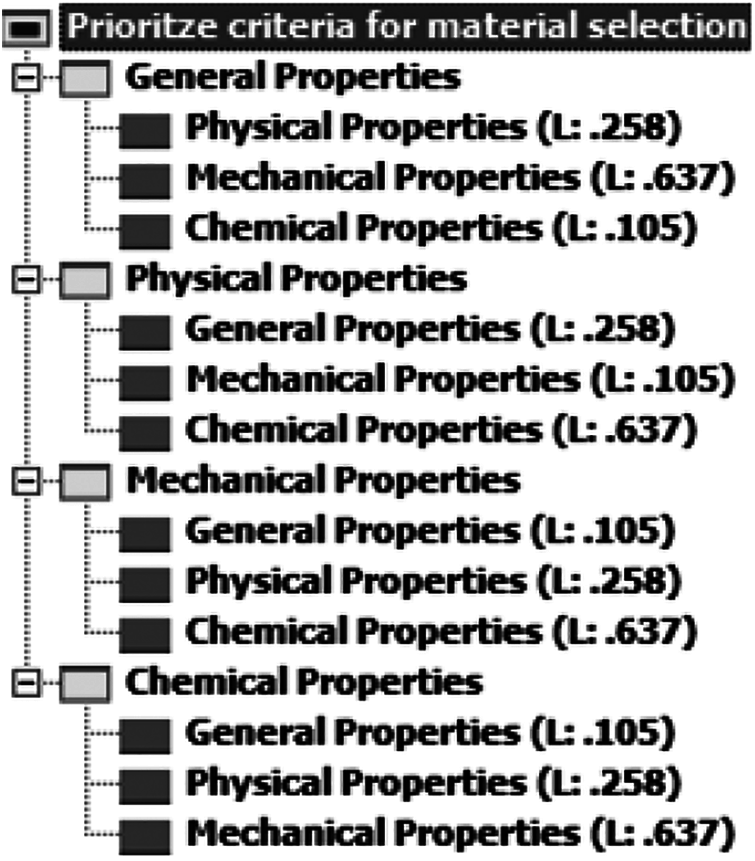

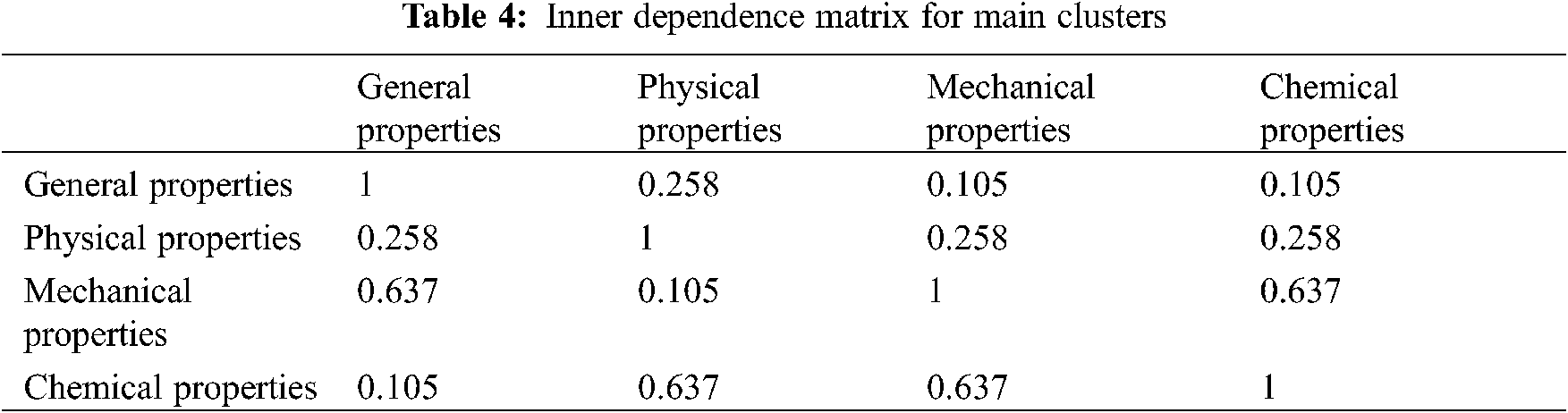

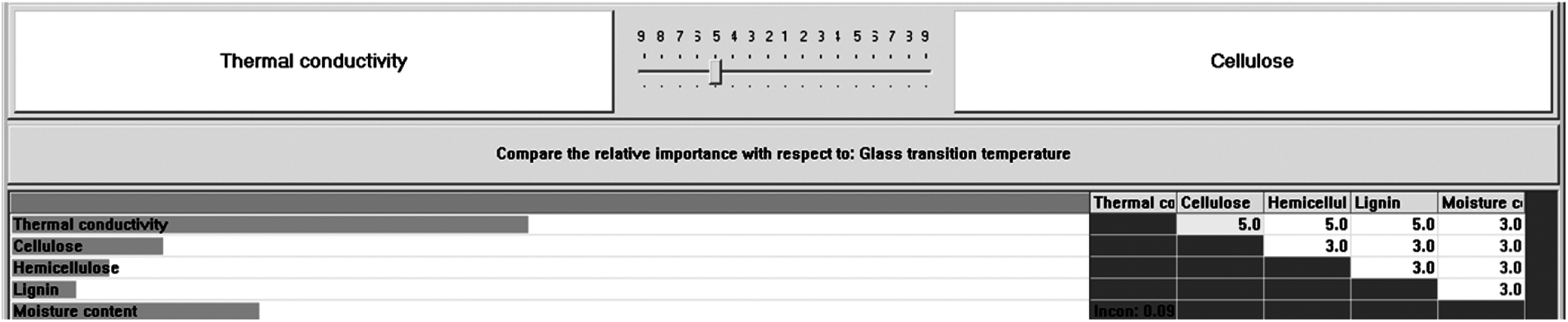

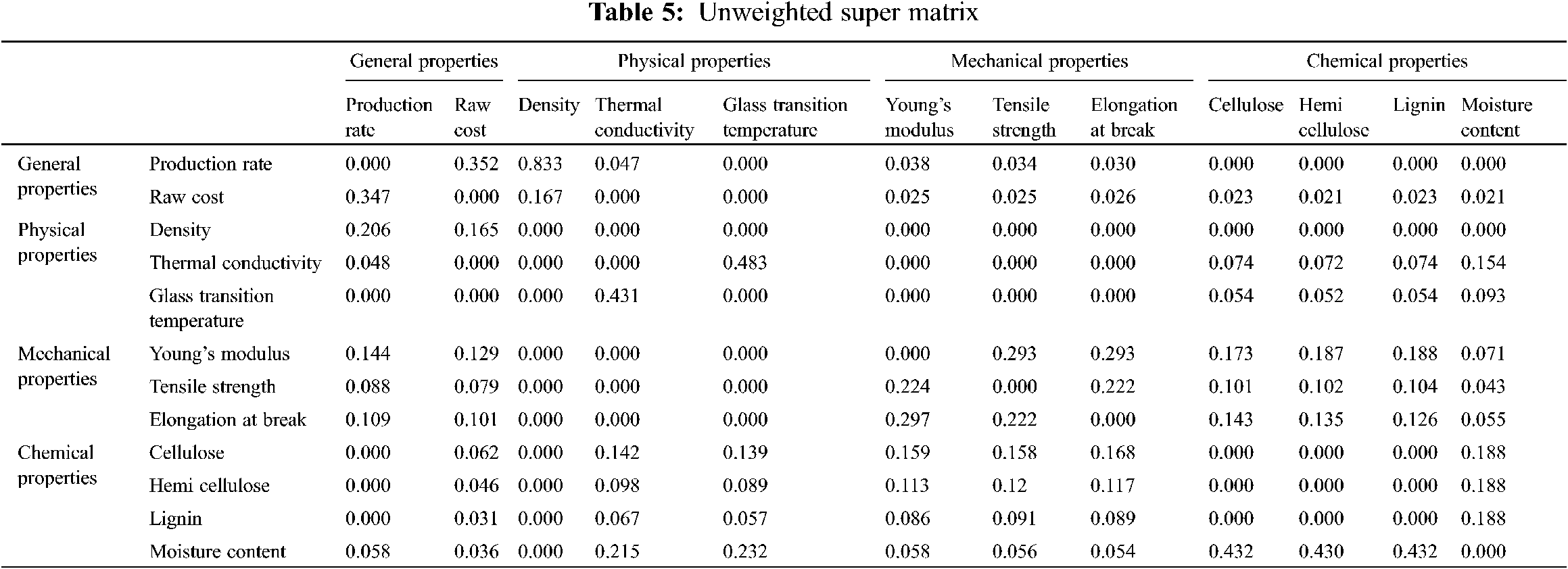

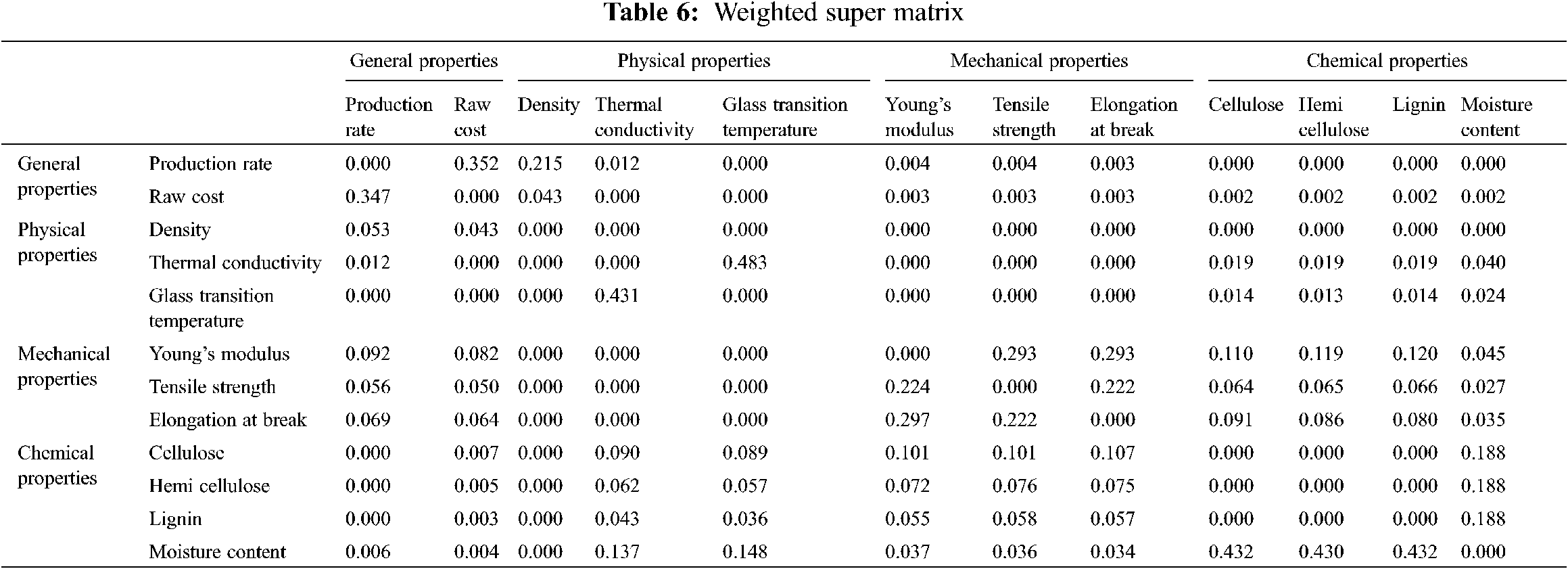

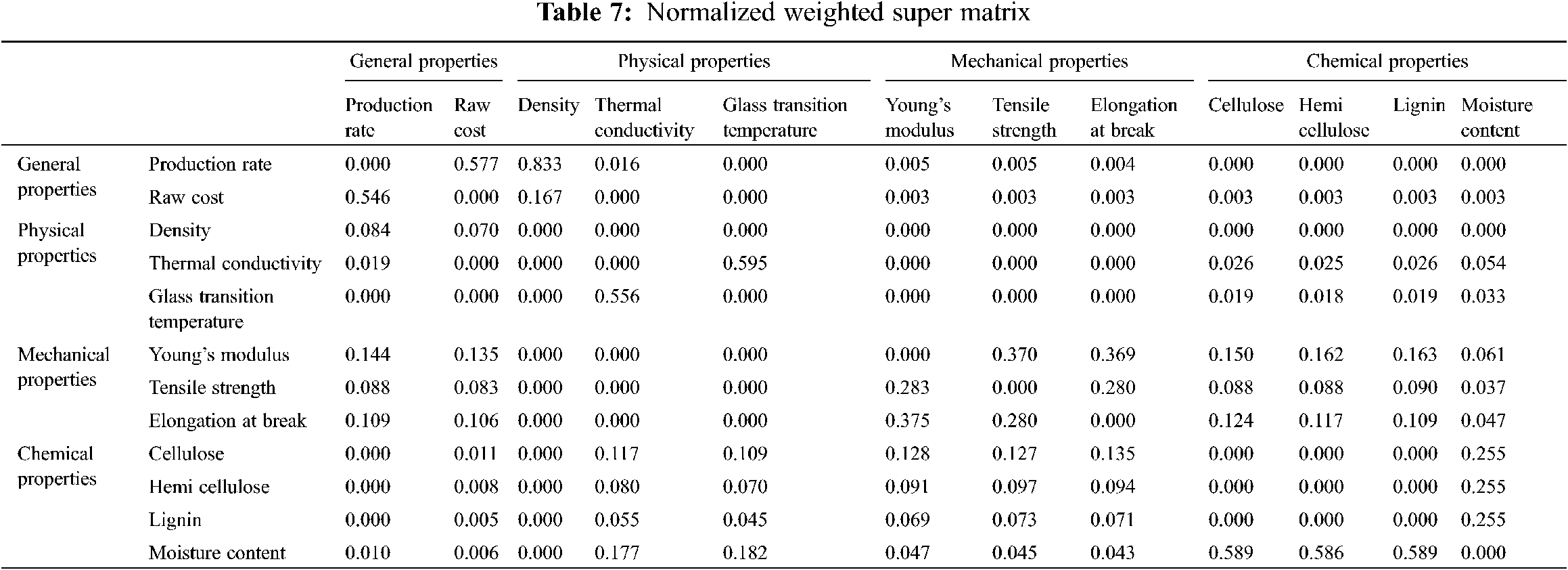

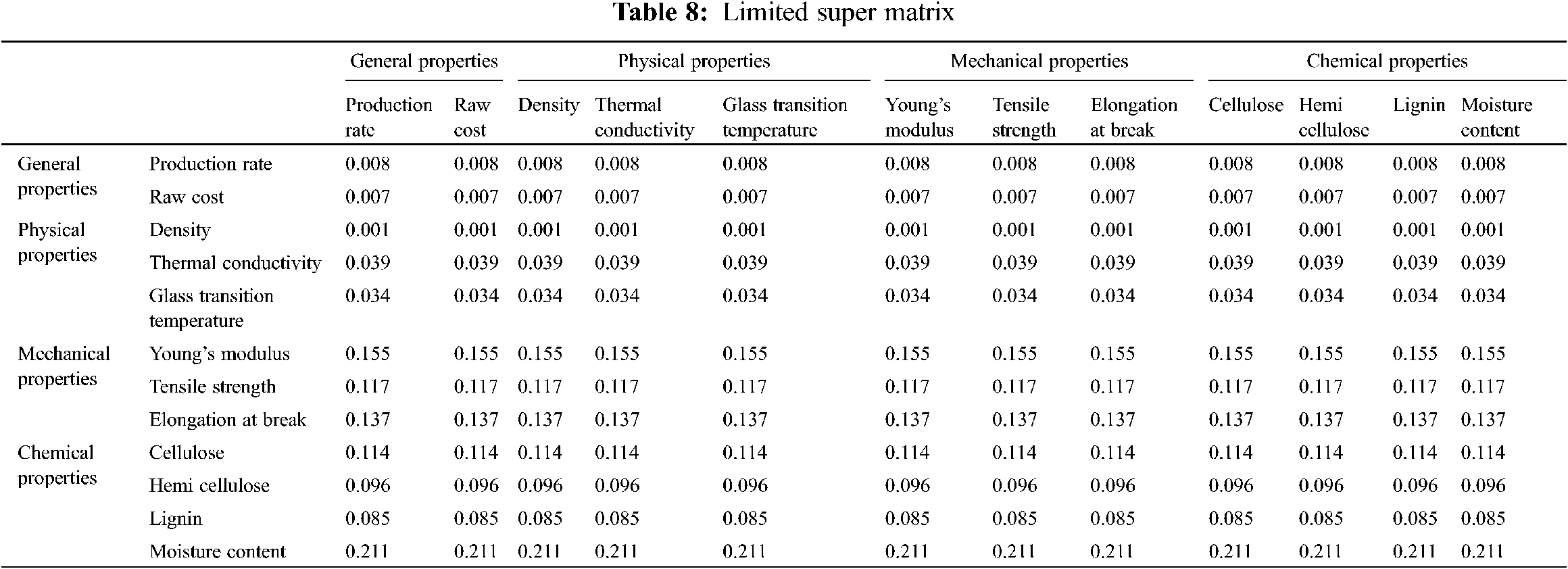

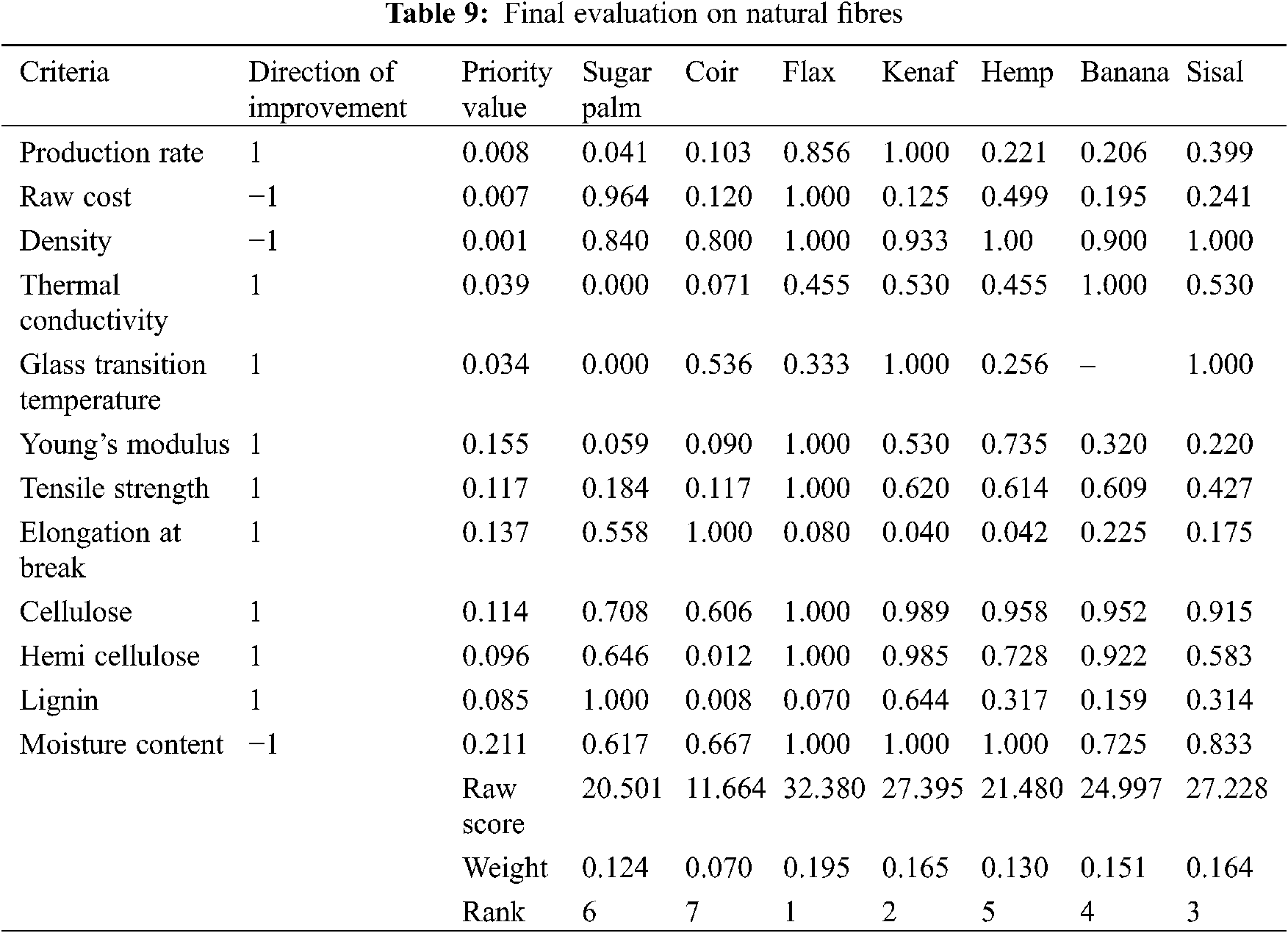

The network model is constructed to obtain the dependency elements among the clusters and criteria, and a supermatrix will be constructed based on this model. Both hierarchical and network models are combined and presented in Fig. 2. At first, the inner dependence matrix based on the pairwise comparison matrix (Fig. 3) of the clusters in Level 2 is constructed as shown in Table 4. This matrix was constructed after the decision-maker determined the importance of each cluster over another. For example, the decision-maker must rate the importance of physical properties compared with mechanical properties to general properties (Fig. 3). When all the judgements have been made for Level 2 using AHP pairwise comparison matrix as shown in Fig. 4, scores for each cluster are obtained and used as input for Table 4. Next, an unweighted supermatrix is developed and constituted with the priority values for each criterion as shown in Table 5. Here, the priority values are obtained from the pairwise comparison matrix (Fig. 5) of criteria in Level 3 as similar approaches as for the main cluster. Due to some limitations, only one pairwise comparison matrix is shown which is the judgement on how important the thermal conductivity, cellulose, hemicellulose, lignin, and moisture content are to the glass transition temperature of the fibres. Weighted supermatrix is derived by multiply the unweighted with the priority values of the clusters obtained earlier in Table 4 and presented in Table 6. Normalization is required if the summation of each column for the weighted supermatrix is not equal to one. In this case, the weighted supermatrix in Table 6 needs to be normalized. The normalized weighted supermatrix is presented in Table 7. In the next stage, the limited supermatrix (Table 8) is calculated by derived the convergent matrix at the high powers of the supermatrix. The priority value of the criteria for goal is obtained from the values of the limited matrix in Table 8 [56]. Finally, the most suitable natural fibre for filament FDM is selected as shown in Table 9. The evaluations are based on the property values of natural fibre for each of the criteria. Raw scores are calculated by the sum products of a column for priority values and score of property values. Weight for each natural fibre is derived by the normalizing value of raw scores and rank is obtained based on this value as shown at the bottom of the table. The summary of the proposed methodology is demonstrated in Fig. 6.

Figure 3: Pairwise comparison matrix for main clusters

Figure 4: Priority values of main clusters based on interdependency

Figure 5: Pairwise comparison matrix for sub-criteria

Figure 6: Methodology of selection of natural fibres for filament FDM

4 Ranking of the Natural Fibres for Filament FDM

After several considerations and calculations, a ranking of the natural fibres for filament FDM is obtained through the integration of AHP/ANP. In an earlier stage, while prioritising the criteria for the selection, criteria from chemical properties obtained the highest priority value. The moisture content of natural fibre obtained 21.1%, followed by Young’s modulus from mechanical properties that obtained 15.5% for the priority value. Hence, these two criteria are considered the most important criteria for selecting natural fibre as reinforced materials for polymer composites. Generally, natural fibres have poor adhesion to hydrophobic polymer matrices because of their hydrophilic nature [61]. As shown in Table 9, the lower moisture content is desirable as the direction of improvement is set as -1 in the final evaluation. The low moisture content of natural fibre is the most desirable criteria for polymer composites that could overcome the problems in terms of dimensional stability, electrical resistivity, tensile strength, porosity, and swelling behaviour of natural fibre in composite materials [62]. Razali et al. [63] had shown a study on the desired moisture content of natural fibre. Their study shows that the lower moisture content of natural fibre exhibits high dimensional stability and quality of the final product. In another study, mechanical properties will increase as the moisture content decreases [64]. Prediction of mechanical properties of natural fibres shows that moisture content has a significant relationship with the other properties and therefore exhibits their dependency among others in the material selection process [65].

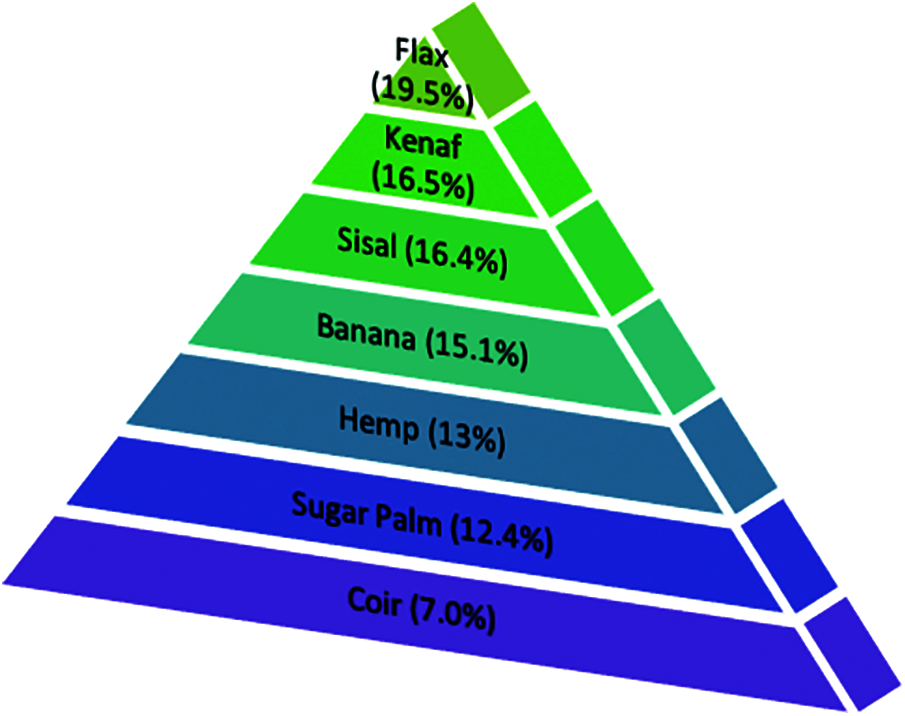

As illustrated in Fig. 7 that based on Table 9, flax fibre (19.5%) scored the highest as the most suitable natural fibres for filament FDM, followed by kenaf (16.5%) and sisal (16.4%). In the final evaluation, it can be concluded that flax fibres satisfied most of the selection criteria by obtained 100% for Young’s modulus, tensile strength, cellulose content, and hemicellulose content. However, flax fibres scored 100% for the moisture content and this result is undesirable for the selection. Here, fibre modification is required to reduce the moisture level significantly [66]. As mentioned earlier, flax reinforced polymer composite filaments are already commercialized in the FDM industry. Flax fibres are widely applied for many polymer composites in various industries because of their superior material properties comparable with synthetic fibres like carbon and glass [67]. Flax fibre reinforced with PLA also shows good properties in preliminary results of extruded compounds. In the latest study by Le Duigou et al. [68], flax fibre was selected as the reinforced materials for developing continuous fibre reinforced bio-composite for FDM. Flax fibre was selected because it exhibits almost the best tensile properties while a low linear weight allowed a reduction in microstructural heterogeneities. Moreover, the rheological behaviour of flax/PLA composites shows enhancement of the rate of crystallization due to the presence of flax fibre as a cellulosic element and effectively accelerate the shear flow of the neat PLA [69]. This condition could overcome an issue of the natural fibres in FDM regarding the rheological properties of deposition materials.

Figure 7: Rank of natural fibres for filament FDM

In summary, the selection of natural fibres for the FDM application has been performed using integrated decision-making tools in the concurrent engineering approach. This study has explained the potential natural fibres that compatible with process parameters of FDM that make them the most suitable candidate as feedstock materials. In consideration of interdependency among the criteria, integration of AHP and ANP has scored flax fibre as the most appropriate natural fibre that satisfies the selection requirements with a score of 19.5%. Coir has scored the lowest as it obtained 7% from the whole evaluation. The results obtained from the integration method of AHP and ANP have been verified by the excellent properties of flax fibres that many researchers have investigated. Moreover, to save more time, cost and energy, a concurrent engineering approach is suggested to be comprehended in the material selection process of natural fibres. This approach included all the elements from different criteria and interdependency among the criteria were evaluated through the selection process. Therefore, it is suggested for further investigation on the suitable polymer matrix using the same approach for flax fibres to develop new composite material as the feedstock of FDM.

Acknowledgement: The authors would like to thank the Ministry of Higher Education Malaysia and Universiti Teknikal Malaysia Melaka for the financial support provided through the Fundamental Research Grant Scheme.

Funding Statement: Mastura M.T. received financial support from the Ministry of Higher Education Malaysia https://(https://www.mohe.gov.my/en/services/research/mygrants) and Universiti Teknikal Malaysia Melaka through the Fundamental Research Grant Scheme (FRGS/1/2020/FTKMP-CARE/F00456).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Sanjay, M. R., Madhu, P., Jawaid, M., Senthamaraikannan, P., Senthil, S. et al. (2018). Characterization and properties of natural fiber polymer composites: A comprehensive review. Journal of Cleaner Production, 172, 566–581. DOI 10.1016/j.jclepro.2017.10.101. [Google Scholar] [CrossRef]

2. Mansor, M. R., Salit, M. S., Zainudin, E. S. (2015). Life cycle assessment of natural fiber polymer composites. In: Agricultural biomass based potential materials, pp. 121–141. Berlin, Germany: Springer. [Google Scholar]

3. Ishak, M. R., Leman, Z., Sapuan, S. M., Rahman, M. Z. A., Anwar, U. M. K. (2013). Impregnation modification of sugar palm fibres with phenol formaldehyde and unsaturated polyester. Fibers and Polymers, 14(2), 250–257. DOI 10.1007/s12221-013-0250-0. [Google Scholar] [CrossRef]

4. Sapuan, S. M. (2014). Tropical natural fibre composites: Properties. In: Manufacture and applications, 1st edition. Singapore: Springer-Verlag Singapur. [Google Scholar]

5. Faruk, O., Bledzki, A. K., Fink, H. P., Sain, M. (2014). Progress report on natural fiber reinforced composites. Macromolecular Materials and Engineering, 299(1), 9–26. DOI 10.1002/mame.201300008. [Google Scholar] [CrossRef]

6. Danso, H., Martinson, D. B., Ali, M., Williams, J. B. (2015). Physical, mechanical and durability properties of soil building blocks reinforced with natural fibres. Construction and Building Materials, 101(1), 797–809. DOI 10.1016/j.conbuildmat.2015.10.069. [Google Scholar] [CrossRef]

7. Sarah, K. (2017). This Thai company makes food packaging out of bamboo to cut down on trash. https://money.cnn.com/2017/02/12/news/thailand-bamboo-cassava-packaging-universal-biopack/index.html. [Google Scholar]

8. Cong, J., Zhang, B. (2011). Methodology for evaluating manufacturability of composite materials. Applied Composite Materials, 19(3–4), 189–201. DOI 10.1007/s10443-011-9195-x. [Google Scholar] [CrossRef]

9. Atiqah, A., Jawaid, M., Sapuan, S. M., Ishak, M. R., Ansari, M. N. M. et al. (2019). Physical and thermal properties of treated sugar palm/glass fibre reinforced thermoplastic polyurethane hybrid composites. Journal of Materials Research and Technology, 8(5), 3726–3732. DOI 10.1016/j.jmrt.2019.06.032. [Google Scholar] [CrossRef]

10. Whyman, S., Arif, K. M., Potgieter, J. (2018). Design and development of an extrusion system for 3D printing biopolymer pellets. International Journal of Advanced Manufacturing Technology, 96(9–12), 3417–3428. DOI 10.1007/s00170-018-1843-y. [Google Scholar] [CrossRef]

11. Farhan Han, S. N. M., Mastura, M. T., Mansor, M. R. (2021). Recent progress on fused filament fabrication research: sustainable materials and processing parameters. In: Design for sustainability, pp. 371–393. Amsterdam, Netherlands: Elsevier. [Google Scholar]

12. Stoof, D., Pickering, K. (2018). Sustainable composite fused deposition modelling filament using recycled pre-consumer polypropylene. Composites Part B: Engineering, 135(10), 110–118. DOI 10.1016/j.compositesb.2017.10.005. [Google Scholar] [CrossRef]

13. Kariz, M., Sernek, M., Obućina, M., Kuzman, M. K. (2018). Effect of wood content in FDM filament on properties of 3D printed parts. Materials Today Communications, 14(11), 135–140. DOI 10.1016/j.mtcomm.2017.12.016. [Google Scholar] [CrossRef]

14. Jiang, S., Liao, G., Xu, D., Liu, F., Li, W. et al. (2018). Mechanical properties analysis of polyetherimide parts fabricated by fused deposition modeling. High Performance Polymers, 31(1), 1–10. DOI 10.1177/0954008317752822. [Google Scholar] [CrossRef]

15. Attoye, S., Malekipour, E., El-Mounayri, H. (2019). Correlation between process parameters and mechanical properties in parts printed by the fused deposition modeling process. Mechanics of Additive and Advanced Manfacturing, 8, 35–41. DOI 10.1007/978-3-319-95083-9. [Google Scholar] [CrossRef]

16. Sheoran, A. J., Kumar, H. (2020). Fused deposition modeling process parameters optimization and effect on mechanical properties and part quality. Review and Reflection on Present Research, Materials Today Proceeding, 21(3), 1659–1672. DOI 10.1016/j.matpr.2019.11.296. [Google Scholar] [CrossRef]

17. Hwang, S., Reyes, E. I., Moon, K. S., Rumpf, R. C., Kim, N. S. (2015). Thermo-mechanical characterization of metal/polymer composite filaments and printing parameter study for fused deposition modeling in the 3D printing process. Journal of Electronic Materials, 44(3), 771–777. DOI 10.1007/s11664-014-3425-6. [Google Scholar] [CrossRef]

18. Wang, X., Jiang, M., Zhou, Z., Gou, J., Hui, D. (2017). 3D printing of polymer matrix composites: A review and prospective. Composites Part B: Engineering, 110, 442–458. DOI 10.1016/j.compositesb.2016.11.034. [Google Scholar] [CrossRef]

19. Mansor, M. R., Sapuan, S. M., Zainudin, E. S., Nuraini, A. A., Hambali, A. (2013). Hybrid natural and glass fibers reinforced polymer composites material selection using analytical hierarchy process for automotive brake lever design. Material and Design, 51, 484–492. DOI 10.1016/j.matdes.2013.04.072. [Google Scholar] [CrossRef]

20. Sanyang, M. L., Sapuan, S. M. (2015). Development of expert system for biobased polymer material selection: Food packaging application. Journal of Food Science and Technology, 52(10), 6445–6454. DOI 10.1007/s13197-015-1759-6. [Google Scholar] [CrossRef]

21. Lam, R. H. W., Chen, W. (2019). Biocompatible Material Selection. In: Biomedical devices, pp. 243–266. Cham: Springer International Publishing. [Google Scholar]

22. Mahmoudkelaye, S., Taghizade Azari, K., Pourvaziri, M., Asadian, E. (2018). Sustainable material selection for building enclosure through ANP method. Case Studies in Construction Materials, 9, e00200. DOI 10.1016/j.cscm.2018.e00200. [Google Scholar] [CrossRef]

23. Govindan, K., Madan Shankar, K., Kannan, D. (2016). Sustainable material selection for construction industry–A hybrid multi criteria decision making approach. Renewable and Sustainable Energy Review, 55, 1274–1288. DOI 10.1016/j.rser.2015.07.100. [Google Scholar] [CrossRef]

24. Naveen, J., Jawaid, M., Zainudin, E. S., Sultan, M. T. H., Yahaya, R. B. (2018). Selection of natural fiber for hybrid kevlar/natural fiber reinforced polymer composites for personal body armor by using analytical hierarchy process. Frontiers in Materials, 5(8), 1–13. DOI 10.3389/fmats.2018.00052. [Google Scholar] [CrossRef]

25. Hambali, A., Sapuan, S. M., Ismail, N., Nukman, Y. (2009). Composite manufacturing process selection using analytical hierarchy process. International Journal of Mechanical and Materials Engineering, 4(1), 49–61. DOI 10.1.1.301.1102. [Google Scholar]

26. Albiñana, J. C., Vila, C. (2012). A framework for concurrent material and process selection during conceptual product design stages. Materials and Design, 41(10), 433–446. DOI 10.1016/j.matdes.2012.05.016. [Google Scholar] [CrossRef]

27. Hambali, A., Sapuan, S. M., Rahim, A. S., Ismail, N., Nukman, Y. (2011). Concurrent decisions on design concept and material using analytical hierarchy process at the conceptual design stage. Concurrent Engineering, 19(2), 111–121. DOI 10.1177/1063293X11408138. [Google Scholar] [CrossRef]

28. Sapuan, S. M., Mansor, M. R. (2014). Concurrent engineering approach in the development of composite products: A review. Materials and Design, 58(6), 161–167. DOI 10.1016/j.matdes.2014.01.059. [Google Scholar] [CrossRef]

29. Bartel, T., Rivard, A., Jimenez, A., Mestres, C. A., Müller, S. (2018). Medical three-dimensional printing opens up new opportunities in cardiology and cardiac surgery. European Heart Journal, 39(15), 1246–1254. DOI 10.1093/eurheartj/ehx016. [Google Scholar] [CrossRef]

30. Kontarova, S., Přikryl, R., Melčová, V., Menčík, P., Horálek, M. et al. (2020). Printability, mechanical and thermal properties of poly(3-hydroxybutyrate)-poly(lactic acid)-plasticizer blends for three-dimensional (3D) printing. Materials (Basel), 13(15), 1–27. DOI 10.3390/ma13214736. [Google Scholar] [CrossRef]

31. Nasereddin, J. M., Wellner, N., Alhijjaj, M., Belton, P., Qi, S. (2018). Development of a simple mechanical screening method for predicting the feedability of a pharmaceutical FDM 3D printing filament. Pharmaceutical Research, 35(151), 1–13. DOI 10.1007/s11095-018-2432-3. [Google Scholar] [CrossRef]

32. Fidan, I., Imeri, A., Gupta, A., Hasanov, S., Nasirov, A. et al. (2019). The trends and challenges of fiber reinforced additive manufacturing. International Journal of Advanced Manufacturing Technology, 102, 1801–1818. DOI 10.1007/s00170-018-03269-7. [Google Scholar] [CrossRef]

33. Graichen, F. H. M., Grigsby, W. J., Hill, S. J., Raymond, L. G., Sanglard, M. et al. (2017). Yes, we can make money out of lignin and other bio-based resources. Industria Crops and Products, 106, 74–85. DOI 10.1016/j.indcrop.2016.10.036. [Google Scholar] [CrossRef]

34. 3D Jake (2019). Extrudr Flax-3DJake Online Shop International. https://www.3djake.com/extrudr/flax. [Google Scholar]

35. Wang, Y., Tong, B., Hou, S., Li, M., Shen, C. (2011). Transcrystallization behavior at the poly (lactic acid)/sisal fibre biocomposite interface. Composites Part A: Applied Science and Manufacturing, 42(1), 66–74. DOI 10.1016/j.compositesa.2010.10.006. [Google Scholar] [CrossRef]

36. Asaithambi, B., Ganesan, G., Ananda Kumar, S. (2014). Bio-composites: Development and mechanical characterization of banana/sisal fibre reinforced poly lactic acid (PLA) hybrid composites. Fibers and Polymers, 15(4), 847–854. DOI 10.1007/s12221-014-0847-y. [Google Scholar] [CrossRef]

37. Šafka, J., Ackermann, M., Bobek, J., Seidl, M., Habr, J. et al. (2016). Use of composite materials for FDM 3D print technology. Material Science Forum, 862, 174–181. DOI 10.4028/www.scientific.net/MSF.862.174. [Google Scholar] [CrossRef]

38. Dong, Y., Ghataura, A., Takagi, H., Haroosh, H. J., Nakagaito, A. N. et al. (2014). Polylactic acid (PLA) biocomposites reinforced with coir fibres: Evaluation of mechanical performance and multifunctional properties. Composites Part A: Applied Science and Manufacturing, 63, 76–84. DOI 10.1016/j.compositesa.2014.04.003. [Google Scholar] [CrossRef]

39. Dunne, R., Desai, D., Sadiku, R. (2017). Material characterization of blended sisal-kenaf composites with an ABS matrix. Applied Acoustics, 125, 184–193. DOI 10.1016/j.apacoust.2017.03.022. [Google Scholar] [CrossRef]

40. AL-Oqla, F. M., Sapuan, S. M. (2014). Natural fiber reinforced polymer composites in industrial applications: Feasibility of date palm fibers for sustainable automotive industry. Journal of Cleaner Production, 66(3), 347–354. DOI 10.1016/j.jclepro.2013.10.050. [Google Scholar] [CrossRef]

41. Design, G. (2013). CES Edupack. https://www.grantadesign.com/products/data/. [Google Scholar]

42. Gohil, P. P., Chaudhary, V., Shaikh, A. A. (2015). Natural fiber-reinforced composites: potential, applications and properties. In: Agricultural biomass based potential materials, pp. 51–72. Cham: Springer. [Google Scholar]

43. Sapuan, S. M., Osman, M. R., Nukman, Y. (2006). State of the art of the concurrent engineering technique in the automotive industry. Journal of Engineering Design, 17(2), 143–157. DOI 10.1080/09544820500275511. [Google Scholar] [CrossRef]

44. Sapuan, S. M. (2001). A knowledge-based system for materials selection in mechanical engineering design. Materials and Design, 22(8), 687–695. DOI 10.1016/S0261-3069(00)00108-4. [Google Scholar] [CrossRef]

45. Sapuan, S. M., Abdalla, H. (1998). A prototype knowledge-based system for the material selection of polymeric-based composites for automotive components. Composites Part A: Applied Science and Manufacturing, 29(7), 731–742. DOI 10.1016/S1359-835X(98)00049-9. [Google Scholar] [CrossRef]

46. Saaty, T. L. (1980). The analytic hierarchy process. New York: McGraw-Hill. [Google Scholar]

47. Nahm, Y. E., Ishikawa, H., Inoue, M. (2013). New rating methods to prioritize customer requirements in QFD with incomplete customer preferences. International Journal of Advanced Manufacturing and Technology, 65, 1587–1604. DOI 10.1007/s00170-012-4282-1. [Google Scholar] [CrossRef]

48. Noryani, M., Sapuan, S. M., Mastura, M. T. (2018). Multi-criteria decision-making tools for material selection of natural fibre composites: A review. Journal of Mechanical Engineering and Sciences, 12(1), 3330–3353. DOI 10.15282/jmes.12.1.2018.5.0299. [Google Scholar] [CrossRef]

49. Sapuan, S. M., Kho, J. Y., Zainudin, E. S., Leman, Z., Ahmed Ali, B. A. et al. (2011). Materials selection for natural fiber reinforced polymer composites using analytical hierarchy process. Indian Journal of Engineering and Material Sciences, 18(4), 255–267. http://nopr.niscair.res.in/handle/123456789/12892. [Google Scholar]

50. Salwa, H., Sapuan, S. M., Mastura, M. T., Zuhri, M. Y. M. (2019). Analytic hierarchy process (AHP)-based materials selection system for natural fiber as reinforcement in biopolymer composites for food packaging. BioResources, 14(4), 10014–10046. DOI 10.15376/biores.14.4.10014-10046. [Google Scholar] [CrossRef]

51. Salwa, H., Sapuan, S. M., Mastura, M. T., Zuhri, M. Y. M. (2021). Conceptual design and selection of natural fibre reinforced biopolymer composite (NFBC) takeout food container. Journal of Renewable Materials, 9(4), 803–827. DOI 10.32604/jrm.2021.013977. [Google Scholar] [CrossRef]

52. Shaharuzaman, A., Sapuan, S. M., Mansor, M. R., Zuhri, M. Y. M. (2019). Decision support strategy in selecting natural fiber materials for automotive side-door impact beam composites. Journal of Renewable Materials, 7(10), 997–1010. DOI 10.32604/jrm.2019.07529. [Google Scholar] [CrossRef]

53. Bakhoum, E. S., Brown, D. C. (2012). A hybrid approach using AHP-TOPSIS–Entropy methods for sustainable ranking of structural materials. International Journal of Sustainable Engineering, 7038(5), 1–13. DOI 10.1080/19397038.2012.719553. [Google Scholar] [CrossRef]

54. Saaty, T. L. (1996). Decision making with dependence and feedback: The analytic network process. New York: RWS Publications. [Google Scholar]

55. Milani, A. S., Shanian, A., Lynam, C., Scarinci, T. (2013). An application of the analytic network process in multiple criteria material selection. Materials and Design, 44, 622–632. DOI 10.1016/j.matdes.2012.07.057. [Google Scholar] [CrossRef]

56. Liu, H. C., You, J. X., Zhen, L., Fan, X. J. (2014). A novel hybrid multiple criteria decision making model for material selection with target-based criteria. Materials and Design, 60, 380–390. DOI 10.1016/j.matdes.2014.03.071. [Google Scholar] [CrossRef]

57. Zhang, H., Peng, Y., Tian, G., Wang, D., Xie, P. (2017). Green material selection for sustainability: A hybrid MCDM approach. PLoS One, 12(5), 1–26. DOI 10.1371/journal.pone.0177578. [Google Scholar] [CrossRef]

58. Sharma, A., Gupta, P., Srivastava, R. K. (2015). Application of AHP and ANP methods for selection of best material for an axle. International Journal of Innovation Research in Science, Engineering and Technology, 4(5), 2894–2901. DOI 10.15680/IJIRSET.2015.0405032. [Google Scholar] [CrossRef]

59. Mastura, M. T., Sapuan, S. M., Noryani, M. (2019). Material selection of natural fibers for composite automotive component using analytic hierarchy process/analytic network process in concurrent engineering approach. Key Engineering Materials, 801(KEM), 53–58. DOI 10.4028/www.scientific.net/KEM.801.53. [Google Scholar] [CrossRef]

60. Ariff, H., Salit, M. S., Ismail, N., Nukman, Y. (2008). Use of analytical hierarchy process (AHP) for selecting the best design concept. Jurnal Teknologi, 49(1), 1–18. DOI 10.11113/jt.v49.188. [Google Scholar] [CrossRef]

61. Mukherjee, T., Kao, N. (2011). PLA based biopolymer reinforced with natural fibre: A Review. Journal of Polymers and the Environment, 19(3), 714–725. DOI 10.1007/s10924-011-0320-6. [Google Scholar] [CrossRef]

62. Jawaid, M., Abdul Khalil, H. P. S. (2011). Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydrate Polymers, 86(1), 1–18. DOI 10.1016/j.carbpol.2011.04.043. [Google Scholar] [CrossRef]

63. Razali, N., Salit, M. S., Jawaid, M., Ishak, M. R., Lazim, Y. (2015). A study on chemical composition, physical, tensile, morphological, and thermal properties of roselle fibre: Effect of fibre maturity. BioResources, 10(1), 1803–1824. DOI 10.15376/biores.10.1.1803-1824. [Google Scholar] [CrossRef]

64. Facca, A. G., Kortschot, M. T., Yan, N. (2006). Predicting the elastic modulus of natural fibre reinforced thermoplastics. Composites Part A: Applied Science and Manufacturing, 37(10), 1660–1671. DOI 10.1016/j.compositesa.2005.10.006. [Google Scholar] [CrossRef]

65. Forest Products Laboratory-USDA (2010). Wood handbook: Wood as an engineering material. USDA-General Technical Report. [Google Scholar]

66. Berthet, M. A., Gontard, N., Angellier-Coussy, H. (2015). Impact of fibre moisture content on the structure/mechanical properties relationships of PHBV/wheat straw fibres biocomposites. Composites Science and Technology, 117, 386–391. DOI 10.1016/j.compscitech.2015.07.015. [Google Scholar] [CrossRef]

67. John, M. J., Anandjiwala, R. D., Pothan, L. A., Thomas, S. (2007). Cellulosic fibre-reinforced green composites. Composite Interfaces, 14(7–9), 733–751. DOI 10.1163/156855407782106546. [Google Scholar] [CrossRef]

68. Le Duigou, A., Barbé, A., Guillou, E., Castro, M. (2019). 3D printing of continuous flax fibre reinforced biocomposites for structural applications. Materials and Design, 180, 107884. DOI 10.1016/j.matdes.2019.107884. [Google Scholar] [CrossRef]

69. Arias, A., Sojoudiasli, H., Heuzey, M. C., Huneault, M. A., Wood-Adams, P. (2017). Rheological study of crystallization behavior of polylactide and its flax fiber composites. Journal of Polymer Research, 24(3), 1–10. DOI 10.1007/s10965-017-1210-y. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |