Open Access

Open Access

ARTICLE

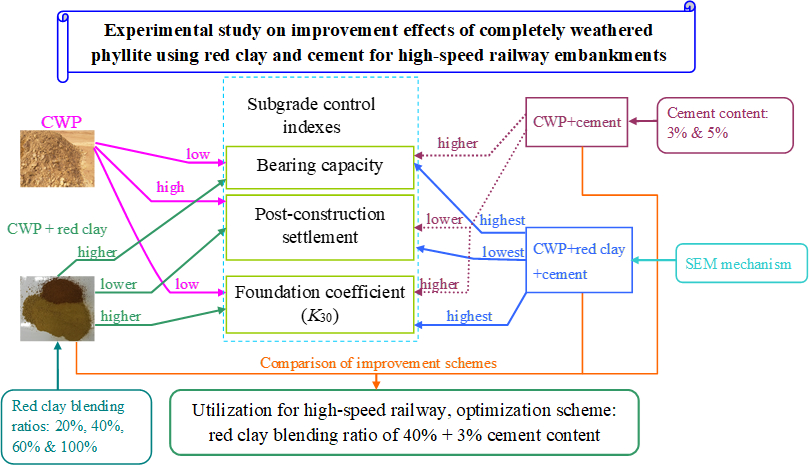

Experimental Study on Improvement Effects of Completely Weathered Phyllite Using Red Clay and Cement for High-Speed Railway Embankments

1 Engineering Research & Development Centre for Underground Technology of Jiangxi Province, East China Jiaotong University, Nanchang, China

2 Arcadis Australia Pacific Pty Ltd., Sydney, Australia

3 School of Qilu Transportation, Shandong University, Jinan, China

* Corresponding Author: Qijing Yang. Email:

(This article belongs to the Special Issue: Renewable Material from Agricultural Waste and By-Product and Its Applications)

Journal of Renewable Materials 2022, 10(5), 1287-1305. https://doi.org/10.32604/jrm.2022.017473

Received 12 May 2021; Accepted 21 June 2021; Issue published 22 December 2021

Abstract

Completely weathered phyllite (CWP) has the characteristics of difficult compaction, low shear strength after compaction and large settlement after construction. The traditional improvement method using a single agent of red clay or cement for CWP satisfies the subgrade requirements for ordinary railway, but cannot meet the requirements of immediate strength and long-term post-construction settlement of high-speed railway at the same time. A series of experimental investigations were undertaken for the blended CWP soils, with three additives used. The first additive was red clay, the second was cement and the third was a combination of both red clay and cement at various portions. Results of consolidation test and shear strength test carried out for the treated CWP soils show that: 1) The effect of cement on improving the compression modulus of CWP is much better than that of red clay; 2) The settlement of an embankment of 10 m high formed by blended soil of CWP with 3% cement can be controlled within 15 mm, while the settlement will be 25.15 mm for the same embankment of blended soil of CWP with 40% red clay; 3) The shear strength and ultimate bearing capacity of CWP improved by red clay are much better than those of 5% cement; 4) The ultimate bearing capacity of CWP improved by 40% red clay is 3.42 times of that by 3% cement and 2.95 times by 5% cement. Furthermore, the bearing capacity of CWP when improved by red clay can meet railway subgrade requirements immediately after compaction, while cement improved CWP needs a curing time of 1 day or longer. This is an impediment to rapid construction process. The improvement mechanism of red clay is mainly filling effect and grading improvement effect, while the improvement mechanism of cement is mainly hardening reaction, which produces high strength material to cement. It is found that 40% red clay and 3% cement treated CWP, which is considered to be optimum, can meet the subgrade requirements of both immediate bearing capacity and long-term post-construction settlement for the high-speed railway.Graphic Abstract

Keywords

Cite This Article

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools