Open Access

Open Access

ARTICLE

Drag Reduction Characteristics of Microstructure Inspired by the Cross Section of Barchan Dunes under High Speed Flow Condition

College of Materials Science and Technology, Nanjing University of Aeronautics and Astronautics, Nanjing, 210016, China

* Corresponding Authors: Yizhou Shen. Email: ; Jie Tao. Email:

(This article belongs to the Special Issue: Computational Tools for Renewable Materials)

Journal of Renewable Materials 2022, 10(3), 781-797. https://doi.org/10.32604/jrm.2022.017230

Received 23 April 2021; Accepted 07 July 2021; Issue published 28 September 2021

Abstract

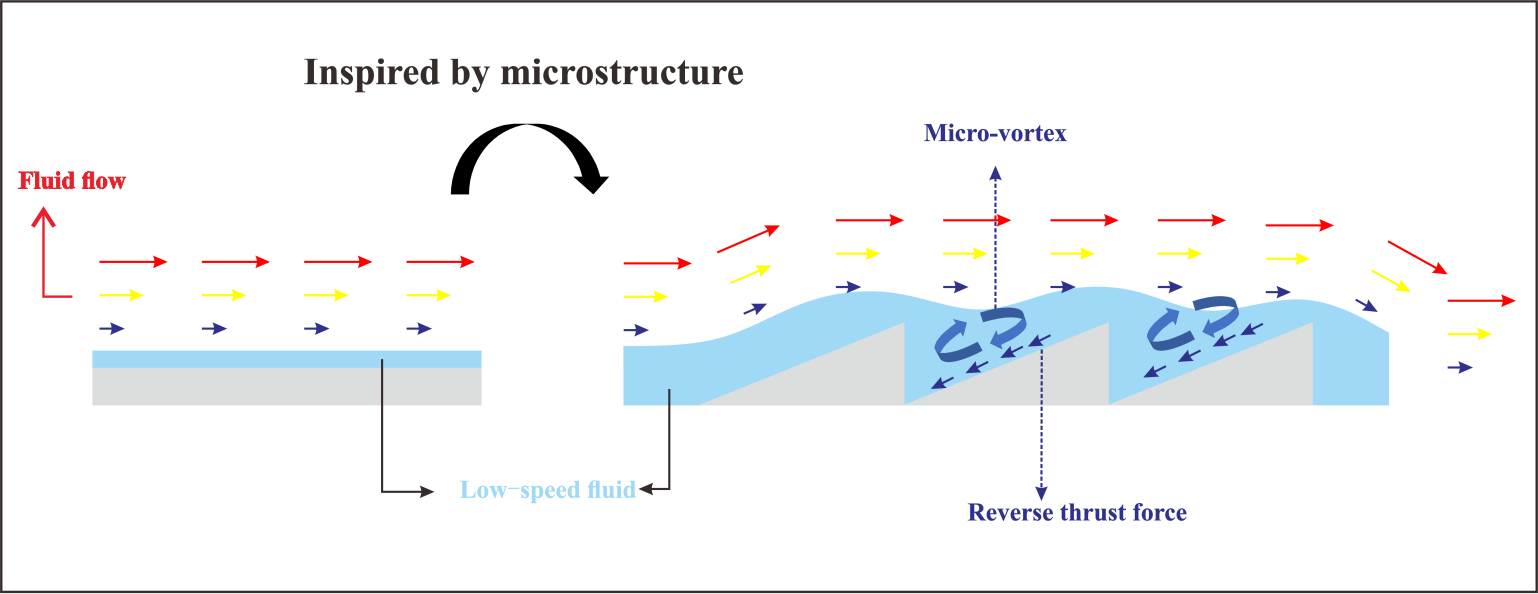

A new type of microstructure inspired by the cross section of barchan dunes was proposed to reduce windage, which was considered as a passive drag reduction technology in aerospace manufacturing field. Computational fluid dynamics method was carried out to discuss the effect of the microstructure on the skin friction reduction under high velocity flow condition. Different microstructure heights were employed to survey the reduction of drag. The results illustrated that the appearance of microstructure led to a generation of pressure drag in non-smooth model (with microstructures inspired by cross section of barchan dune) in contrast to smooth model. However, the microstructure significantly increased the thickness of the low-speed fluid by 11.4% in the near-wall flow field, causing the low-speed fluid to rise and decreasing the velocity gradient near the wall, thereby reducing viscous resistance. In addition, high-speed fluid flowed above the microstructure units instead of along the inner side of the units due to the influence of micro-vortex, resulting in a reduction of friction near the surface. Furthermore, micro-vortex was considered to be the significant internal factor to achieve turbulent drag reduction since it could not only reduce the viscous resistance by promoting the fluid flow above the microstructure but also provide a reverse thrust force. The understanding of the mechanism of drag reduction provides theoretical guidance for further fabrication of drag reduction coatings using renewable materials.Graphic Abstract

Keywords

Cite This Article

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools