Open Access

Open Access

ARTICLE

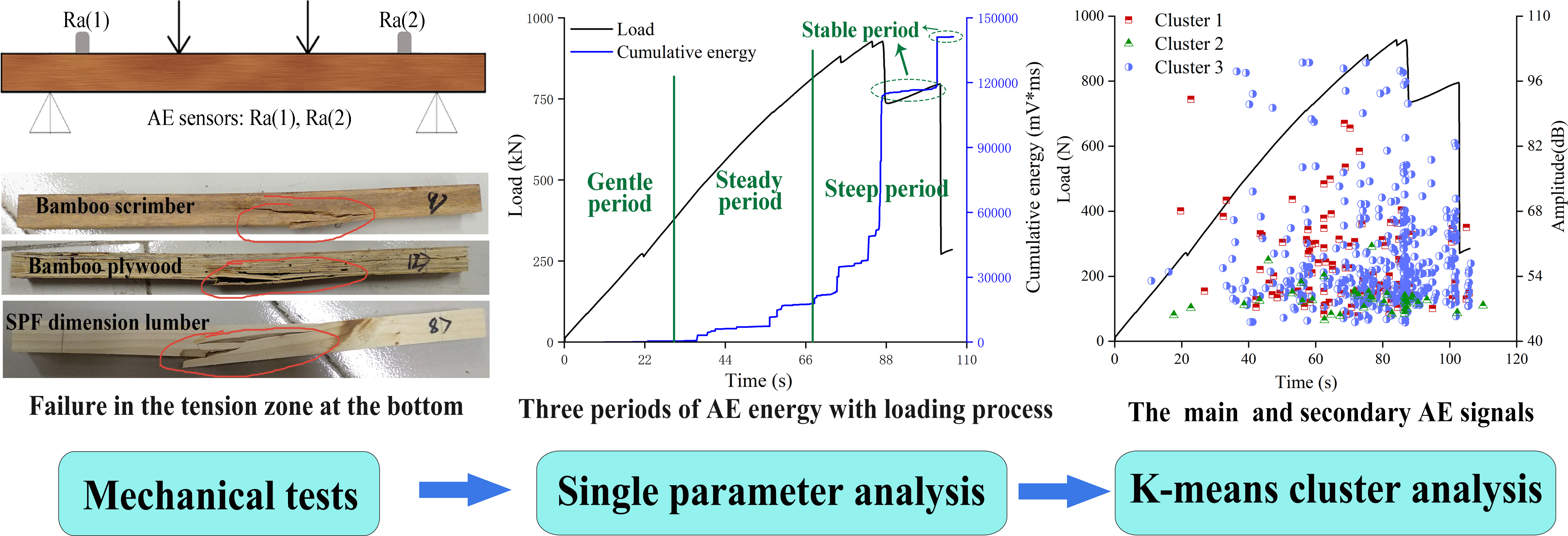

Acoustic Emission Characteristics of Different Bamboo and Wood Materials in Bending Failure Process

1 College of Materials Science and Engineering, Nanjing Forestry University, Nanjing, China

2 School of Engineering, University of Northern British Columbia, Prince George, Canada

* Corresponding Authors: Zhiqiang Wang. Email: ; Jianhui Zhou. Email:

(This article belongs to the Special Issue: Bio-Composite Materials and Structures-2021)

Journal of Renewable Materials 2022, 10(2), 527-540. https://doi.org/10.32604/jrm.2022.017955

Received 19 June 2021; Accepted 03 August 2021; Issue published 30 August 2021

Abstract

The acoustic emission (AE) technique can perform non-destructive monitoring of the internal damage development of bamboo and wood materials. In this experiment, the mechanical properties of different bamboo and wood (bamboo scrimber, bamboo plywood and SPF (Spruce-pine-fir) dimension lumber) during four-point loading tests were compared. The AE activities caused by loadings were investigated through the single parameter analysis and K-means cluster analysis. Results showed that the bending strength of bamboo scrimber was 3.6 times that of bamboo plywood and 2.7 times that of SPF dimension lumber, respectively. Due to the high strength and toughness of bamboo, the AE signals of the two bamboo products were more abundant than those of SPF dimension lumber. However, the AE evolution trend of the three materials was similar, which all experienced three stages, including gentle period, steady period and steep period, and the area of rupture precursor characteristics could be recognized before the specimen destroyed. Due to the bottom layer was first tensile failure, the main structure of bamboo plywood was destroyed after the stress redistribution. The rupture precursor characteristics could be observed before each peak. Findings put in evidence a good correlation between AE clusters of two bamboo products, while the amplitude and energy of wood signals were lower than those of bamboo. The amplitude and energy from the propagation and aggregation of cracks were greater than those related to micro-cracks initiation.Graphic Abstract

Keywords

Cite This Article

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools