Open Access

Open Access

ARTICLE

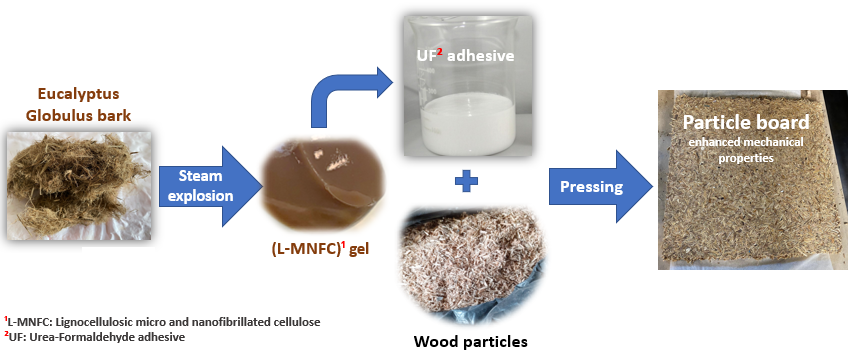

Lignocellulosic Micro and Nanofibrillated Cellulose Produced by Steam Explosion for Wood Adhesive Formulations

1 Laboratoire d’Etude et de Recherches sur le Matériau Bois–Green Process For Wood (LERMaB-GP4W), Faculté des Sciences et Technologies, Université de Lorraine, Vandœuvre-lès-Nancy, France

2 Laboratoire de Génie des Procédés Papetiers (LGP2), Saint Martin D’Hères, France

3 Unidad de Desarrollo Tecnológico (UDT), Universidad de Concepción, Coronel, Chile

4 Centre d’Essais TEchnique LORrain (CETELOR), Épinal, France

* Corresponding Author: Nicolas Brosse. Email:

(This article belongs to the Special Issue: Renewable and Biosourced Adhesives-2021)

Journal of Renewable Materials 2022, 10(2), 263-271. https://doi.org/10.32604/jrm.2022.017923

Received 22 June 2021; Accepted 16 July 2021; Issue published 30 August 2021

Abstract

The reinforcing impact of Lignocellulosic micro and nanofibrillated cellulose (L-MNFCs) obtained from Eucalyptus Globulus bark in Urea-Formaldehyde UF adhesive was tested. L-MNFCs were prepared by an environmentally friendly, low-cost process using a combination process involving steam explosion followed by refining and ultra-fine grinding. Obtained L-MNFCs showed a web-like morphology with some aggregates and lignin nanodroplets. They present a mixture of residual fibers and fine elements with a width varying between 5 nm to 20 μm, respectively. The effects of the addition of low amounts of L-MNFCs (1% wt.) on the properties of three different adhesives (Urea-Formaldehyde UF, Phenol-Formaldehyde PF, and Tannin-Hexamine TH) were studied by the evolution of the pH, the viscosity, and the mechanical properties. Results showed that the viscosity of PF and UF adhesives increased with the addition of L-MNFCs, unlike TH. Meanwhile, the addition led to better mechanical behavior for the three adhesives. Particleboards were then prepared using modified UF with L-MNFCs and tested. Results showed that an amount of 1% wt. of L-MNFCs was sufficient to increase the internal bonding by ≈67%, the modulus of elasticity by ≈43%, and the modulus of rupture by ≈29%.Graphic Abstract

Keywords

Cite This Article

Citations

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools