| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.016380

ARTICLE

Study on Performance Regulation and Mechanism of Quicklime and Biopolymer on Hemihydrate Phosphogypsum

1College of Civil and Resource Engineering, University of Science and Technology Beijing, Beijing, 100083, China

2Beijing Key Laboratory of Urban Underground Space Engineering, University of Science and Technology Beijing, Beijing, 100083, China

3State Key Laboratory of High-Efficient Mining and Safety of Metal Mines, Ministry of Education, University of Science and Technology Beijing, Beijing, 100083, China

*Corresponding Author: Juanhong Liu. Email: juanhong1966@hotmail.com

Received: 01 March 2021; Accepted: 19 April 2021

Abstract: In order to reduce the influence of impurities in hemihydrate phosphogypsum(HPG) on the environment and improve the workability of HPG, the effects of the content of quicklime and types of biopolymer (hydroxypropyl methylcellulose, xanthan gum, sodium polyacrylate(PAANa)) on the compressive strength, softening coefficient and ultrasonic velocity of HPG were evaluated. When the content of quicklime was 1.5% and the content of PAANa was 0.2%, HPG had the best mechanical properties and workability, its water retention rate can be increased by 5.8%, and unconfined compressive strength of 3 days increased by 10.3% and 7 days increased by 13.1%. Through the analysis of scanning electron microscope and X-ray diffraction, it was found that the hydration reaction of HPG was more sufficient, the pores size and number decreased, the number of impurities on the crystal surface decreased obviously, and CaF2 and other substances were formed by the reaction after the addition of quicklime. After adding quicklime and PAANa, the indicators of gypsum self-leveling mortar prepared by HPG meet the requirements of the standard.

Keywords: Hemihydrate phosphogypsum; quicklime; biopolymer; mechanical properties; workability; gypsum self-leveling mortar

Phosphogypsum(PG) is a solid waste produced during the production of phosphoric acid and phosphate fertilizer from phosphate rock [1,2]. Making 1 ton of phosphoric acid will produce about 5 tons of PG, and the annual output of PG in the world is about 100 Mt–280 Mt [3,4]. At present, the total utilization rate of PG worldwide is less than 15% [5,6]. The primary treatment of PG is storage and dumping, which occupies many lands, pollutes the environment, and has excellent hidden dangers of safety [7]. The leaching of harmful elements such as soluble phosphorus, fluorine and heavy metal ions in PG can easily cause severe soil and water pollution and endanger human health [8,9]. Therefore, the treatment of PG has become the key to the sustainable development and green development of phosphoric acid industry.

In order to improve the utilization rate of PG, researchers have developed different application approaches. Li et al. studied the effects of the type and content of gypsum on workability and mechanical properties of red mud-slag grouting materials. PG can improve the homogeneity and the denseness of the paste matrix of the red mud-slag grout, and with the increase of PG content, the compressive strength increases at first and then decreases [10]. Huang et al. studied a cementitious material with PG, steel slag, ground granulated blast-furnace slag and limestone, which 28 days compressive strength exceed 40 MPa. The hydration products of this new cementitious material are mainly ettringite and CSH gel [11]. Chen et al. prepared backfill materials for mining using PG, phosphate tailings, lime, slag powder and cement. The 28 days strength of the backfill materials can reach 4.4 MPa [12]. Because PG has low thermal conductivity, it can be used to produce fireproof and thermal insulation materials or aerated concrete [13]. New subgrade materials can also be prepared by using PG and adding a certain amount of slag and cement to increase the added value of PG [14]. The mechanical properties of PG are improved mainly by adding slag and cement to prepare cementitious materials and backfilling materials. There are few studies on the preparation of gypsum self-leveling mortar with PG.

Phosphoric acid is mainly produced by semi-aqueous wet process because of its low energy consumption and high concentration of phosphoric acid [15]. Semi-aqueous wet process produces a large amount of hemihydrate phosphogypsum(HPG), so the output of HPG is getting higher and higher. HPG contains harmful impurities such as phosphate, fluoride salt, trace elements and organic matter [16]. These impurities will deposit on the crystal surface, affect the crystal lap, affect the hydration process of gypsum, and lead to low mechanical strength of gypsum after hardening. Jiang and Chen found that quicklime can reduce the number of bubbles formed by HPG and improve cementation performance. HPG can be used to prepare backfill materials [17,18]. Quicklime can not only adjust the pH value, but also convert soluble impurities into insoluble precipitates and eliminate the adverse effects of impurities on the hydration process [19]. Wu et al. studied the effects of different polycarboxylates on the water absorption and strength of gypsum. The synthesized polycarboxylate can capture Ca2+, and delay the hydration reaction. At the same time, it has high hydrophilicity and can improve mechanical strength [20]. Most of the current research on gypsum is the sole effect of quicklime or polymer on gypsum. There are few studies on the coupling of quicklime and biopolymer to compressive strength and workability of HPG.

The presence of phosphate (P2O5) and fluoride (F−) impurities in HPG affects the use of HPG. In order to apply HPG to the field of building materials, its harmful impurities should be purified, the mechanical properties and workability improved. The effects of quicklime content on unconfined compressive strength (UCS) and absolute dry compressive strength (DCS), compactness and softening coefficient were studied. SEM and XRD were used to analyze the microscopic crystal morphology and hydration product composition. The optimum ratio of quicklime and biopolymer to improve the performance of HPG was determined by studying the quicklime content and the coupling effect of different biopolymer. Gypsum self-leveling mortar was prepared by HPG after adding quicklime and biopolymer, and under the action of water reducer and retarder. This article provides theoretical reference and engineering guidance for the application of HPG in subgrade materials, backfill materials and preparation of new cementitious materials.

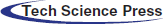

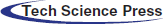

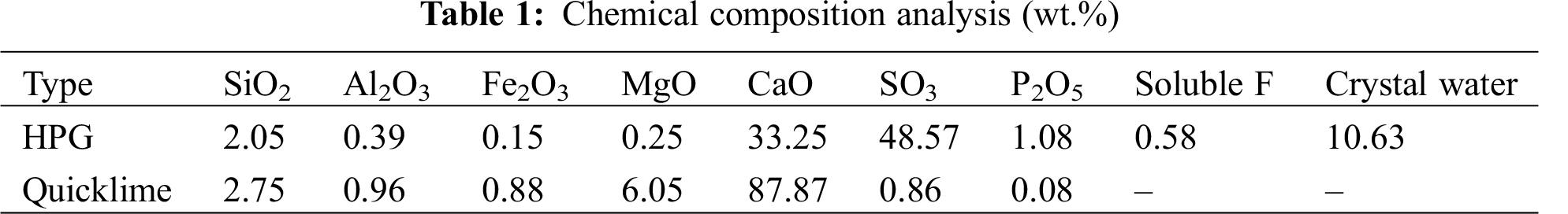

The test raw materials used in this paper were HPG, quicklime, three kinds of biopolymer (hydroxypropyl methylcellulose(HPMC), relative molecular weight is 100000, xanthan gum(XG), relative molecular weight is 1000000, sodium polyacrylate(PAANa), relative molecular weight is 100000), polycarboxylic acid water reducing agent powder and protein retarder. The schematic diagram of the molecular structure of different biopolymer was shown in Fig. 1. HPG was a solid waste from the preparation of phosphoric acid from phosphoite ore. HPG was taken from a phosphogypsum production workshop in Guizhou, China, and its appearance was gray, mineral composition analysis as shown in Fig. 2. The internal exposure index and external exposure index of HPG meet the requirements of the standard (GB 6566-2010). The chemical composition was analyzed by X-ray fluorescence (XRF-1800, Shimadzu, Japan), presented in Tab. 1. It can be seen from the analysis results that the main component of HPG was CaSO4 · 1/2H2O, containing a small amount of CaSO4 · 2H2O and soluble P and F. Its pH was 3.5 due to the presence of soluble P2O5 and soluble fluoride. Quicklime was purchased from the market. The chemical composition analysis was shown in the Tab. 1. HPMC, XG, PAANa, polycarboxylic acid water reducing agent powder and protein retarder came from Shandong Huadi Construction Technology Co., Ltd., China.

Figure 1: Schematic diagram of molecular structure of different biopolymer (a) HPMC (b) XG (c) PAANa

Figure 2: Mineral composition analysis

2.2.1 Determination of Compressive Strength

Load the uniformly mixed slurry into the standard mold test (70.7 mm · 70.7 mm · 70.7 mm). The test block was placed at room temperature (20°C ± 2°C) for 24 h to remove the mold, and placed in the standard curing box (set temperature of 20°C, relative humidity of 90%), and cured to the specified age for UCS test. The compressive strength was determined by using a universal testing machine (WDW-50) according to the standard test method in GB/T 17669.3-1999. The test piece for determining the absolute dry compressive strength should be baked to a constant weight in an oven at 40°C ± 4°C, and then the strength should be measured. Because the compressive strength of HPG increases slowly after 7 days, this experiment only measured the compressive strength of 3 days and 7 days.

2.2.2 Determination of Compactness

The compactness of HPG was determined by ultrasonic detection (Concord non-metallic ultrasonic detector). The forming surface of the test block and its opposite face were selected as the test surface, and each test surface was divided into 9 regions, and each area was tested by ultrasonic. The average value of the ultrasonic result was taken as the compactness test result. The softening coefficient of HPG was the ratio of compressive strength to absolute dry compressive strength after water absorption saturation.

2.2.3 Water Retention Rate and Evaluation of Gypsum Self-Leveling Mortar

The water retention rate was determined by French filter paper method. The smaller the water absorption of the filter paper was, the better the water retention of the pulp was. Test methods of pH value and gypsum self-leveling mortar index refer to T/CBMF82-2020 standard.

2.2.4 Analysis of Crystal Morphology and Hydration Products

After gold spraying, the surface morphology of the samples was observed by environmental scanning electron microscope (SEM, Quanta250, Hillsboro, OR, USA). The hydration products were analyzed by X-ray diffractometer (XRD, D/max-2550, physiology, Japan). The experimental conditions were 40 kV, 40 mA, Cu target, scanning speed 10 °min−1, scanning range: 10°~80°.

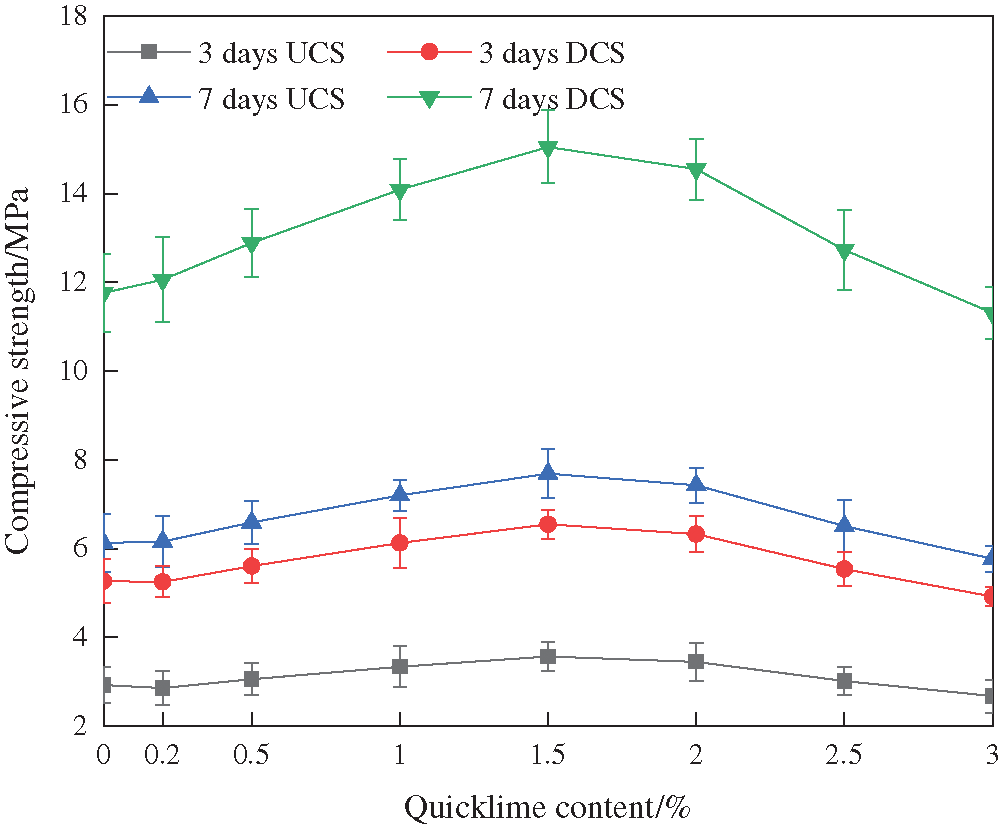

3.1 Effect of Quicklime Content on Compressive Strength of HPG

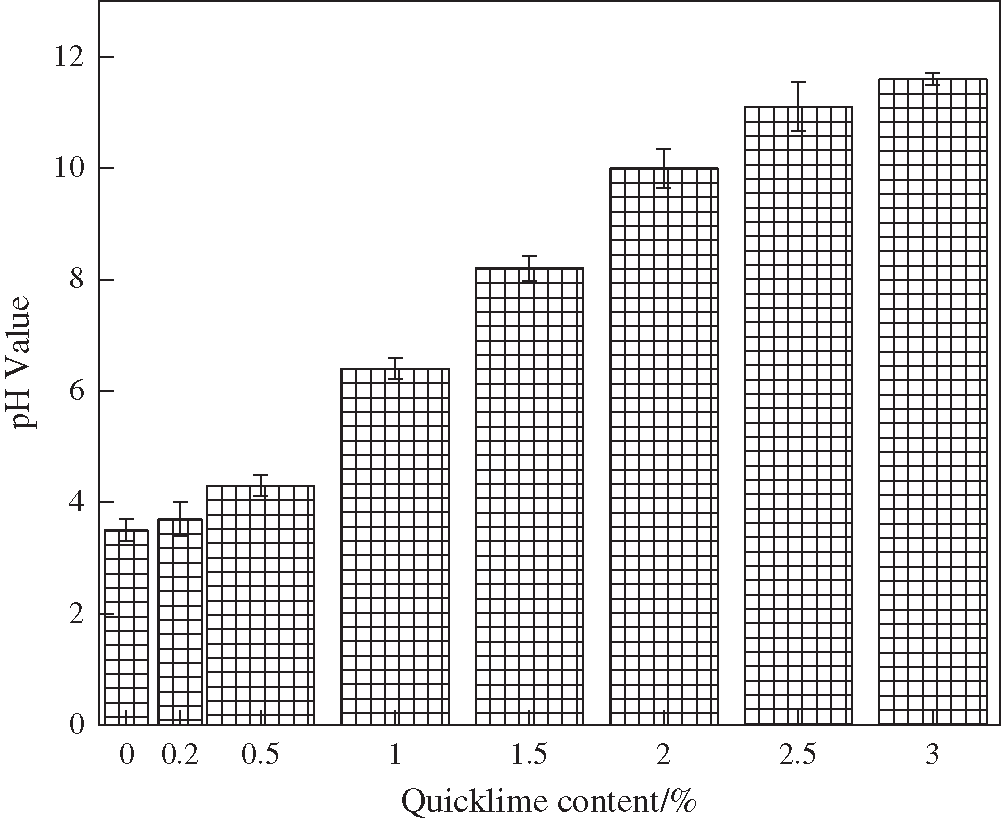

The effects of different amounts of quicklime (0.2%, 0.5%, 1%, 1.5%, 2%, 2.5%, 3%) on the unconfined compressive strength(UCS), absolute dry compressive strength (DCS) and pH value of HPG paste were studied. The test results were shown in the Fig. 3. From the test results, it can be seen that the content of quicklime had a great influence on the compressive strength of HPG. When the content of quicklime was small, it had little effect on the compressive strength. When the content of quicklime was not more than 1.5%, the compressive strength of the hardened body increased continuously with the increase of the content. When the content of quicklime was 1.5%, compared with the blank group, the UCS of 3 days increased by 21.8%, the DCS of 3 days increased by 24.3%, the UCS of 7 days increased by 25.4%, and the DCS of 7 days increased by 27.9%. The increasing proportion of DCS was obviously larger than that of UCS, and the increasing proportion of compressive strength of 7 days was also significantly higher than 3 days. When the content of quicklime was more than 1.5%, the compressive strength decreased gradually. When the content of quicklime was 3%, compared with the blank group, the UCS of 3 days decreased by 8.5%, the DCS of 3 days decreased by 6.6%, the UCS of 7 days decreased by 5.8%, and the DCS of 7 days decreased by 3.8%. The main reason was that quicklime can adjust the pH value of slurry, the result was shown in Fig. 4. Quicklime can convert phosphorus and fluorine impurities precipitate, improve the growth of gypsum crystals, fully connect the crystals, make the structure more compact, improve the micro-pore structure and increase the strength [17].

Figure 3: Effect of quicklime content on compressive strength

Figure 4: Effect of quicklime content on pH value

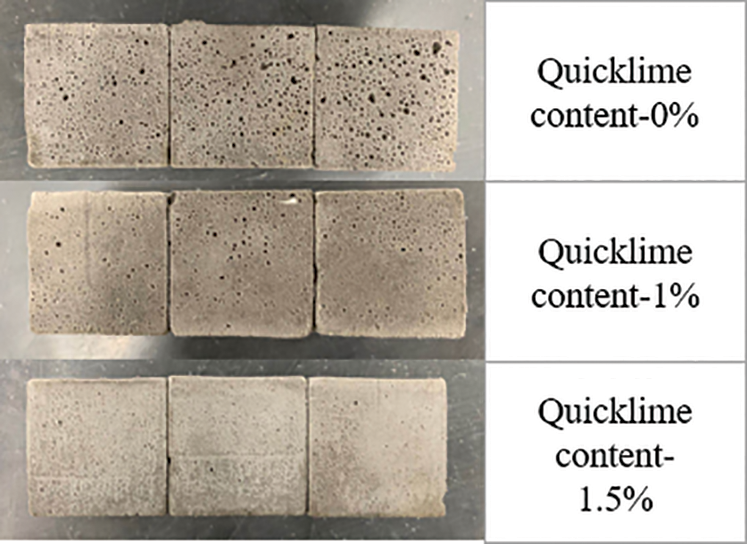

3.2 Effect of Quicklime Content on HPG Compactness

HPG contains a variety of soluble acidic substances, which can easily form hydrogen sulfide, sulfur dioxide and carbon dioxide during hydration, resulting in loose internal structure of the hardened body. The addition of quicklime can reduce the formation of these gases, reduce the porosity and improve the compactness. As shown in the Fig. 5. In order to further quantify the effect of quicklime content on the compactness of HPG, ultrasonic transmission time (UT), softening coefficient test (KR), scanning electron microscope analysis (SEM)and X-ray diffraction analysis (XRD) were carried out. The specific results were shown in Figs. 6 to 8.

Figure 5: Surface porosity diagram with different lime content

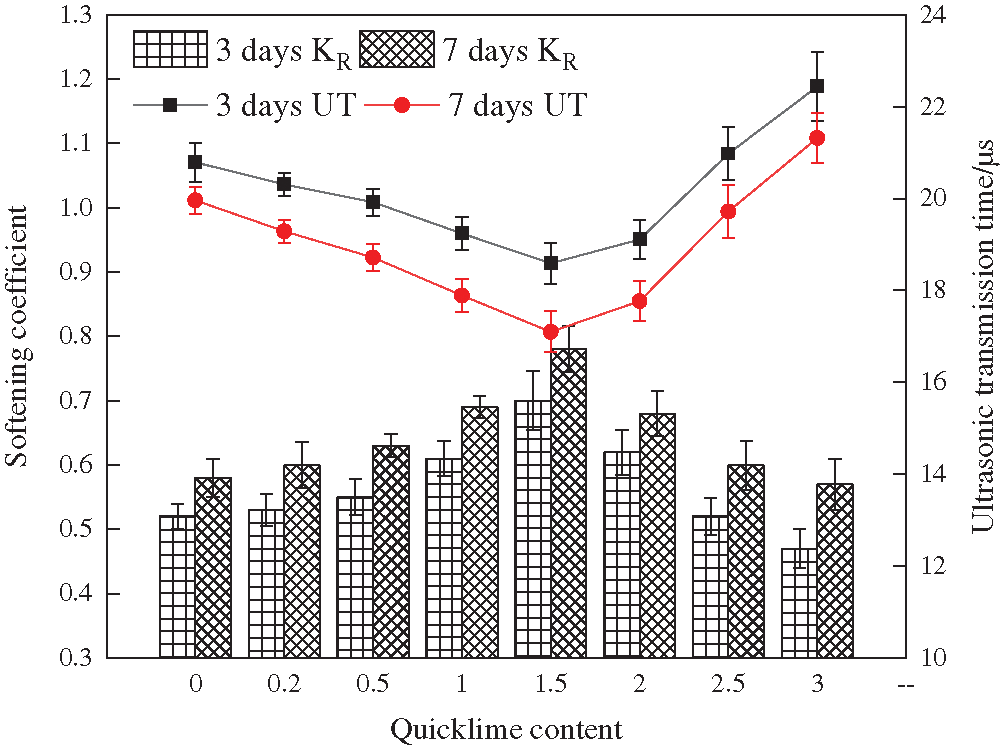

Figure 6: Effect of quicklime content on UT and KR

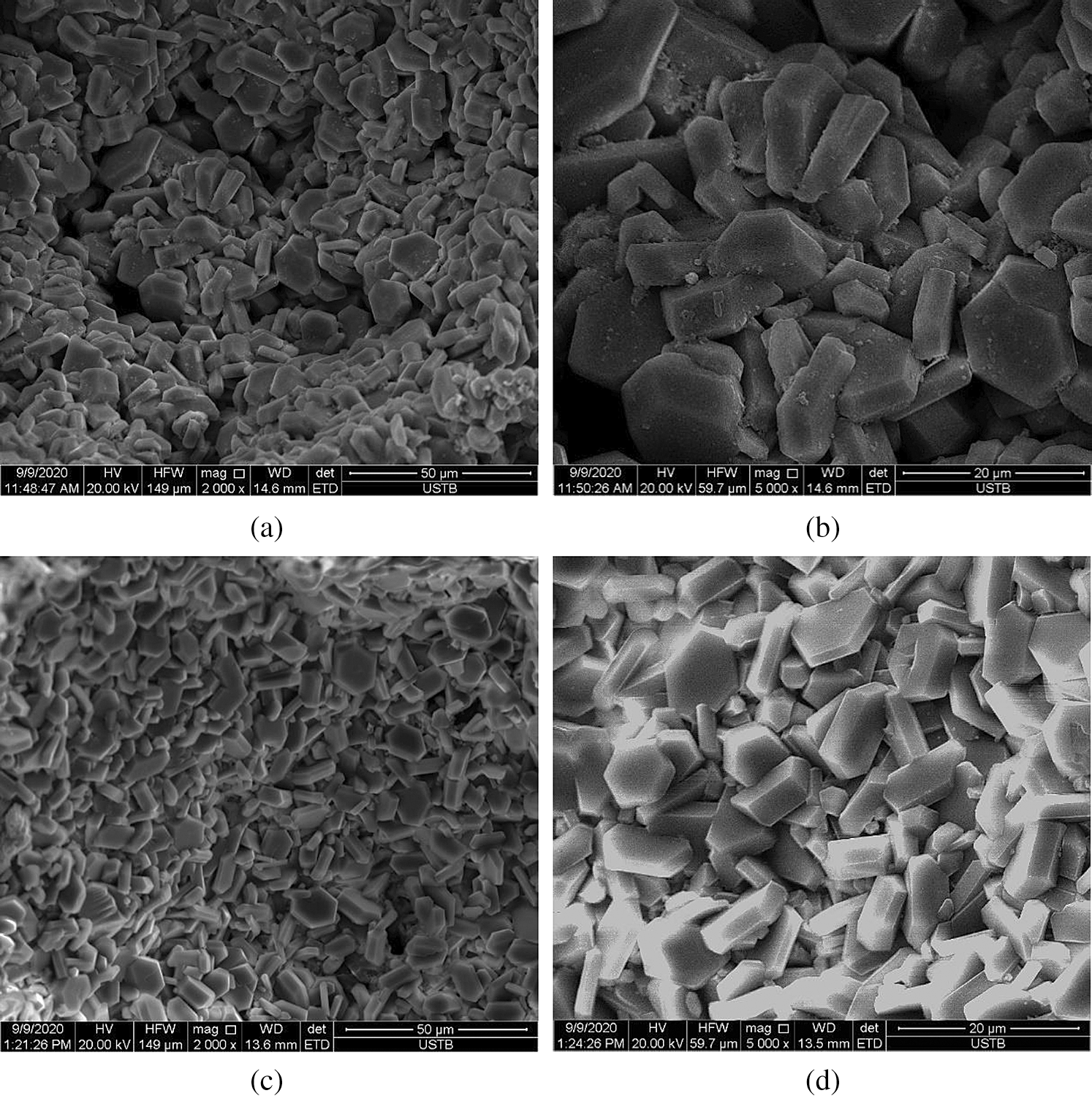

Figure 7: Effect of quicklime on micro-morphology of HPG (a) No quicklime and magnified 2000 times (b) No quicklime and magnified 5000 times (c) 1.5% quicklime and magnified 2000 times (d) 1.5% quicklime and magnified 2000 times

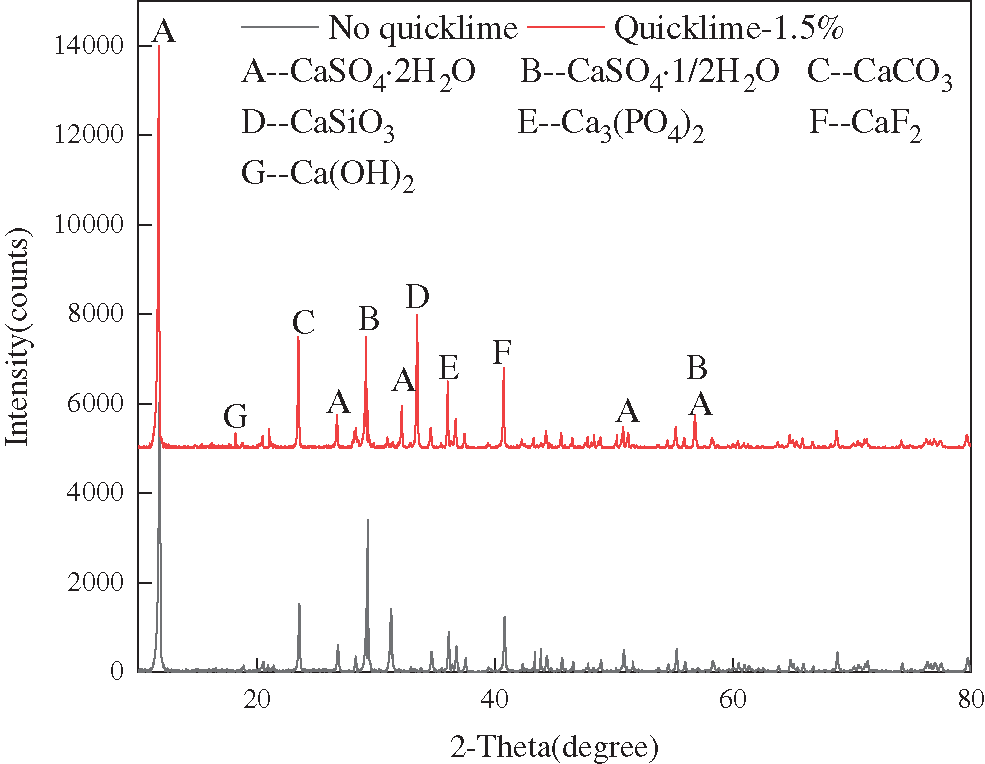

Figure 8: Effect of quicklime on hydration products of HPG

It can be seen from the results of Fig. 6 that the content of quicklime had a great influence on both UT and KR. With the increase of quicklime content, the ultrasonic transmission speed decreased at first and then increased. If there are pores and other defects in the material, when the ultrasonic wave propagates to the defect interface, it is easy to partially reflect or refract, which affects the propagation speed of the ultrasonic wave. When the quicklime content was 1.5%, the ultrasonic transmission speed was the fastest, indicating that the internal defects of the material were the least and the structure was the densest. Compared with the blank group, the ultrasonic propagation speed can be reduced by 10.6%. When the content of quicklime was less than 1.5%, the KR of HPG increased gradually. This is mainly due to the gradual decrease of the porosity of the hardened body and the improvement of water resistance. At the same time, quicklime reacts with carbonate ions in the paste to form calcium carbonate film, which reduces the solubility of CaSO4, which can effectively prevent the erosion of water on the hardened body of HPG. When the content of quicklime was more than 1.5%, KR decreased continuously. On the one hand, the internal pore size of HPG hardened body increases, which leads to the obvious deterioration of its water resistance; on the other hand, excessive quicklime can easily lead to poor volume stability of HPG hardening body.

Considering the results of HPG compressive strength and compactness test, the optimal content of quicklime was determined to be 1.5%. The micro-crystal morphology of HPG before and after adding quicklime was analyzed by scanning electron microscope (SEM). The experimental results were as shown in the Fig. 7. From the results of the analysis, it can be found that the crystal morphology of HPG without quicklime was mainly short rod-like, a small amount in plate-like form; the overlap between crystals was not close, and there were many gaps; in addition, there were a large number of impurities of small particles on the surface of gypsum crystal. It can be seen from Fig. 7c that gypsum crystals were closely overlapped and the gap between crystals was not obvious, which indicates that quicklime promoted the development of gypsum crystals and reacted with free acid ions in HPG paste and solidifies, thus filling the gap between crystals and forming a dense microstructure. In addition, the small particle impurities on the surface of gypsum crystal were obviously reduced, and there were flaky calcium hydroxide crystals around the gypsum crystal, which showed that quicklime can remove impurities and adjust the pH of paste to make HPG have better performance in alkaline environment.

As can be seen from Fig. 8, CaSO4 · 2H2O, CaSiO3, CaCO3, Ca(OH)2, CaF2 and Ca3(PO4)2 were formed after hydration of HPG. Compared with mineral composition analysis in Fig. 2, the hydration reaction newly formed Ca(OH)2, CaF2 and Ca3(PO4)2. Without quicklime, the diffraction peak intensity of CaSO4 · 1/2H2O was larger, which indicated that the hardened body contains a certain amount of unhydrated HPG. With the addition of quicklime, the diffraction peak intensity of CaSO4 · 1/2H2O decreased, the diffraction peak intensity of CaSO4 · 2H2O and Ca(OH)2 increased obviously, and the diffraction peak intensity of CaCO3, CaF2 and Ca3(PO4)2 increased to a certain extent, which shows that quicklime can remove free phosphorus and fluorine impurities, and promote the conversion of a certain amount of CaSO4 · 1/2H2O into CaSO4 · 2H2O. CaSO4 · 2H2O and Ca(OH)2 overlap each other to improve the compactness and the compressive strength of hardened body.

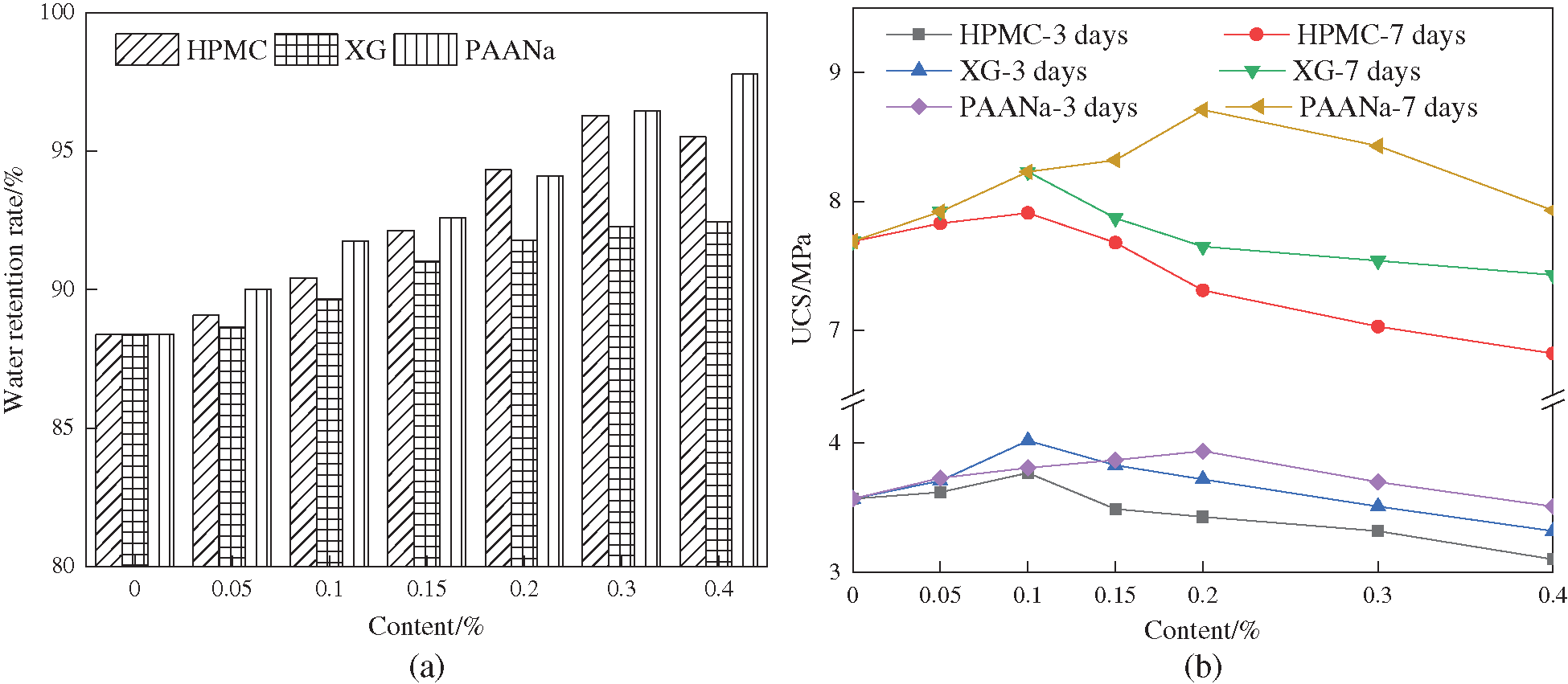

3.3 Synergistic Improvement Effect of Quicklime and Biopolymers on HPG

Because of its coarse particles, HPG has poor water retention and impermeability, and it is easy to bleeding in the process of application. In order to overcome these performance defects and make HPG meet the specifications of general gypsum products and promote its application, HPMC, XG and PAANa were used to study the modification of HPG. On the basis of 1.5% quicklime, the effects of the type and content of biopolymers on the water retention and compressive strength of HPG were studied. The test results were shown in Fig. 9. From the test results, it can be found that with the increase of biopolymer content, the water retention performance of HPG continues to improve. The water retention performance of HPMC and PAANa was obviously better than that of XG. The main reason is that the hydroxyl and ether bonds in the molecular structure form hydrogen bonds with the free water in the paste, which plays the role of curing, preventing the loss of water molecules and improving the performance of water retention. The alkyl group in HPMC can reduce the surface tension of water and has the function of gas entrainment. Bubbles will increase the porosity of HPG, lead to loose internal structure, and affect the mechanical properties of HPG. Therefore, when the content of HPMC was higher than 0.1%, the UCS decreased continuously. The molecular structure of PAANa contains a large number of carboxyl groups, which can be adsorbed on the surface of HPG particles, resulting in electrostatic repulsion, preventing particle agglomeration and improving uniformity [21,22]. The effect of PAANa on the strength of HPG was less than that of HPMC. When the content of PAANa was 0.2%, the UCS reached the maximum. Compared with the blank group, UCS of 3 days can increased by 10.3% and 7 days can increased by 13.1%, while water retention increased by 5.7%. In order to improve the workability of HPG and reduce the impact of HPG on the environment, it is recommended that the content of quicklime is 1.5% and the content of gravity PAANa is 0.2%.

Figure 9: Test results of coupling of biopolymers and lime (a) Effect of biopolymers on water retention (b) Effect of biopolymers on UCS

In order to implement the relevant policies of energy saving and emission reduction in the construction industry and improve the added value of HPG, combined with the research results of quicklime and PAANa, a new type of gypsum self-leveling floor material was prepared by using HPG. The material is used for the construction of ground leveling layer, ground heating backfilling and floor bottom leveling layer material. The research and development of gypsum self-leveling materials is in line with the concept of green development, and can realize the reuse of industrial waste, and has high economic value and environmental protection value.

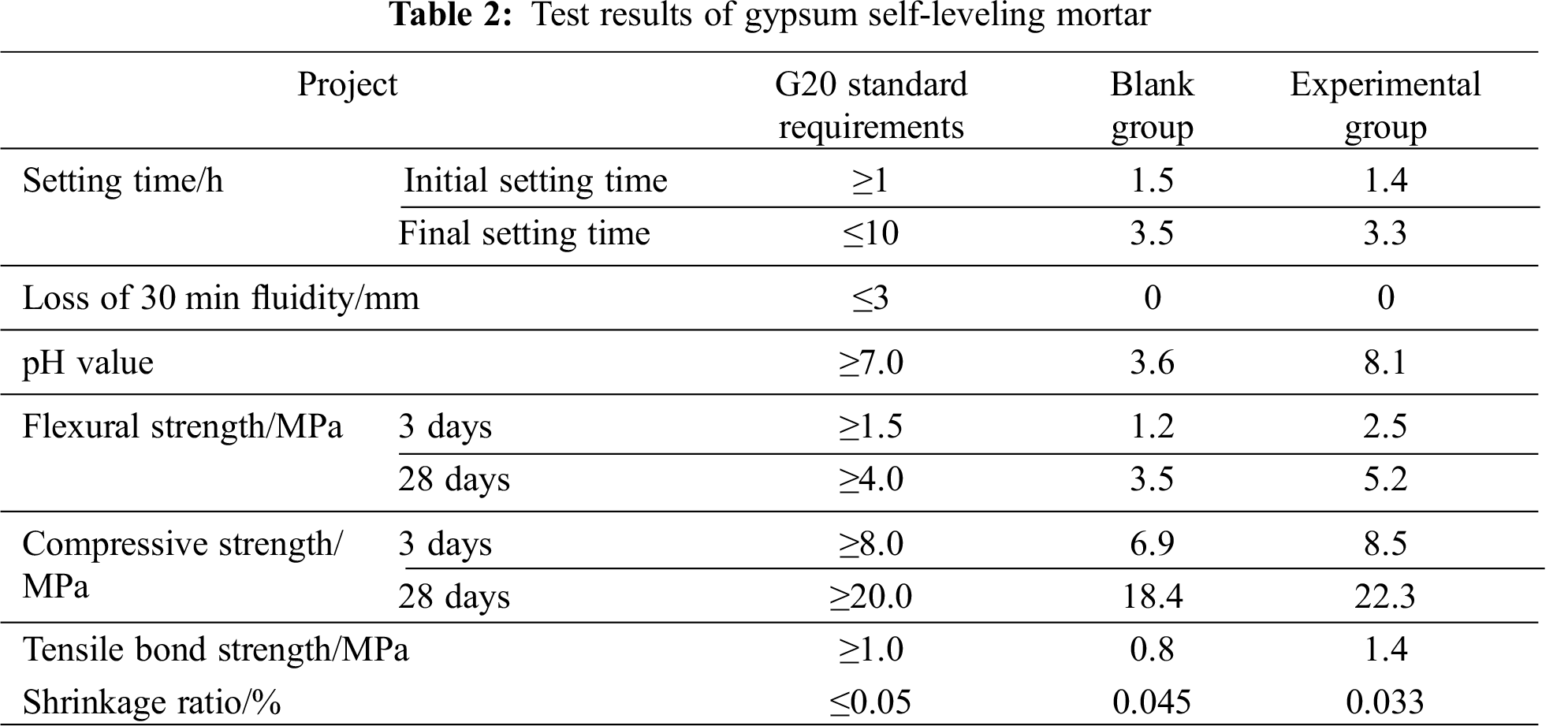

In order to meet the requirements of T/CBMF82-2020 standard, 0.3% polycarboxylate superplasticizer powder and 0.45% protein retarder were added to HPG, and this group was set as a blank group. To verify the effect of quicklime and PAANa, 1.5% quicklime and 0.2% PAANa were added to the blank group, and this group was set as the test group. The indexes of gypsum self-leveling mortar were tested, and the test results were shown in Tab. 2. It can be seen from the test results that the setting time and fluidity loss completely meet the standard requirements after adding water reducer and retarder into HPG, but the strength and pH value were small. With the addition of quicklime and PAANa, the pH value increased by 4.5, the flexural strength at 3 days and 28 days increased by 108% and 48.5%, respectively, the compressive strength at 3 days and 28 days increased by 23.2% and 21.2%, respectively, the tensile bond strength increased by 75%, and the shrinkage rate also improved. After adding quicklime and polymer, all indexes fully meet the standard requirements. HPG can be used to produce gypsum self-leveling mortar.

The experiment separately evaluated influence of quicklime content (0.2%, 0.5%, 1%, 1.5%, 2%, 2.5%, 3%), biopolymers type (HPMC, XG and PAANa), biopolymers content (0.05%, 0.1%, 0.15%, 0.2%, 0.3%, 0.4%) on the pH value, UCS, DCS, UT, KR, water retention rate and microcosmic structure of the HPG. The following conclusions can be drawn.

With the increase of the content of quicklime, the UCS, DCS, KR of HPG increased at first and then decreased, pH value increased continuously, and UT decreased at first and then increased. When the content of quicklime is 1.5%, the mechanical properties and compactness of HPG are the best. With the addition of quicklime, the CaSO4 · 1/2H2O diffraction peak decreases, the CaSO4 · 2H2O diffraction peak increases, the HPG reaction is more sufficient, and the impurities on the surface of gypsum crystal are obviously reduced, resulting in CaF2, Ca3(PO4)2 and other substances. After the addition of quicklime, the number of bubbles on the surface of the test piece is reduced, the crystals become closer and the density increases. Compared with the blank group, the ultrasonic propagation speed can be reduced by 10.6%, the DCS of 3 days increased by 24.3% and the DCS of 7 days increased by 27.9%.

The water retention properties of HPMC and PAANa are better, and the effect of PAANa on the strength of HPG is less than that of HPMC. When the content of PAANa is 0.2%, the UCS reached the maximum, and the UCS of 3 days and 7 days increased by 10.3% and 13.1%, respectively. When the content of quicklime is 1.5% and the content of PAANa is 0.2%, the gypsum self-leveling mortar prepared by HPG meets the requirements of the standard. The composite research of quicklime and polymer can provide technical guarantee for the application of HPG in the fields of roadbed materials and backfill materials.

Acknowledgement: We are grateful to University of Science and Technology Beijing for providing us with the experimental platform and all the re-viewers for their specific comments and suggestions.

Funding Statement: This study was financially supported by National Natural Science Foundation of China (Grant No. 51834001) and Fundamental Research Funds for the Central University (Grant No. FRF-BD-20-01B).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Gijbels, K., Landsberger, S., Samyn, P., Iacobescu, R. I., Pontikes, Y. et al. (2019). Radiological and non-radiological leaching assessment of alkali-activated materials containing ground granulated blast furnace slag and phosphogypsum. Science of the Total Environment, 660, 1098–1107. DOI 10.1016/j.scitotenv.2019.01.089. [Google Scholar] [CrossRef]

2. Amrani, M., Taha, Y., Kchikach, A., Benzaazoua, M., Hakkou, R. (2020). Phosphogypsum recycling: New horizons for a more sustainable road material application. Journal of Building Engineering, 30, 101267. DOI 10.1016/j.jobe.2020.101267. [Google Scholar] [CrossRef]

3. Tayibi, H., Choura, M., López, F. A., Alguacil, F. J., López-Delgado, A. (2009). Environmental impact and management of phosphogypsum. Journal of Environmental Management, 90(8), 2377–2386. DOI 10.1016/j.jenvman.2009.03.007. [Google Scholar] [CrossRef]

4. Jiang, G., Wu, A., Wang, Y., Li, J. (2019). The rheological behavior of paste prepared from hemihydrate phosphogypsum and tailing. Construction and Building Materials, 229, 116870. DOI 10.1016/j.conbuildmat.2019.116870. [Google Scholar] [CrossRef]

5. Fornés, V., Vaičiukynienė, I., Nizevičienė, D., Doroševas, D., Dvořák, V. K. (2021). A method to prepare a high-strength building material from press-formed phosphogypsum purified with waste zeolite. Journal of Building Engineering, 34, 101919. DOI 10.1016/j.jobe.2020.101919. [Google Scholar] [CrossRef]

6. Zeng, L., Bian, X., Zhao, L., Wang, Y., Hong, Z. (2021). Effect of phosphogypsum on physiochemical and mechanical behaviour of cement stabilized dredged soil from fuzhou, China. Geomechanics for Energy and the Environment, 25, 100195. DOI 10.1016/j.gete.2020.100195. [Google Scholar] [CrossRef]

7. Wei, J., Gu, Y., Lv, H., Wu, X. (2021). A zero-emission method for recycling phosphogypsum using Na2SO4 electrolysis: Preliminary study. Separation and Purification Technology, 259, 118168. DOI 10.1016/j.seppur.2020.118168. [Google Scholar] [CrossRef]

8. Gijbels, K., Nguyen, H., Kinnunen, P., Samyn, P., Schroeyers, W. et al. (2020). Radiological and leaching assessment of an ettringite-based mortar from ladle slag and phosphogypsum. Cement and Concrete Research, 128, 105954. DOI 10.1016/j.cemconres.2019.105954. [Google Scholar] [CrossRef]

9. Millan-Becerro, R., Perez-Lopez, R., Macias, F., Canovas, C. R. (2020). Design and optimization of sustainable passive treatment systems for phosphogypsum leachates in an orphan disposal site. Journal of Environmental Management, 275, 111251. DOI 10.1016/j.jenvman.2020.111251. [Google Scholar] [CrossRef]

10. Li, Z., Zhang, J., Li, S., Gao, Y., Liu, C. et al. (2020). Effect of different gypsums on the workability and mechanical properties of red mud-slag based grouting materials. Journal of Cleaner Production, 245, 118759. DOI 10.1016/j.jclepro.2019.118759. [Google Scholar] [CrossRef]

11. Huang, Y., Lin, Z. (2010). Investigation on phosphogypsum–steel slag–granulated blast-furnace slag–limestone cement. Construction and Building Materials, 24(7), 1296–1301. DOI 10.1016/j.conbuildmat.2009.12.006. [Google Scholar] [CrossRef]

12. Chen, Q., Zhang, Q., Fourie, A., Xin, C. (2017). Utilization of phosphogypsum and phosphate tailings for cemented paste backfill. Journal of Environmental Management, 201, 19–27. DOI 10.1016/j.jenvman.2017.06.027. [Google Scholar] [CrossRef]

13. Rahman, R. A., Fazlizan, A., Asim, N., Thongtha, A. (2021). A review on the utilization of Waste material for autoclaved aerated concrete Production. Journal of Renewable Materials, 9(1), 61–72. DOI 10.32604/jrm.2021.013296. [Google Scholar] [CrossRef]

14. Gu, Z., Fang, A., Hua, S., Zhao, Q., Sun, L. et al. (2021). Development of a soil stabilizer for road subgrade based on original phosphogypsum. Journal of Renewable Materials, 9(2), 253–268. DOI 10.32604/jrm.2021.011912. [Google Scholar] [CrossRef]

15. Cánovas, C. R., Macías, F., Pérez-López, R., Basallote, M. D., Millán-Becerro, R. (2018). Valorization of wastes from the fertilizer industry: Current status and future trends. Journal of Cleaner Production, 174, 678–690. DOI 10.1016/j.jclepro.2017.10.293. [Google Scholar] [CrossRef]

16. Lütke, S. F., Oliveira, M. L. S., Silva, L. F. O., Cadaval, T. R. S., Dotto, G. L. (2020). Nanominerals assemblages and hazardous elements assessment in phosphogypsum from an abandoned phosphate fertilizer industry. Chemosphere, 256, 127138. DOI 10.1016/j.chemosphere.2020.127138. [Google Scholar] [CrossRef]

17. Jiang, G., Wu, A., Wang, Y., Lan, W. (2018). Low cost and high efficiency utilization of hemihydrate phosphogypsum: Used as binder to prepare filling material. Construction and Building Materials, 167, 263–270. DOI 10.1016/j.conbuildmat.2018.02.022. [Google Scholar] [CrossRef]

18. Chen, Q., Zhang, Q., Fourie, A., Xin, C. (2017). Utilization of phosphogypsum and phosphate tailings for cemented paste backfill. Journal of Environmental Management, 201, 19–27. DOI 10.1016/j.jenvman.2017.06.027. [Google Scholar] [CrossRef]

19. Chen, X., Gao, J., Liu, C., Zhao, Y. (2018). Effect of neutralization on the setting and hardening characters of hemihydrate phosphogypsum plaster. Construction and Building Materials, 190, 53–64. DOI 10.1016/j.conbuildmat.2018.09.095. [Google Scholar] [CrossRef]

20. Wu, H., Xia, Y., Hu, X., Liu, X. (2014). Improvement on mechanical strength and water absorption of gypsum modeling material with synthetic polymers. Ceramics International, 40(9), 14899–14906. DOI 10.1016/j.ceramint.2014.06.085. [Google Scholar] [CrossRef]

21. Mardani-Aghabaglou, A., Boyacı, O. C., Hosseinnezhad, H., Felekoğlu, B., Ramyar, K. (2016). Effect of gypsum type on properties of cementitious materials containing high range water reducing admixture. Cement and Concrete Composites, 68, 15–26. DOI 10.1016/j.cemconcomp.2016.02.007. [Google Scholar] [CrossRef]

22. Pundir, A., Garg, M., Singh, R. (2015). Evaluation of properties of gypsum plaster-superplasticizer blends of improved performance. Journal of Building Engineering, 4, 223–230. DOI 10.1016/j.jobe.2015.09.012. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |