Open Access

Open Access

ARTICLE

Process Evaluation, Tensile Properties and Fatigue Resistance of Chopped and Continuous Fiber Reinforced Thermoplastic Composites by 3D Printing

1 School of Mechanical Engineering, Jiangnan University, Wuxi, 214122, China

2 Jiangsu Province Key Laboratory of Advanced Food Manufacturing Equipment and Technology, Jiangnan University, Wuxi, 214122, China

* Corresponding Author: Qiuju Zhang. Email:

(This article belongs to the Special Issue: Green, Recycled and Intelligent Technologies in Printing and Packaging)

Journal of Renewable Materials 2022, 10(2), 329-358. https://doi.org/10.32604/jrm.2022.016374

Received 03 March 2021; Accepted 15 April 2021; Issue published 30 August 2021

Abstract

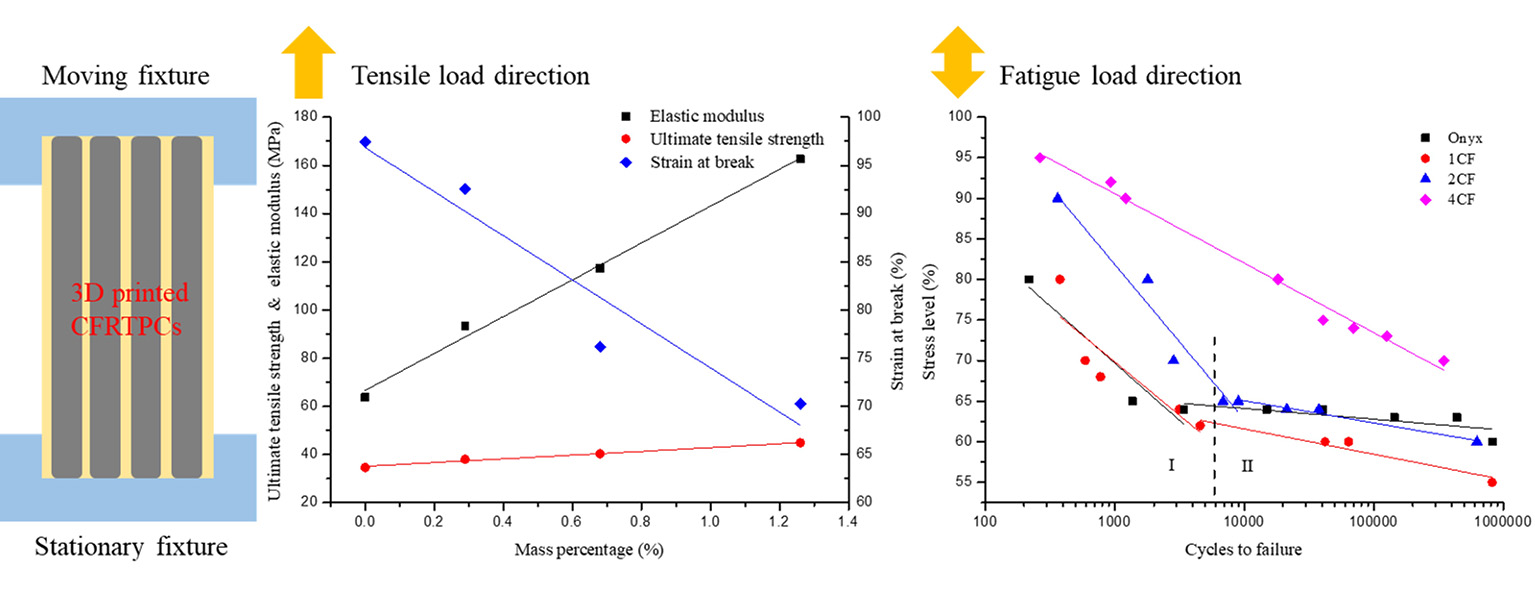

The aim of this article was to comprehensively evaluate the manufacturing process, tensile properties and fatigue resistance of the chopped and continuous fiber reinforced thermoplastic composites (CFRTPCs) by 3D printing. The main results included: the common defects of the printed CFRTPCs contained redundant and accumulation defects, scratch and warping defects; the continuous fiber contributed to the dimensional stability and accuracy of width and thickness; associations between mass percentage of fiber reinforcement and the averages of elastic modulus, strain at break and ultimate tensile strength were approximately linear based on tensile test results; the fatigue resistance improved with the increasing fiber reinforcement based on fatigue test results. As for specimens with four fiber rings, there was a good linear relationship between the stress level and logarithm value of cycles during the whole life while those of pure matrix and specimens with one and two fiber rings were piecewise linear, taking about 10,000 cycles as boundary. The micro morphology showed that the fatigue failure behaved as matrix fracture, large and small fiber bundles and single fibers extracted from matrix. Under the tension-tension fatigue load, the deformations where easily concentrating stress behaved as sunken surfaces along thickness and width directions, and the deformation along width direction was greater than that along thickness direction.Graphic Abstract

Keywords

Cite This Article

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools