| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.022171

REVIEW

A Review of Fibre Reinforced Polymer (FRP) Reinforced Concrete Composite Column Members Modelling and Analysis Techniques

1College of Civil Engineering, Nanjing Forestry University, Nanjing, 210037, China

2Joint International Research Laboratory for Bio-Composite Building Materials and Structures, Nanjing Forestry University, Nanjing, 210037, China

3Jiangsu Fiber Composite Co., Ltd., Yancheng, 224700, China

4Nantong Shirui Reinforced Plastic Products Co., Ltd., Nantong, 226002, China

5University College London, London, WC1E 6BT, UK

6University of Naples Federico II, Via Claudio 21, Naples, 80133, Italy

*Corresponding Authors: Mahdi Hosseini. Email: civil.mahdi.hosseini@gmail.com; Haitao Li. Email: lhaitao1982@126.com

Received: 24 February 2022; Accepted: 21 April 2022

Abstract: The use of fibre-reinforced polymer (FRP) to confine concrete columns improves the strength and ductility of the columns by reducing passive lateral confinement pressure. Many numerical and analytical formulations have been proposed in the literature to describe the compressive behaviour of FRP confined concrete under both monotonic and cyclic loads. However, the effect of a stress/strain level in the columns has not been well defined because of the lack of well-defined strategies of modelling and oversimplification of the model. This paper reviews the existing FRP combinations and the available numerical and analytical methods to determine the effectiveness of the adopted method. An effort has been made to examine the usage of FRP materials in column applications in existing building regimes and highlights the possible future scopes to improve the use of FRP confined concrete in civil applications.

Keywords: FRP confined concrete column; FRP tube; FRP jackets; CFRP; GFRP; stress-strain models

The environmental friendliness of building materials [1–5] is crucial to the construction sector’s transition to sustainable development. Multiple review articles have been published those deals with using different materials and methods to enhance the concrete strength and represent the economic and environmental benefits [6–10]. Although FRP composite materials have historically been used primarily in the aerospace and military industries, there has been a growing awareness among civil engineers. These materials have gained prominence in civil engineering applications over the last three decades [11–15] because of their superior mechanical qualities when compared to standard construction materials. FRP materials are corrosion resistant and can be used to reinforce existing concrete elements or to construct new composite members. Reduced construction time and cheaper maintenance costs over the life of the structure are only a few of the benefits of FRP members [16,17].

Over the last decade, the building sector has experienced a surge in the usage of FRP columns due to their superior mechanical properties [18,19]. Additionally, due to the continued decline in the cost of various fibrous materials, they are being evaluated as a substitute for traditional steel in reinforced-concrete construction. FRP profiles are commonly used in beam and column applications as supporting elements of a structure [20–22]. In column applications, there are three types of FRP tubes: (a) FRP tubes, (b) FRP profiles, and (c) hybrid columns made of steel, concrete, and fibre-reinforced plastic tubes. The primary objective of FRP columns is to use the FRP’s strength to create confining pressure in the transverse direction of concrete columns. On the other hand, the second category of FRP profiles is intended to be used to create lightweight structural column components [23,24]. Pultruded FRP profiles, which are comparable to current steel profiles, have recently gained appeal due to their cost-saving fabrication process. Liang et al. [25] evaluated sandwich panels at component and full scales under four-point flexural test and their mechanical responses were further investigated using standard finite element models. They concluded that CFRP panels were 50%–100% stiffer than GFRP panel, 10%–15% stronger, and 15%–20% lighter than GFRP panel. There are many materials [26,27] which could be used for reinforcing concrete columns such as steel, bamboo, CFRP, GFRP, BFRP, AFRP and so on. However, this paper will mainly pay attention for FRP concrete columns.

Most researchers are being directed to focus on developing fibre-reinforced composite columns as they are highly suitable for enhancing strength, stiffness, and ductility, which is the current trend [28,29]. A search in the open-source domain using the keywords “FRP columns” suggests that at least 1013 papers were published in this area in 2021. As shown in Fig. 1, there has been an increase in the trend in this area of research.

Figure 1: Publications in the last 12 years on FRP composite columns

While the transverse steel confinement substantially increases the concrete’s strength, the column’s outward local buckling reduces the efficiency of the lateral steel confinement, resulting in a loss of the column’s axial load-bearing capacity and ductility [30–32]. Thus, the FRP’s addition to the structure results in enhanced confinement, and it prevents outward local buckling.

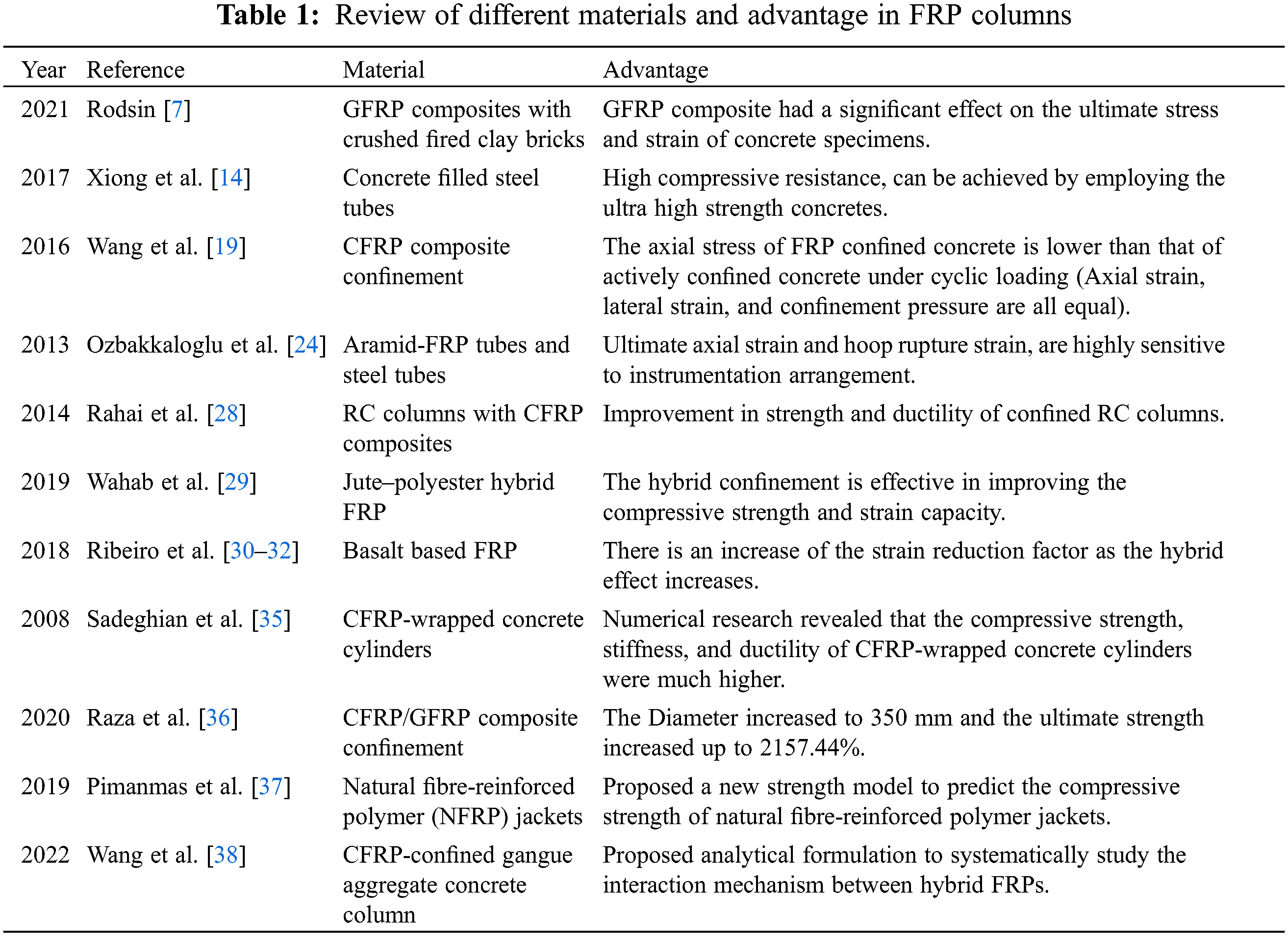

The mechanical and physical properties of FRP composites have been extensively discussed in literature worldwide. However, there is no clear direction on which fiber material and polymer matrix to choose, which are important for both performance and cost-savings. To bridge this knowledge gap, this study aims to review the recent research on the use of FRP concrete columns in civil structures. To do this, different fiber materials like glass, carbon, aramid, bamboo [33,34], jute, and others used in civil structures have been considered, and an attempt has been made to suggest the type of fiber to be selected for the desired application as shown in Table 1. There are a few studies discussing different methods to predict the strength parameters of FRP composites based on numerical or analytical formulations. Thus, this study collectively presents experimental, numerical, and analytical methods proposed in the literature with their efficiency in predicting the desired result.

2 Confinement Effect on Recycled Concrete with FRP

Recently, jacketing with FRP has been presented as an appealing alternative to using recycled aggregate concrete (RAC) structurally. Low cost, high strength, and stiffness are the primary benefits of FRP composites. To improve the strength and stiffness of concrete, various types of FRP composites have been used in the past. Circular concrete columns with crushed fire clay bricks as coarse aggregates were found to have enhanced ultimate load-bearing capacity and stiffness when reinforced with glass FRP (GFRP) composites [12]. FRP jacketing is a well-known technique that is particularly effective for members subjected to compressive loading or components with a circular or annular cross-sectional shape because the concrete in such a section can benefit significantly from the confinement and corrosion-resistant capability provided by the FRP [23–27]. The sections that follow discuss the influence of various fibers types on the compressive behaviour of concrete columns.

2.1 Use of Carbon Fibers (CF) as Confinements in Concrete

Concrete structures have several advantages, including high strength, good corrosion resistance, and high resistance to deformation, especially suitable for high-rise buildings as it facilitates reduced column size [28–33]. Due to concerns about brittleness, these structures’ applications in building structures are still limited, but their ductility can be greatly improved by implementing sufficient lateral confinement. While a high-tensile strength steel tube can be used to confine the core concrete, the diameter-to-thickness ratio must be kept as small as possible to avoid a local buckling problem. In aggregate, this results in material waste, a relatively heavy structural weight, and a high cost [34–39]. The CFRP (carbon fiber reinforced polymer) material has a high strength-to-weight ratio, and has excellent durability and fatigue resistance, making it an effective material for enhancing the strength and deformability of core concrete [40–44]. However, sudden rupture failure is frequently observed, resulting in brittle failure. As a result, the CFRP sheets and steel tubes may complement one another and offer sufficient confinement for the FRP concrete structure.

Chen et al. [22] conducted axial compression tests on cylinders made of carbon fiber-reinforced polymer (CFRP) and recycled aggregate/natural aggregate concrete at three different sizes with diameters ranging from 150 to 300 mm. A potential size effect in CFRP-confined RAC was investigated, and it was concluded that the compressive behaviour of CFRP-confined RAC and NAC is similar compared across all specimen sizes analyzed, with the stiffness of the FRP confinement having a similar role in both types of concrete. In general, CFRP-confined RAC has a lower compressive strength and a greater ultimate axial strain than CFRP-confined NAC. This discrepancy does not imply that the use of recycled aggregate has a substantial influence on the efficacy of FRP confinement since the enhancement ratios for compressive strength and ultimate axial strain of the two types of concrete were fairly similar under the same confinement ratio. Rather than that, this discrepancy is considered to be mostly due to the RAC’s reduced strength and axial stiffness. Islam et al. [26] studied the lateral dilatation of CFRP constrained square concrete columns of 10 and 20 mm, constructed using RBA and RCA. Natural aggregates were used to replace recycled aggregates at various replacement rates, such as 15%, 30%, 60%, and 100%. One, two, and three layers of CFRP were used to reinforce the concrete. The maximum strength and compressibility of concrete built using RBA and RCA were both altered and in comparison to other replacement rates, such as 15%, 30%, and 60%, the CFRP confinement efficacy for concrete built with 100% RBA and RCA was determined to be lower.

A CFRP confined recycled brick aggregate (RBA) concrete was examined by Jiang et al. [27] where the replacement rate of RBA with natural aggregates was 15%, 30%, 60%, and 100%. It was concluded that CFRPs are useful to enhance the ultimate strength of the concrete when fabricated using unidirectional carbon fabric layers of 1, 2, and 3 were employed with epoxy resin. The effectiveness of the carbon FRP confinement was determined to be lower with the increase in replacement rates. Fig. 2 represents the different failure modes observed in the experiment where the different size of aggregate was used by different authors.

Figure 2: Different failure modes (a) Failure modes based on sample size [22] (b) Progressive failure of a CFRP confined concrete of 150 * 150 * 300 mm dimension [26] (c) Comparison of confined and CFRP confined samples [27]

2.2 Comparison of Carbon and Glass Fibers as Confinements in Concrete

Gao et al. [45] conducted a systematic investigation of the axial compressive behaviour of glass and carbon fiber-reinforced polymer tubes encased in recycled aggregate concrete using recycled clay brick aggregate. Glass fiber reinforced polymer (GFRP) and carbon fiber reinforced polymer (CFRP) tubes were fabricated utilizing unidirectional glass and carbon fabrics reinforced in epoxy resin with PVC pipes as moulds. The tubes were constructed using two, four, and six layers of GFRP and CFRP. The brick aggregates were replaced with natural aggregates at various replacement rates, including 50%, 70%, and 100%. The results indicate that the introduction of GFRP and CFRP tubes is favorable since the confinement of RAC with recycled clay brick aggregates (RCBA) enhanced the compressive strength almost 5.5 times while utilizing 6-layer GFRP tube. However, Fig. 3 represents a typical stress-strain curve for GFRP and CFRP composites and from the experimental results, it was determined that compared to GFRP tube concrete, CFRP tube confined concrete had a lower axial strain and a greater compressive strength. Fig. 4 shows the failed specimens of neat, CFRP and GFRP confined concretes. In the case of GFRP confined concretes, the wrapping failed at half the lateral strain obtained by the wrapped pre-tensioned jacket with three layers, signifying 100% fiber utilization whereas for CFRP confined concretes, the lateral and longitudinal stresses were about 10 times higher than in unconfined concrete [41].

Figure 3: Tensile stress-strain curves of GFRP and CFRP composites [45]

Figure 4: Failed specimens under compressive load (a) Plain (b) GFRP confined concrete (c) CFRP confined concrete [45]

2.3 Summary of Different FRP Confined Concrete Columns

FRP jackets allow concrete to achieve higher compressive strength and ultimate axial and lateral stresses, which helps prolong concrete crack propagation and avoid displacement of disaggregated concrete particles. Tensile tension needs to be established in the FRP confined concrete materials to maintain a high degree of confinement. This is why most studies have tried to incorporate the majority of fibres along the column member’s transverse direction to create tensile stress in the FRP material, which produces lateral confining pressure.

3 Hybrid FRP Composites Columns

Traditional structural elements such as steel concrete can be combined with FRP profiles to create a hybrid FRP column member. There are two primary areas of research on which researchers concentrated their efforts, namely: a) FRP composites’ performance in retrofitting existing concrete columns [42–46] and b) the construction of new FRP reinforced concrete as high-performance composite columns [46–48]. The FRP material’s action creates a confining pressure on the concrete, which protects the steel profile from buckling. Researchers have examined cost-effective, and high-performance hybrid FRP column members using different types of unidirectional and bi-directional fiber combinations in hybrid FRPs to confine concrete by combining the benefits of each component in the resultant structure [49–52].

3.1 Hybrid FRP Composites Columns with a Cylindrical Cross-Section

Chaiyasarn et al. [53] developed a novel, low-cost, high-performance hybrid FRP composite using basalt fabrics and E-glass fibers with resin to test its ability to increase the RAC’s strength and stiffness with CBA. Under axial compression tests on a set of 36 concrete cylinders, it was determined that recycling aggregate concrete using clay brick aggregates may be made stronger and more ductile using hybrid basalt/E-glass FRP composites. For recycled aggregate concrete containing clay brick aggregates, hybrid basalt/E-glass FRP composites are more effective at increasing ultimate strength and strain when using low-strength RAC than when using high-strength RAC. Using a filament winding procedure, Xia et al. [54] investigated unidirectional flax–basalt hybrid fiber reinforced polymer plates and tubes for their mechanical and compressive characteristics. In comparison to flax fiber-reinforced polymers, hybrid fiber–reinforced polymers demonstrated significantly improved tensile characteristics. The lateral–axial interaction between the hybrid fiber-reinforced polymer–confined cylinders is determined by the fiber layer configuration.

Fanggi et al. [55] investigated the effects of the compressive behaviour of concrete-filled double-skin tubular columns and two concrete-filled FRP tubes that were manufactured with S-Glass FRP tubes. The FRP tubes of a diameter of 152.5 mm and a height of 305 mm were made using S-Glass fiber layup process in the hoop direction and the filler’s strength in the unconfined concrete ranged from 82.4 to 96.2 MPa. Due to the dual impacts of FRP and steel confinement on the concrete, it was observed that the specimen with FRP and steel reinforcement demonstrate a higher degree of improvement than those confined by FRP tubes alone. Thus, researchers have established that specimens constructed of dual grade concrete display superior compressive strength than those constructed of single grade concrete [56].

Zhang et al. [57] conducted an experimental study on hybrid double-skin tubular columns filled with HSC that were subjected to axial compression and cyclic lateral loading over a relatively large column section to allow for reliable experimental modelling of real columns. However, when high strength concrete with a cylinder compressive strength of approximately 120 MPa is employed, hybrid DSTCs show good ductility, seismic resistance and higher moment capacity but a smaller deformation capacity. Cao et al. [58] reported the findings of an experimental investigation of the behaviour of circular concrete-filled steel tubes enclosed in FRP under axial compression, intending to develop a thorough knowledge of structural behaviour and valid theoretical models. The results of the tests indicated that the FRP wrap can significantly defer, the development of local buckling deformation in the steel tube. As a result, FRP confinement may significantly improve the load-carrying capacity and ductility of concrete-filled thin steel tubes. Also, the number of FRP layers and steel tube diameter are critical elements affecting the prestress of FRP concrete columns [59,60].

3.2 Hybrid FRP Composites Columns with a Square Cross-Section

To evaluate the validity and performance of concrete confined with the hybridization of jute and polyester (FRP) composite sheets to utilize its superior properties, Wahab et al. [29] presented experimental and analytical results of square concrete columns confined with jute–polyester hybrid FRP composites. 32 plain, square concrete specimens were tested under monotonic axial compressive loads, all of which were wrapped with an external layer of a jute–polyester FRP composite. The results indicate that jute-based FRP confinement enhanced the strength, strain, and ductility of the specimen, whereas wrapping had a substantial influence on the low-strength specimens with a circular cross-section. While due to the substantial rupture strain of the outer polyester jacket on the high strength specimens, the outer polyester jacket dominated the post-peak stress-strain behaviour.

3.3 Hybrid FRP Composites Columns with Concrete-Encased Steel I-Section Columns

Yu et al. [61] presented a combined experimental and theoretical study on the behaviour of FRP-confined concrete-encased steel I-section columns. From the standard coupon tests, the elastic modulus, yield stress, and tensile strength average values are 218.1 GPa, 321.7 MPa, and 447.0 MPa, respectively. Under both concentric and eccentric stress, the steel I-section buckling as well restricted, and the concrete was well contained, resulting in a very ductile reaction. Experimental and computational analyses of axially loaded steel-reinforced concrete-filled GFRP tubular columns are presented by Xue et al. [62]. The specimens fail by the rupture of the GFRP tubes under hoop tension and only outward buckling was observed because of the presence of the concrete core and steel section. The numerical analysis was conducted, and two failure modes considered for the study were equivalent stress-strain relationship for the concrete core and bilinear stress-strain response for the FRP-confined concrete model.

3.4 Hybrid Layer of FRP in a Concrete Column

It is known that the ultimate tensile strain of conventional FRP jackets is lower than that observed in tensile tests of laminates of non-hybrid FRP of the same material. Thus, there is scope to further enhance the performance of FRP-confined concrete [63]. Ribeiro et al. [30] concentrated on pure compression testing on small-scale plain concrete columns confining with 16 unidirectional interlayer hybrid composite combinations, making use of the hybrid effect and pseudo-ductility of this confining material. The FRP tensile strain at failure was determined to be inaccessible in situ with FRP jackets. However, hybridization showed that this drop in efficiency may be mitigated, if not removed. In fact, for a substantial number of hybrid combinations, the strain reduction factor was found to be more than one [31].

3.5 Summary for Hybrid FRP Composites Columns

It is determined from the literature that, concrete-filled steel tubes are frequently utilized as columns in many structural applications, and a prevalent form of failure for such tubular columns is inelastic outward local buckling near the column end. The use of FRP in these steel structures as jackets/wraps to minimize such local buckling has been proposed by many researchers and they demonstrated to have promising outcomes in both retrofit/strengthening and new construction. As hybrid FRP columns are constantly changing through the use of fillers, steel tubes, and steel I sections, their primary objective for development is to offer lightweight structures. Table 2 gives a review of the existing hybrid FRP combinations from the literature.

4 Finite Element Analysis of FRP Columns

FRP provides an intuitive and reliable way to reinforce existing RC columns. However, because classical mechanics cannot accurately estimate lateral strain due to axial load, an assessment of the confinement effects of the FRP is required. As an aid to this problem, the finite element (FE) method can provide a comprehensive view of the stress and strain created in a typical cross-section, from linear elastic to ultimate failure stresses.

4.1 FE Model Developed Using ANSYS

Chakrabarti et al. [40] developed a nonlinear FE model for the study of plain and reinforced concrete column sections with circular and square cross-sections that are confined by FRP sheets. The proposed FE model was used to analyze the behaviour of small and large-sized FRP-wrapped concrete columns subjected to uniaxial compression loading. Following validation, a comprehensive parametric investigation was performed to quantify the influence of the FRP sheets’ thickness, stiffness, and fibre orientation, as well as the unconfined concrete strength, on the confinement and stiffness of the FRP reinforced columns. Additionally, the study findings provide an appropriate stress distribution in concrete and FRP, which assists in the understanding of the concrete columns’ confinement mechanism. Similar studies were carried out using CFRP-wrapped concrete cylinders [35]. The numerical analysis findings indicated that the compressive strength, stiffness, and ductility of the CFRP-wrapped concrete cylinders were significantly increased when compared to the unconfined concrete cylinders.

Zakir et al. [64] conducted the first experimental and analytical study to assess the effect of stiffening steel tubes on the confined concrete behaviour of square-shaped double-skin tubular columns. A total of 18 specimens were tested by varying steel stiffener properties such as quantity, configuration for a similar total stiffener-rib area, effective placement, and rib cross-section dimensions and shape, and it was discovered that stiffened steel tubes specimens had a significant increase in axial load capacity of about 52% with enhanced ductility compared to unstiffened specimens. Ibrahim et al. [65] developed a sophisticated three-dimensional finite element model to assess the structural performance of FRP-steel RC columns, taking into account the influence of various bond conditions between FRP bars and concrete. Since ANSYS does not directly model steel bar buckling, the solution was terminated after the lateral displacement reached a value equivalent to the maximum displacement attained during the experimental test before failure.

4.2 FE Model Developed Using ABAQUS

Under axial concentric and eccentric loadings, the structural behaviour of fiber-reinforced polymer (FRP) reinforced concrete columns confined by FRP tubes was investigated by Raza et al. [36]. A commercially available FE tool ABAQUS was used to construct FEA model of FRP-tube confined concrete columns with longitudinal reinforcements of CFRP and/or GFRP bars. It was determined that increasing the diameter of the column has a stronger influence on improving the ultimate strength of columns. When the diameter was increased to 350 mm and the GFRP reinforcement was increased from 1.2% to 2.2%, the ultimate strength increased up to 2157.44%. It can be concluded that, by using the 3D finite element model for FRP-confined concrete in compression, a very good agreement between experimental, analytical and numerical compressive stress-strain and lateral strain-axial strain curves can be reached [66–68].

Mohammadi et al. [69] studied large rupture strain FRPs which enhance the strength and ductility of concrete columns with the same mechanism as conventional FRPs by rendering passive lateral confinement pressure. The concrete damage plasticity module (CDPM) was calibrated in the FE model using the confinement pressure and stiffness approach where the active confinement pressure technique demonstrates that the secondary stiffness of the large rupture strain FRP jacket dominates the concrete plastic flow of FRP-confined concrete. Results demonstrated that the plastic dilation angle of the proposed FRP confined concrete changed about 3 times faster than that of conventional FRP confined concrete. The geometric factors are included in the estimation of plastic dilation angle, allowing for the development of a novel plastic dilation angle model for the FEA of non-circular FRP-confined concrete columns.

4.3 FE Model Developed Using User Defined Failures

Incorrect strength prediction can be caused by inaccurate modelling of FRP reinforced concrete behavior [70]. As a result, sophisticated constitutive models capable of modelling well-suited stress-strain relation of FRP reinforced concrete with accurate failure models are required. The stress-strain model of FRPs-confined concrete was used by Ismail et al. [67] to estimate the lateral response of RC columns under axial and lateral loads. The adopted model was used to simulate the seismic response of RC-circular columns retrofitted with FRP jackets, but the simulation results showed that all stress-strain models could not accurately predict the columns’ ultimate lateral displacements. The stress-strain model used was altered to take into account the eccentricity ratio, and it was determined that it had a significant impact on the modelling of the seismic response of RC columns under combined bending and axial loadings.

Piscesa et al. [68] presented 3D nonlinear FEM for conventional steel stirrups and FRP-wrapped concrete columns. To solve the equilibrium forces in the global solution, the FEA employed the initial stiffness approach with “process modification”. The constitutive model is based on the plasticity formulation, which captures the constraining concrete specimen’s effective lateral modulus. This lateral modulus is calculated by measuring the primary incremental stresses and strains at the gauss points of each element. It was determined that the boundary condition, the dilatant behaviour of the constitutive model, and the Poisson’s ratio of the external confining device had a significant impact on the lateral modulus. Fig. 5 depicts the meshes of the finite element models for the specimens with circular ties as transverse reinforcement and spirals as transverse reinforcement.

Figure 5: 3D FE mesh model (a) specimen has circular ties as the transverse reinforcement (b) specimen has spirals as the transverse reinforcement [68]

Lo et al. [71] applied 2-D FE methodologies on the cross-sections of axially loaded FRP-confined rectangular concrete columns with no assumptions or constraints on the non-uniform and the failure under triaxial compression was defined by Eq. (1)

where ξ represents hydrostatic length, ρ represents the deviatoric length and θ represents lode angle. The numerical findings for determining the effects of structural characteristics revealed that aspect ratio and corner roundness have little effect on yield strength and yield strain, but they may have a considerable effect on post-yield behaviour.

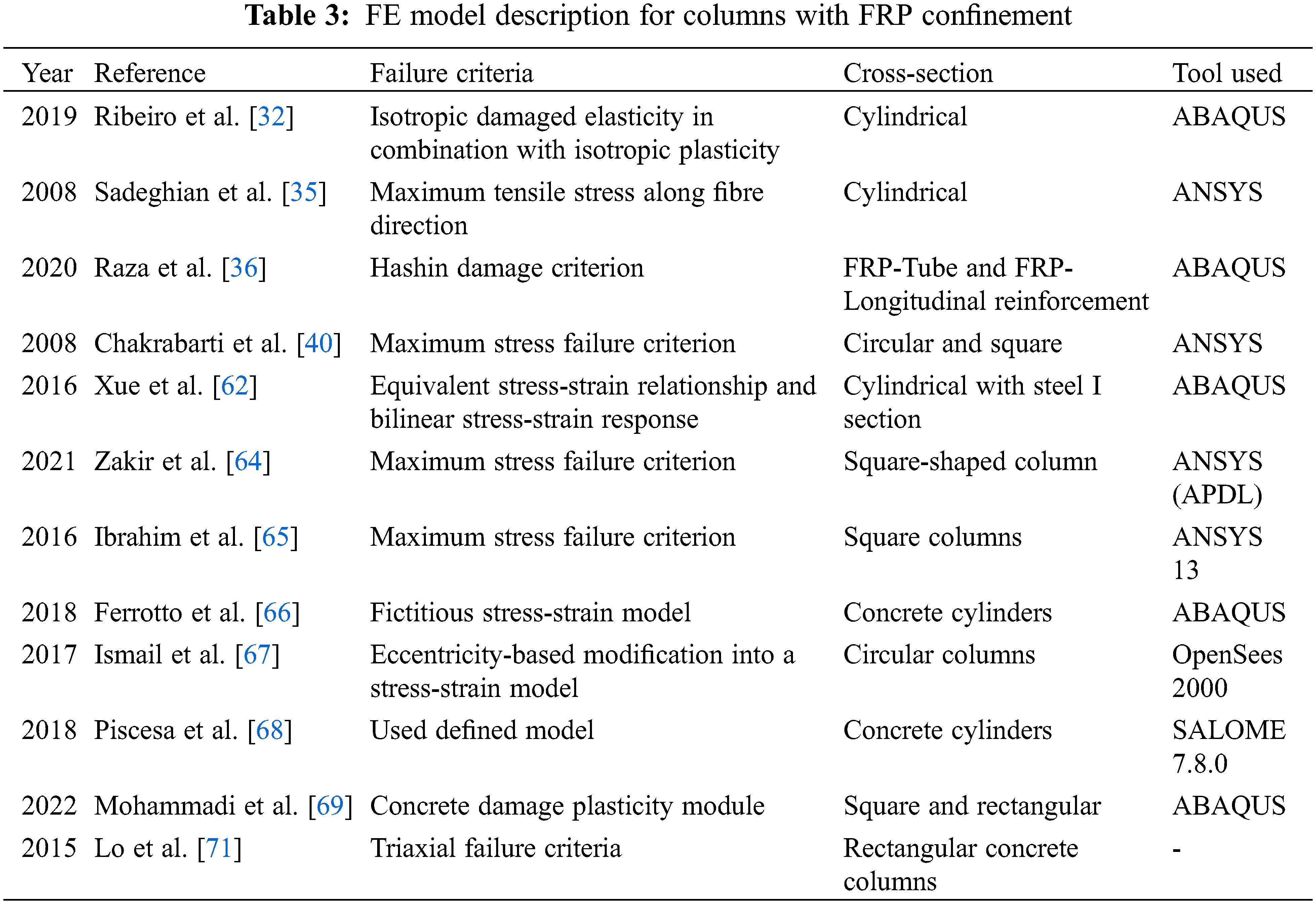

Strengthening reinforced concrete (RC) columns with external confining devices such as FRP wraps or steel tubes is widely used in construction. By using external confining devices, both the strength and ductility of RC columns are significantly improved. However, numerical modelling to predict the capacity of strengthened RC columns is limited and often oversimplified. Thus, the available FE models have been reviewed and the development of a sophisticated FE model to simulate accurate FRP and concrete interaction has been determined. An overview of various FE models developed has been presented in Table 3.

In general, the axial stress vs. strain behaviour of FRP constrained concrete specimens can be divided into three categories. a) The first portion is often linear and identical to the unconfined concrete’s axial stress vs. strain response. b) The second portion of the axial stress vs. strain relationship is typically regarded as a transition zone, and c) the third part is once again linear, similar to the first part, but the stiffness of the third part is usually significantly lower than the stiffness of the first part. Fig. 6 depicts typical axial stress vs. strain responses of unconfined and FRP confined concrete specimens.

Figure 6: Axial stress vs. strain response for FRP confined and unconfined concrete [53]

In general, design-oriented models are more accurate in predicting ultimate strength and strain enhancement ratios, and all analysis-oriented models are explicitly derived from FRP-confined and actively confined concrete dilation relationships, which perform better than implicitly adopted dilation relationships [72–74]. The design-oriented models express a linear relationship of strength-to-lateral confining pressure in the following possible ways:

where k1 is 4.1 and 2.33 for bonded and unbonded FRP, respectively.

Xiao et al. [75] presented modelling of the stress-strain behaviour of confined high-strength concrete without silica fume. After examining the behaviour of actively confined high-strength concrete, a unified active-confinement model is proposed for both high and normal-strength concrete and demonstrated that the presence of silica fume in HSC decreases the efficiency of confinement in terms of strain capacity. A new class of composites based on basalt fibers bonded with a cement-based matrix as a strengthening material could be a promising solution to overcome some of the limitations of epoxy-based FRP laminates [76].

Wang et al. [77] presented a cyclic axial stress-strain model for CFRP-confined RC square columns, which consists of a monotonic stress-strain model to describe the envelope curve, a polynomial expression for the unloading path, and a straight line for the reloading path. In the proposed model, the effect of internal longitudinal and hoop steel reinforcement on ultimate stress and strain is also considered. Concrete-filled FRP tubes can be used instead of traditional steel reinforcement because they provide better confinement, reduce construction time, and are resistant to corrosion. Steel in the form of rebar, embedded steel sections, and inner steel tubes is needed to strengthen these structures and avoid the brittle failure of FRP tubes after they break. An innovative confinement system with an inner steel wire mesh is shown in Fig. 7. Because of the confinement offered by the FRP tube, this method enhances concrete strength while also preventing the brittle failure of the concrete once the FRP ruptures owing to the ductile inner wire mesh [78].

Figure 7: Proposed concrete-filled FRP tubes with wire mesh [75]

Using a database of 212 GFRP-confined cylindrical concrete specimens, Huang et al. [79] reported a detailed review of 22 existing stress models and 13 strain models created for GFRP-confined concrete under uniaxial compression. The Pearson correlation coefficient r was utilised to assess the accuracy and applicability, and the Monte Carlo–JC approach was employed to measure the reliability of the stress and strain models. According to the findings, the unconfined concrete strength was determined to be the most critical factor in determining the validity of GFRP-confined concrete stress and strain models. Pimanmas et al. [37] proposed a new strength model to predict the compressive strength of natural fibre-reinforced polymer jackets confined concrete structures of circular and square sections. Both circular and square concrete specimens benefit from the use of natural sisal fibres to improve strength and deformability and it was determined that by increasing the shell thickness on the natural FRP, there was a considerable increase in the compressive strength and deformability. Wang et al. [38] worked on improving the utilization rate of gangue aggregate concrete and proposed a theoretical analysis to systematically study the interaction mechanism between hybrid FRPs. Table 4 represents the existing analytical model for concrete confinement models.

A review of the literature shows that the vast majority of the research was conducted using circular concrete specimens with a height-to-diameter ratio of approximately 2. Based on general solid mechanics theory, it is a known fact that short columns do not fail under buckling. Several experimental studies on the behaviour of FRP confined concrete columns in various sections, with or without internal steel reinforcement, have been conducted. Literature is scarce, that deals with columns with a height-to-diameter ratio greater than 5 to specify how the axial strength and ductility of slender columns can be improved. Based on the detailing of the FRP strengthening, internal reinforcement, and cross-section of the concrete column, the existing experiments revealed different trends among tested columns confined with FRPs. The majority of the models apply to columns with ascending second branches, but rectangular columns can have descending second branches, according to a review of the literature. As a result, existing models are unable to adequately describe the behaviour of the columns.

Confinement to concrete, such as steel tubes or stirrups, FRP tubes or wrappings, is widely recognized for its effectiveness in improving the mechanical characteristics of ordinary aggregate concrete. The pre-fabricated FRP tube in a concrete-filled FRP tube acts as permanent formwork for concrete structure while also providing confinement to the infilled concrete to improve its strength and ductility. However, it should be noted that most recycled aggregate used in concretes comes from demolished old concrete components. If recycled clay brick aggregate from demolished brick waste is utilized as confined concrete, the concrete industry would be on the verge of becoming sustainable. To comprehend the compressive behaviour of FRP constrained RAC incorporating RCBA, more study is required.

The use of lightweight concrete will allow for the preservation of most of the lightweight features of the FRP profiles, as more research in these areas will help to address knowledge gaps, hence improving the usage of FRP tubes in the building sector.

The following studies need to be done to solve major problems with the use of hybrid FRP profiles in structural application:

• The tensile testing of the jute FRP composite showed a linear stress-strain response, whereas the polyester FRP composite showed a bi-linear stress-strain response.

• The hybrid confinement can be utilized to keep the concrete cover from spalling and to make it moisture resistant. Because it has low to moderate strength and high ductility, it can also be used in an earthquake-prone areas where these things need to be met.

• While examining the improvements in the concrete columns’ stress and strain capacity, it was determined that improvement can be achieved by constraining the concrete column’s core with an FRP tube with solely hoop-oriented fibers. This allows the column to retain its original form while increasing its load-bearing capability.

In this paper the use of different FRP types as confining materials in concretes and various methods to estimate the effect of these FRPs in concretes has been reviewed. Based on a comprehensive review in this research area, the following conclusions can be drawn:

• Over the last three decades, research on FRP as confinement has been well established, resulting in improved structural applications.

• RAC-RCBA cylinders made with recycled aggregates from old concrete components have reduced compressive strength and dilation rate. When the replacement ratio of RCBA was more than 70%, there was no noticeable effect on the compressive strength of RAC-RCBA cylinders.

• A major problem with FRP profiles is that buckling can have a negative effect on axial performance. This means that the cross-sections must be changed so that the mechanical properties of the structure can be used to their fullest extent.

Acknowledgement: The writers gratefully acknowledge Ben Chen, Zhen Wang, Han Zhang, Ke Zhou, Xiaoyan Zheng, Shaoyun Zhu, Liqing Liu, Dunben Sun, Jing Cao, Yanjun Liu, Junhong Xu and others from the Nanjing Forestry University for helping.

Funding Statement: The research work presented in this paper is supported by the Foreign Young Talents Project China (No. QN2021014006L), National Natural Science Foundation of China (Nos. 51878354 & 51308301), the Natural Science Foundation of Jiangsu Province (Nos. BK20181402 & BK20130978), 333 Talent High-Level Projects of Jiangsu Province and Qinglan Project of Jiangsu Higher Education Institutions. Any research results expressed in this paper are those of the writers and do not necessarily reflect the views of the foundations.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Lopez-Anido, R. A., Naik, T. R. (2000). Emerging materials for civil infrastructure: State of the art. USA: American Society of Civil Engineering. [Google Scholar]

2. Liang, R. F., Stanislawski, D., Hota, G. (2021). Material characterization and structural response under earthquake loads of hakka rammed earth building. Sustainable Structures, 1(1), 000003. DOI 10.54113/j.sust.2021.000003. [Google Scholar] [CrossRef]

3. Cheng, X., Wei, Y., Nie, Y., Wang, G., Li, G. (2021). Compressive behavior of bamboo sheet twining tube-confined concrete columns. Polymers, 13, 4124. DOI 10.3390/polym13234124. [Google Scholar] [CrossRef]

4. Nie, Y., Wei, Y., Zhao, K., Ding, M., Huang, L. (2022). Compressive performance of bamboo sheet twining tube-confined recycled aggregate concrete columns. Construction and Building Materials, 323, 126544. DOI 10.1016/j.conbuildmat.2022.126544. [Google Scholar] [CrossRef]

5. Zhou, Y. H., Huang, Y. J., Sayed, U., Wang, Z. (2021). Research on dynamic characteristics test of wooden floor structure for gymnasium. Sustainable Structures, 1(1), 000005. DOI 10.54113/j.sust.2021.000005. [Google Scholar] [CrossRef]

6. O’Shea, M. D., Bridge, R. Q. (2000). Design of circular thin-walled concrete filled steel tubes. Journal of Structural Engineering, 126, 1295–1303. DOI 10.1061/(ASCE)0733-9445(2000)126:11(1295). [Google Scholar] [CrossRef]

7. Rodsin, K. (2021). Confinement effects of glass FRP on circular concrete columns made with crushed fired clay bricks as coarse aggregates. Case Studies in Construction Materials, 15, e00609. DOI 10.1016/j.cscm.2021.e00609. [Google Scholar] [CrossRef]

8. Felice, P., di Cesare, A., Lamarucciola, N., Domenico, N. (2021). Experimental estimation of energy dissipated by multistorey post-tensioned timber framed buildings with anti-seismic dissipative devices. Sustainable Structures, 1(2), 000007. DOI 10.54113/j.sust.2021.000007. [Google Scholar] [CrossRef]

9. Deskovic, N., Triantafillou, C., Meier, U. (1995). Innovative design of FRP combined with concrete: Short-term behavior. Journal of Structural Engineering, 121, 1069–1078. DOI 10.1061/(ASCE)0733-9445(1995)121:7(1069). [Google Scholar] [CrossRef]

10. Assima, D., Li, H., Xiong, Z. H., Lorenzo, R. (2021). A review of mechanical behavior of structural laminated bamboo lumber. Sustainable Structures, 1(1), 000004. DOI 10.54113/j.sust.2021.000004. [Google Scholar] [CrossRef]

11. Teng, J. G., Lam, L. (2004). Behavior and modeling of fiber reinforced polymer-confined concrete. Journal of Structural Engineering, 130, 1713–1723. DOI 10.1061/(ASCE)0733-9445(2004)130:11(1713). [Google Scholar] [CrossRef]

12. Cheng, S., Feng, P., Bai, Y., Ye, L. P. (2016). Load-strain model for steel-concrete-FRP-concrete columns in axial compression. Journal of Composites for Construction, 20, 04016017. DOI 10.1061/(ASCE)CC.1943-5614.0000664. [Google Scholar] [CrossRef]

13. Li, P., Wu, Y. F. (2016). Stress–strain behavior of actively and passively confined concrete under cyclic axial load. Composite Structures, 149, 369–384. DOI 10.1016/j.compstruct.2016.04.033. [Google Scholar] [CrossRef]

14. Xiong, M. X., Xiong, D. X., Liew, J. Y. R. (2017). Axial performance of short concrete filled steel tubes with high- and ultra-high- strength materials. Engineering Structures, 136, 494–510. DOI 10.1016/j.engstruct.2017.01.037. [Google Scholar] [CrossRef]

15. Ashraf, M., Hasan, M. J., Al-Deen, S. (2021). Semi-rigid behaviour of stainless steel beam-to-column bolted connections. Sustainable Structures, 1(1), 000002. DOI 10.54113/j.sust.2021.000002. [Google Scholar] [CrossRef]

16. Punurai, W., Hsu, C. T. T., Punurai, S., Chen, J. (2013). Biaxially loaded RC slender columns strengthened by CFRP composite fabrics. Engineering Structures, 46, 311–321. DOI 10.1016/j.engstruct.2012.07.014. [Google Scholar] [CrossRef]

17. Faustino, P., Chastre, C. (2015). Analysis of load–strain models for RC square columns confined with CFRP. Composites Part B: Engineering, 74, 23–41. DOI 10.1016/j.compositesb.2015.01.002. [Google Scholar] [CrossRef]

18. Dundar, C., Erturkmen, D., Tokgoz, S. (2015). Studies on carbon fiber polymer confined slender plain and steel fiber reinforced concrete columns. Engineering Structures, 102, 31–39. DOI 10.1016/j.engstruct.2015.08.011. [Google Scholar] [CrossRef]

19. Wang, D. Y., Wang, Z. Y., Smith, S. T., Yu, T. (2016). Size effect on axial stress-strain behavior of CFRP-confined square concrete columns. Construction and Building Materials, 118, 116–126. DOI 10.1016/j.conbuildmat.2016.04.158. [Google Scholar] [CrossRef]

20. Chen, P., Wang, Y., Liu, C. (2018). Confinement path-dependent analytical model for FRP-confined concrete and concrete-filled steel tube subjected to axial compression. Composite Structures, 201, 234–247. DOI 10.1016/j.compstruct.2018.06.008. [Google Scholar] [CrossRef]

21. Corbi, O., Alessandro, B., Ileana, C., Francesca, T., Eugenio, L. (2021). Design issues for smart seismic isolation of structures: Past and recent research. Sustainable Structures, 1(1), 000001. DOI 10.54113/j.sust.2021.000001. [Google Scholar] [CrossRef]

22. Chen, G. M., Zhang, J. J., Jiang, T., Lin, C. J., He, Y. H. (2018). Compressive behavior of CFRP-confined recycled aggregate concrete in different-sized circular sections. Journal of Composites for Construction, 22, 04018021. DOI 10.1061/(ASCE)CC.1943-5614.0000859. [Google Scholar] [CrossRef]

23. Xiao, Y. (2004). Applications of FRP composites in concrete columns. Advances in Structural Engineering, 7, 335–343. DOI 10.1260/1369433041653552. [Google Scholar] [CrossRef]

24. Ozbakkaloglu, T., Lim, J. C. (2013). Axial compressive behavior of FRP-confined concrete: Experimental test database and a new design-oriented model. Composites Part B: Engineering, 55, 607–634. DOI 10.1016/j.compositesb.2013.07.025. [Google Scholar] [CrossRef]

25. Liang, R., Hota, G. (2021). Development and evaluation of load-bearing fiber reinforced polymer composite panel systems with tongue and groove joints. Sustainable Structures, 1(2), 000008. DOI 10.54113/j.sust.2021.000008. [Google Scholar] [CrossRef]

26. Islam, M. M., Choudhury, M. S. I., Amin, A. F. M. S. (2016). Dilation effects in FRP-confined square concrete columns using stone, brick, and recycled coarse aggregates. Journal of Composites for Construction, 20(1). DOI 10.1061/(ASCE)CC.1943-5614.0000574. [Google Scholar] [CrossRef]

27. Jiang, T., Wang, X. M., Zhang, W. P., Chen, G. M., Lin, Z. H. (2020). Behavior of FRP-confined recycled brick aggregate concrete under monotonic compression. Journal of Composites for Construction, 24, 04020067. DOI 10.1061/(ASCE)CC.1943-5614.0001080. [Google Scholar] [CrossRef]

28. Rahai, A., Akbarpour, H. (2014). Experimental investigation on rectangular RC columns strengthened with CFRP composites under axial load and biaxial bending. Composite Structures, 108, 538–546. DOI 10.1016/j.compstruct.2013.09.015. [Google Scholar] [CrossRef]

29. Wahab, N., Srinophakun, P., Hussain, Q., Chaimahawan, P. (2019). Performance of concrete confined with a jute–polyester hybrid fiber reinforced polymer composite: A novel strengthening technique. Fibers, 7, 72. DOI 10.3390/fib7080072. [Google Scholar] [CrossRef]

30. Ribeiro, F., Sena-Cruz, J., Branco, F. G., Júlio, E. (2018). Hybrid FRP jacketing for enhanced confinement of circular concrete columns in compression. Construction and Building Materials, 184, 681–704. DOI 10.1016/j.conbuildmat.2018.06.229. [Google Scholar] [CrossRef]

31. Ribeiro, F., Sena-Cruz, J., Branco, F. G., Júlio, E. (2018). Hybrid effect and pseudo-ductile behaviour of unidirectional interlayer hybrid FRP composites for civil engineering applications. Construction and Building Materials, 171, 871–890. DOI 10.1016/j.conbuildmat.2018.03.144. [Google Scholar] [CrossRef]

32. Ribeiro, F., Sena-Cruz, J., Branco, F. G., Júlio, E. (2019). 3D finite element model for hybrid FRP-confined concrete in compression using modified CDPM. Engineering Structures, 190, 459–479. DOI 10.1016/j.engstruct.2019.04.027. [Google Scholar] [CrossRef]

33. Liu, K., Durai, J., Shi, Y., Kent, H., Yang, J. et al. (2022). Bamboo: A very sustainable construction material. Sustainable Structures, 2(1), 000015. DOI 10.54113/j.sust.2022.000015. [Google Scholar] [CrossRef]

34. Su, J., Li, H., Xiong, Z., Lorenzo, R. (2021). Structural design and construction of an office building with laminated bamboo lumber. Sustainable Structures, 1(2), 000010. DOI 10.54113/j.sust.2021.000010. [Google Scholar] [CrossRef]

35. Sadeghian, P., Rahai, A. R., Ehsani, M. R. (2008). Numerical modeling of concrete cylinders confined with CFRP composites. Journal of Reinforced Plastics and Composites, 27, 1309–1321. DOI 10.1177/0731684407084212. [Google Scholar] [CrossRef]

36. Raza, A., Rehman, A. R., Masood, B., Hussain, I. (2020). Finite element modelling and theoretical predictions of FRP-reinforced concrete columns confined with various FRP-tubes. Structures, 26, 626–638. DOI 10.1016/j.istruc.2020.04.033. [Google Scholar] [CrossRef]

37. Pimanmas, A., Hussain, Q., Panyasirikhunawut, A., Rattanapitikon, W. (2019). Axial strength and deformability of concrete confined with natural fibre-reinforced polymers. Magazine of Concrete Research, 71, 55–70. DOI 10.1680/jmacr.17.00312. [Google Scholar] [CrossRef]

38. Wang, J., Xia, J., Chang, H., Han, Y., Yu, L. (2022). The axial compressive experiment and analytical model for FRP-confined gangue aggregate concrete. Structures, 36, 98–110. DOI 10.1016/j.istruc.2021.12.013. [Google Scholar] [CrossRef]

39. Lim, J. C., Ozbakkaloglu, T. (2015). Hoop strains in FRP-confined concrete columns: Experimental observations. Materials and Structures, 48, 2839–2854. DOI 10.1617/s11527-014-0358-8. [Google Scholar] [CrossRef]

40. Chakrabarti, A., Chandra, A., Bharagava, P. (2008). Finite element analysis of concrete columns confined with FRP sheets. Journal of Reinforced Plastics and Composites, 27, 1349–1373. DOI 10.1177/0731684408089859. [Google Scholar] [CrossRef]

41. Mortazavi, A. A., Pilakoutas, K., Son, K. S. (2003). RC column strengthening by lateral pre-tensioning of FRP. Construction and Building Materials, 17, 491–497. DOI 10.1016/S0950-0618(03)00046-1. [Google Scholar] [CrossRef]

42. Abdelrahman, K., Raafat, H. (2020). Behavior of large-scale concrete columns wrapped with CFRP and SFRP sheets. Journal of Composites for Construction, 16(4), 430–439. DOI 10.1061/(ASCE)CC.1943-5614.0000278. [Google Scholar] [CrossRef]

43. Al-Kamaki, Y. S. S. (2021). Ultimate strain models derived using a digital image correlation (DIC) system for preloaded RC columns subjected to heating and cooling and confined with CFRP sheets. Journal of Building Engineering, 41, 102306. DOI 10.1016/j.jobe.2021.102306. [Google Scholar] [CrossRef]

44. Wang, W., Wu, C., Liu, Z. (2019). Compressive behavior of hybrid double-skin tubular columns with ultra-high-performance fiber-reinforced concrete (UHPFRC). Engineering Structures, 180, 419–441. DOI 10.1016/j.engstruct.2018.11.048. [Google Scholar] [CrossRef]

45. Gao, C., Huang, L., Yan, L., Kasal, B., Li, W. (2016). Behavior of glass and carbon FRP tube encased recycled aggregate concrete with recycled clay brick aggregate. Composite Structures, 155, 245–254. DOI 10.1016/j.compstruct.2016.08.021. [Google Scholar] [CrossRef]

46. Xie, J., Wang, Z., Yan, J. B. (2022). Axial compression behaviours of seawater and sea sand concrete-filled GFRP stub tubes at Arctic low temperatures. Thin-Walled Structures, 170, 108566. DOI 10.1016/j.tws.2021.108566. [Google Scholar] [CrossRef]

47. Vincent, T., Ozbakkaloglu, T. (2015). Influence of slenderness on stress-strain behavior of concrete-filled FRP tubes: Experimental study. Journal of Composites for Construction, 19, 04014029. DOI 10.1061/(ASCE)CC.1943-5614.0000489. [Google Scholar] [CrossRef]

48. Ozbakkaloglu, T., Akin, E. (2012). Behavior of FRP-confined normal- and high-strength concrete under cyclic axial compression. Journal of Composites for Construction, 16, 451–463. DOI 10.1061/(ASCE)CC.1943-5614.0000273. [Google Scholar] [CrossRef]

49. Taherirani, M., Noroozolyaee, M., Salimian, M. S., Mostofinejad, D. (2022). Evaluation of square slender RC columns subjected to eccentric loading strengthened with longitudinal FRP sheets based on PIV analysis. Construction and Building Material, 324, 126635. DOI 10.1016/j.conbuildmat.2022.126635. [Google Scholar] [CrossRef]

50. Xiao, J. Z., Liu, H. R., Ding, T., Ma, G. W. (2021). 3D printed concrete components and structures: An overview. Sustainable Structures, 1(2), 000006. DOI 10.54113/j.sust.2021.000006. [Google Scholar] [CrossRef]

51. Huang, L., Yu, T., Wang, Z. Y., Zhang, S. S. (2020). Compressive behaviour of slender FRP-confined concrete-encased cross-shaped steel columns. Construction and Building Materials, 258, 120356. DOI 10.1016/j.conbuildmat.2020.120356. [Google Scholar] [CrossRef]

52. Wu, G., Wu, Z. S., Lu, Z. T., Ando, Y. B. (2008). Structural performance of concrete confined with hybrid FRP composites. Journal of Reinforced Plastics and Composites, 27, 1323–1348. DOI 10.1177/0731684407084989. [Google Scholar] [CrossRef]

53. Chaiyasarn, K., Hussain, Q., Joyklad, P., Rodsin, K. (2021). New hybrid basalt/E-glass FRP jacketing for enhanced confinement of recycled aggregate concrete with clay brick aggregate. Case Studies in Construction Materials, 14, e00507. DOI 10.1016/j.cscm.2021.e00507. [Google Scholar] [CrossRef]

54. Xia, Y., Xian, G. (2020). Hybrid basalt/flax fibers reinforced polymer composites and their use in confinement of concrete cylinders. Advances in Structural Engineering, 23, 941–953. DOI 10.1177/1369433219886084. [Google Scholar] [CrossRef]

55. Fanggi, B. A. L., Ozbakkaloglu, T. (2015). Behavior of hollow and concrete-filled FRP-HSC and FRP-HSC-steel composite columns subjected to concentric compression. Advances in Structural Engineering, 18, 715–738. DOI 10.1260/1369-4332.18.5.715. [Google Scholar] [CrossRef]

56. Ozbakkaloglu, T. (2015). A novel FRP–dual-grade concrete–steel composite column system. Thin-Walled Structures, 96, 295–306. DOI 10.1016/j.tws.2015.08.016. [Google Scholar] [CrossRef]

57. Zhang, B., Teng, J. G., Yu, T. (2015). Experimental behavior of hybrid FRP–concrete–steel double-skin tubular columns under combined axial compression and cyclic lateral loading. Engineering Structures, 99, 214–231. DOI 10.1016/j.engstruct.2015.05.002. [Google Scholar] [CrossRef]

58. Cao, Q., Tao, J., Wu, Z., Ma, Z. J. (2017). Behavior of FRP-steel confined concrete tubular columns made of expansive self-consolidating concrete under axial compression. Journal of Composites for Construction, 21, 04017037. DOI 10.1061/(ASCE)CC.1943-5614.0000818. [Google Scholar] [CrossRef]

59. Zhou, Y., Liu, X., Xing, F., Li, D., Wang, Y. et al. (2017). Behavior and modeling of FRP-concrete-steel double-skin tubular columns made of full lightweight aggregate concrete. Construction and Building Materials, 139, 52–63. DOI 10.1016/j.conbuildmat.2016.12.154. [Google Scholar] [CrossRef]

60. Hu, Y. M., Yu, T., Teng, J. G. (2011). FRP-confined circular concrete-filled thin steel tubes under axial compression. Journal of Composites for Construction, 15, 850–860. DOI 10.1061/(ASCE)CC.1943-5614.0000217. [Google Scholar] [CrossRef]

61. Yu, T., Lin, G., Zhang, S. S. (2016). Compressive behavior of FRP-confined concrete-encased steel columns. Composite Structures, 154, 493–506. DOI 10.1016/j.compstruct.2016.07.027. [Google Scholar] [CrossRef]

62. Xue, B., Gong, J. (2016). Study on steel reinforced concrete-filled GFRP tubular column under compression. Thin-Walled Structures, 106, 1–8. DOI 10.1016/j.tws.2016.04.023. [Google Scholar] [CrossRef]

63. Wu, Y. F., Jiang, J. F. (2013). Effective strain of FRP for confined circular concrete columns. Composite Structures, 95, 479–491. DOI 10.1016/j.compstruct.2012.08.021. [Google Scholar] [CrossRef]

64. Zakir, M., Sofi, F. A., Naqash, J. A. (2021). Compressive testing and finite element analysis-based confined concrete model for stiffened square FRP-concrete-steel double-skin tubular columns. Journal of Building Engineering, 44, 103267. DOI 10.1016/j.jobe.2021.103267. [Google Scholar] [CrossRef]

65. Ibrahim, A. M. A., Fahmy, M. F. M., Wu, Z. (2016). 3D finite element modeling of bond-controlled behavior of steel and basalt FRP-reinforced concrete square bridge columns under lateral loading. Composite Structures, 143, 33–52. DOI 10.1016/j.compstruct.2016.01.014. [Google Scholar] [CrossRef]

66. Ferrotto, M. F., Fischer, O., Cavaleri, L. (2018). A strategy for the finite element modeling of FRP-confined concrete columns subjected to preload. Engineering Structures, 173, 1054–1067. DOI 10.1016/j.engstruct.2018.07.047. [Google Scholar] [CrossRef]

67. Ismail, A. M., Fahmy, M. F. M., Wu, Z. (2017). Simulating the lateral performance of FRP-confined RC circular columns using a new eccentric-based stress-strain model. Composite Structures, 180, 88–104. DOI 10.1016/j.compstruct.2017.07.075. [Google Scholar] [CrossRef]

68. Piscesa, B., Attard, M. M., Samani, A. K. (2018). 3D finite element modeling of circular reinforced concrete columns confined with FRP using a plasticity based formulation. Composite Structures, 194, 478–493. DOI 10.1016/j.compstruct.2018.04.039. [Google Scholar] [CrossRef]

69. Mohammadi, M., Bai, Y. L., Yang, H. L., Lin, G., Dai, J. G. et al. (2022). FE modeling of non-circular LRS FRP-confined concrete columns. Composite Structures, 286, 115314. DOI 10.1016/j.compstruct.2022.115314. [Google Scholar] [CrossRef]

70. Meng, X., Zhang, D., Feng, P., Hu, N. (2021). Review on mechanical behavior of solar cells for building integrated photovoltaics. Sustainable Structures, 1(2), 000009. DOI 10.54113/j.sust.2021.000009. [Google Scholar] [CrossRef]

71. Lo, S. H., Kwan, A. K. H., Ouyang, Y., Ho, J. C. M. (2015). Finite element analysis of axially loaded FRP-confined rectangular concrete columns. Engineering Structures, 100, 253–263. DOI 10.1016/j.engstruct.2015.06.010. [Google Scholar] [CrossRef]

72. Teng, J. G., Jiang, T., Lam, L., Luo, Y. Z. (2009). Refinement of a design-oriented stress–strain model for FRP-confined concrete. Journal of Composites for Construction, 13, 269–278. DOI 10.1061/(ASCE)CC.1943-5614.0000012. [Google Scholar] [CrossRef]

73. Teng, J. G., Huang, Y. L., Lam, L., Ye, L. P. (2007). Theoretical model for fiber-reinforced polymer-confined concrete. Journal of Composites for Construction, 11, 201–210. DOI 10.1061/(ASCE)1090-0268(2007)11:2(201). [Google Scholar] [CrossRef]

74. Moran, D. A., Pantelides, C. P. (2002). Variable strain ductility ratio for fiber-reinforced polymer-confined concrete. Journal of Composites for Construction, 6, 224–232. DOI 10.1061/(ASCE)1090-0268(2002)6:4(224). [Google Scholar] [CrossRef]

75. Xiao, Q. G., Teng, J. G., Yu, T. (2010). Behavior and modeling of confined high-strength concrete. Journal of Composites for Construction, 14, 249–259. DOI 10.1061/(ASCE)CC.1943-5614.0000070. [Google Scholar] [CrossRef]

76. di Ludovico, M., Prota, A., Manfredi, G. (2010). Structural upgrade using basalt fibers for concrete confinement. Journal of Composites for Construction, 14, 541–552. DOI 10.1061/(ASCE)CC.1943-5614.0000114. [Google Scholar] [CrossRef]

77. Wang, Z., Wang, D., Smith, S. T., Lu, D. (2012). CFRP-Confined square RC columns. II: Cyclic axial compression stress-strain model. Journal of Composites for Construction, 16, 161–170. DOI 10.1061/(ASCE)CC.1943-5614.0000246. [Google Scholar] [CrossRef]

78. Gao, C., Huang, L., Yan, L., Ma, G., Xu, L. (2015). Compressive behavior of CFFT with inner steel wire mesh. Composite Structures, 133, 322–330. DOI 10.1016/j.compstruct.2015.07.075. [Google Scholar] [CrossRef]

79. Huang, L., Gao, C., Yan, L., Kasal, B., Ma, G. et al. (2016). Confinement models of GFRP-confined concrete: Statistical analysis and unified stress–strain models. Journal of Reinforced Plastics and Composites, 35, 867–891. DOI 10.1177/0731684416630609. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |