| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.021120

ARTICLE

Evaluation and Analysis of the Effect of Lignin Amelioration on Loess Collapsibility

1Key Laboratory of Loess Earthquake Engineering, China Earthquake Administration & Gansu Province, Lanzhou, 730000, China

2Department of Civil Engineering and Mechanics, Lanzhou University, Lanzhou, 730000, China

*Corresponding Authors: Yuxin Liang. Email: liangyx20@lzu.edu.cn; Qian Wang. Email: wangq0930@126.com

Received: 29 December 2021; Accepted: 01 March 2022

Abstract: The road subgrade and road surface in collapsible loess area are prone to many engineering diseases such as uneven subgrade settlement, insufficient bearing capacity of soaked foundation, collapse and instability of subgrade side slope due to the special properties of loess. As an environment-friendly, low-cost soil modifier with good adhesion and chelation properties, lignin has been considered to be used in highway subgrade construction. In order to explore the effect of lignin on loess, the compressive and collapsible properties of modified loess with different lignin contents were analyzed based on consolidation compression test. The improvement mechanism of lignin on loess collapsibility was studied by means of infiltration test and SEM test. The results show that lignin fibers can promote the agglomeration of loose particles and form a network structure in the soil particle pores, enhance the cementation strength between particles and soil skeleton, and reduce the permeability of loess. With the increase of lignin fiber content, the improvement degree of loess collapsibility shows a trend of first increasing and then decreasing. When the lignin fiber content is 2%, the effect is the best, and the improved loess collapsibility is eliminated.

Keywords: Collapsible loess; lignin; distribution characteristics of pore particles; SEM; permeability characteristics

Loess is a kind of quaternary sediments, with rich pores, loose structure, vertical joint development and varying degrees of collapsibility generally. Its color is gray yellow, brownish yellow or even brownish red, and its particle composition is mainly silt. Loess is widely distributed in Asia, Europe, North America and South America, covering an area of about 13 × 106 km2, accounting for about 9.8% of the earth’s total land area. In China, loess is mainly distributed in Gansu, Qinghai, Ningxia, Shaanxi, Shanxi and Henan provinces, covering an area of about 6.4 × 105 km2, accounting for 6.6% of China’s territory, existing high geohazard risks under rainfall, irrigation and earthquakes [1,2].

According to the “Building Standard for Collapsible Loess Area” (GB50025-2018), collapsibility of loess refers to the loess being soaked by water under a certain pressure, which results in rapid destruction of soil microstructure and significant additional subsidence deformation [3]. Literature shows that the distribution area of collapsible loess in China accounts for about 60% of the total area of loess in China, most of which is distributed in the middle reaches of the Yellow River. The formation of collapsible loess is mainly related to the weak chemical action, shallow leachate depth and little viscidity during the soil-forming process in arid and semi-arid areas. These causes lead to the formation of unstable pore structure in loess which lacks clay and chemical cement [4–8].

The collapsibility mechanism of loess is that under the action of water and external forces, the special overhead structure system of loess is damaged, pore collapse and soil particle slip, and the structure is restructured [9–11]. With the development of western China and other national strategies, the construction of infrastructure and key projects in northwest China have been increasing year by year, but collapsible loess brought great difficulties to the construction in these areas. The damage of collapsible loess to the foundation and subgrade is that its strength decreases when it meets water, and the structural stress is much greater than the actual strength of soil structure. When the external load increases, the loess will have secondary subsidence or even multiple subsidence after repeated immersion [12,13], which is usually manifested as serious engineering diseases such as uneven settlement deformation of foundation, subgrade subsidence collapse, building wall cracking or even overall inclined damage [14–17]. It has been proved by scientific research and engineering practice that the collapsible loess can be modified to improve its engineering properties and avoid the occurrence of engineering diseases effectively.

At present, the improvement methods of collapsible loess foundation and subgrade mainly include physical reinforcement and chemical improvement. The physical methods mainly include compaction and drainage depressurization. Common methods include setting plain soil or lime soil cushion, dynamic compaction and compaction pile, etc. [18]. However, the improvement effect is not obvious in the case of complicated construction and high-water content [19]. The chemical method can improve the performance of soil by chemical reaction between mineral components and additives by adding highly active additives. At present, common modifiers include cement [20], lime [21], fly ash [22], salt solution [23] and other chemicals. Although the modified loess has obvious effect, it has some defects such as environmental pollution and seasonal influence.

Following the principle of environmental friendliness and engineering applicability, many scholars have gradually adopted new materials such as lignin in the research of soil improvement in recent years. Lignin is an organic polymer in the xylem of plants with an annual output of hundreds of billions of tons. Lignin is a rich renewable energy material, but it has not been widely and effectively used at present. By studying the mechanical properties and constitutive relationship of lignin modified soil, it has been proved that lignin can effectively improve the physical and mechanical properties of soil due to its good cohesiveness, dispersion and chelation [24–26]. The compressive strength of sand samples modified with lignin was tested by unconfined compression test and triaxial shear test. The results showed that the compressive strength of sand samples modified with lignin was significantly improved, and the modification effect was the best when the content of lignin was 2%–12% [27–31]. The sand modifier based on lignin has obvious cementation ability and can effectively strengthen the surface layer of sand and improve the permeability resistance [32]. By testing dynamic shear modulus, damping ratio and other mechanical indexes, it is concluded that adding lignin can effectively improve the dynamic characteristics of silt in the Yellow River Basin, and the optimal content of lignin is 5%. Based on the principle of conservation of energy, a theoretical model was established to describe the erosion rate of silty soil after lignin curing. It was proved that lignin had obvious impact on soil improvement, and the calculated results of the model were in good agreement with the experimental results [33]. Based on a series of cyclic triaxial tests, comparing the sandy silt with and without lignin, it is concluded that lignin improves the mechanical properties of soil [34,35]. The modification mechanism of lignin modified soil is mainly that the lignin covers soil particles and fills in particle pores, improving the strength and compactness of soil. The cementation between soil particles is enhanced through ion exchange between lignin and soil [36–40].

In addition, lignin has a good improvement effect on some special soils. X-ray diffraction, Fourier transform infrared spectroscopy, scanning electron microscopy and other means were used to analyze and prove the improvement effect of lignin on the erosion resistance of clay, and a theoretical model was established to describe the mechanical properties of improved clay [41,42]. Calcium lignosulfonate and basalt fiber were used to improve expansive soil, and the test showed that the lignin-basalt fiber dosage could improve soil strength within a certain range, and the optimal dosage was 3% [43]. The effects of freezing-thawing cycles and lignin fiber content on soil mechanical properties were analyzed, and the results showed that lignin fiber improved soil had obvious advantages in resisting repeated freezing-thawing [44].

At present, the researches of lignin soil improvement mainly focuses on improving the strength of sand, silt and clay, but there are few reports on the improvement of the poor engineering properties of collapsible loess. It was determined by dynamic triaxial test and seismic subsidence test that lignin could significantly improve the liquefaction resistance and shear deformation resistance of saturated loess [45,46]. Based on soil-water character curve test and wet disintegration test, the water holding capacity and water stability of modified loess with different lignin contents were studied. The results show that the improved loess with 1%–2% lignin content has the best water holding capacity and water stability [47,48]. Therefore, based on existing research results, this paper selects the lignin as modified materials of collapsible loess. The results of the consolidation compression test are used to analyze the effect law of lignin content under different compaction condition on collapsibility of loess. The inner mechanism of the lignin to improve the loess collapsibility is discussed by supplementing penetration test and SEM test. In addition, this paper combined the experimental results with the existing research results, deepened the understanding of lignin as a soil modifier, clarified its potential in improving the poor engineering properties of collapsible loess, and provided a new idea for highway subgrade construction in loess region.

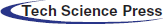

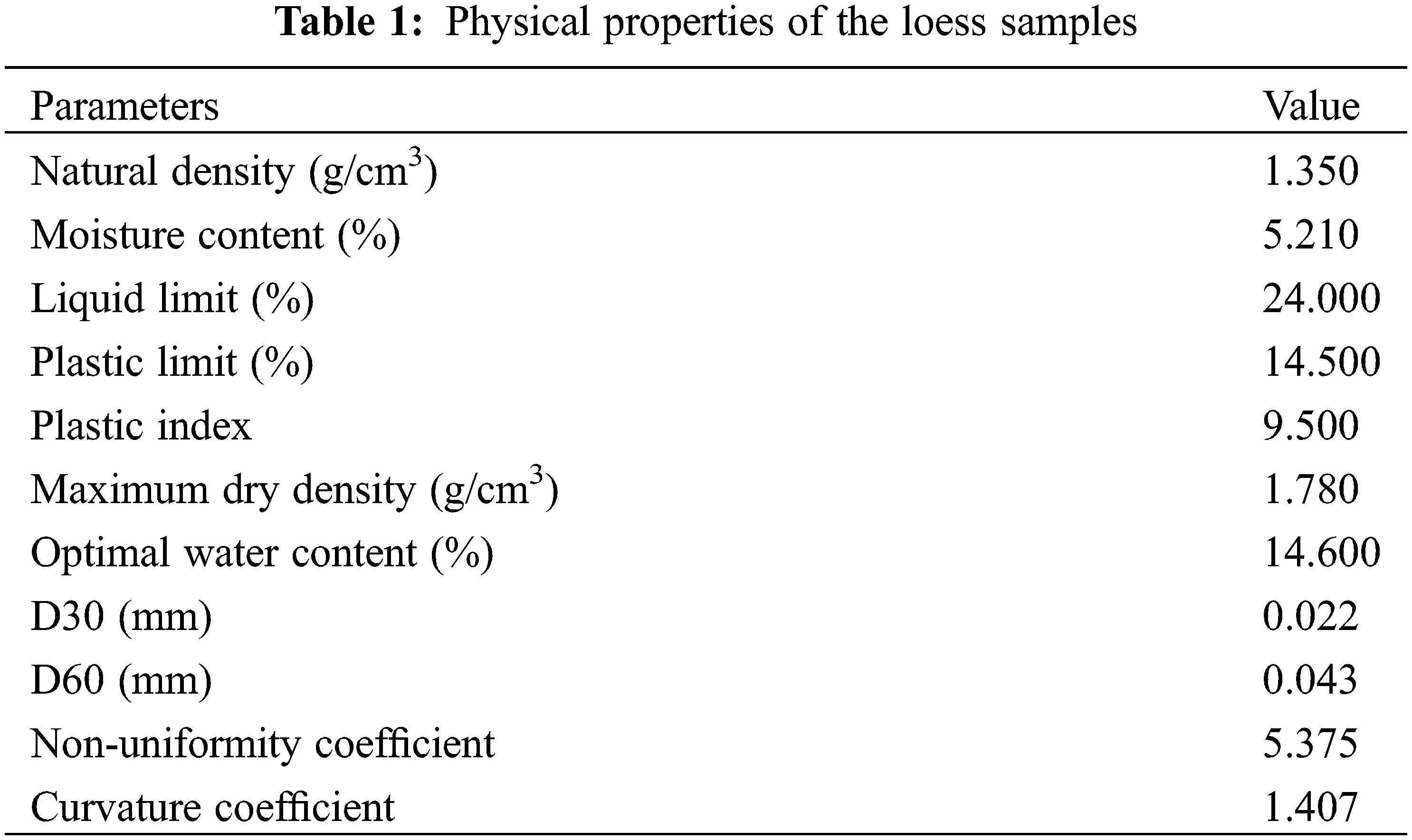

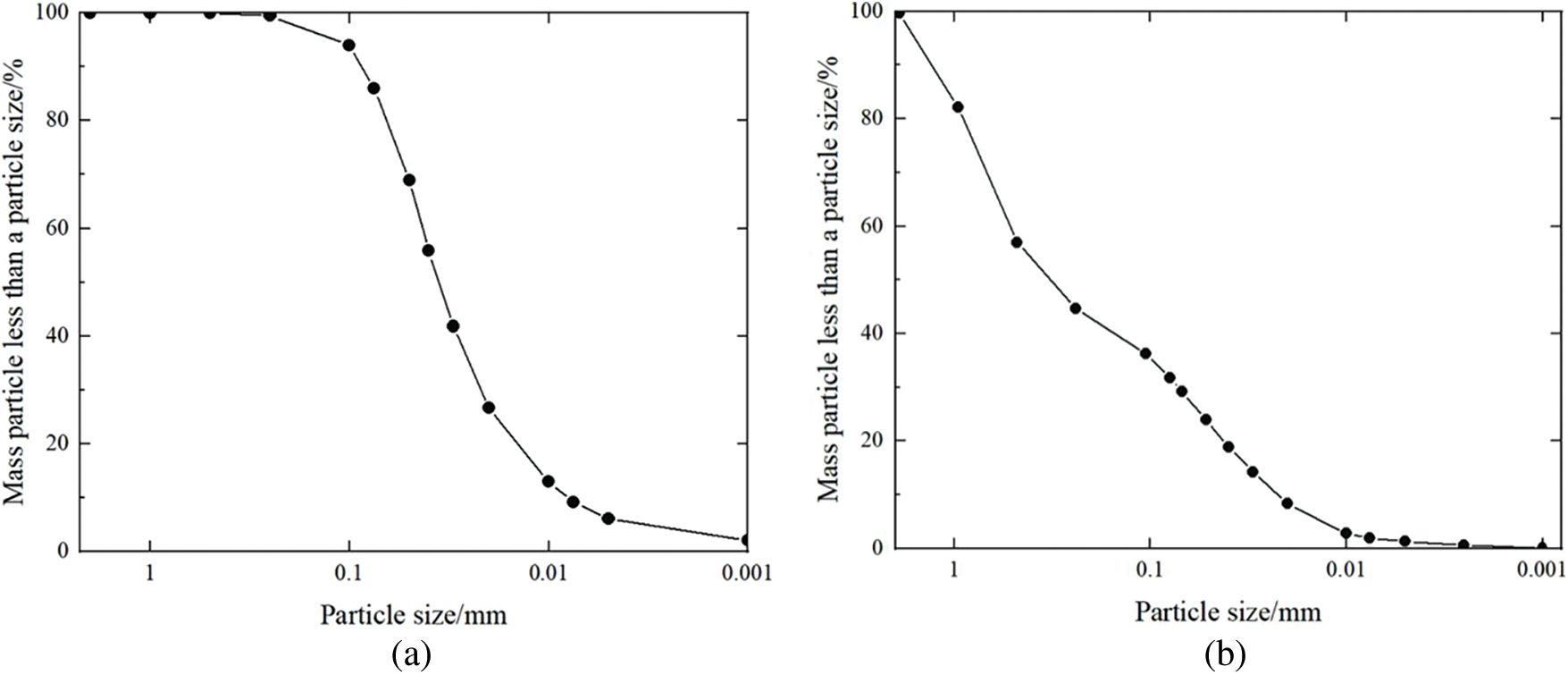

The undisturbed loess and loose loess used in the experiment were taken from Xiji County, Guyuan City, Ningxia Hui Autonomous Region (China), and the soil depth was 3 meters below the surface. Undisturbed loess was used to measure the property parameters and collapsibility of soil samples. Loose loess was used to prepare remolded soil samples. The basic physical indicators of the loess soil samples were laboratory-tested and are shown in Table 1 [49]. The maximum dry density and optimal moisture content of soil samples were determined by compaction test, which were 1.78 g/cm3 and 14.6%, respectively. The liquid limit and plastic limit of soil samples were determined by the limit moisture content test, which were 24% and 14.5%, respectively. Fig. 1 shows the particle size distribution curve of soil samples and lignin fiber measured by particle analysis test. The content of powder particles in soil samples accounted for 80.2%. Sand and clay accounted for 13.7% and 6.1%, respectively. The collapsibility coefficient of the loess soil samples was measured according to the indoor compression test stipulated in the “Building Standard for Collapsible Loess Areas” (GB 50025-2018). The test was terminated when the samples were saturated in water and settled down under the specified pressure of 200 kPa by grading loading. Finally, it is concluded from the test that the coefficient of soil collapsibility is 5.45 at 200 kPa, indicating strong collapsibility [3].

Figure 1: Particle size distribution curve: (a) Loess, (b) Lignin

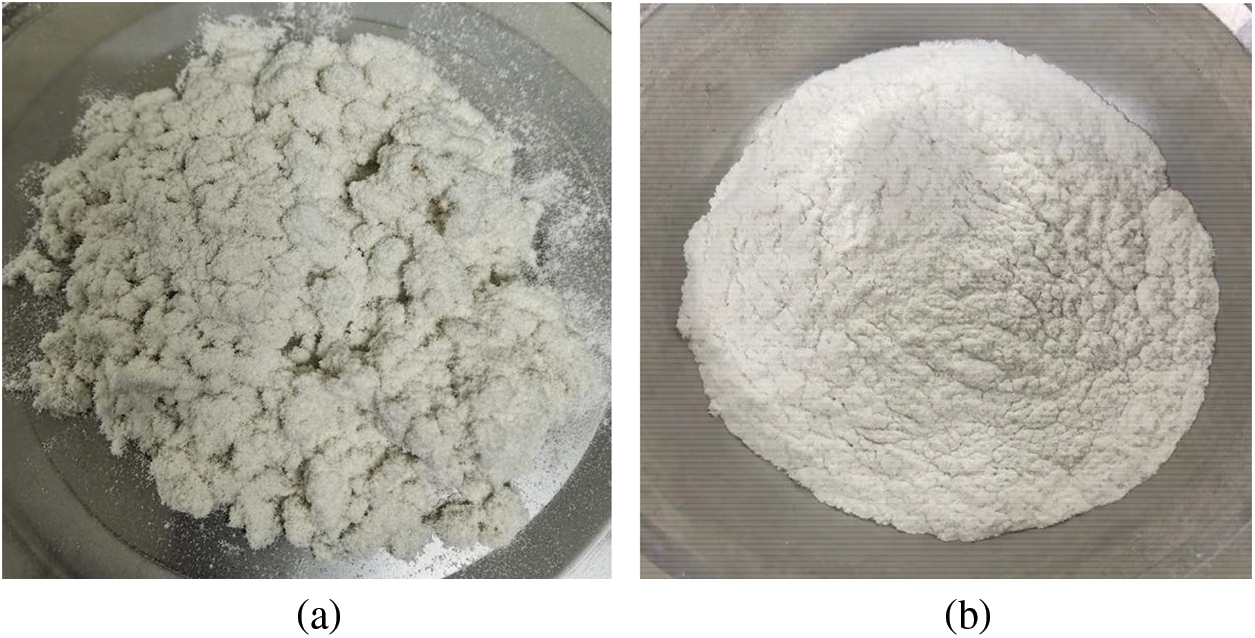

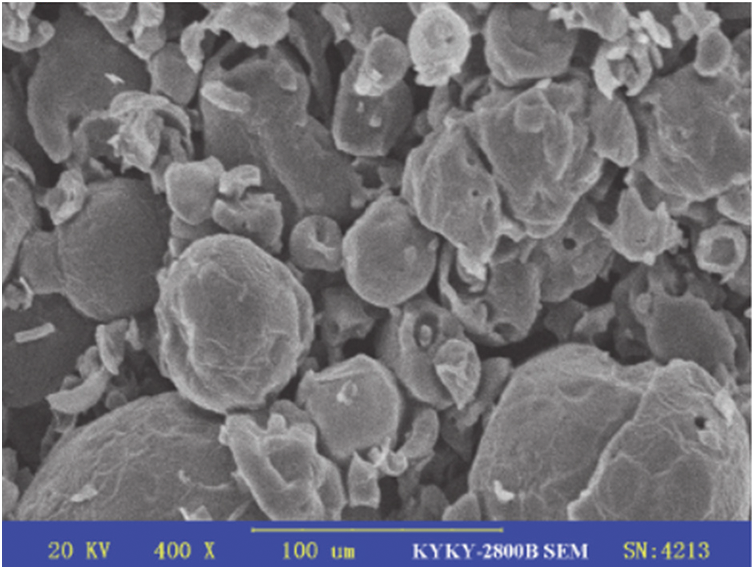

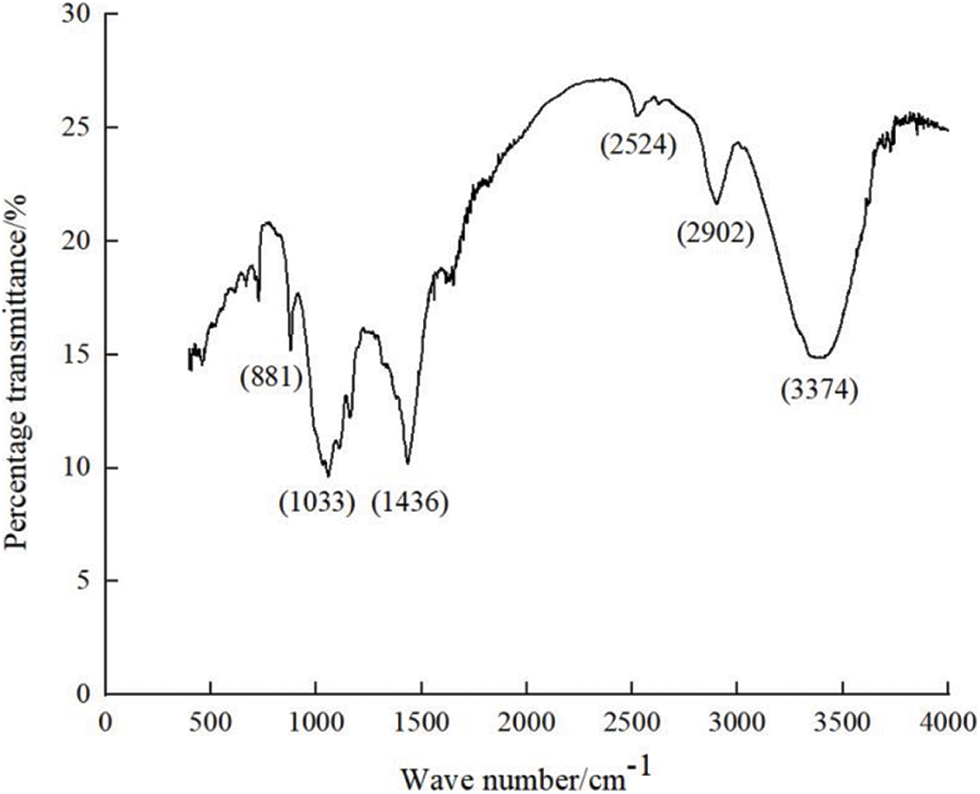

The lignin used in the test (Fig. 2) was derived from the by-product produced in the process of papermaking in a paper mill. After purification, it turned into a white floc powder with a pungent smell and good dispersity in water. Lignin fiber itself belongs to environment-friendly natural organic matter and can be used in environmental pollution prevention and control projects [50]. Studies have shown that, through XRD analysis, no new mineral components were generated in the soil after adding lignin, and lignin did not significantly change the pH of the soil, so lignin does not react with the original mineral components in the soil [51,52]. Scanning electron microscopy (Fig. 3) showed that the microparticle composition of this lignin was mainly powder particles. Fourier transform infrared spectroscopy (FTIR) was used to analyze the chemical composition and molecular structure of lignin. The test results are shown in Fig. 4.

Figure 2: Lignin: (a) Lignin before screening, (b) Lignin after screening

Figure 3: Microstructure of the lignin based on SEM test

Figure 4: Image of lignin infrared spectrum analysis

Liu et al. studied the water holding capacity and water stability of modified loess with different lignin contents, and the research results showed that the modified loess with 1%–2% lignin content had higher strength and the strongest water holding capacity [47,53]. In addition, the loess used in this study and the loess used in the above study were taken from Xiji County, Ningxia Hui Autonomous Region, China. Thus, the loess properties are basically the same. Therefore, on the basis of the above research results, the remolded loess soil samples used in the experiment in this paper were set with 4 kinds of lignin dosages (0%, 1%, 2%, 3%) according to the mass ratio of lignin to loess. According to the subgrade compactness corresponding to different highway technology grades specified in “Highway Engineering Technical Standard” (JT GB01-2014), 0.85 and 0.90 were selected as the initial compactness of the samples prepared in this test [54].

The sample preparation method is as follows: In order to ensure the improved loess sample has good uniformity, the required mass of loose loess is naturally air-dried and screened by 2 mm. According to the set lignin dosage ratio, the corresponding quality of lignin was weighed and put into a 2 mm sieve, a small amount of it was repeatedly sieved into the dry loess and mixed evenly, and then the corresponding quality of distilled water was added to the optimal moisture content of the soil sample. After being added into the previously uniform dry mixed soil and fully mixed again, the soil mixture was put into the sealed plastic bag and stood for 24 h. After the water diffuses fully in the mixed soil sample, the improved cylindrical loess sample with preset moisture content and compacting degree was prepared by using the sample preparation mold (Fig. 5) with static pressure at both ends. The sample size is ф 80 mm × 40 mm (Fig. 6). The prepared soil samples were wrapped with plastic wrap and placed in a standard curing environment (temperature 20°C ± 2°C, relative humidity ≥ 95%) for 28 d, and reserved for subsequent tests [47,53].

Figure 5: Sample preparation machine

Figure 6: Cylindrical soil sample

2.3.1 Consolidation Compression Test

The purpose of the loess collapsibility test is to analyze the effect of different lignin contents on loess collapsibility by measuring the relationship between the collapsibility deformation and the pressure.

The instrument used in the test was WG-1B medium pressure triple consolidation instrument (Fig. 7). The test process was carried out according to the provisions of the collapsibility test in “The Standard for Geotechnical Test Methods” (GB/T 50123-2019). After the sample preparation and installation met the standards, the consolidation compression test was carried out by the double-lines method. Compared with the single-line method, the double-lines method has the advantage of being able to measure the deformation of the modified loess samples under different pressure levels, and has the advantages of simple operation, less samples and less workload. Two samples of modified loess soil with each lignin content were prepared. A sample is pressurized step by step at a preset moisture content to a specified flooding pressure. When applying the first stage of pressure, the deformation reading shall be taken every 1 h according to the pressure grade. After the specimen deformation is stabilized, the second stage pressure is applied, and so on. As the depth of the original obtained loess is less than 10 meters from the surface, the pressure levels are set as 25, 50, 100, 150, and 200 kPa [49]. After the deformation of the sample is stabilized under the specified immersion pressure of 200 kPa, pure water is injected into the container of the consolidation instrument from top to bottom, and water injection is stopped when the water surface is higher than the top surface of the sample. The deformation reading is measured every 1 h until the deformation of the sample is stabilized. The other sample is soaked after applying the first stage pressure at a preset moisture content. After the deformation of soil sample is stabilized under the first stage pressure, the graded pressure is applied. The deformation readings at all levels of pressure were recorded after the sample was immersed in water and stabilized.

Figure 7: Medium pressure triplex consolidation instrument

The purpose of loess permeability test is to analyze the seepage characteristics of saturated compacted loess modified with lignin by using loess samples with different compacted degrees and different lignin contents.

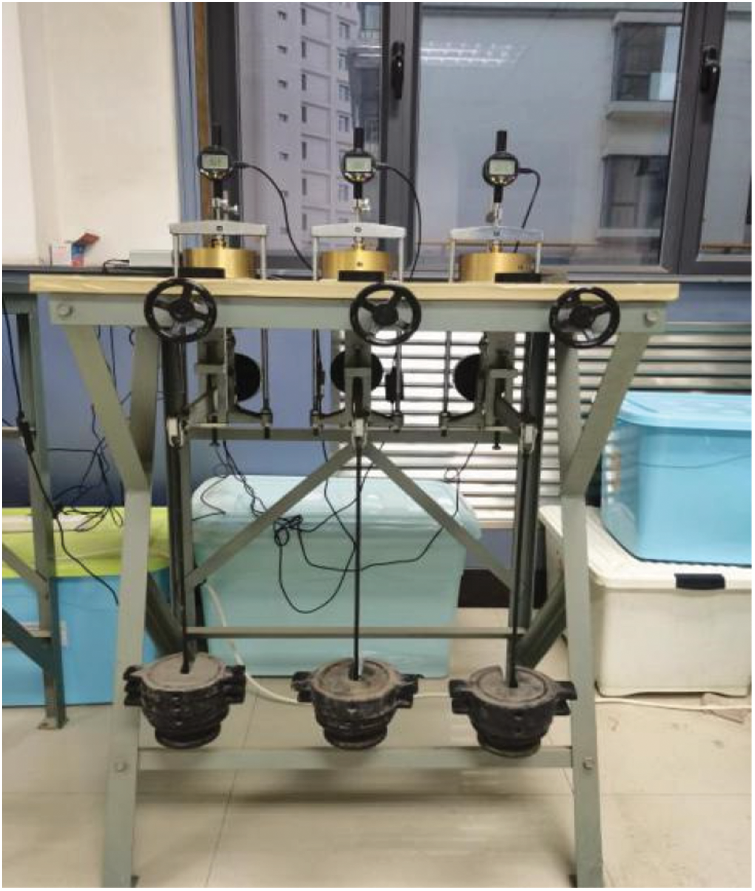

As the modified loess is fine grained soil, variable waterhead permeability method was adopted in the test [55]. The instrument used in the experiment was TST-55 permeameter (Fig. 8). Before the test begun, the sample was saturated from the bottom by using the water head method. When the water was outlet at the top of the permeometer overflows, the soil sample was considered to be saturated as required by the test. The test procedure was carried out in accordance with the provisions of the variable waterhead penetration test in “The Standard for Geotechnical Test Methods” (GB/T50123-2019), and a reading was recorded every half an hour, including the start waterhead and the end waterhead. In order to reduce the error and ensure the reliability of data, three repeated readings of each sample were recorded as a group of tests. Finally, the average value was taken as the permeability coefficient of the sample [49].

Figure 8: TST-55 permeameter

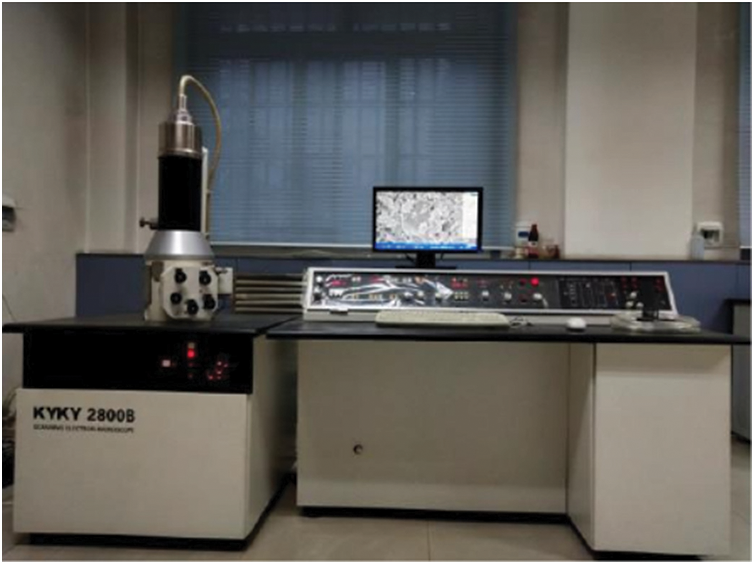

2.3.3 Scanning Electron Microscope Test

By scanning electron microscopy (SEM), the distribution characteristics of particles and pores of modified loess with different lignin contents can be reflected, and the internal mechanism of lignin improving loess collapsibility can be revealed. KYKY-2800B scanning electron microscope was used in the experiment (Fig. 9). During the test, vacuum freeze-drying method was adopted for the sample before drying, and then fresh sections were taken from the sample to prepare slices with an area of about 1 cm2 and a thickness of 2 mm (Fig. 10). In order to make the thin section sample surface conductive and able to reflect secondary imaging, the prepared thin section sample should be sprayed with gold in ion sputtering apparatus. During the scanning electron microscopy test, the instrument voltage was set at 20 kV, and two magnifications of 100 and 500 times were selected to facilitate the observation of the overall morphology and microscopic structure of the sample. After the focal length of the image was adjusted clearly, it could be simulated to take photos. The loess with 0.85 compaction degree and the modified loess with the optimal lignin content obtained by consolidation compression test were selected.

Figure 9: KYKY-2800B scanning electron microscope

Figure 10: Scanning electron microscope sample

3.1 Consolidation and Compression Properties of Loess Improved by Lignin

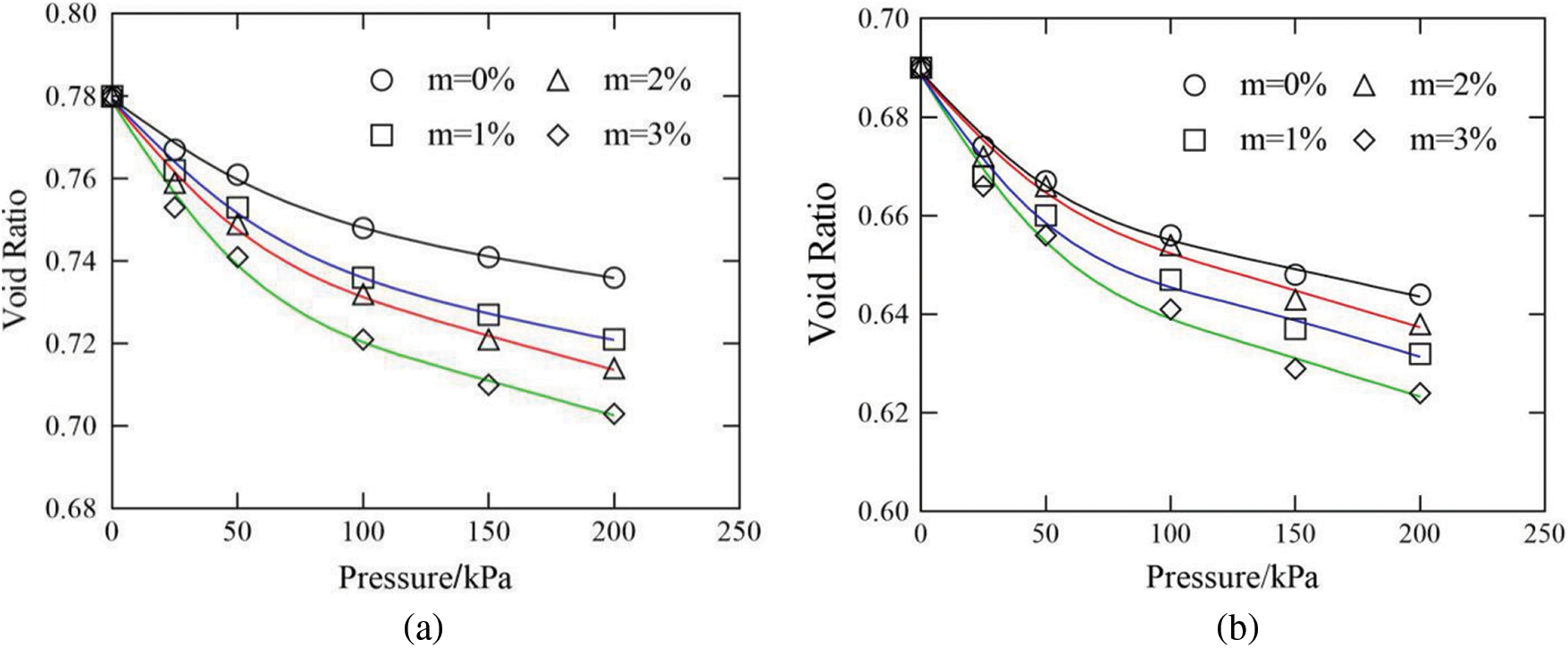

Based on the results of consolidation compression test, Fig. 11 shows the e-p curves of modified loess with different lignin contents under two initial compaction degrees of 0.85 and 0.90 (“m” in the figure refers to lignin content). To facilitate comparison of test results, 0.85 and 0.90 compactness refer to the compactness of plain loess. It can be seen from the figure that the e-p curves of plain loess and lignin-modified loess are basically the same, that is, the consolidation pressure is negatively correlated with the soil void ratio. With the increase of consolidation pressure, the higher the compactness of soil sample is, the smaller the compressible space of soil sample is, and the compression coefficient of soil sample decreases continuously. The slope of the e-p curve represents the compressibility of soil at different pressure section. With the increase of lignin content, the slope of the corresponding curve increases gradually with the same vertical stress, and the effect of lignin on compressibility of soil is gradually significant. In addition, the void ratio of lignin modified soil sample is less than that of plain soil sample under the same pressure level. With the increase of lignin content, the void ratio decreases continuously.

Figure 11: The void ratio-pressure curve (e-p curve) of consolidation compression test specimen, (a) e-p curve of sample with 0.85 compactness; (b) e-p curve of sample with 0.90 compactness

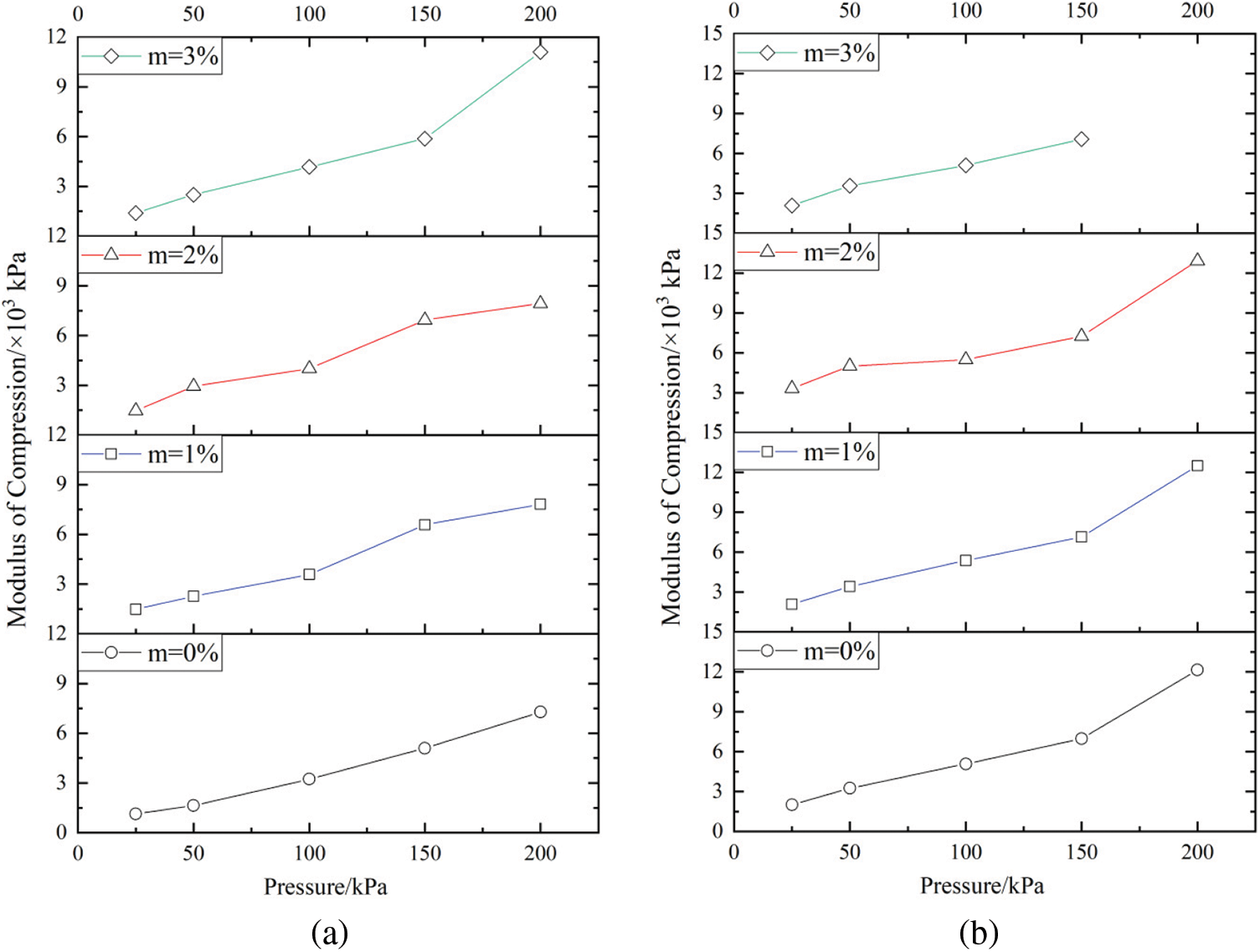

Fig. 12 shows the curves of compressive modulus of modified loess with different lignin contents as a function of vertical stress under initial compaction degree of 0.85 and 0.90 respectively after immersion. In this figure, the effect of lignin on soil compressibility is more intuitive. As a compressibility index of soil, compression modulus directly reflects the compressibility of soil. Under the same degree of compaction, the compressive modulus of soil is positively correlated with the vertical stress. When the compaction degree is 0.85, the compression modulus of lignin modified loess samples increases significantly compared with plain soil samples under the same vertical stress. The compressive modulus of plain soil sample and modified loess sample with 1%, 2% and 3% lignin content under standard stress (200 kPa) are 7.28 × 103, 7.81 × 103, 7.94 × 103 and 11.11 × 103 (kPa), respectively. When the compaction degree is 0.90, the compression modulus of lignin modified loess is generally larger than that of plain loess under the same vertical stress, but the increase is not obvious. The compression modulus of the sample with the same lignin content increases with the increase of the compaction degree. The reason for the above experimental results is that the addition of lignin plays a wrapping role on soil particles and effectively fills the pores between soil particles. Besides, its favorable cohesiveness weakens the fluidity of soil particles, increases the compression modulus of soil and makes the soil sample more difficult to compress.

Figure 12: The compression moduli-pressure curve (Es-p curve), (a) Es-p curve of sample with 0.85 compactness; (b) Es-p curve of sample with 0.90 compactness

3.2 Collapsibility of Loess Improved by Lignin

The collapsibility coefficient is an important index to characterize the collapsibility of loess. It reflects the water sensitivity of loess, and the initial pressure of collapsibility can be determined according to the collapsibility coefficient.

The calculation formula of the collapsibility coefficient is as follows:

δs is the collapsibility coefficient; hp is the height which the soil sample with natural humidity is stabilized after being pressurized to a certain value;

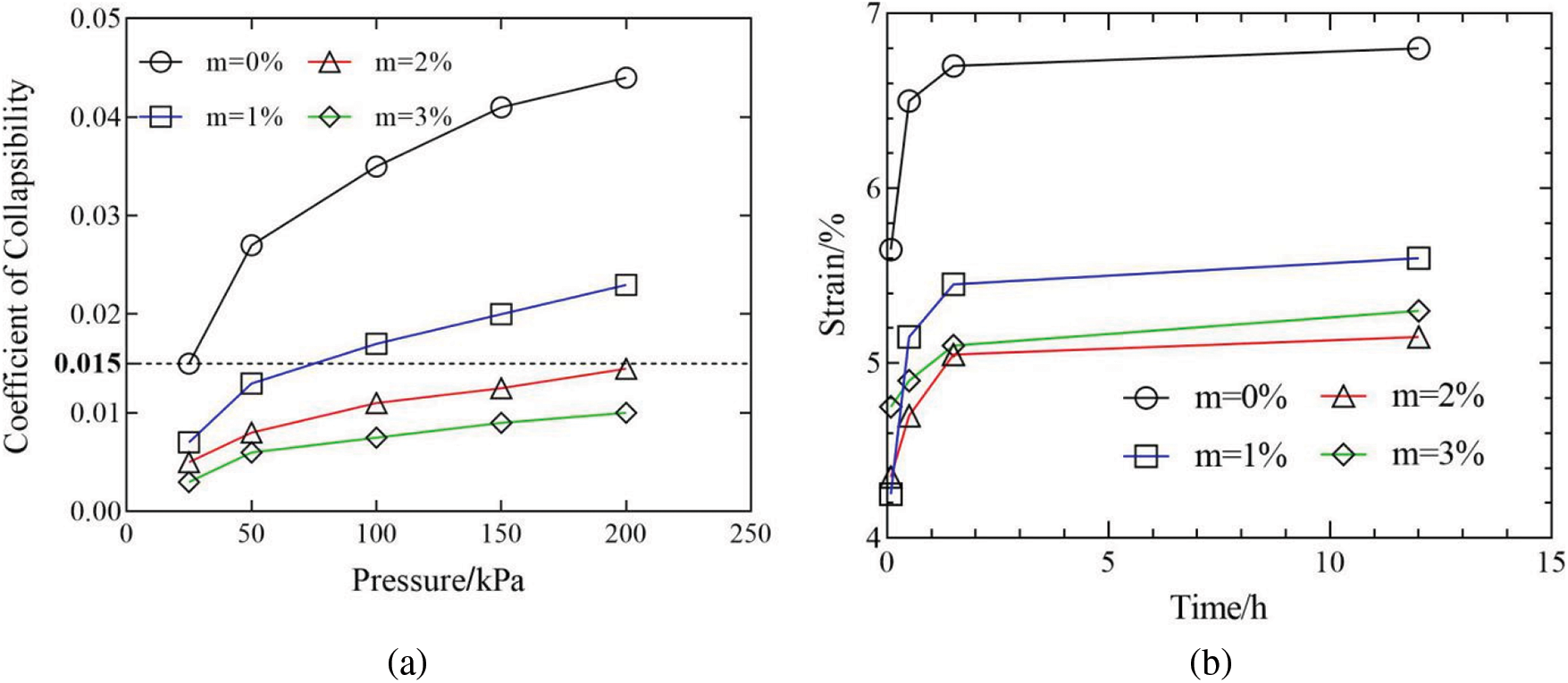

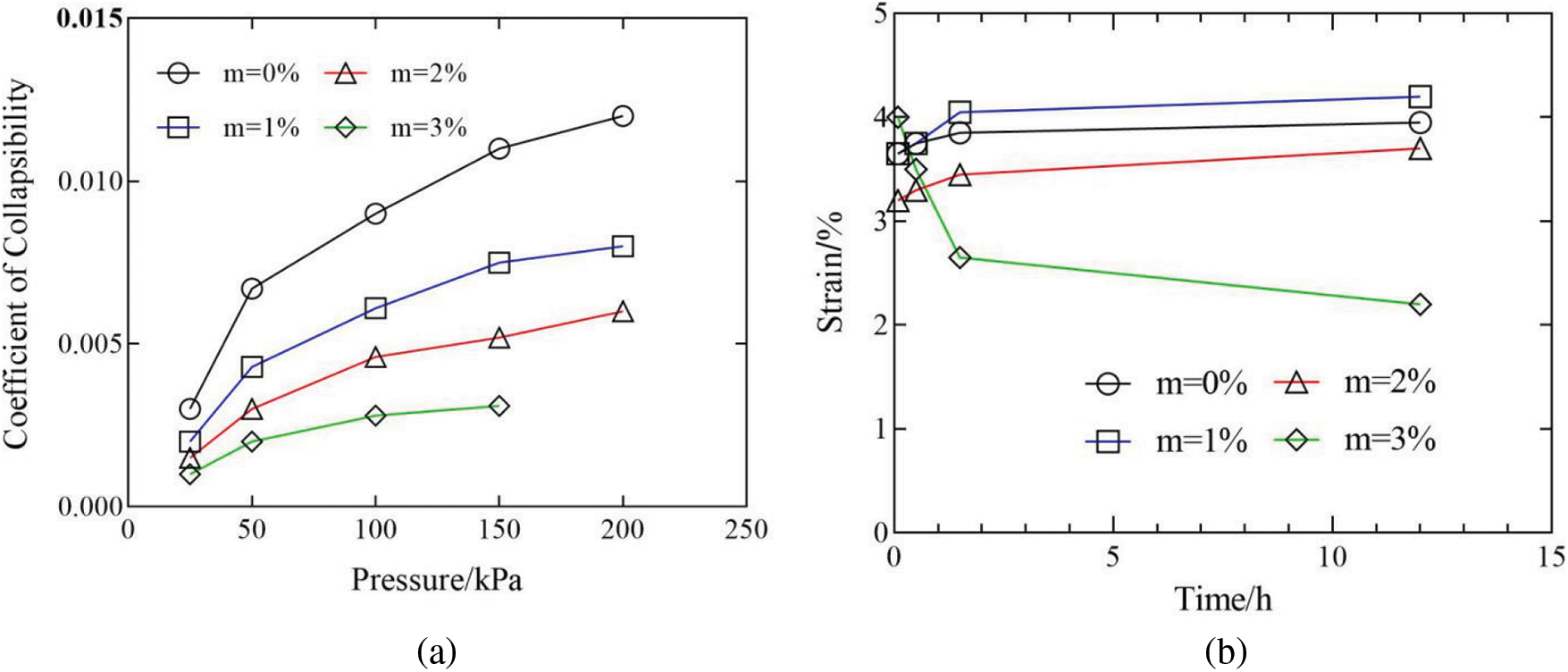

When the consolidation pressure increases to a certain value and the soil sample is saturated with water, the total deformation of the soil sample includes compression deformation and subsidence deformation. Therefore, collapsibility coefficient-vertical stress curve and strain-time curve of modified loess samples with different lignin contents under 0.85 and 0.90 compaction degree were drawn according to the deformation amount of samples with dry and wet lines under different pressure levels in the two-lines consolidation compression test (Figs. 13 and 14).

Figure 13: Collapsibility characteristic curve of sample with 0.85 compactness, (a) collapsibility coefficient-vertical stress curve, (b) strain-time curve

Figure 14: Collapsibility characteristic curve of sample with 0.90 compactness, (a) collapsibility coefficient-vertical stress curve; (b) strain-time curve

It can be seen from Fig. 13a that the collapsibility coefficient of each sample with initial compacting degree of 0.85 rises rapidly in the whole process during compression to 200 kPa after immersion. This indicates that the collapsibility deformation of the sample is obvious. With the increasing of lignin content, the collapsibility coefficient at all pressure levels decreases, and the steepness of the collapsibility coeffect-vertical stress curve gradually decreases. The initial pressure of the collapsibility coefficient of 0.015 gradually increases, indicating that the addition of lignin has a significant effect on loess collapsibility. Combined with Fig. 13b, it can be seen that under the standard pressure (200 kPa), loess samples with different lignin contents have obvious deformation within 1.5 h after soaking, among which, the plain soil sample has the largest deformation and the sample with 2% lignin content has the smallest deformation. As time goes on, the deformation continues but very slowly. Finally, the collapsible deformation stabilized after 12h immersion. The corresponding subsidence coefficients of samples with 0%, 1%, 2% and 3% lignin content are 0.044, 0.023, 0.014 and 0.010, respectively. According to the collapsible loess collapsibility evaluation stipulated in “Building Standard for Collapsible Loess Areas” (GB 50025-2018), the loess is judged as the collapsible loess when the collapsible coefficient is greater than or equal to 0.015, and the non-collapsible loess is judged as the collapsible coefficient is less than 0.015 [3]. Therefore, compared with the plain loess sample, the collapsibility of the sample with 1% lignin content is not eliminated although the collapsibility of the sample decreases. However, the collapsibility coefficients of samples with 2% and 3% lignin content are all less than 0.015. In this case, lignin has a better effect on loess collapsibility, and loess collapsibility is basically eliminated.

It can be seen from Fig. 14a that the collapsibility coefficient of each sample with an initial compacting degree of 0.90 changes slowly with the increase of vertical pressure. At the same pressure level, with the increase of lignin content, the collapsibility coefficient also presents a decreasing trend. Among them, the collapsibility coefficient of plain soil sample is 0.012 under 200 kPa standard pressure. This indicates that the plain soil sample has no collapsibility without lignin. The reason is that the original elevated structure of loess is completely destroyed under high pressure compaction, and plain soil sample has been fully compressed. Therefore, structural damage and collapsibility deformation are not likely to occur after saturated water [56]. It is worth noting that Fig. 14b reflects that the modified loess sample with 3% lignin content under 0.90 compaction degree experienced slight subsidence deformation within 5 min after soaking under 200 kPa standard pressure, followed by rapid expansion, and the expansion deformation tends to be stable after 12 h.

3.3 Infiltration Characteristics of Loess Improved by Lignin

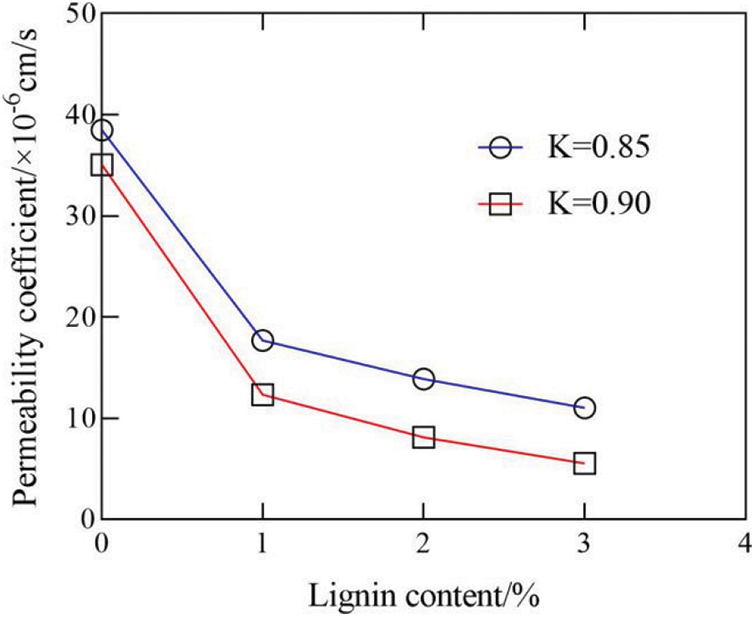

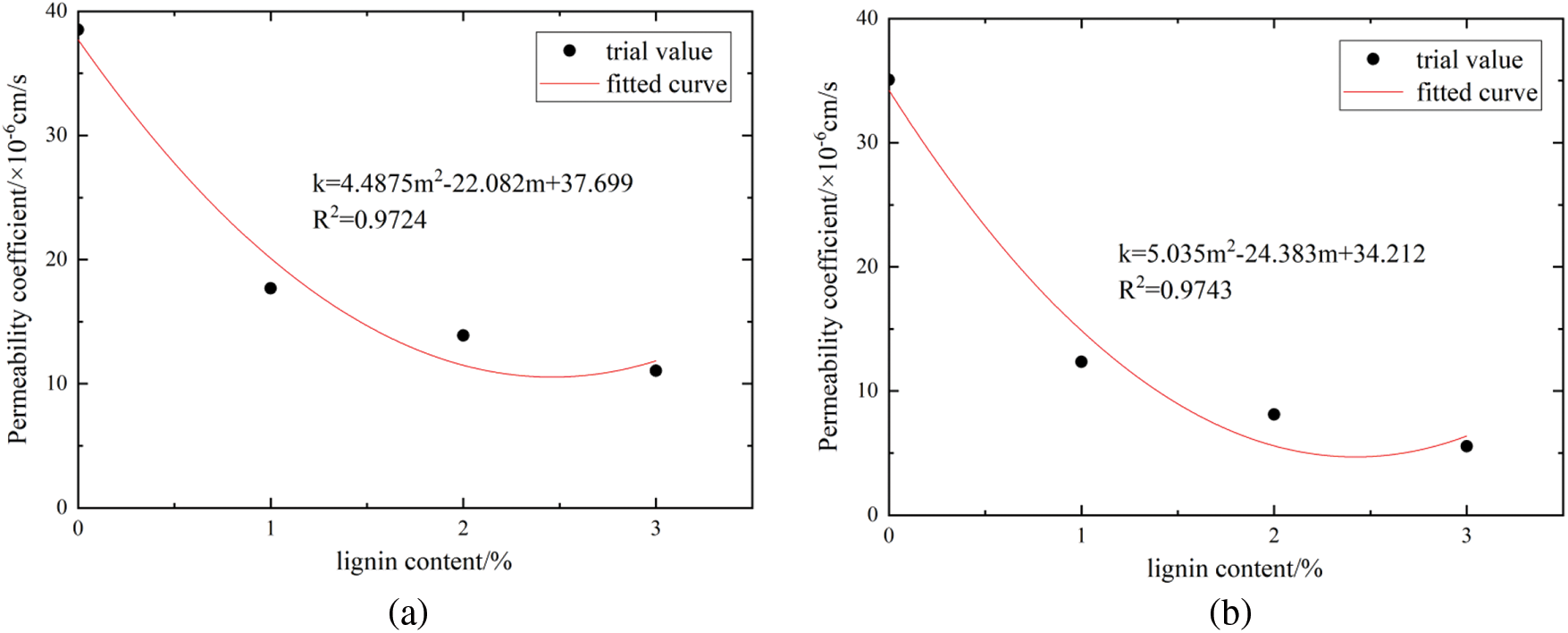

The saturated permeability coefficient of modified loess samples with different lignin contents was measured by indoor variable waterhead permeability test under the condition of 0.85 and 0.90 compactivity respectively. The relationship between the saturated permeability coefficient of modified loess with lignin content was obtained, as shown in Fig. 15 (“K” in the figure refers to the degree of compaction).

Figure 15: Relationship curve of permeability coefficient-lignin incorporation amount

Fig. 15 shows that, at the same degree of compaction, the saturated permeability coefficient of water-saturated lignin modified loess samples are lower than that of plain soil samples, and the corresponding saturated permeability coefficient decreases monotonically in a piecewise manner with the increase of lignin content. Taking the sample with 0.85 compactness as an example, the saturated permeability coefficient of the modified loess sample with 1% lignin content decreases by 54% compared with the plain soil sample. The higher the lignin content is, the slower the decrease trend of saturated permeability coefficient becomes, and the difference between the collapsibility coefficient of modified loess samples with 2% and 3% lignin content is only 2.85 × 10−6. In addition, the comparison between two curves shows that the corresponding saturated permeability coefficient decreases with the increase of soil compaction degree under the same lignin content. The saturated permeability coefficient decreases between 30% and 50% at different lignin dosage. In addition, combined with Figs. 13b and 14b, it can also be concluded that under the same external force, the saturated deformation of modified loess containing lignin tends to stay stabilization faster after soaking.

According to Figs. 11–14, soil samples with 1% lignin content under the condition of 0.85 compactness have improved but not eliminated loess collapsibility compared with plain soil samples. When the compaction degree is 0.90, the sample with 3% lignin content is soaked in water at the standard pressure of 200 kPa. The reason for this phenomenon is that the limited intergranular pores of the modified soil sample with high density lignin content are fully filled by the rapidly expanding lignin fibers after contacting water. In addition, if the lignin content is too large, the lignin will give priority to combine with themselves and unable to effectively reinforce the soil mass. Also, too much lignin fiber may lead to the loess particles partially separate from each other. While the cohesive force of soil increased, the friction has fallen sharply, which reduces the intensity of soil [57]. The above is the macro performance of the expansion deformation of foundation soil. In turn, uneven settlement of buildings will lead to cracks and tilt, which is not conducive to the construction. Although the addition of lignin can mitigate the collapsibility of loess, the effectiveness is not greater with the continuous increase of lignin content. However, at 200 kPa standard pressure, the collapsibility coefficients of the two modified loess with 2% lignin content are 0.014 and 0.006, respectively, which are both less than 0.015. There is no expansion deformation occurring after saturating with water, which effectively eliminated the collapsibility of the loess. Thus, 2% lignin content is the optimal selection. In addition, compared with plain loess, the collapsibility of modified loess with lower compactness has a larger decreasing trend, which has better effectiveness on eliminating the collapsibility of loess.

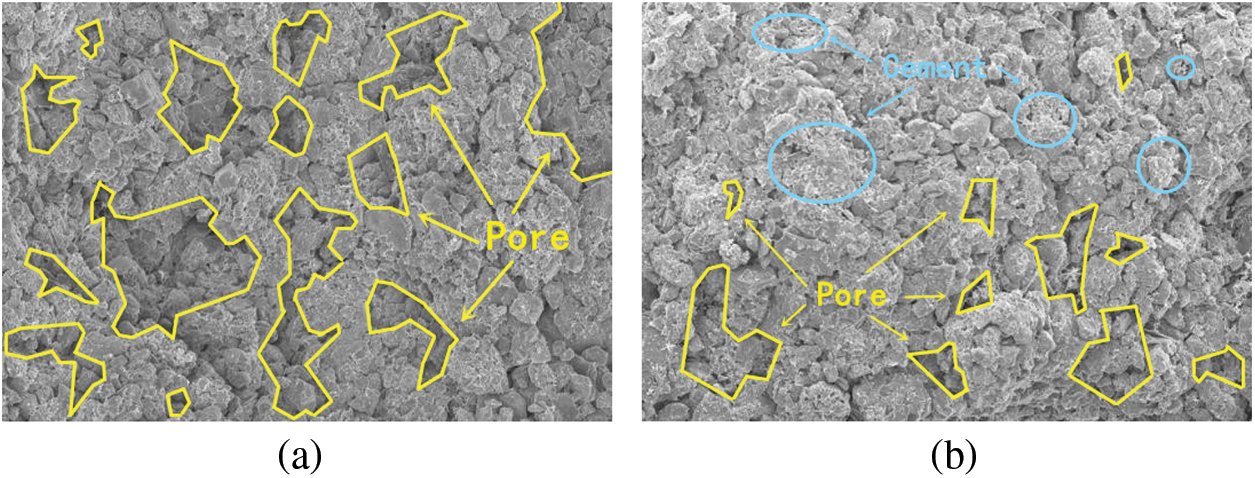

By comparing the 100 times SEM images of the plain loess sample with the modified loess sample (Fig. 16), it can be seen that the plain loess sample has been reshaped and compressed, but there are still many pores and fine loose particles in the soil structure, and the connection between particles is not close enough. After adding lignin, the porosity of modified loess has decreased obviously, and the cement between grains has increased significantly.

Figure 16: SEM image magnified 100 times, (a) 100X-Lignin content 0%; (b) 100X-Lignin content 2%

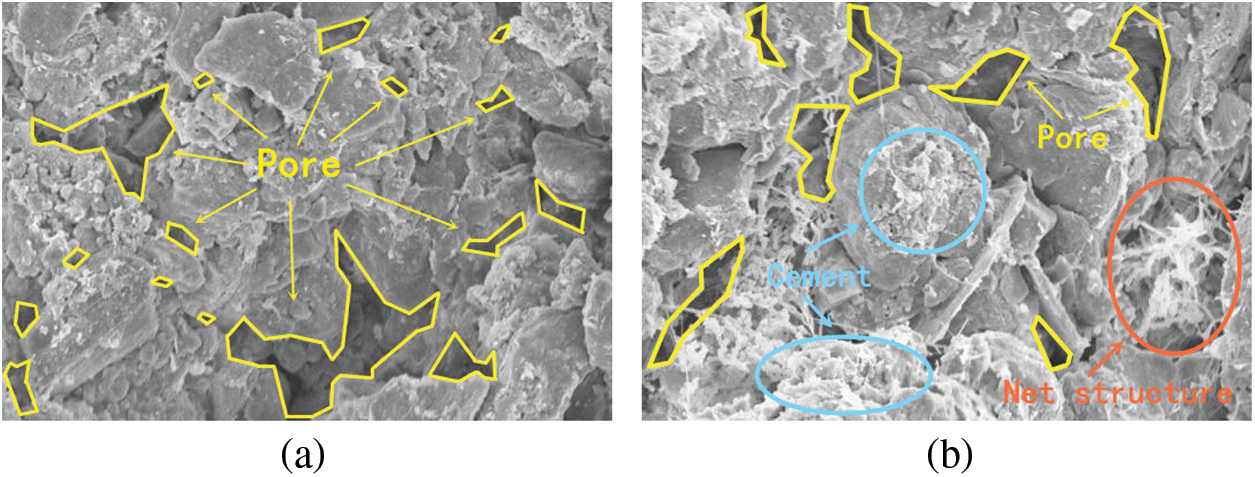

In the SEM image of 500 times magnification (Fig. 17), skeleton particle morphology, arrangement and connection mode of the sample can be observed more clearly. According to Fig. 17a, the structure type of plain soil sample is Mosaic structure. There are many large and medium pores between grains, and the connection between grains is mainly lap connection. Some small particles can be observed attaching to large particles, and the content of intergranular cement is little, showing a flocculent structure. According to the Fig. 17b, pore between particles of modified loess samples is medium and small given priority to. Granular or spherical lignin fibers between the soil particle pore gather themselves together and form a “network”. The amount of flocculent cement has significantly increased, and the soil structure is changed from mosaic structure to a massive cementation structure, where the effective contact area between the particles is increased. Therefore, the cementation between soil particles and the strength of soil skeleton are enhanced. And the observed results are basically consistent with the changes in microstructure observed by Zhang et al. in the study of lignin-cured silty sand [58].

Figure 17: SEM image magnified 500 times, (a) 500X-Lignin content 0%; (b) 500X-Lignin content 2%

In addition, other studies have shown that hydrophobic groups such as carbon and hydrogen atoms in lignin can wrap loess particles to improve the water stability of loess, and there will be no chemical reaction after mixing lignin and loess. Compared with compaction loess, lignin modified mineral composition of compacted loess, which appears only a small amount of calcite and dolomite, because of sodium ion in the lignin and calcium ion in loess exchanged. At the same time, this kind of ion exchange facilitates loess particles and lignin fiber bonding together. Thus, the cementation strength of soil particles could be improved [56]. Through the chemical index determination of lignin in the improved soil, it can be found that hydrophobic groups in the lignin, composed of carbon and hydrogen atoms, form oil layer between soil particles. And the layer destroys the adsorbed water film between the soil particles, which improve the intergranular adsorption force. At the same time, hydrophobic groups are able to package the loess particles to improve the water stability of loess [59,60].

According to the principle of effective stress, under the condition of the invariant vertical stress, the collapsible loess soak in water, which results in the increase of soil saturation and decrease of the matrix suction in the soil at the same time. The overall shows a trend of decrease of soil effective stress. In the micro point of view, water flow penetration between particles weaken cementation between particles, leading to soil structure damage and loss of strength. Finally, the soil will have subsidence deformation [61]. When the humidity or overburden pressure of loess increases, the loess is likely to have multiple collapsible deformation. The reason for this phenomenon is that the hydraulic coupling effect cannot completely eliminate the collapsibility of loess, and the potential collapsibility of loess is sometimes not reflected in the dry environment or low pressure state. It can be seen that permeability directly affects the generation and development of collapsibility, so permeability and collapsibility are two parts of a unified process.

Based on the measured data obtained in the permeability test, the relationship between permeability coefficient and lignin content in Fig. 15 was fitted, and the fitting formula was obtained as follows:

In the formula, k is the permeability coefficient, M is the lignin content, a, b, c are fitting parameters respectively. It can be seen from Fig. 18 that the correlation coefficients of the experimental value and the theoretical value under the conditions of 0.85 and 0.90 compacting degree are 0.9724 and 0.9743, respectively, both greater than 0.95. It indicates that the change of permeability coefficient with lignin content is in line with the polynomial relationship obtained by fitting, that is, with the increase of lignin content, the permeability coefficient of the improved loess decreases first and then increases, and the minimum value occurs between 2% and 3%. With the increasing degree of compaction, the initial hydraulic gradient of seepage will appear after the compaction loess is soaked, and the initial hydraulic gradient must be overcome before seepage may occur [62]. Based on the Fourier infrared spectrum experiment, after loess is mixed, lignin is qualitative with secondary alcohol hydroxyl oxygen by hydrolysis. This prompts neutralization between positive charge of lignin fibers and negative charge on the surface of the soil particles, which enhance the adsorption effect of electric double layer, making the soil particle spacing decreases and the soil structure more compact [31]. Combined with the coefficient of permeability changing with lignin content of fitting model (Fig. 18), overhead structure in the body has been damaged after penetrating water. A new secondary Mosaic structure is gradually formed with humidifying slip, and the addition of lignin is equivalent to increase the soil compaction degree. Compared with the same degree of compaction of loess, the permeability coefficient decreases gradually with the increase of dosage of lignin. This reflects its permeability is constantly weakening. It is difficult for seepage to occur after immersion, so the infiltration and consolidation of soil is limited under the action of water flow, and the soil subsidence deformation is reduced and the collapsibility is improved. Therefore, when lignin modified loess is saturated with water and then compressed again, its saturated deformation will be significantly reduced, greatly reducing the risk of secondary and multiple collapse [63]. This is consistent with Alaoui’s conclusion that the saturated permeability coefficient of soil has a positive exponential relationship with porosity [64]. In addition, the fitting model still has some defects. The errors in sample preparation before the test, the sparse gradient of lignin content in the test, and the errors in data collection after the test all affect the accuracy of the fitting model.

Figure 18: Fitting curve of permeability coefficient with lignin content, (a) Fitting curve of 0.85 compactness; (b) Fitting curve of 0.90 compactness

Although lignin itself does not have any toxic substances, but it comes from industrial by-products, in the process of industrial separation may remain some heavy metal ions. As a roadbed modifier, it may be infiltration with rain, causing hidden dangers to the surrounding environment and groundwater. However, some studies have shown that the soil quality of the subgrade silt modified by lignin after 8 d and 15 d curing meets the soil environmental quality standards [65]. Overall, lignin is applied in the loess area highway roadbed filler modified with good economic and social benefits. It not only can effectively improve the engineering properties of loess, but also its moisture absorption performance can reduce the moisture loss of subgrade filling at the beginning of the maintenance to a certain extent. This could enhance the capacity of the soil moisture, so lignin is a kind of soil modifier of wide application prospect.

In conclusion, lignin can improve the collapsibility of loess through pore filling, cementing anchorage, ion exchange and adsorption of hydrophobic groups.

In this paper, the collapsibility, permeability and microstructure characteristics of lignin fiber modified loess were analyzed. According to the test results, the following conclusions were drawn:

(1) Different lignin contents can improve loess collapsibility to a certain extent, and the improvement effect is more obvious under the condition of relatively lower compactness. Finally, it is concluded that the modified loess with 2% lignin content can eliminate loess collapsibility under the conditions of 0.85 and 0.90 compactness, which is the optimal proportion.

(2) The addition of lignin reduces the permeability of soil and makes the loess rapidly stabilize in the process of gradual saturation after soaking in water, and the collapsibility deformation is significantly reduced, which effectively reduces the risk of repeated collapsibility of loess.

(3) Through the observation of scanning electron microscopy (SEM) images can be found that lignin fiber filling pore between soil particles, which can effectively improve the cementation between soil particles, and can be generated in the loess particle pore mesh structure, the structure of the bond anchorage effect can significantly improve the strength of the soil skeleton, macro embodied in physical and mechanical properties of loess.

Acknowledgement: Authors are grateful for the support provided by Master students Fuqiang Liu and Chao Cheng who provided useful suggestion for the data processing and analyzing of this work.

Funding Statement: This work was funded under Funding of Science for Earthquake Resilience (Grant No. XH21034), the Special Fund for Innovation Team, Gansu Earthquake Agency (Grant No. 2020TD-01-01), and the grant of the National Natural Science Foundation of China (Nos. 51778590, 51408567), the Fundamental Research Funding for the Institute of Earthquake Forecasting, China Earthquake Administration (Grant Nos. 2021IESLZ03, 2018IESLZ06).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Wang, L. M. (2003). Loess dynamics. Beijing: Seismological Press. [Google Scholar]

2. Ma, H. P., Wu, Y. Q., Feng, J. G. (2019). Crustal movement characteristics in the northeastern region of the qinghai-tibet plateau based on GPS reference station. IOP Conference Series: Earth and Environmental Science, pp. 384012209. Beijing China. [Google Scholar]

3. National Standards Writing Group of the People’s Republic of China (2018). Building Standard for Collapsible Loess Areas. Beijing: China Architecture and Architecture Press. [Google Scholar]

4. Smalley, I., Obreht, I. (2018). The formation of loess ground by the process of loessification: A history of the concept. Geologos, 24(2), 163–170. DOI 10.2478/logos-2018-0015. [Google Scholar] [CrossRef]

5. Liu, D. S. (1985). Loess and environment. Beijing: Science Press. [Google Scholar]

6. Liu, Z., Liu, F. Y., Ma, F. L., Wang, M., Bai, X. H. et al. (2016). Collapsibility, composition, and microstructure of loess in China. Canadian Geotechnical Journal, 53(4), 673–686. DOI 10.1139/cgj-2015-0285. [Google Scholar] [CrossRef]

7. Liu, X. L., Zhang, M. S., Zhang, H., Jia, Y. G., Zhu, C. Q. et al. (2017). Physical and mechanical properties of loess discharged from the yellow river into the Bohai sea. Engineering Geology, 227, 4–11. DOI 10.1016/j.enggeo.2017.04.019. [Google Scholar] [CrossRef]

8. Wang, L. Q., Shao, S. J., She, F. T. (2020). A new method for evaluating loess collapsibility and its application. Engineering Geology, 264, 105376. DOI 10.1016/j.enggeo.2019.105376. [Google Scholar] [CrossRef]

9. Wei, Y. N. (2019). Three dimensional microstructure evolution and collapsibility mechanism of loess under water action (Master Thesis). Xi’an: Chang’an University. [Google Scholar]

10. Wang, L., Li, X. A., Li, L. C., Hong, B., Yao, W. et al. (2020). Characterization of the collapsible mechanisms of malan loess on the Chinese loess plateau and their effects on eroded loess landforms. Human and Ecological Risk Assessment: An International Journal, 26(9), 2541–2566. DOI 10.1080/10807039.2020.1721265. [Google Scholar] [CrossRef]

11. Zhang, X. Z., Lu, Y. D., Li, X., Lu, Y. C., Pan, W. S. (2019). Microscopic structure changes of malan loess after humidification in south jingyang plateau. Environmental Earth Sciences, 10(78), 1–12. DOI 10.1007/s12665-019-8290-4. [Google Scholar] [CrossRef]

12. Wang, H. M., Ni, W. K., Yuan, K. Z., Li, L., Nie, Y. P. et al. (2021). Microstructure evolution of loess under multiple collapsibility based on nuclear magnetic resonance and scanning electron microscopy. Journal of Mountain Science, 18(10), 2612–2625. DOI 10.1007/s11629-021-6838-8. [Google Scholar] [CrossRef]

13. Wang, Q., Ma, W., Zhang, Z., Zhao, S. P., Li, G. Y. et al. (2013). Effects of freeze-thaw cycles on secondary collapsibility of loess. Journal of Glaciology and Geocryology, 35(2), 376–382. DOI 10.7522/j.issn.1000-0240.2013.0045. [Google Scholar] [CrossRef]

14. Luo, Y. S. (2008). Treatment of collapsible loess foundation. Beijing: China Architecture and Architecture Press. [Google Scholar]

15. Li, H. F. (2020). Study on roadbed diseases and prevention in loess region. Engineering and Technological Research, 5(17), 166–167. DOI 10.19537/j.cnki.2096-2789.2020.17.075. [Google Scholar] [CrossRef]

16. Li, Y. W. (2001). Research on roadbed disease analysis and prevention countermeasures in loess region (Master Thesis). Xi’an: Chang’an University. [Google Scholar]

17. Chen, X. J. (2004). Main types and analysis and evaluation of geological hazards in loess tunnel engineering (Master Thesis). Xi’an: Chang’an University. [Google Scholar]

18. Xu, Y. B., Sun, Y. F. (2012). The selection of the collapsible loess foundation treatment methods. Applied Mechanics and Materials, 170, 331–334. DOI 10.4028/www.scientific.net/AMM.170-173.331. [Google Scholar] [CrossRef]

19. Mu, Y. Q., Dang, Y. J., Dong, Q., Liao, H. J., Dong, H. (2019). Comparative experimental study on water retention and collapsibility of undisturbed and compacted loess. Journal of Geotechnical Engineering, 41(8), 1496–1504. DOI 10.11779/CJGE201908014. [Google Scholar] [CrossRef]

20. Zhou, M. R., Chen, Z. C., Luo, X. B., Zhou, G. K., Lu, C. G. (2017). Reinforcement mechanism of cement grout in collapsible loess. Journal of Building Science and Engineering, 34(6), 65–70. DOI 10.3969/j.issn.1673-2049.2017.06.009. [Google Scholar] [CrossRef]

21. Zhou, J. J., Liang, S. Y., Zhang, F. Y., Wu, W. J., Yan, X. D. (2014). Experimental study on engineering properties of lime modified loess. Railway Engineering, (9), 105–108. DOI 10.3969/j.issn.1003-1995.2014.09.29. [Google Scholar] [CrossRef]

22. Gao, Z. L., Liu, J. X., Wei, H. B., Chang, S. J. (2007). The influence of fly ash on engineering properties of collapsibility loess. Journal of North China University of Technology, 19(1), 91–94. DOI 10.3969/j.issn.1001-5477.2007.01.020. [Google Scholar] [CrossRef]

23. Wang, Y. M., Gao, L. C. (2012). Experimental study on chemical improvement of loess. Journal of Engineering Geology, 20(6), 1071–1077. DOI 10.3969/j.issn.1004-9665.2012.06.022. [Google Scholar] [CrossRef]

24. Jiang, T. D. (2008). Lignin. Beijing: Chemical Industry Press. [Google Scholar]

25. Henri, B., Marielle, C., Bernard, M., Brigitte, P., Catherine, L. (1997). Lignin structure in buxus sempervirens reaction wood. Phytochemistry, 44(1), 35–39. DOI 10.1016/S0031-9422(96)00499-2. [Google Scholar] [CrossRef]

26. Ysbrandy, R. E., Sanderson, R. D., Gerischer, G. F. R. (1992). The physical properties of laminates made with phenolated lignin novolacs. Holzforschung, 46(3), 249–252. DOI 10.1515/hfsg.1992.46.3.249. [Google Scholar] [CrossRef]

27. Puppala, A. J., Hanchanloet, S. (1999). Evaluation of a new chemical stabilization method on physical and strength properties of cohesive soils. Washington DC: Transportation Research Board. [Google Scholar]

28. Tingle, J. S., Santoni, R. L. (2003). Stabilization of clay soils with nontraditional additives. Transportation Research Board, 1819, 72–84. DOI 10.3141/1819b-10. [Google Scholar] [CrossRef]

29. Cai, G. J., Zhang, T., Liu, S. Y., Li, J. H., Jie, D. B. (2016). Stabilization mechanism and effect evaluation of stabilized silt with lignin based on laboratory data. Mar. Georesour. Geotechnol, 34(4), 331–340. DOI 10.1080/1064119X.2014.966217. [Google Scholar] [CrossRef]

30. Zhang, T., Liu, S. Y., Cai, G. J., Anand, J. P. (2015). Experimental investigation of thermal and mechanical properties of lignin treated silt. Engineering Geology, 196, 1–11. DOI 10.1016/j.enggeo.2015.07.003. [Google Scholar] [CrossRef]

31. Hou, X., Ma, W., Li, G. Y., Mu, Y. H., Zhou, Z. W. et al. (2017). Influence of lignosulfonate on mechanical properties of lanzhou loess. Eng. Geol, 38(2), 18–26. DOI 10.16285/j.rsm.2017.S2.003. [Google Scholar] [CrossRef]

32. Shulga, G., Rekner, F., Varslavan, J. (2001). Lignin-based interpolymer complexes as a novel adhesive for protection against erosion of sandy soil. Journal of Agricultural Engineering Research, 78(3), 309–316. DOI 10.1006/jaer.2000.0599. [Google Scholar] [CrossRef]

33. Zhang, J. W., Han, Y., Wang, X. J., Bian, H. L. (2021). Experimental investigation of the dynamic characteristics of treated silt using lignin: Case study of yellow river flood basin. International Journal of Geomechanics, 21(5), 1–11. DOI 10.1061/(ASCE)GM.1943-5622.0002018. [Google Scholar] [CrossRef]

34. Indraratna, B., Athukorala, R., Vinod, J. (2013). Estimating the rate of erosion of a silty sand treated with lignosulfonate. Journal of Geotechnical and Geoenvironmental Engineering, 139(5), 701–714. DOI 10.1061/(ASCE)GT.1943-5606.0000766. [Google Scholar] [CrossRef]

35. Chen, Q. S., Indraratna, B. (2015). Deformation behavior of lignosulfonate-treated sandy silt under cyclic loading. Journal of Geotechnical and Geoenvironmental Engineering, 141(1), 1–5. DOI 10.1061/(ASCE)GT.1943-5606.0001210. [Google Scholar] [CrossRef]

36. Palmer, J. T., Edgar, T. V., Boresi, A. P. (1995). Strength and density modification of unpaved road soils due to chemical additives. Laramie, WY: University of Wyoming. [Google Scholar]

37. Blanck, G., Cuisinier, Q., Masrouri, F. (2014). Soil treatment with organic non-traditional additives for the improvement of earthworks. Acta Geotech, 9(6), 1111–1122. DOI 10.1007/s11440-013-0251-6. [Google Scholar] [CrossRef]

38. Liu, S. Y., Zhang, T., Cai, G. J., Li, J. H., Jie, D. B. (2014). Research progress of soil stabilization with lignin from bio-energy by-products. Journal of Traffic and Transportation Engineering, 27(8), 1–10. DOI 10.19721/j.cnki.1001-7372.2014.08.001. [Google Scholar] [CrossRef]

39. Wang, Q., Zhong, X. M., Ma, H. P., Wang, S. Y., Liu, Z. Z. et al. (2020). Microstructure and reinforcement mechanism of lignin-modified loess. Journal of Materials in Civil Engineering, 11(32), 1–14. DOI 10.1061/(ASCE)MT.1943-5533.0003422. [Google Scholar] [CrossRef]

40. Zhu, F., Li, J. Y., Jiang, W. H., Zhang, S., Dong, W. Z. (2021). Freeze-thaw performance of silt sand treated with lignin. Advances in Civil Engineering, 2021,1–10. DOI 10.1155/2021/6639268. [Google Scholar] [CrossRef]

41. Vinod, J. S., Indraratna, B., Mahamud, M. A. A. (2010). Stabilisation of an erodible soil using a chemical admixture. Proceedings of the ICE: Ground Improvement, 163(1), 43–51. DOI 10.1680/grim.2010.163.1.43. [Google Scholar] [CrossRef]

42. Alazigha, D. P., Vinod, J. S., Indraratna, B., Heitor, A. (2018). Mechanisms of stabilization of expansive soil with lignosulfonate admixture. Transportation Geotechnics, 14,81–92. DOI 10.1016/j.trgeo.2017.11.001. [Google Scholar] [CrossRef]

43. Li, J. R. (2021). Experimental study on engineering properties of lignin-basalt fiber modified expansive soil (Master Thesis). Mianyang: Southwest University of Science and Technology. [Google Scholar]

44. Chen, C., Guo, W., Ren, Y. X. (2020). Properties and microstructure analysis of lignin fiber modified soil under freeze-thaw cycles. Journal of Geotechnical Engineering, 42(S2), 135–140. DOI 10.11779/CJGE2020S2024. [Google Scholar] [CrossRef]

45. Liu, W., Wang, Q., Lin, G. C., Tian, X. X. (2021). Variations of suction and suction stress of unsaturated loess due to changes in lignin content and sample preparation method. Journal of Mountain Science, 18(8), 2168–2183. DOI 10.1007/s11629-020-6028-0. [Google Scholar] [CrossRef]

46. Liu, W., Wang, J., Lin, G. C., Wen, L., Wang, Q. (2019). Microscopic mechanism affecting shear strength in lignin-treated loess samples. Advances in Materials Science and Engineering, 2019(3), 1–12. DOI 10.1155/2019/7126040. [Google Scholar] [CrossRef]

47. Liu, Z. Z., Wang, Q., Zhong, X. M., Liu, F. Q., Liang, S. Y. et al. (2020). Water retention and stability of loess improved by lignin. Chinese Journal of Rock Mechanics and Engineering, 39(12), 2582–2592. DOI 10.13722/j.cnki.jrme.2020.0416. [Google Scholar] [CrossRef]

48. Wang, Q., Liu, Z. Z., Zhong, X. M., Gao, Z. N., Liu, F. Q. (2021). Dynamic elastic modulus and damping ratio of lignin-modified loess. Journal of Renewable Materials, 9(3), 523–540. DOI 10.32604/jrm.2021.014114. [Google Scholar] [CrossRef]

49. National Standards Writing Group of the People’s Republic of China (2019). GB/T 50123-2019 Standard for Geotechnical Test Methods. Beijing: China Planning Press. [Google Scholar]

50. Zhang, Z. Y., Mu, H. Z., Huang, Y. C., Liu, C. (2006). Application of lignin and its modifiers in environmental pollution control. Journal of Agro-Environment Science, S1, 360–364. DOI 10.3321/j.issn:1672-2043.2006.z1.084. [Google Scholar] [CrossRef]

51. Indraratna, B., Muttuvel, T., Khabbaz, H., Armstrong, R. (2008). Predicting the erosion rate of chemically treated soil using a process simulation apparatus for internal crack erosion. Journal of Geotechnical and Geoenvironmental Engineering, 141(1), 837–844. DOI 10.1061/(ASCE)1090-0241(2008)134:6(837). [Google Scholar] [CrossRef]

52. Zhang, C., Yang, Q. W., Huang, J. (2019). Lignin with and without polymerization for soil stabilization. Journal of Materials in Civil Engineering, 31(12), 1–11. DOI 10.1061/(ASCE)MT.1943-5533.0002935. [Google Scholar] [CrossRef]

53. Liu, Z. Z. (2020). Study on mechanical properties and reinforcement mechanism of loess improved by lignin (Master Thesis). Lanzhou: Lanzhou University. [Google Scholar]

54. National Standards Writing Group of the People’s Republic of China (2014). JTG B01-2014 Highway Engineering Standard Specifications. Beijing: China Communications Press. [Google Scholar]

55. Ma, Y. W., Chen, W. W., Bi, J., Guo, G. H., Jiao, D. G. (2018). Effect of dry density on soil permeability of loess. Journal of Geotechnical Engineering, 40(S1), 165–170. DOI 10.11779/CJGE2018S1027. [Google Scholar] [CrossRef]

56. Zhang, Y., Hu, Z. Q., Chen, H., Li, B., Song, Z. Y. (2018). Experimental study on structural improvement of loess by acidic solution. Journal of Geotechnical Engineering, 40(4), 681–688. DOI 10.11779/CJGE201804012. [Google Scholar] [CrossRef]

57. Wang, J. E., Mi, J. T., Zheng, J. (2010). Experimental study on solidification of loess by lignin sand-fixing agent. Yellow River, 32(12), 170–171. DOI 10.3969/j.issn.1000-1379.2010.12.071. [Google Scholar] [CrossRef]

58. Zhang, T., Cai, G. J., Liu, S. Y. (2018). Reclaimed lignin-stabilized silty soil: Undrained shear strength, atterberg limits, and microstructure characteristics. Journal of Materials in Civil Engineering, 30(11), 1–9. DOI 10.1061/(ASCE)MT.1943-5533.0002492. [Google Scholar] [CrossRef]

59. He, Z. Q. (2015). Study on the influencing factors and mechanism of soil reinforcement by biological soil curing agent (Master Thesis). Xi’an: Northwest Agriculture & Forestry University. [Google Scholar]

60. He, Z. Q., Fan, H. H., Wang, J. Q., Liu, G., Wang, Z. N. et al. (2017). Experimental study on engineering performance of loess reinforced by lignin. Rock and Soil Mechanics, 38(3), 731–739. DOI 10.16285/j.rsm.2017.03.015. [Google Scholar] [CrossRef]

61. Yuan, Z. X., Wang, L. M. (2009). Collapsibility and seismic settlement of loess. Engineering Geology, 105(1), 119–123. DOI 10.1016/j.enggeo.2008.12.002. [Google Scholar] [CrossRef]

62. Li, H., Zhang, Y. M., Xu, H., Zheng, G. Y., Lu, X. Y. et al. (2012). A constitutive model for collapsible loess material: I analytic formulation. Advanced Materials Research, 511, 117–121. DOI 10.4028/www.scientific.net/AMR.511.117. [Google Scholar] [CrossRef]

63. Zhang, Y., Hu, Z. Q., Chen, H., Xue, T. (2018). Experimental investigation of the behavior of collapsible loess treated with the acid-addition pre-soaking method. KSEC Journal of Civil Engineering, 22(11), 4373–4384. DOI 10.1007/s12205-017-0170-4. [Google Scholar] [CrossRef]

64. Alaoui, A., Lipiec, J., Gerke, H. H. (2011). A review of the changes in the soil pore system due to soil deformation: A hydrodynamic perspective. Soil & Tillage Research, 115, 1–15. DOI 10.1016/j.still.2011.06.002. [Google Scholar] [CrossRef]

65. Liu, S. Y., Zhang, T., Cai, G. J. (2018). Industrial waste lignin modified silt roadbed solidification technology and application. China Journal of Highway and Transport, 31(3), 1–11. DOI 10.19721/j.cnki.1001-7372.2018.03.001. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |