Open Access

Open Access

ARTICLE

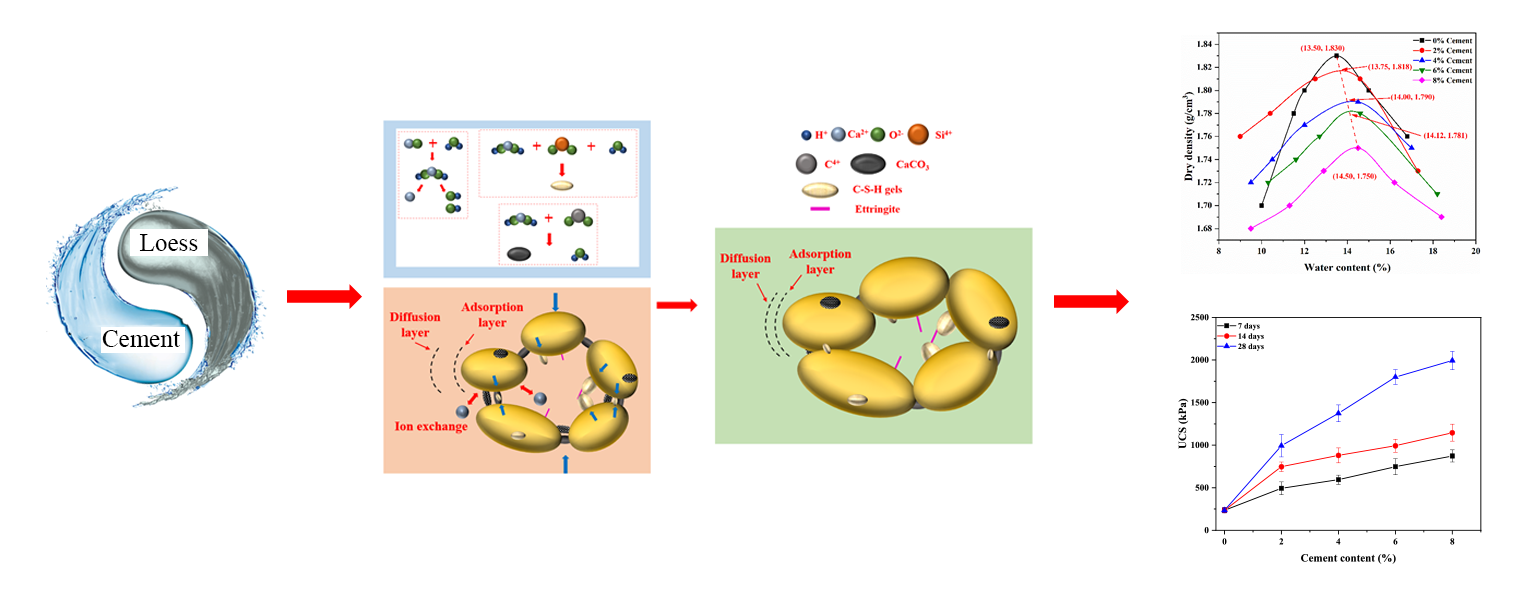

Mechanical Properties and Evolution of Microstructure of Cement Stabilized Loess

1

College of Geological Engineering and Geomatics, Chang’an University, Xi’an, China

2

China Information Industry Engineering Investigation and Research Institute, Xi’an, China

3

School of Civil Engineering, Chang’an University, Xi’an, China

* Corresponding Author: Kui Liu. Email:

Journal of Renewable Materials 2022, 10(12), 3611-3627. https://doi.org/10.32604/jrm.2022.022458

Received 10 March 2022; Accepted 08 April 2022; Issue published 14 July 2022

Abstract

Cement Stabilized Loess (CSL) sample has a long history as a method of improving building foundations. In this paper, the main physical (specific gravity, consistency limit, optimum moisture content, and maximum dry density) and mechanical properties (Unconfined Compressive Strength (UCS) and shear strength parameters) of CSL samples with different cement content were investigated, and the change reasons were explored by mean of SEM test. Meanwhile, quantitative analysis software Image-Pro Plus (IPP) 6.0 was used to characterize the microstructural evolution of pores in compacted loess and CSL sample. As the cement content increased, the specific gravity and optimum water content in the CSL samples increased and the liquid limit and maximum dry density decreased. The plastic limit exhibits an increase followed by a decrease, with the plasticity index changing in the opposite tendency. The UCS and shear strengths of the CSL samples increased with increasing cement content, and the USC and cement content was better fitted using the Asymptotic model under the same curing time. The growth rate of the UCS and shear strength parameters were significantly reduced at cement contents above 2%. The results of Scanning Electron Microscopy (SEM) showed that the structure of the CSL samples was denser and had no obvious inter-aggregate pores. Meanwhile, compared to compacted loess, produced C-S-H gel and ettringite. Quantitative analysis of compacted loess and CSL sample by IPP software. Compared to compacted loess, the average pore diameter and average pore area of the CSL sample decreased from 12.44 μm and 229.04 μm2 to 8.72 μm and 84.68 μm2 , a reduction of 29.9% and 63.0%, respectively. The pore shape tends to flatten, but there is basically no effect on the pore angle distribution. Finally, a systematic description of the physicochemical reactions occurring during the formation of the CSL sample structure was made, and a schematic diagram of the formation of the CSL sample structure was created.Graphic Abstract

Keywords

Cite This Article

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools