| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.019735

ARTICLE

Environmental Protection and Energy Color Changing Clothing Design under the Background of Sustainable Development

1College of Art Design and Media, Sanda University, Shanghai, 201209, China

2Data science institute, Vanderbilt University, Nashville, 37212, USA

3Center of Art Education, Shanghai University of Medicine & Health Sciences, Shanghai, 201318, China

4PSG College of Technology, Coimbatore, 641004, India

*Corresponding Author: Jingyu Dai. Email: daijingyu2021@yahoo.com

Received: 11 October 2021; Accepted: 07 December 2021

Abstract: In order to promote the application of clean energy technology in clothing and promote the integration of industrial development and artificial intelligence wearable technology, this study elaborates the energy application characteristics of intelligent wearable products at home and abroad and its application in different fields, aiming at the current research status of wearable technology in the field of textile and clothing. The wearable distributed generation technology is classified, and a creative clothing design for detecting climate temperature is designed. Based on the monitoring of body temperature, the changes in clothing pattern color can reflect people’s health and emotional status. At the same time, it can also be applied to the screening of abnormal body temperature during the COVID-19.

Keywords: Clean energy; temperature variable materials; wearable; clothing design

Wearable devices mainly refer to electronic devices that can be directly worn on people. They are electronic products that can be integrated into clothes or similar clothes [1]. It is a device that can be worn on or close to the body and can send and transmit information. More specifically, it is a portable device with some special functions by integrating the device into clothing or accessories [2].

With the background of sustainable development, wearable clothing has developed rapidly and is increasingly integrated into life. In wearable clothing, battery is not only an important component of wearable devices, but also the key to determine whether a product can be commercialized. The self powered equipment avoids the problem of charging difficulty caused by the large volume and difficult to carry of the battery. At present, the research direction of power generation devices in most wearable devices is lithium polymer batteries with light weight, variable shape and size. Most of the electronic devices are protected by hard shell, which brings some problems for wearing comfort and machine washability. However, lithium polymer batteries have a large number of conducting wires and electronic components, which pose the risk of electric leakage and electronic radiation. There are also information security risks in the process of data transmission. Washing will affect their service life, and the safety performance cannot be guaranteed. In particular, most health smart wearable devices for women, the elderly and children are in direct contact with the surface of women’s body. Such smart devices should have high safety, which is an important reason for the low acceptance of consumers in the current market. At the same time, the battery life of lithium battery is short and the viscosity to users is reduced.

Due to the lack of research on temperature change in existing fashion design. This paper reviews the latest research results of energy storage in wearable smart clothing in the world in recent years. This study was jointly developed by the clothing designer team and the material research team. The goal of work is tries to comprehensively show the research status and latest progress of distributed generation based on wearable devices, and through the development of an intelligent clothing suitable for clean energy and traditional energy, the scope of work includes based on the monitoring of body temperature and the changes in clothing pattern color, so as to reflect people’s health and emotional status. Through comparison, the complement of different energy technologies is analyzed, and the future development prospect is prospected.

2 Energy Application Status of Smart Clothing

Lithium ion battery has become the most common power generation device in wearable clothing. Its charging and energy storage is based on the back and forth movement of lithium ions between the battery anode (negative) and cathode (positive). Lithium ions with current move from the anode to the cathode through non-aqueous liquid electrolyte and diaphragm, and the charging process are the opposite. In 2012, Adidas hotpants rechargeable thermal insulation sports pants built-in lithium-ion battery in the trouser legs to maintain the athletes’ leg muscles at the ideal 38°C, so as to obtain lasting power. In order to better serve flexible wearable electronic devices, many research groups have carried out related research. City University Hong Kong branch Chun Yat and Shenzhen University Huang Yang research team published a name of ARLIB. It has flexibility and safety, and is also a choice for wearable [3]. The research team of Fudan University professor Peng Huisheng uses the characteristics of LDPE (low density polyethylene) membrane to block water vapor and combines with the gel electrolyte containing lithium/redox medium to achieve the ultra long cycle life of lithium air battery in air for up to 610 times, and has good water resistance [4].

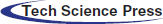

Aiming at the flexible wearable devices in clothing, a series of flexible batteries have been developed and utilized to overcome the rigid characteristics of traditional batteries. At present, flexible electrodes are mainly made of carbon nanotubes, rapheme, conductive polymers, carbon paper/carbon fiber cloth, conductive paper and conductive fabrics. Deformable flexible batteries are developed by printing, spraying, deposition, lamination, textile and other processes using traditional liquid and flexible solid electrolytes [5]. Fig. 1 shows a flexible laminated structure battery with excellent bending performance [6].

Figure 1: Photo graph of flexible battery with layered structure

LG has developed a cable type battery with excellent bending and torsion capacity [7]. In addition to focusing on the bending and torsion function, its innovation is mainly based on the design of electrolyte and hollow structure, which is wrapped by battery pet non-woven diaphragm. The spiral type of Ni Sn alloy is its negative electrode, and aluminum foil lithium cobalt oxide (LCO) is its positive electrode. In addition, in order to overcome the problems of capacity and energy density of lithium-ion batteries, flexible batteries such as li-S cells, solar cells and fuels have been developed [8].

Solar cell is a promising renewable energy storage device, which can meet the challenges of future energy demand. Human use of solar energy resources has a long history and is becoming more and more common. In 1996, American Lapidus designed a solar Hoodie, equipped with micro lithium battery and photovoltaic silicon solar collector, which can charge MP3, mobile phone and other equipment; American researchers have designed a solar bikini, which uses conductive fibers to sew photovoltaic film strips together for use, which can charge MP3 and other portable electronic equipment; others have designed solar pants, which are made of waterproof and oil-proof fabrics, with pockets on both sides and solar panels attached to the surface to provide electric energy for portable electronic equipment.

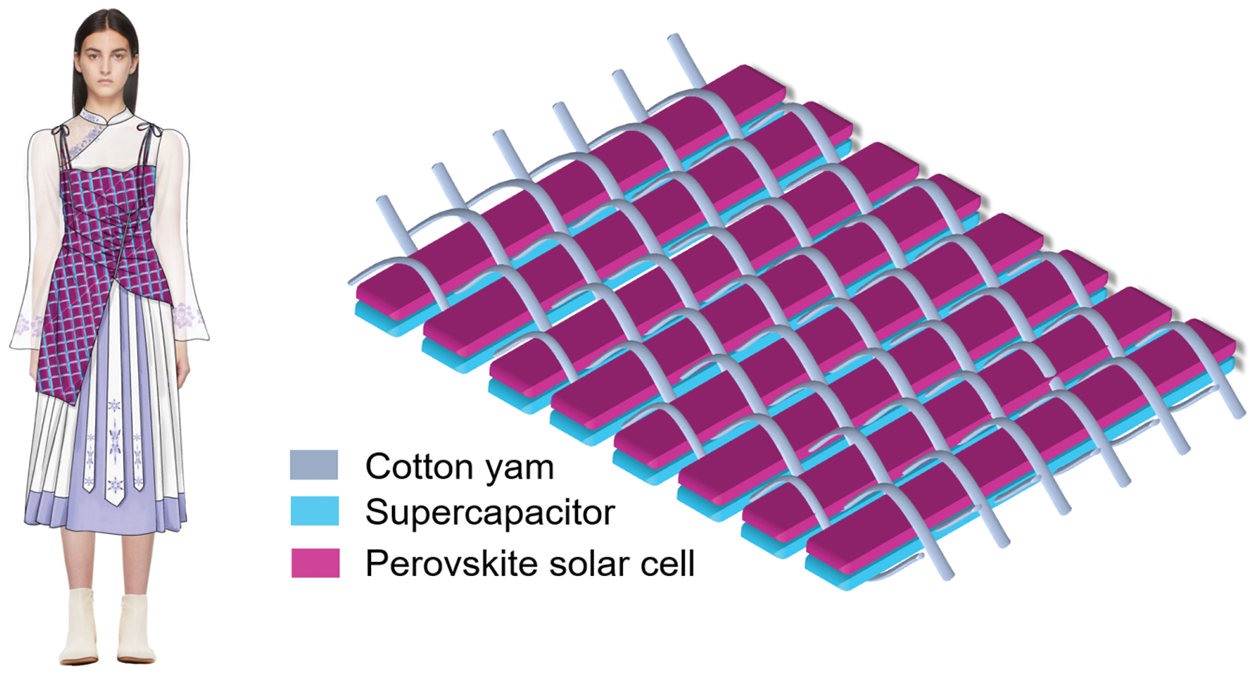

Flexible solar cells often use polymer organic semiconductors [9] and amorphous silicon as photosensitive devices (Fig. 2). Among them, the flexible amorphous silicon thin film solar cell is a new product with light weight, bendability, easy cutting and high conversion rate. At the same time, the solar panel is combined with the clothing body in the form of independent accessories. Its combination with the clothing is fixed with velcro or buckle, and can be disassembled for cleaning. Li et al. [10] developed a garment that can absorb and store solar energy at the same time. The copper strip composed of solar panels and supercapacitors is woven together with yarn and embedded into the garment to realize wearability.

Figure 2: Flexible thin film a-Si solar cells

In 2017, Ren et al. [10] designed a warm and charged clothing for the elderly around devices such as flexible amorphous silicon solar panel, carbon fiber USB heating film, multi-functional USB socket and intelligent temperature controller. It has the characteristics of continuous solar power supply, rapid heating and controllable clothing, and its multi-functional USB socket can meet the needs of different electronic devices.

In 2009, Ma [11] applied for a solar cap patent for solar charging, which can avoid the summer and charge MP3 and mobile phones; Xu et al. [12] applied for the patent of solar luminous clothes, which mainly uses solar charging and lamp body warning device, which has the function of warning and performance; Liu et al. [13] developed a functional solar garment, which installed the solar panel on the upper arm to charge the portable electronic equipment; these functional solar clothing, generally made of anti radiation fabrics, have the functions of decoration, warning, lighting, alarm and daily charging.

Supercapacitor is also called electrochemical capacitor and double-layer capacitor. The composition material contains carbon material, conductive polymer and metal oxide [14]. It is a new type of energy storage device, whose performance is between the traditional capacitor and rechargeable battery. It can not only store energy, but also quickly release points for many times. Moreover, the charging time is short and the service life is long. From the perspective of sustainable development, it is relatively environmentally friendly and suitable for wearable clothing design. Fiber like flexible supercapacitors have been prepared by compounding carbon nanotubes and polypyrrole nanowires with flexible textile fibers [15]. Supercapacitors can be printed directly on textiles by screen printing technology. From the perspective of future development, some scholars believe that improving the specific surface area, conductivity and pore diameter of electrode materials is the key to improve the mass specific capacitance and energy density of supercapacitors [16]. By combining the supercapacitor with the energy collection device, a fabric like electronic component [17] that can generate and store electric energy is manufactured, which has the potential to be worn and commercialized.

The team of Professor Shen Guozhen of Institute of semiconductors, Chinese Academy of Sciences has developed a braidable linear supercapacitor with a length of up to 1.2 m, which can be used as a wearable energy storage unit and provide electric energy for personal electronic devices, and has a good application prospect [15]. The solid state micro supercapacitor developed by the State Key Laboratory of fiber material modification, Donghua University, consists of polyvinyl alcohol (PVA)/H3PO4 gel as electrolyte and 3D porous graphene film as electrode material. Its innovation is characterized by good flexibility, high specific capacitance, good durability and high output power. Micro devices based on 3D graphene film are expected to play a role in wearable, flexible robot and other fields [17]. However, compared with this study, Donghua’s team did not apply the results to fashion ready to wear design.

2.5 Ble Bluetooth Low Power Technology

Ble Bluetooth low power technology enables small power supply equipment to transmit data through Bluetooth wireless link, and has the characteristics of low power consumption, low cost, wide control range, flexible use and so on. It is applied to hid devices, smart home appliances and health care devices, and provides an ultra-low power wireless transmission scheme for wearable devices such as smart Bracelet watches, wearable pulse oximeters and heart rate bands. Yang et al. [18] used the development platform of body sensor network (BSN) to integrate fabric sensors into clothes and designed a wearable sleep breathing monitoring system. Söderström et al. [19] designed a multifunctional smart watch with high-speed embedded MCU as the core, and realized the communication and function setting management between smart watch and Android mobile phone by using low version Bluetooth communication technology. Ji et al. [20] applied the highly integrated sensor technology, Bluetooth low power (BLE) technology and mobile communication technology to the development practice of intelligent health monitoring watch. BSLE wireless communication is used as the core technology to realize the functions of heart rate monitoring, step measurement, health movement analysis and so on. BLE Bluetooth low power technology can effectively reduce transmission power consumption and prolong battery life. However, its efficacy is still unable to support the use of high-power equipment on clothing. BLE Bluetooth low power technology is an alternative power supply for this study.

Lin et al. [21] discovered and developed the triboelectric nano generator, which can convert very small mechanical energy into electrical energy. It has the characteristics of high power density, high energy conversion rate, low cost and good sustainability. It is more suitable for portable electronic products, smart clothing and sensor terminals. Its innovation lies in that when it encounters friction electrification or electrostatic reflection, it can smoothly convert the mechanical energy generated by human movement into electrical energy. The flexible nano generator can continuously supply energy to the flexible device to realize self driving [22]. In the field of wearable clothing, scientists use the change of contact area between two different materials caused by external force to make them have opposite charges (usually positive charge in metal coating and negative charge in polymer), or use the growth of zinc oxide nanowires on fabric or the change of force on nanorod piezoelectric materials to generate current [23,24] The flexible electronic device is assembled and integrated into the garment. The energy conversion device is combined with energy storage devices such as supercapacitors and integrated into garment fabrics, opening up a new way for continuous power supply of wearable electronic devices.

Zeng et al. studied a nano generator completely based on cellulose, which can be used to collect the kinetic energy generated in the movement of textiles [25]. By using the natural swing in the movement of human body, it can generate low-frequency and low-voltage AC [26]. Yu [27] studied a wearable friction power generation fabric with warp and weft weaving structure, wrapped fibers with different electronegativity (such as polyester, polypropylene, etc.) on conductive copper wire to form a friction nano generator single fiber with a single electrode, and then prepared the friction power generation fabric with one electrode by different weaving methods. When the human body wears this fabric, the low-frequency disordered mechanical energy can be transformed into electrical energy. Wang Hongzhi realized the continuous and large-scale production of stretchable friction power generation yarn by using industrial spinning equipment, and put forward the hypothesis of potential/polarization coupling effect of friction power generation devices [28]. With the special skin core structure design and coupled gain power generation mechanism, the power generation yarn can generate electricity by itself without the interaction with other objects.

The self powered system using energy conversion components such as wind energy, steam and thermoelectricity combined with energy storage components such as secondary battery and supercapacitor provides a new idea and way for flexible wearable devices, which has become the focus of scholars’ increasing attention.

Among them, wearable thermoelectric generator using temperature difference power generation can directly convert heat energy into electric energy [29]. Thermoelectric materials can directly convert thermal energy from temperature difference into electric energy. So as to supply power to wearable electronic devices. There are mainly two types of wearable thermoelectric devices studied. One is the device prepared by flexible thermoelectric materials such as polymers. Limited by the low ZT value of polymer based thermoelectric materials, the output power per unit area of this kind of thermoelectric devices is 0.1 μ. The order of W/cm2 is even lower. The other is flexible thermoelectric devices made of rigid inorganic thermoelectric materials connected with flexible fillers or flexible electrodes. Due to the high thermoelectric performance of electrodeless thermoelectric materials, the output power of such flexible devices is generally higher than that of devices based on flexible polymer thermoelectric materials.

Kim et al. [30] printed thermoelectric materials on glass fiber and developed a power generation device that can generate electricity by using body temperature. This power generation device can reduce heat loss and increase power output by using glass fiber and inorganic materials, and the prepared device is thinner (about 500 mm thick) (μm) Lighter (area density about 0.13 g/cm2) (Wang et al. [31]).

3 Application of Temperature Variable Materials

Thermochromic powder is an organic chromophore composed of electron transfer organic compounds inside and a transparent shell that can neither dissolve nor melt outside [32]. The swimsuit developed by the photosensitive color changing fabric developed by Kanebo company in Japan is made of thermochromic fiber, which can change different colors on the shore, water, field, indoor or beach. At a specific temperature, the molecular structure of organic matter changes due to electron transfer, so as to realize color change [33]. British fashion designer Lauren Bowker has launched a series of sci-fi clothes, including a mobile color changing jacket and a shoulder bag that can show pollution. The clothes are made of a kind of temperature sensitive color changing (TLC) fabric containing liquid crystal. As soon as the temperature changes, the color of the clothes surface changes. The photochromic and photochromic dyes produced by jpiles are sensitive to the photochromic and photochromic changes of pH and pH value of special dyes. The US Army human engineering laboratory in Aberdeen, Maryland, developed a photochromic dye that can change the color with the light color change of the surrounding environment. Once the environment changes, the photochromic dye can become a color suitable for the new environment.

The color of thermochromic materials changes after being heated to a certain temperature, but the color cannot be recovered or changed during cooling. This kind of materials is called irreversible thermochromic materials. Its color change is irreversible, so it can only remember the highest temperature it has withstood. Organic reversible temperature sensitive materials (huancaibs) are composed of electron donor, electron acceptor, regulator, sensitizer and other solvents. Electron transfer occurs between electron donor and electron acceptor due to temperature change. In the process of electron transfer, a certain wave of color change is absorbed or radiated, and a long light composed of leuco dye, chromogenic agent and color change temperature control solvent is absorbed or radiated, Reversible thermochromic microcapsules were produced on the surface. Irreversible thermochromic materials commonly used include phosphate, sulfate, nitrate, oxide, sulfide, methyl violet, phenol compound, acid clay, azo pigment, arylmethane pigment, etc., of lead, manganese, chromium, zinc, iron, cobalt, nickel, cadmium, strontium, magnesium, barium and molybdenum. Temperature sensitive color changing capsule changes color by sensing heat. The color changing process is in a range, not at a point. For example, the positive and negative difference of 31 degrees red is 1–2 degrees. After the temperature reaches 30 degrees, it begins to change to light red. After 31 degrees, the microcapsule completely changes color and is colorless.

The color change range includes red to orange and purple; purple to blue; green to yellow; blue turns purple, yellow and red; peach red to yellow; brown to green; orange turns yellow; rose red turns yellow; black turns red and blue. Temperature change can realize color change effect, including color elimination, that is, the color change powder changes from color to colorless with the increase of temperature; color development, that is, when the temperature decreases, the color changing powder changes from colorless to colored; two color, that is, the color changing powder at high or low temperature changes from color to colorless. The selection temperature of discoloration powder includes: when the ambient temperature is 24 degrees in winter, select 28 degrees for discoloration; in autumn and spring, the ambient temperature changes color from 24 to 29 degrees to 31 degrees; in summer, if the ambient temperature is above 27 degrees, choose 33 degrees to change color; high temperature color changing cup selects 45 degrees color changing; in summer, it turns cold, colorless and colored, and 22 degrees discoloration is selected.

In order to make sure that the material of this dress is monitoring the body temperature but not the environment temperature. Select an enclosed space to test. Reference physiological indexes for evaluating thermal comfort in closed environment.

Intelligent clothing integrates physiological signal acquisition and processing equipment into clothing to achieve the purpose of real-time monitoring of various physiological indexes of human body during daily clothing. As an important physiological index of human body, body temperature is of great value in special populations. This design is based on the monitoring of body temperature and the change of clothing pattern color, so as to reflect people’s health and emotional status.

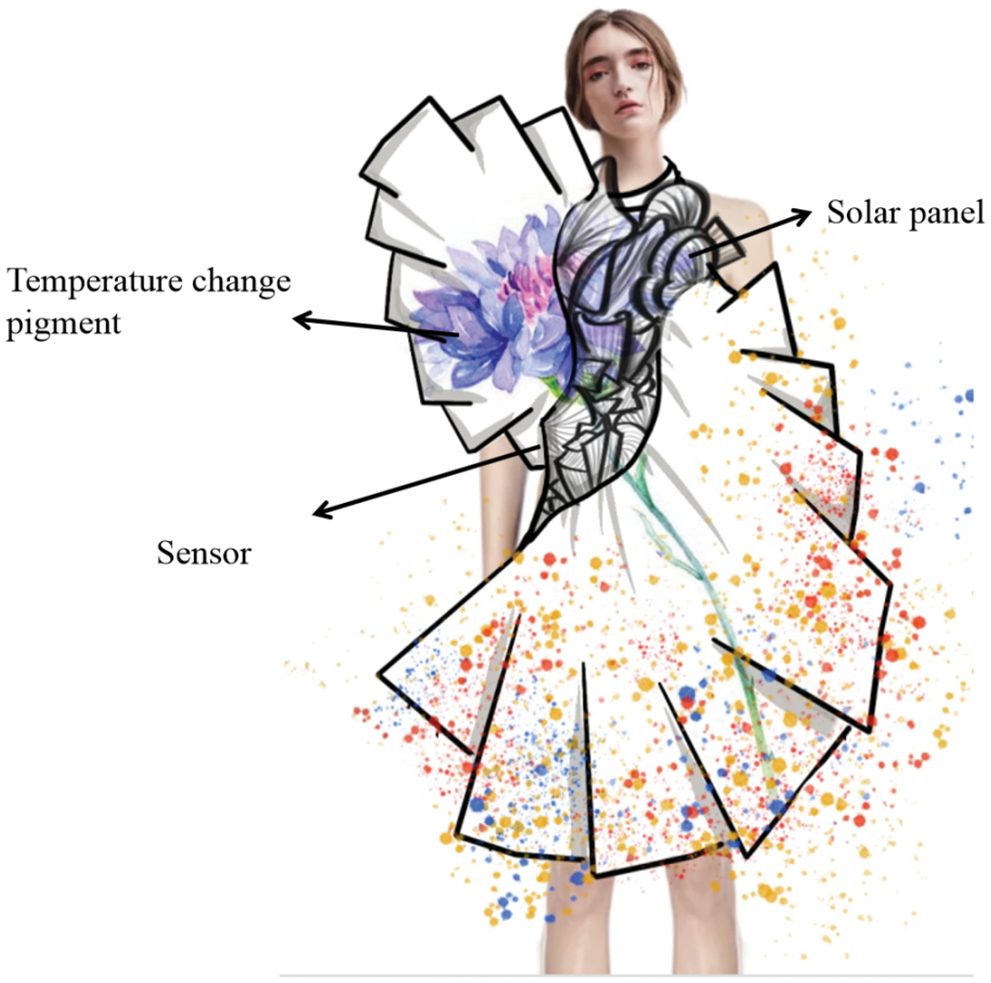

Based on the development of clean energy, the flexible amorphous silicon thin film solar cell is used as the power source of the overall design scheme. At present, the price of a solar panel (with high material and conversion rate) in the market is about 20 yuan, and four electric panels are required to meet the power supply demand. Based on the consideration of cost performance, solar panel is selected as the power generation device of clean energy. The utility model is combined with the clothing body in the form of solar panels and independent accessories, and is fixed on the clothing fabric with Velcro. At the same time, it is also convenient for cleaning after disassembly. The whole system includes clothing body, flexible amorphous silicon thin film solar panel accessories, lithium battery modules, temperature change materials, flexible thin wires and other elements. This design is based on different intensities of pulse, thus showing different color effects in clothing details. The whole system is based on the full utilization of solar energy resources and the concept of sustainable development of clean energy. The design of the whole system is reasonable and can show discoloration effect.

5 Development of Clothing for Detecting Body Temperature and Intelligent Color Change

Smart clothing design is often limited to the design rationality of clothing materials and wires, but also ignores the unity of fashion and function. Based on the daily dress needs of fashion consumers, a medium and long dress is designed. The whole is loose, and the waist is close to the human body structure. The hollowed out design of the waist increases the highlights of fashion design, which is in line with the characteristics of fashion trends. The color matching of black and white is also in line with the love of the majority of fashionable young people, which is easy to be versatile. At the same time, a pocket is set to facilitate the loading of electronic equipment.

The placement of solar panels needs to be exposed to the sun. At the same time, considering that they cannot be directly exposed to the outside, the solar panels are placed at the waist. The design features of weaving hollow out are adopted to cover the texture of the solar panels without affecting the use. At the same time, although the soft connecting lines are sewn in the clothing as covertly as possible, they will still be easily exposed, so the fabrics with the same color as the circuit lines are selected, With “weaving” as the design feature, the circuit line can be further hidden.

As shown in Fig. 3, 1 is a sensor and circuit device, which is placed in the outer pocket. There is a small patch pocket specially designed for it, and the small pocket is detachable; 2 is the area of flexible amorphous silicon thin film solar panel. The braided pattern outside echoes with the pattern composed of surface solar panels. The braided belt can be disassembled for easy cleaning. 3 is the temperature change area. The starting area has been painted with temperature change material. When the sensor senses the change of body temperature, the color here will change. When the body temperature exceeds 37.3, all the villains in the pattern will turn red. When the body temperature is higher than 36.5 degrees, the villain will remain purple. When the body temperature is lower than 36.5 degrees, the villain will remain blue. If temperatures do not fall in those values, the clothes will keep their original color.

Figure 3: Design sketch

The solar panel is embedded in the clothes of the accessories in the way of assembly and disassembly, so as to maximize the effective daylighting area of the solar panel. The dark part in the figure is the flexible amorphous silicon thin film solar panel, and the remaining graphics are cloth embroidered patterns, which echo with the pattern shape composed of the surface solar panel.

All devices and components are connected by flexible thin wires, which are hidden at the seams of clothes. The solar panel and other auxiliary equipment are designed to be removable, and the auxiliary electrical circuit is fixed with the seam, which reduces the difficulty in technology, saves the process time and saves the cost; At the same time, it also conforms to the guidance of Ergonomics (as shown in Fig. 4).

Figure 4: Production process

The new silver fiber blended fabric is used as the main material of the new miner’s clothing. The fabric is composed of 9.4% silver fiber, 84.6% cotton fiber and 6% hemp fiber. Silver fiber has good conductivity, which can ensure the anti-static performance of the fabric. The antistatic performance of the fabric was tested according to GB/T12703.1-2008, GB/T12703.3-2009 and GB/T12703.4-2010. The test results show that the the material meets the purpose of this experiment.

The temperature change area involves material elements, including flora development board, body temperature sensor, crocodile clip, jumper, bread board, diode, triode, flexible amorphous silicon thin film solar cell, temperature variable material, sewing thread with conductive function thread and hot melt adhesive film.

In the experiment. in the first is the preparation stage of the experiment, the warm pigment should be melted into water, which is drawn on the surface of the cut garment. Step two, the length of conductive sewing thread must be accurately calculated, and it cannot be too long or too short (influencing factors: the resistance of the sewing thread and the voltage of the flexible amorphous silicon thin film solar cell used). The third step is hide the circuit to make the appearance of clothes beautiful into the pattern. Out of consideration of design richness the pattern needs to be sewn on the surface with soft fabric. The sewing thread will be exposed from the front. Therefore, this design sewing thread sewn on nonwoven pattern fabric, and then bonded with hot-melt film between the two fabrics.

Conductive sewing thread port 1-solar cell-flora development board port 1, flora development board port 9-bread board, flora development board port 1-bread board *-conductive sewing thread port 2, flora development board-body temperature sensor, diodes and triodes are connected to bread board. The temperature change area is programmed for the inlet temperature sensor,and the different voltage is transmitted to different areas of the garment through the 300D/3 conductive sewing thread. The conductive sewing thread is obtained by the following algorithm.

Finally, touch the body temperature sensor, the device is placed in the sun and powered on, and the temperature change area begins to change color in turn according to the program written into the flora development board. The solar panel charges the lithium battery through the collected electric energy, and the electric energy of the lithium battery outputs a stable 5 V constant voltage power supply through the boost circuit to meet the requirements of temperature change.

Power supply for daily wearable clothing, gentle and breathable, and washing are necessary conditions, and the stretchable power generation device is particularly practical. The ideal power supply on wearable devices should technically require the miniaturization and flexibility of batteries, sensors, chips, screens and other hardware, and improve the battery life while developing low-power processors. The flexible wearable triboelectric nano generator is a material more in line with the above characteristics, but it still has some disadvantages, such as low temperature resistance, poor stability and air permeability.

Through this study, some progress has been made in the research of clean energy, especially solar clothing, but more research is still needed to complete commercial mass production. The flexible amorphous silicon thin film solar panel is combined with clothing in the form of accessories, and it is very soft and easy to fold and bend, which solves the discomfort in wearing performance. At the same time, it has the biggest advantage of strong security and high cost performance. The generated voltage is about 5 V, which meets the needs of charging devices such as mobile phones and will not cause harm to human body; In the operation of connecting the whole system, the insulated thin wire is used, which is anti heating, durable and highly flexible. There will be no potential safety hazards due to working for a long time. However, the conversion rate and area of solar panels, the intelligence of solar panels, the rationality of circuit design and manufacturing technology need to be further improved in order to achieve industrialized application.

Temperature change and clean energy application belong to relatively rare research in smart clothing, but now the categories of the market are more and more subdivided, that is, pay more attention to the characteristics and needs of special people, and focus on smart clothing research will be more and more. It provides more possible multi-dimensional design for different clothing groups.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Huang, T. L. (2017). Wearable clothing structure and technology research. Beauty and Times, 20(1), 102–106. [Google Scholar]

2. Kwak, S. I., Sim, D. U., Kwon, J. H., Choi, H. D. (2010). Design of wearable communication device for body protection from EM wave using the EBG structure. The 40th European Microwave Conference, 28(2), 1433–1436. [Google Scholar]

3. Liu, Z. X., Li, H. F., Zhu, M. S., Huang, Y., Tang, Z. J. et al. (2018). Towards wearable electronic devices: A quasi-solid-state aqueous lithiumion battery with outstanding stability, flexibility, safety and breathability. Nano Energy, 44, 164–167. DOI 10.1016/j.nanoen.2017.12.006. [Google Scholar] [CrossRef]

4. Wang, L., Pan, J., Zhang, Y., Cheng, X. L., Liu, L. M. et al. (2018). A li-air battery with ultralong cycle life in ambient air. Advanced Materials, 30(3), 1704378. DOI 10.1002/adma.201704378. [Google Scholar] [CrossRef]

5. Li, W. W., Wang, X. F., Liu, B., Luo, S. J., Liu, Z. et al. (2013). Highly reversible lithium storage in hierarchical Ca2Ge7O16 nanowire arrays/carbon textile anodes. Chemistry–A European Journal, 19(26), 8650–8656. DOI 10.1002/chem.201300115. [Google Scholar] [CrossRef]

6. Wang, X. F., Liu, B., Hou, X. J., Wang, Q. F., Li, W. W. et al. (2014). Ultralong-life and high-rate web-like Li4Ti5O12 anode for high-performance flexible lithium-ion batteries. Nano Research, 7(7), 1073–1082. DOI 10.1007/s12274-014-0470-7. [Google Scholar] [CrossRef]

7. Kown, Y. H., Woo, S. W., Jung, H. R., Yu, H. K., Kim, K. et al. (2012). Cable-type lithium ion battery based on hollow multi-helix electrodes. Advanced Materials, 24(38), 5192–5197. DOI 10.1002/adma.201202196. [Google Scholar] [CrossRef]

8. Lee, J., Wu, J., Shi, M., Yoon, J., Park, S. I. et al. (2011). Stretchable GaAs photovoltaics with designs that enable high areal coverage. Advanced Materials, 23(8), 986–991. DOI 10.1002/adma.201003961. [Google Scholar] [CrossRef]

9. Choi, D., Lee, K. Y., Jin, M. M. J., Ihn, S. G., Yun, S. Y. et al. (2011). Control of naturally coupled piezoelectric and photovoltaic properties for multi-type energy scavengers. Energy & Environmental Science, 4(11), 4607–4613. DOI 10.1039/c1ee02080c. [Google Scholar] [CrossRef]

10. Li, C., Islam, M. M., Moore, J., Sleppy, J., Morrison, C. et al. (2016). Wearable energy-smart ribbons for synchronous energy harvest and storage. Nature Communications, 7(1), 13319. DOI 10.1038/ncomms13319. [Google Scholar] [CrossRef]

11. Ma, D. (2009). A solar cap with solar energy charging and MP3/FM function. China, C200820004370. 2 P,01-07. [Google Scholar]

12. Xu, P., Shi, J., Pan, X. L., Chen, Z. Q. (2009). Solar Luminous clothes. China, CN201020141497. 6P.2010-12-22. [Google Scholar]

13. Liu, Z., Wang, X. C. (2012). Manufacture and performance evaluation of solar garment. Journal of Cleaner Production, 42(3), 96–102. DOI 10.1016/j.jclepro.2012.11.015. [Google Scholar] [CrossRef]

14. Johnson, J. T., Barksdale Jr, H. C., Boles, J. S. (2003). Factors associated with customer willingness to refer leads to salespeople. Journal of Business, 56(4), 257–263. DOI 10.1016/S0148-2963(02)00436-8. [Google Scholar] [CrossRef]

15. Wang, J., Li, X. H., Zi, Y. L., Wang, S. H., Li, Z. L. et al. (2015). A flexible fiber-based supercapacitor-triboelectric-nanogenerator power system for wearable electronics. Advanced Materials, 27(33), 4830–4836. DOI 10.1002/adma.201501934. [Google Scholar] [CrossRef]

16. Kent, W. E., Shock, P. J., Snow, R. E. (1983). Shopping: Tourism’s unsung hero(ine). Journal of Travel, 21(4), 2–4. DOI 10.1177/004728758302100401. [Google Scholar] [CrossRef]

17. Pu, X., Li, L. X., Liu, M. M., Jiang, C. Y., Du, C. H. et al. (2016). Wearable self-charging power textile based on flexible yarn supercapacitors and fabric nanogenerators. Advanced Materials, 28(1), 98–105. DOI 10.1002/adma.201504403. [Google Scholar] [CrossRef]

18. Yang, C. M., Huang, W. T., Yang, T. L., Hsieh, M. C., Liu, C. T. (2008). Textiles digital sensors for detecting breathing frequency. Proceeding of the 5th International Work shop on Wearable and Implantable BSN, pp. 276–279. HK-SAR, China. [Google Scholar]

19. Söderström, T., Haug, F. J., Terrazzoni-Daudrix, V., Ballif, C. (2008). Optimization of amorphous silicon thin film solar cells for flexible photovoltaics. Journal of Applied Physics, 103(11), 114509. DOI 10.1063/1.2938839. [Google Scholar] [CrossRef]

20. Ji, W., Guo, H., Ren, X. (2017). Intelligent watch system for health monitoring based on Bluetooth low energy technology. Journal of Biomedical Engineering, 34(4557–564. DOI 10.7507/1001-5515.201606087. [Google Scholar] [CrossRef]

21. Lin, L., Xie, Y. N., Wang, S. H., Wu, W. Z., Niu, S. M. et al. (2013). Triboelectric active sensor array for self-powered static and dynamic pressure detection and tactile imaging. ACS Nano, 7(9), 8266–8274. DOI 10.1021/nn4037514. [Google Scholar] [CrossRef]

22. Sariciftci, N. S., Smilowitz, L., Heeger, A. J., Wudl, F. (1992). Photoinduced electron transfer from a conducting polymer to buckminsterfullerene. Science, 258(5087), 1474–1476. DOI 10.1126/science.258.5087.1474. [Google Scholar] [CrossRef]

23. Guo, Y. B., Li, K. R., Hou, C. Y., Li, Y. G., Zhang, Q. H. et al. (2016). Fluoroalkylsilane-modified textile-based personal energy management device for multifunctional wearable applications. ACS Applied Materials & Interfaces, 8(7), 4676–4683. DOI 10.1021/acsami.5b11622. [Google Scholar] [CrossRef]

24. Seung, W. C., Gupta, M. K., Lee, K. Y., Shin, K. S., Lee, J. H. et al. (2015). Nanopatterned textile-based wearable triboelectric nanogenerator. ACS Nano, 9(4), 3501–3509. DOI 10.1021/nn507221f. [Google Scholar] [CrossRef]

25. Zeng, W., Tao, X. M., Chen, S., Shang, S. M., Chan, H. L. W. et al. (2013). Highly durable all-fiber nanogenerator for mechanical energy harvesting. Energy & Environmental Science, 6(9), 2631–2638. DOI 10.1039/c3ee41063c. [Google Scholar] [CrossRef]

26. Jung, S., Lee, J., Hyeon, T., Lee, M., Kim, D. H. (2014). Fabric-based integrated energy devices for wearable activity monitors. Energy & Environmental Science, 6(9), 2631–2638. DOI 10.1002/adma.201402439. [Google Scholar] [CrossRef]

27. Yu, B. (2015). Preparation and research of wearable friction power generation fabric. 30th Annual Academic Conference of Chinese Chemical Society. [Google Scholar]

28. Guo, Y. B., Li, K. R., Hou, C. Y., Li, Y. G., Zhang, Q. H. et al. (2016). Fluoroalkylsilane-modified textile-based personal energy management device for multifunctional wearable applications. ACS Applied Materials & Interfaces, 8(7), 4676–4683. DOI 10.1021/acsami.5b11622. [Google Scholar] [CrossRef]

29. Bell, L. E. (2008). Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science, 321(5895), 1457–1461. DOI 10.1126/science.1158899. [Google Scholar] [CrossRef]

30. Kim, S. J., We, J. H., Cho, B. J. (2014). Wearable thermoelectric generator fabricated on glass fabric. Energy & Environmental Science, 7(6), 1959–1965. DOI 10.1039/c4ee00242c. [Google Scholar] [CrossRef]

31. Wang, Y. C., Shi, Y. J., Mei, D. Q., Chen, Z. C. (2018). Wearable thermoelectric generator to harvest body heat for powering a miniaturized accelerometer. Applied Engergy, 215(15), 690–698. DOI 10.1016/j.apenergy.2018.02.062. [Google Scholar] [CrossRef]

32. Zhang, Y. F., Xin, Z. (2006). Isothermal and nonisothermal crystallization kinetics of isotactic polypropylene nucleated with substituted aromatic heterocyclic phosphate salts. Journal of Applied Polymer Science, 101(5), 3307–3316. DOI 10.1002/(ISSN)1097-4628. [Google Scholar] [CrossRef]

33. Zhang, Y. F., Xin, Z. (2006). Effects of substituted aromatic heterocyclic phosphate salts on properties, crystallization, and melting behaviors of isotactic polypropylene. Journal of Applied Polymer Science, 100(6), 4868–4874. DOI 10.1002/(ISSN)1097-4628. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |