Open Access

Open Access

ARTICLE

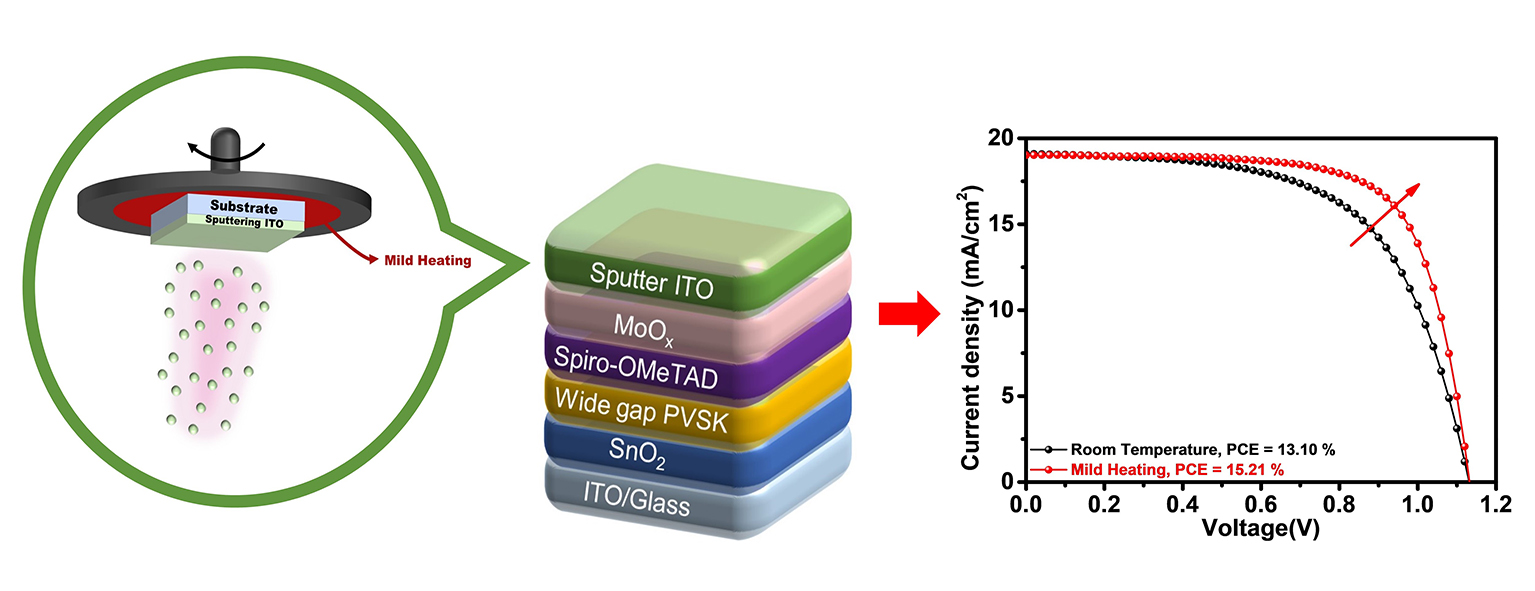

Sputtering under Mild Heating Enables High-Quality ITO for Efficient Semi-Transparent Perovskite Solar Cells

1 Xiamen Key Laboratory of Optoelectronic Materials and Advanced Manufacturing, Institute of Luminescent Materials and Information Displays, College of Materials Science and Engineering, Huaqiao University, Xiamen, 361021, China

2 MOE Engineering Research Center for Brittle Materials Machining, Huaqiao University, Xiamen, 361021, China

* Corresponding Authors: Liqiang Xie. Email: ; Xipeng Xu. Email:

# These authors contributed equally to this work

(This article belongs to the Special Issue: Perovskite Solar Cells)

Journal of Renewable Materials 2022, 10(10), 2509-2518. https://doi.org/10.32604/jrm.2022.021400

Received 12 January 2022; Accepted 01 March 2022; Issue published 08 June 2022

Abstract

Semi-transparent perovskite solar cells (ST-PSCs) are promising in building-integrated photovoltaics (BIPVs) and tandem solar cells (TSCs). One of the keys to fabricate high-performance ST-PSCs is depositing efficient transparent electrodes. Indium tin oxide (ITO) is an excellent transparent conductive oxide with good light transmittance and high conductivity. However, the high sheet resistance of ITO sputtered at room temperature leads to the low fill factor (FF) and poor power conversion efficiency (PCE) of the ST-PSCs. Here, we study the effect of the sputtering temperature on the properties of ITO and the performance of ST-PSCs. We find that when the sputtering temperature increases from the room temperature to 70°C, the crystallinity of the sputtered ITO gradually improves. Therefore, the sheet resistance decreases and the corresponding device performance improves. However, once the sputtering temperature further increases over 70°C, the underlying hole transport layer will be damaged, leading to poor device performance. Therefore, the optimized mild heating temperature of 70°C is applied and we obtain ST-PSCs with a champion PCE of 15.21%. We believe this mild heating assisted sputtering method is applicable in fabricating BIPVs and TSCs.Graphic Abstract

Keywords

Cite This Article

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools