Open Access

Open Access

ARTICLE

Mechanical Properties and Constitutive Relationship of the High-Durable Parallel Strand Bamboo

1

Department of Civil Engineering, Beijing Forestry University, Beijing, 100083, China

2

Department of Architecture and the Built Environment, Lund University, Lund, 22100, Sweden

3

Civil Engineering Department, Amran University, Amran, Yemen

* Corresponding Author: Xinmiao Meng. Email:

Journal of Renewable Materials 2022, 10(1), 219-235. https://doi.org/10.32604/jrm.2021.016013

Received 31 January 2021; Accepted 04 March 2021; Issue published 27 July 2021

Abstract

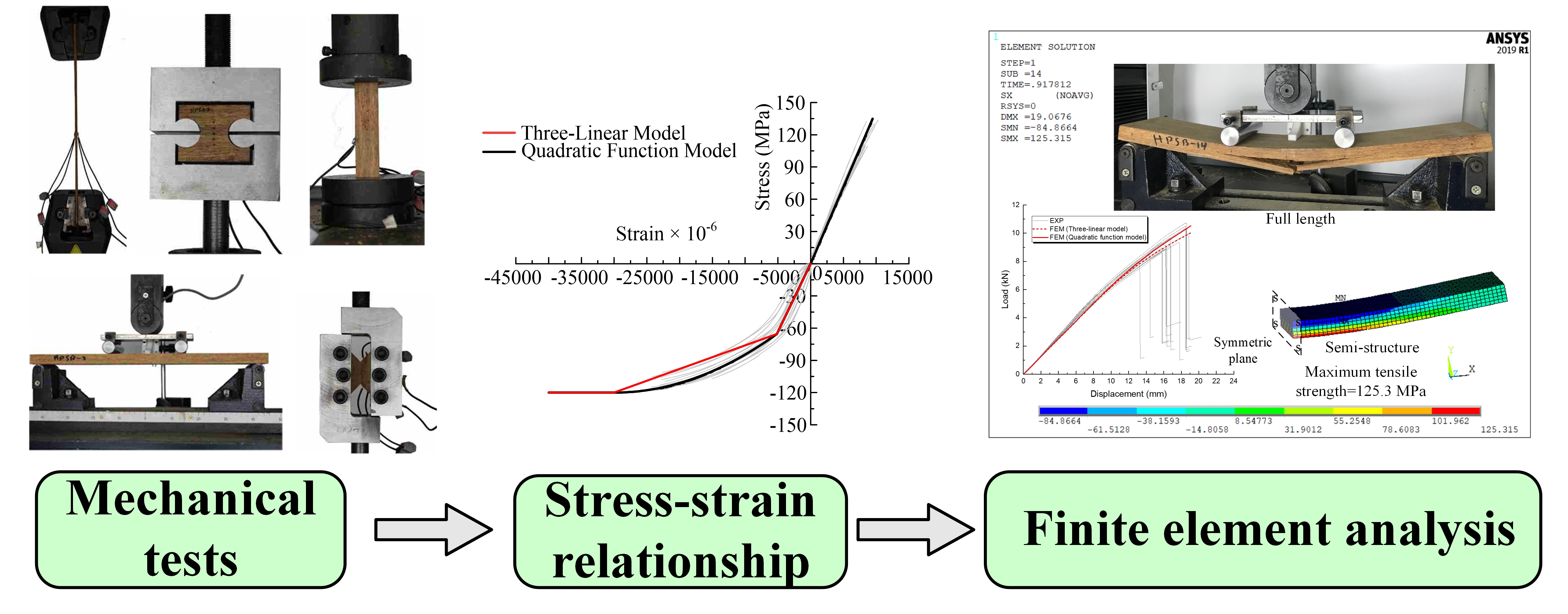

Engineered bamboo has recently received lots of attention of civil engineers and professional researchers due to its better mechanical performance than that of softwood timber. Parallel strand bamboo is one important part of engineered bamboo for its excellent durable performance compared to the laminated veneer bamboo. The required curing temperature in hot-pressing process is usually higher than 120°C to reduce the content of nutritional ingredients and hemy cellulose, and to avoid the decay from the environment and insects. Nonetheless, the appearance of engineered bamboo gets darker with the increase of temperature during the hot-pressing process. In order to minimize the color deepening while maintaining the durability, a high-durable parallel strand bamboo (HPSB) with relative high hot-pressing temperature (140°C) was produced and tested. The present study investigates the mechanical performance through tension, compression, shear and bending tests. The experimental behavior of the specimens was identified, including the failure mode and load-displacement relationship. It was demonstrated that the HPSB material had better mechanical performance parallel to grain, making it as a considerable structural material. The average elastic modulus parallel to grain was 14.1 GPa, and the tensile and compressive strengths were 120.7 MPa and 121.0 MPa, respectively. The tension perpendicular to grain should be avoided in the practical application due to the lower strength and elastic modulus. Two stress-strain relationships of tension and compression parallel to grain, including three-linear and quadratic function models, were proposed and compared with the experimental results. The three-linear model was then applied to the finite element model. The finite element analysis using ANSYS software was conducted to validate the feasibility of the constitutive relationship. The quadratic function model showed better agreement with the experimental results, but the three-linear relationship was also precise enough to analyze the bending tests of HPSB material, whereas being less accurate to describe the elastic-plastic compression behavior.Graphic Abstract

Keywords

Cite This Article

Citations

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools