Open Access

Open Access

ARTICLE

Pushing the Boundaries of Starch Foams: Novel Laminar Composites with Paper Reinforcement

Department of Tool and Materials Engineering, Faculty of Engineering, King Mongkut’s University of Technology Thonburi, Bangkok, 10140, Thailand

* Corresponding Author: Manisara Phiriyawirut. Email:

Journal of Renewable Materials 2025, 13(1), 101-114. https://doi.org/10.32604/jrm.2024.056830

Received 31 July 2024; Accepted 11 October 2024; Issue published 20 January 2025

Abstract

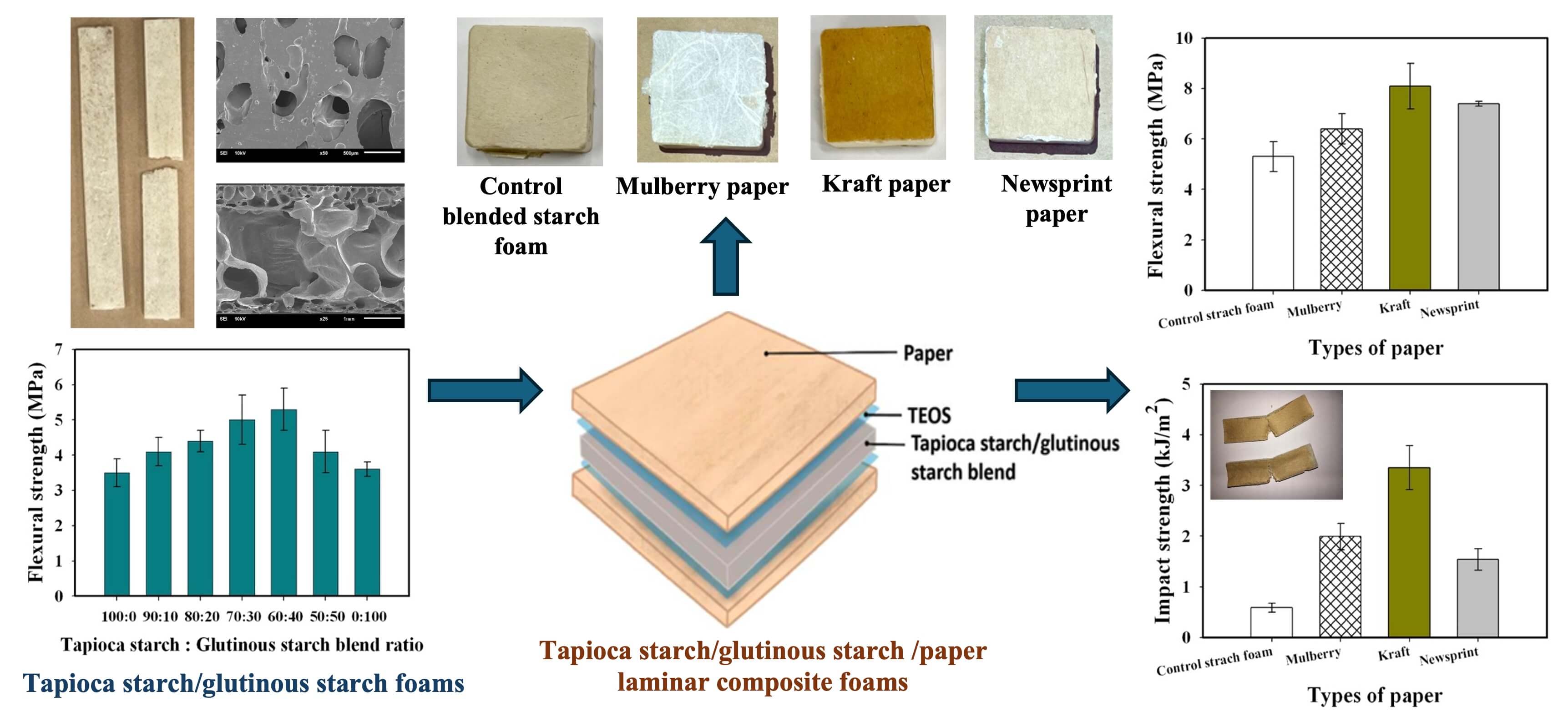

This work explores the development of biodegradable laminar composite foams for cushioning applications. The focus lies on overcoming the inherent brittleness of starch foams by incorporating various paper types as reinforcement. Tapioca starch and glutinous starch were blended in varying ratios (100:0–0:100) to optimize the base material’s properties. The morphology, density, flexural strength, and impact strength of these starch blends were evaluated. The results revealed a trade-off between impact strength and density, with increasing glutinous starch content favoring impact resistance but also leading to higher density. The optimal ratio of tapioca to glutinous starch for achieving maximum flexural strength and modulus was determined to be 60:40. The flexural strength of the composite material at this ratio reached a peak value of 5.3 ± 0.6 MPa, significantly surpassing the flexural strength of pure tapioca foam, which was measured to be 3.5 ± 0.4 MPa. Building on this foundation, novel laminar composite foams were fabricated using the 60:40 starch blend reinforced with mulberry paper, kraft paper, and newsprint paper. To enhance the interfacial adhesion between the starch matrix and paper reinforcement, a silane coupling agent was employed at a 10 wt% loading on the paper. The incorporation of paper reinforcement into starch foams was found to enhance their mechanical properties. Specifically, flexural strength values increased from 5.3 ± 0.6 MPa for the unreinforced starch foam to 6.8 ± 0.6 MPa, 8.1 ± 0.9 MPa, and 7.4 ± 0.1 MPa when reinforced with mulberry paper, kraft paper, and newsprint paper, respectively. Notably, kraft paper reinforcement led to the most enhancements in flexural strength, flexural modulus, and impact strength. This research paves the way for developing sustainable cushioning materials with competitive mechanical properties using bio-based resources like starch and paper.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools