Open Access

Open Access

ARTICLE

Mono Ethanol Amine (MEA) Pulping of Wheat Straw: An Environmentally Friendly Suggestion for the Fluff Pulp Production

1 Wood and Forest Products Division, Research Institute of Forest and Rangelands, Agricultural Research Education and Extension Organization (AREEO), Tehran, 14968-13111, Iran

2 Forest Research Division, Research Institute of Forests and Rangelands, Agricultural Research Education and Extension Organization (AREEO), Tehran, 14968-13111, Iran

3 Department of Wood and Paper Science and Technology, Faculty of Natural Resources, University of Zabol, Zabol, 98613-35856, Iran

4 Department of Wood and Paper Science and Technology, Faculty of Natural Resources, University College of Agriculture & Natural Resources, University of Tehran, Karaj, 77871-31587, Iran

* Corresponding Authors: Saeed Ismaeilimoghadam. Email: ; Mehdi Jonoobi. Email:

(This article belongs to the Special Issue: Recent Advances on Renewable Materials)

Journal of Renewable Materials 2024, 12(10), 1771-1789. https://doi.org/10.32604/jrm.2024.054888

Received 10 June 2024; Accepted 04 September 2024; Issue published 23 October 2024

Abstract

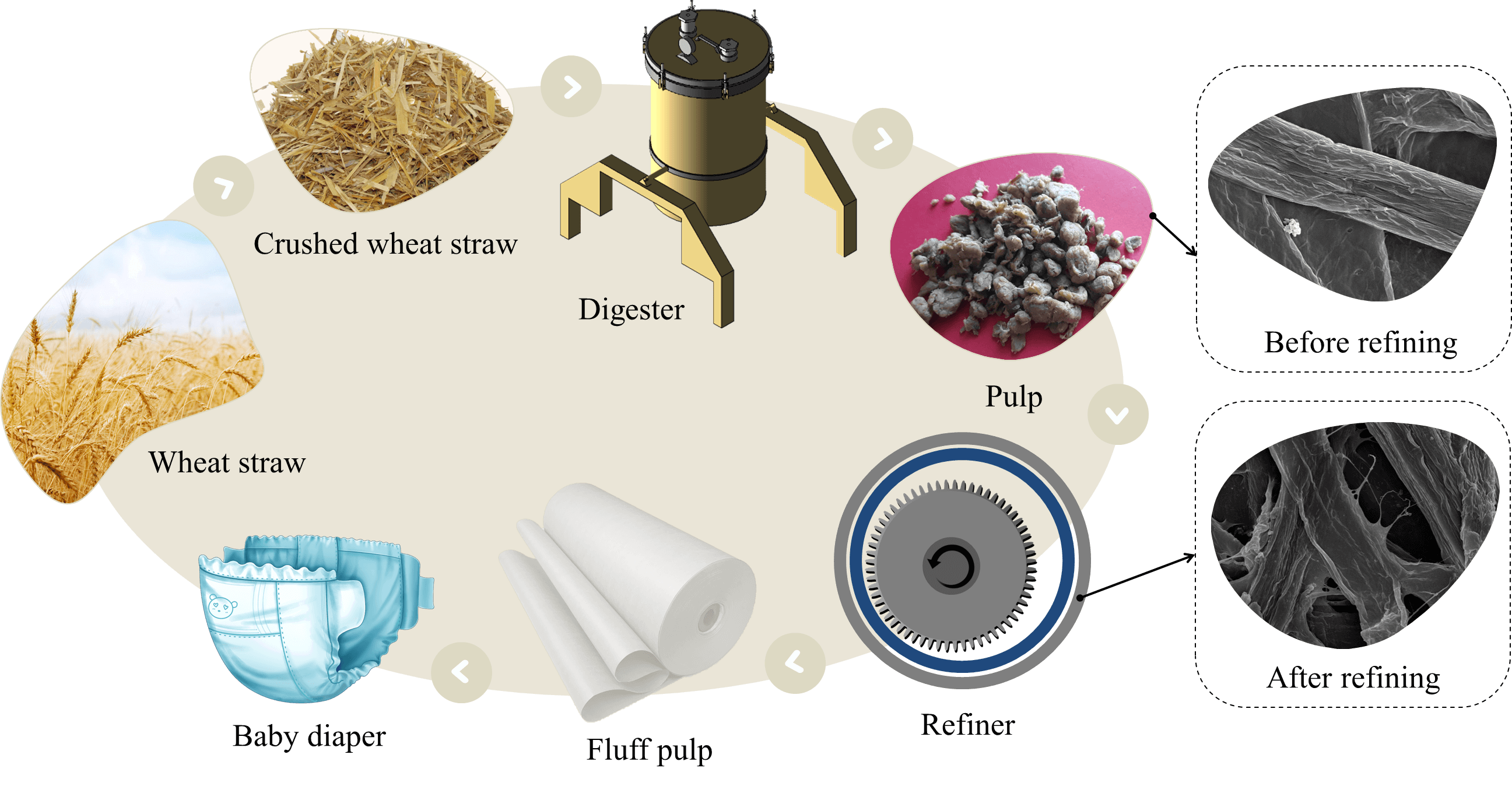

This research aimed to investigate the effect of pulping conditions and refining intensities of wheat straw to be recommended for fluff pulp production. For this purpose, mono ethanol amine (MEA) was selected as a de-lignification agent at three levels of 50:50, 25:75, and 15:85 (MEA/water, W/V %), and soda-AQ 14 W/V % was used as a reference pulping. To investigate the optimal refining intensity, the obtained pulp was passed through a single disk laboratory refiner from 0 to 6 times and in two different consistencies (1.5 and 2.5 W/V %). Total yield, kappa number, ash content, and the Schopper-Riegler (SR°) freeness of the prepared pulps were investigated. Finally, hand sheets with a targeted basic weight of 70 g/m2 were made according to the related standards. The hand sheets were characterized using Fourier transform infrared (FTIR) spectroscopy and a field emission scanning electron microscope (FE-SEM). Sheet density, brightness, and mechanical properties such as burst, tensile, and tear indices were also investigated. The FE-SEM photographs showed that the texture of the hand sheet became denser as the refining intensity increased. External fibrillation on the surface of the fibers was also observed, especially on those refined with 2.5% consistency. The results of the chemical composition of wheat straw indicated that wheat straw containing a high percentage of holocellulose is an excellent candidate for the production of fluff pulp. The total yield and kappa number of MEA pulps increased with the decrease in MEA concentration. FTIR results indicated the presence of a peak related to amino groups in the pulp related to MEA pulp. The results also indicated that the mechanical properties of the papers, except for the tear index, were enhanced as the intensity of refining and the pulp consistency during refining increased.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools