Open Access

Open Access

ARTICLE

Effect of Processing and Cultivar on Thermo-Chemical Properties of Australian-Grown Hemp Hurd (Cannabis sativa L.)

1 School of Agriculture, Food and Ecosystem Sciences (SAFES), Faculty of Science, The University of Melbourne, Melbourne, 3121, Australia

2 Research Center for Biomass and Bioproducts, National Research and Innovation Agency (BRIN), Jakarta, 16911, Indonesia

* Corresponding Author: Johannes Fehrmann. Email:

Journal of Renewable Materials 2024, 12(8), 1475-1493. https://doi.org/10.32604/jrm.2024.053741

Received 09 May 2024; Accepted 19 June 2024; Issue published 06 September 2024

Abstract

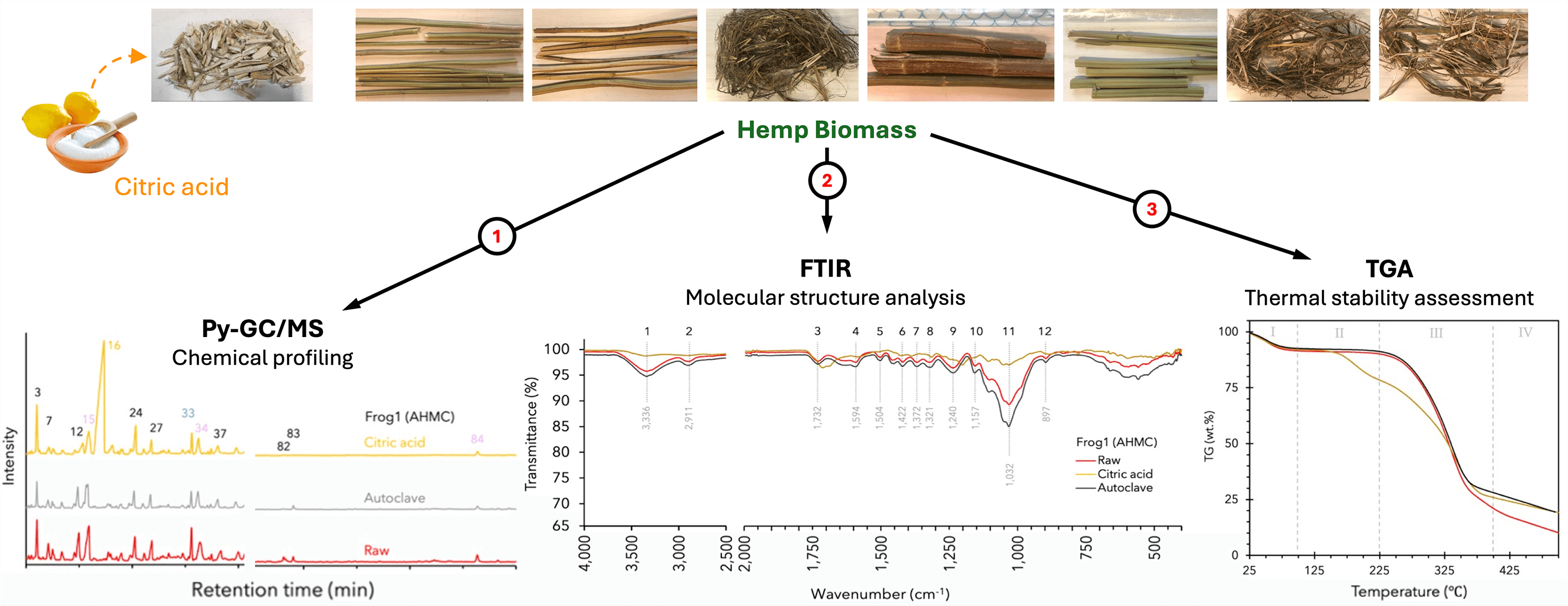

This study explored the thermo-chemical properties of industrial hemp hurd with different provenances, maturity stages, and retting protocols. The findings were then compared to hemp hurd used in the fabrication of citric acid-bonded ultra-low-density hemp hurd particleboard. Pyrolysis-gas chromatography-mass spectrometry (Py-GC/MS), Fourier-transform infrared spectroscopy (FTIR), and thermogravimetric analysis (TGA) were employed to document the variability of the hurd and comprehend the potential impact on biobased composite applications. The choice of cultivar, maturity stage, and processing modality significantly influenced the chemical composition, presence of functional groups, and thermal stability of the hurd. Py-GC/MS revealed substantial variations in the lignin-to-carbohydrate (L/C) ratio, along with the absence of fatty acids in certain cultivars. While FTIR signals confirmed consistent functional groups, differences in peak intensities were indicative of carbohydrate variations associated with maturity and retting duration, impacting the availability of hydroxyl groups for, i.e., interparticle bonding in citric acid-based bio-composites. Furthermore, it was observed that shorter retting durations initially enhanced the thermal resistance, but prolonged retting led to accelerated degradation, significantly reducing the hurd’s residual mass. The findings indicated notable differences among the samples, emphasizing the importance of investigating variables such as provenance/cultivar, maturity, and processing modality. This assessment is essential to ensure effective agronomic practices that align the raw material characteristics with the specific requirements of intended applications, such as the fabrication of biobased hemp hurd composites.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools