Open Access

Open Access

ARTICLE

Water Absorption Capacity and Coating Adhesion on Thermally Modified and Not-Modified Spruce Wood (Blue Stained or Free of Blue Stained)

1

Key Lab of State Forest and Grassland Administration on “Wood Quality Improvement & High Efficient Utilization”, School of

Forestry & Landscape Architecture, Anhui Agricultural University, Hefei, 230036, China

2

Faculty of Technical Engineering, Department of Wood Science and Technology, University of Bihać, Bihać, 7700, Bosnia and

Herzegovina

3

Department of Natural Resources and Earth Science, Shahrekord University, Shahrekord, 64165478, Iran

4

Biotechnical Faculty, Department of Wood Science, University of Ljubljana, Ljubljana, 1501, Slovenia

* Corresponding Author: Mohsen Bahmani. Email:

(This article belongs to the Special Issue: Special Issue in Celebration of JRM 10 Years)

Journal of Renewable Materials 2023, 11(12), 4061-4078. https://doi.org/10.32604/jrm.2023.043657

Received 08 July 2023; Accepted 18 August 2023; Issue published 10 November 2023

Abstract

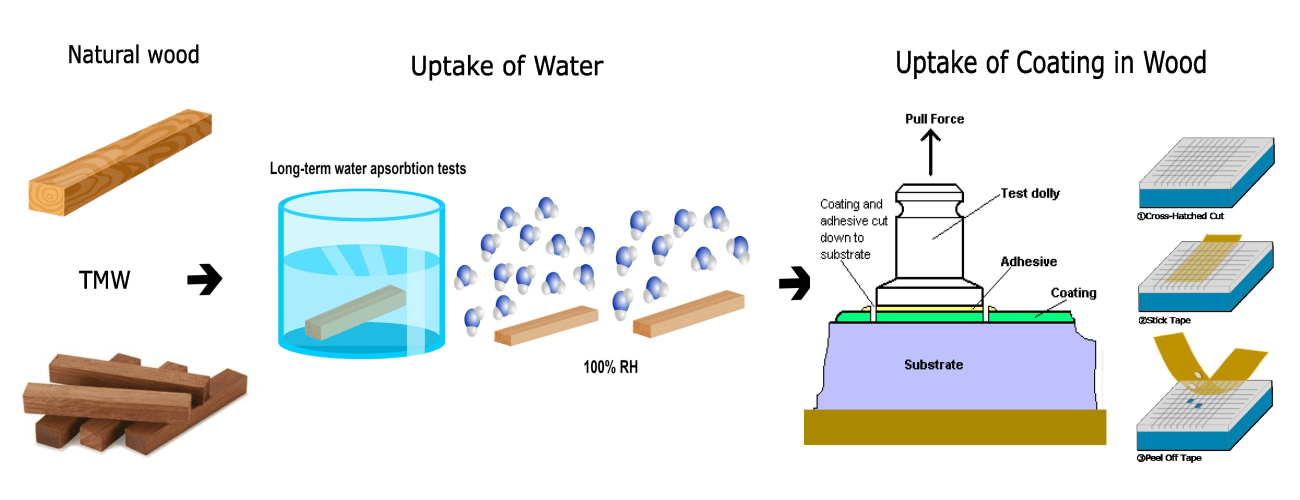

This study aimed to investigate the water absorption capacity of thermally modified and non-modified spruce and blue-stained spruce wood. The wettability of wood depends on various factors, including its type, density, porosity, and surface treatment. Wood can swell and become distorted when exposed to water or humidity, impacting its structural integrity. Hence, it is crucial to consider the water and water vapour uptake in the wood when choosing materials for applications that are likely to be exposed to moisture. Various moisture absorption tests were conducted to assess water absorption capacity, including short-term and long-term water absorption and water vapour absorption. The results showed a significant difference in the long-term exposure to water, which was related to the density of the wood. The study examined the influence of thermal treatment on the physical properties of wood and observed significant variations in mass change due to coating, indicating differences in adhesion among different wood types. Vacuum-treated blue-stained Norway spruce demonstrated higher adhesion (5%–15%) compared to air-treated samples. Furthermore, cohesion tests revealed lower cohesion force in blue-stained Norway spruce (approximately 20%–30%) compared to Norway spruce. The study also used industry-standard tests to investigate the adhesion and cohesion of nano-coatings on wood surfaces. The results provided valuable information on the properties of coatings applied to wood, which is vital in protecting and decorating wood while also providing preventive protection against wood pests, weathering, and mechanical influences. Wood modification in vacuum involves subjecting the wood to a low-pressure environment to remove air and moisture, allowing for deeper and more uniform penetration of treatment chemicals. In contrast, wood modification in air relies on the natural circulation of air to facilitate the absorption of chemical treatments, without the need for a vacuum chamber.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools