Open Access

Open Access

ARTICLE

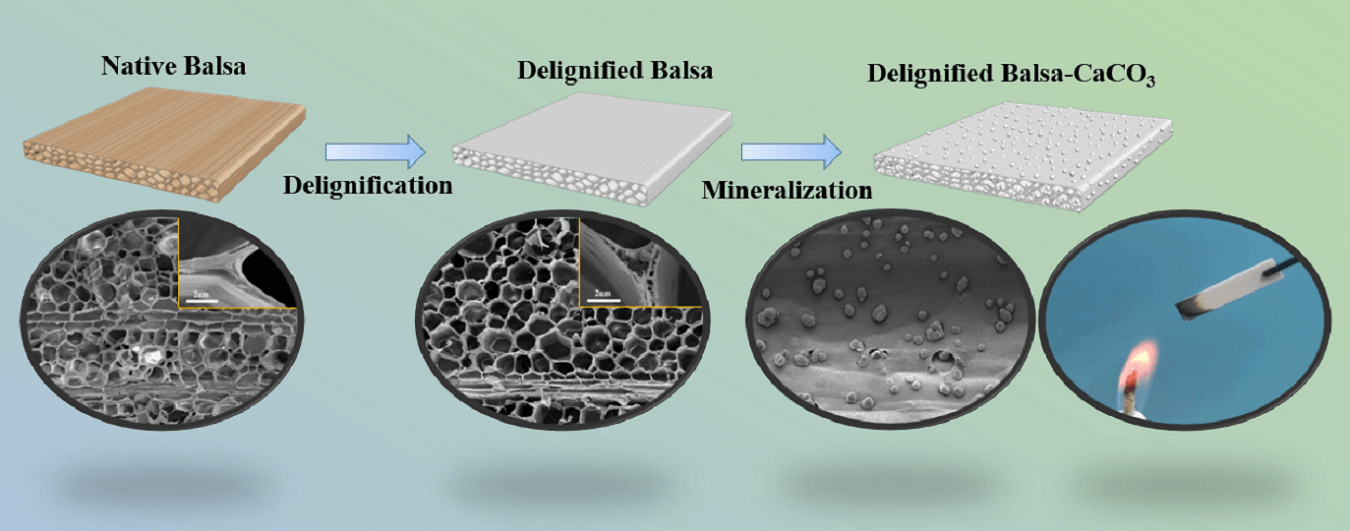

Flame Retardant Material Based on Cellulose Scaffold Mineralized by Calcium Carbonate

State Key Laboratory of Pulp and Paper Engineering, School of Light Industry and Engineering, South China University of Technology, Guangzhou, 510640, China

* Corresponding Author: Chuanfu Liu. Email:

(This article belongs to the Special Issue: Process and Engineering of Lignocellulose Utilization)

Journal of Renewable Materials 2024, 12(1), 89-102. https://doi.org/10.32604/jrm.2023.029057

Received 30 January 2023; Accepted 13 March 2023; Issue published 23 January 2024

Abstract

Wood-based functional materials have developed rapidly. But the flammability significantly limits its further application. To improve the flame retardancy, the balsa wood was delignified by NaClO2 solution to create a cellulose scaffold, and then alternately immersed in CaCl2 ethanol solution and NaHCO3 aqueous solution under vacuum. The high porosity and wettability resulting from delignification benefited the following mineralization process, changing the thermal properties of balsa wood significantly. The organic-inorganic wood composite showed abundant CaCO3 spherical particles under scanning electron microscopy. The peak of the heat release rate of delignified balsa-CaCO3 was reduced by 33% compared to the native balsa, according to the cone calorimetric characterization. The flame test demonstrated that the mineralized wood was flame retardant and self-extinguish. Additionally, the mineralized wood also displayed lower thermal conductivity. This study developed a feasible way to fabricate a lightweight, fire-retardant, self-extinguishing, and heat-insulating wood composite, providing a promising route for the valuable application of cellulosic biomass.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools