Open Access

Open Access

ARTICLE

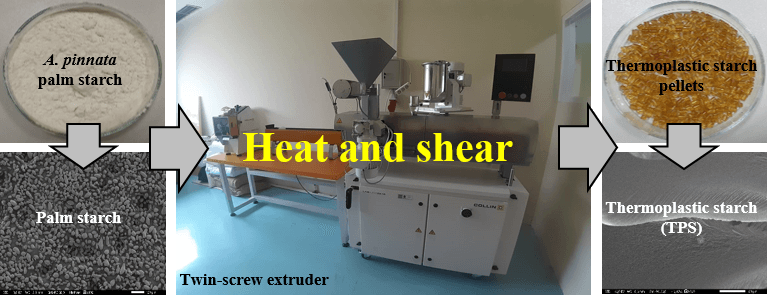

Preparation and Characterization of Thermoplastic Starch from Sugar Palm (Arenga pinnata) by Extrusion Method

1

Departement of Metallurgy and Material, Universitas Indonesia, Depok, 16424, Indonesia

2

Research Center for Chemistry, National Research and Innovation Agency (BRIN), Kawasan PUSPIPTEK Serpong, Tangerang

Selatan, 15314, Indonesia

3

Research Center for Biomass and Bioproducts, National Research and Innovation Agency (BRIN), Jl Raya Bogor KM 46 Cibinong,

Bogor, 16911, Indonesia

4

Faculty of Forest Industry, University of Forestry, Sofia, 1797, Bulgaria

* Corresponding Author: Mochamad Chalid. Email:

Journal of Renewable Materials 2023, 11(4), 1963-1976. https://doi.org/10.32604/jrm.2023.026060

Received 12 August 2022; Accepted 20 September 2022; Issue published 01 December 2022

Abstract

Sugar palm (Arenga pinnata) starch is considered an important renewable, biodegradable, and eco-friendly polymer, which is derived from agricultural by-products and residues, with great potential for the development of biocomposite materials. This research was aimed at investigating the development of TPS biocomposites from A. pinnata palm starch using an extrusion process. Palm starch, glycerol, and stearic acid were extruded in a twin-screw extruder. Scanning electron microscopy (SEM) analysis of TPS showed that the starch granules were damaged and gelatinized in the extrusion process. The density of TPS was 1.3695 g/mL, lower than that of palm starch, and the addition of stearic acid resulted in increased TPS density. X-ray diffraction (XRD) results showed that palm starch had a C-type pattern crystalline structure. The tensile strength, elongation at break, and modulus of elasticity of TPS were 7.19 MPa, 33.95%, and 0.56 GPa, respectively. The addition of stearic acid reduced the tensile strength, elongation at break and modulus of elasticity of TPS. The rheological properties, i.e., melt flow rate (MFR) and viscosity of TPS, were 7.13 g/10 min and 2482.19 Pa.s, respectively. The presence of stearic acid in TPS resulted in increased MFR and decreased viscosity values. The peak gelatinization temperature of A. pinnata palm starch was 70°C, while Tg of TPS was 65°C. The addition of stearic acid reduced the Tg of TPS. The thermogravimetric analysis (TGA) analysis showed that the addition of glycerol and stearic acid decreased the thermal stability, but extended the temperature range of thermal degradation. TPS derived from A. pinnata palm starch by extrusion method has the potential to be applied in industrial practice as a promising raw material for manufacturing bio-based packaging as a sustainable and green alternative to petroleum-based plastics.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools