Open Access

Open Access

ARTICLE

Study on Microwave Pretreatment Technology to Improve the Effect of Shellac Impregnation of Fast-Growing Chinese Fir

1 College of Material Engineering, Fujian Agriculture and Forestry University, Fuzhou, 350002, China

2 Fujian Provincial Forestry Survey and Design Institute, Fuzhou, 350001, China

3 Nanocellulose and Biocomposites Research Centre, College of Engineering, Design and Physical Sciences, Brunel University,

London, UB8 3PH, UK

* Corresponding Authors: Qinzhi Zeng. Email: ; Weigang Zhao. Email:

(This article belongs to the Special Issue: Renewable and Biosourced Adhesives-2021)

Journal of Renewable Materials 2022, 10(8), 2041-2053. https://doi.org/10.32604/jrm.2022.018027

Received 24 June 2021; Accepted 11 August 2021; Issue published 25 April 2022

Abstract

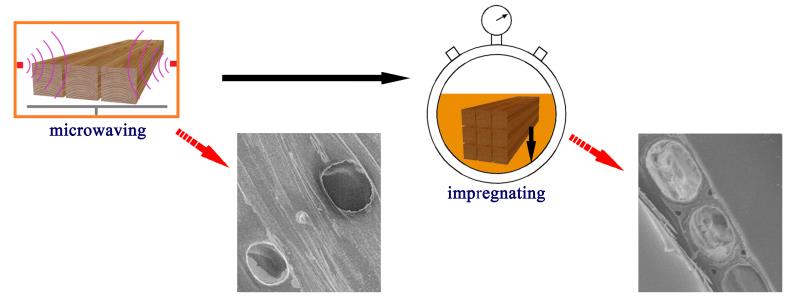

To improve the mechanical properties of fast-growing Chinese fir (Cunnighamia lanceolate), expand its range of application, increase its value, and avoid the environmental pollution caused by impregnation with synthetic resin, Chinese fir was impregnated with a shellac solution. Since the shellac solution was difficult to penetrate into fast-growing Chinese fir, so microwave pretreatment was used to irradiate the wood to improve the permeability. This study investigated the effects of four factors, including the content of moisture in the wood before it was microwaved, the chamber pressure of microwave, the time of microwaving and the vacuum impregnation on the mechanical properties of Chinese fir wood. When the moisture content of wood before microwave was approximately 50%–60%, after microwaving and impregnation, the ultimate strength in static bending (modulus of rupture [MOR]) and strength in compression perpendicular to the grain (SCPG) of the wood increased significantly. A microwave time of 100 seconds was more effective at improving the MOR and SCPG of the wood. If the wood was microwaved for too short or long period of time, the microwave pretreatment was not effective. When the samples were immersed in shellac for a longer period, the MOR and SCPG of Chinese fir gradually increased, but when the wood was impregnated for more than 12 hours, the increases were not significant. After the shellac penetrated the Chinese fir wood, it spread on the inner wall surface of tracheid to form a shellac film and easily formed plug-like deposits in microcapillaries. The use of Fourier-transform infrared spectroscopy, scanning electron microscopy and scanning electron microscopy-energy dispersion x-ray indicated that the microwave pretreatment can destroy the pit membranes on tracheids and facilitate the ability of shellac to penetrate the channel.Graphic Abstract

Keywords

Cite This Article

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools