Open Access

Open Access

ARTICLE

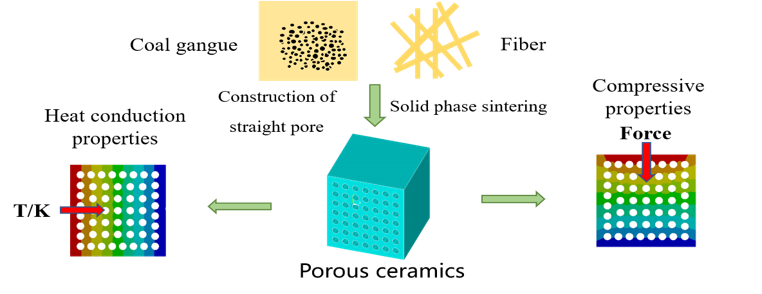

Constructing Straight Pores and Improving Mechanical Properties of Gangue-Based Porous Ceramics

School of Materials Science and Engineering, Xi’an University of Science and Technology, Xi’an, 710054, China

* Corresponding Author: Huiling Du. Email:

(This article belongs to the Special Issue: New Trends in Sustainable Materials for Energy Conversion, CO2 Capture and Pollution Control)

Journal of Renewable Materials 2021, 9(12), 2129-2141. https://doi.org/10.32604/jrm.2021.016090

Received 05 February 2021; Accepted 23 March 2021; Issue published 22 June 2021

Abstract

The large-scale accumulation and pollution of solid mining waste is an urgent issue. Coal gangue is a prominent type of solid waste, and shows promise for use in high value-added products due to its content of many important compounds, including SiO2 and Al2O3. This study proposed the preparation of highly porous ceramics from coal gangue, coal slime, and coconut palm fibers. The ceramics were produced at a sintering temperature of 950°C with a fiber content of 6 wt%, which led to the formation of porous ceramics with a porosity of 66.93%, volume density of 1.0329 g/cm3 , compressive strength of 1.1025 MPa, and thermal conductivity is 0.3919 K(W/mk). A finite element model of the porous ceramics was established using the Abaqus module in ANSYS software, where the stress distribution and compressive strength were simulated. Further, the relationship between porosity and compressive strength was analyzed. The thermal properties of the porous ceramics were analyzed using the Fluent module, where the simulated changes in porosity under various sintering temperatures were consistent with the experimental data. The preparation of this highly porous ceramic from solid waste coal gangue shows promise for the minimizing the impact of waste gas and wastewater pollution in the future.Graphic Abstract

Keywords

Cite This Article

Citations

Copyright © 2021 The Author(s). Published by Tech Science Press.

Copyright © 2021 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools