Open Access

Open Access

ARTICLE

Effect of Thermal Ageing on the Thermal and Mechanical Properties of Polypropylene and Polypropylene Micro-Composites

1 Mechanical Engineering Department, Faculty of Science and Technology, Mustapha Stambouli University of Mascara, Mascara, 29000, Algeria

2 LMPM, Mechanical Engineering Department, University of Sidi Bel Abbes, Sidi Bel Abbes, 22000, Algeria

3 Department of Mechanical Engineering, University of Saida, Saida, 20015, Algeria

* Corresponding Authors: Bel Abbes Bachir Bouiadjra. Email: ,

Journal of Polymer Materials 2024, 41(3), 143-158. https://doi.org/10.32604/jpm.2024.056385

Received 22 July 2024; Accepted 13 September 2024; Issue published 30 September 2024

Abstract

The use of polypropylene composites in various industrial fields has expanded considerably in recent years. A number of researches have been carried out to characterize the performance of polypropylene and its composites. However, the effects of ageing on the long-term behaviour of this thermoplastic are not well understood. The purpose of this study is to analyse the consequences of thermal degradation on the thermal and mechanical properties of three distinct materials: virgin Polypropylene (PP), virgin Polypropylene + talc (PP/talc), and virgin Polypropylene + Carbon Black (PP/CB) micro-composites. Specimens of these materials underwent exposure in an oven at a temperature of 50°C for 7 days. This temperature was chosen because previous research has shown that the PP analyzed completely loses its mechanical properties and would be unusable at 60°C. A comprehensive set of tests and analyses, including Thermo-gravimetric Analysis (TGA), Differential Scanning Calorimetry (DSC) analysis, Dynamic Mechanical Analysis (DMA), and micro-hardness tests, were conducted both before and after thermal ageing. The obtained results indicate that reinforcing polypropylene with mineral particles generally enhances its thermal and mechanical properties. After ageing, the degradation temperature of PP increases by 3% when 4% talc is added, whereas this increase is of the order of 0.2% when 4% carbon black is added. These particles mitigate the adverse effects of thermal ageing on various properties, with the exception of micro-hardness, where higher values were observed for pure polypropylene after thermal ageing. The results show that the addition of talc or carbon black particles improves polypropylene’s thermal stability, crystallinity and mechanical properties. In addition, this addition reduces the negative effects of thermal ageing on the mechanical and thermal properties of PP. The drop in storage modulus after ageing, ageing is of the order of 14% for pure polypropylene, 11% for PP/CB composite and 8% for PP/talc composite.Keywords

Polypropylene (PP) is one of the most versatile polymers. It is used both as a thermoplastic and as a fiber. Polypropylene is semi-crystalline, its melting temperature is between 165°C and 175°C and its glass transition temperature is around −10°C. The glass transition (Tg) corresponds to a softening of the material due to the movement of long chain segments [1–3]. The value of Tg (Boundary between two basic states: rubbery state or soft at “high temperatures” and the glassy state or hard and brittle at “low temperatures”. The high crystallinity of PP gives it good mechanical strength [4,5].

The inherent high crystallinity of PP contributes to its commendable mechanical strength. However, challenges arise in its application due to its limited service temperature and vulnerability to external factors such as heat, light, and oxidation, rendering the polymer brittle and fragile [6,7]. The susceptibility to degradation is primarily linked to the reaction of free radicals within the PP, causing chain rupture, particularly given the presence of tertiary carbon atoms [8–10]. Thermoplastic polypropylene was exposed to the coupling condition of elevated temperature, water immersion and sustained bending loading for as long as 90 days [3]. Water uptake, mechanical and thermal properties tests were conducted to obtain the long-term evolution. It was shown that Long-term life prediction of tensile strength showed when the service time was 500 days, the retention of tensile strength for polypropylene was close to 90% at 8.8°C [3].

Temperature sensitivity, a characteristic of all thermoplastic polymers, makes PP prone to thermal ageing under prolonged exposure to elevated service temperatures [11–13]. Addressing the adverse effects of thermal ageing necessitates innovative solutions, such as incorporating nano or micro-particles with higher temperature resistance into the polymer matrix [14–16]. The development of nano or micro composites, especially those with mineral fillers, emerges as a promising avenue to enhance the resilience of thermoplastic polymers, potentially broadening their utility.

In the realm of thermoplastic composites, isotactic polypropylene (iPP) often serves as a matrix due to its favorable mechanical properties and cost-effectiveness. Studies reveal that thermal degradation in thermoplastic composites involves various factors, with the addition of particles like titanium dioxide or carbon black significantly influencing thermal stability [17–19]. For instance, the inclusion of titanium dioxide has been shown to enhance thermal stability, with the improvement correlating with increased TiO2 content [20].

Carbon black (CB), a widely employed conductive particle in composites and conductive polymers, offers advantages in terms of cost and density. Its impact on polypropylene’s light and weather stability is well-documented, with particle size inversely proportional to the observed improvement [21,22]. Meanwhile, talc, with its lamellar structure, emerges as a preferred mineral reinforcement for PP due to its positive effects on stiffness and crystallization [23–25]. Despite the abundance of talc in nature, challenges arise from the strength of the talc-PP interface and the non-uniform distribution of talc particles in the PP matrix, potentially diminishing the strength of the resulting composite.

Studies comparing talc and carbon black as reinforcement for thermoplastic polymers are rare in the literature. The novelty of our study is to compare the thermal and mechanical properties of PP + talc and PP + CB composites before and after thermal ageing. These characteristics are compared with those of pure polypropylene. This study delves into the effects of accelerated thermal ageing on the physical properties of pure virgin polypropylene and micro-composites, specifically those filled with 4% talc and 4% carbon black particles. Through comprehensive physical analyses, including Thermo-gravimetric Analysis (TGA), Differential Scanning Calorimetry (DSC), and Dynamic Mechanical Analysis (DMA), we aim to elucidate the intricate interplay between thermal ageing and the physical characteristics of these materials.

2.1 Micro-Composites Fabrications

The polymer chosen for this investigation is a homopolymer polypropylene equivalent to the standard grade, specifically Borealis PP HD120MO. This polypropylene exhibits a well-balanced set of mechanical properties designed for injection molding applications. Primarily employed for producing injection-molded articles requiring high rigidity, PP HD120MO is the raw material for manufacturing food packageing containers, household items, small appliances, and technical components. Fundamental physical properties of this polypropylene include a melt index (230°C/2.169 kg) of 8 g/10 min, a density of 0.9 g/cm3, and a melt temperature of approximately 240°C.

To fabricate two distinct micro-composites from polypropylene, two reinforcements were employed:

Fine talc powder, derived from the original talc with a 2.78 g/cm3 density and an average particle size of about 1 µm. The talc/polypropylene mixture was composed of 60% polypropylene and 4% talc.

Carbon black (CB) particles are obtained through the pyrolysis of used car tires, constituting 4% of the composition. Tires were made from natural rubber, which was filled with carbon black and silica. After the tire is burned, the carbon black is extracted from the residue.

The preliminary process involved mixing the PP resin with the respective fillers in a rotary mixer at a speed of 90 rpm for 15 min. The resulting mixture was then fed into an extruder, introduced into the extruder barrel without pre-processing, and melted through heating devices along the cylinder. The molten mixture was extruded through a die, emerging as elongated strands that were cut into cylindrical pellets measuring 2 mm in length.

Various specimens were manufactured from the PP/talc and PP/CB micro-composites using an injection molding machine with a screw temperature of 190°C and a mold temperature of 30°C. To assess the impact of thermal ageing on the properties of the micro-composites, specimens from pure PP, PP/talc composite, and PP/CB composite were exposed to a temperature of 50°C in an oven for 7 days. This temperature was chosen because previous research [23] has shown that the PP analyzed completely loses its mechanical properties and would be unusable at 60°C. This study aims to elucidate the effects of thermal ageing on micro-composites’ properties through a comprehensive analysis of the fabricated specimens. Fig. 1 show the process of the composites manufacturing and the different materials.

Figure 1: Schematic diagram for the fabrication process. (a) Process of the composites manufacturing, (b) Photos of the different materials

2.2 Micro-Composites Characterization

Different analyses were performed on pure PP, PP/talc, and PP/CB to study the effect of thermal ageing on the physical properties of the two micro-composites. The properties of the pure PP are taken as references for comparison.

We used energy dispersive X-ray spectrometry (EDS) on the Bruker S2-PUMA-EDXRF spectrometer (Karlsruhe, Germany) to analyze the talc and carbon particles in PP/talc and PP/CB composites. Fig. 2 presents the EDS spectrum of pure PP, we can see a carbon proportion of 70%. Fig. 3 shows the EDS spectrum of the PP/talc composite, noting that the weight percentage of calcium is around 4.16%. At the same time, other minerals are detected, particularly Silicon, Iron, Sulfur, Magnesium and Aluminum. Fig. 4 presents the spectrum of PP/CB, noting the proportion of the carbon is about 84%.

Figure 2: EDS spectrum of pure PP

Figure 3: EDS spectrum of PP/talc composite

Figure 4: EDS spectrum of PP/CB composite

The DSC analysis was performed on DSC 131 evo using CALISTO software, CETARAM Instrumentation (Caluire, France) on samples of pure PP (non-aged and aged), PP/talc composite (non-aged and aged) and of PP/CB (non-aged and aged). This test allowed us to determine the glass transition temperature, the rate of crystallinity, and the melting temperature. The test conditions for the DSC analysis were as follows:

Heating program:

- 1 min at 20°C

- Heating at 10°C/min to 250°C

- Cooling at 10°C/min to 20°C

- Heating at 10°C/min to 250°C

- Return Tamb

Sample weight: between 5 and 10 mg

The TGA analysis was also carried out by LABSYS evo using CALISTO software, CETARAM Instrumentation (Caluire, France) on samples of aged and non- aged pure PP, PP/talc composite, and PP/CB composite. This test allowed us to determine the degradation temperature, which was performed according to the standard NF EN ISO 11358. The heating program was from room temperature to 700°C with heating speed of 10°C/min.

The Dynamic Mechanical Analysis (DMA) test was carried out on a Solids Analyzer-METRAVIB DMA 50, ACOEM, (Lyon, France) on pure PP, PP/talc and PP/CB samples (aged and unaged according to NF EN ISO 6721. The samples were rectangular with dimensions 20 × 5 × 0.8 mm. The temperature range used was 25–120°C with a heating rate of 10°C/min. It maintained a gap of 15 mm, and the maximum strain was recalculated for each composite. From these tests, we extracted the variation of the storage modulus (E′) and the damping factor (E″) as a function of the temperature for each aged and non-aged material).

In order to establish the relationship between the mechanical properties of the different materials and thermal ageing, we performed Vickers hardness tests with an FM-ARS9000 (Fully-Automatic Micro-hardness Testing System, Future-Tech Corp., Tokyo, Japan) on flat specimens of dimensions: 120 m × 10 m × 2 mm. The tests were done in five points in each specimen. The test consisted of printing the specimen with a square-based pyramid indenter under an applied load of 300 g for 10 s. The micro-hardness tests were carried out on specimens in aged and unaged materials.

3.1 Effects of Minerals Particles on Thermal Stability

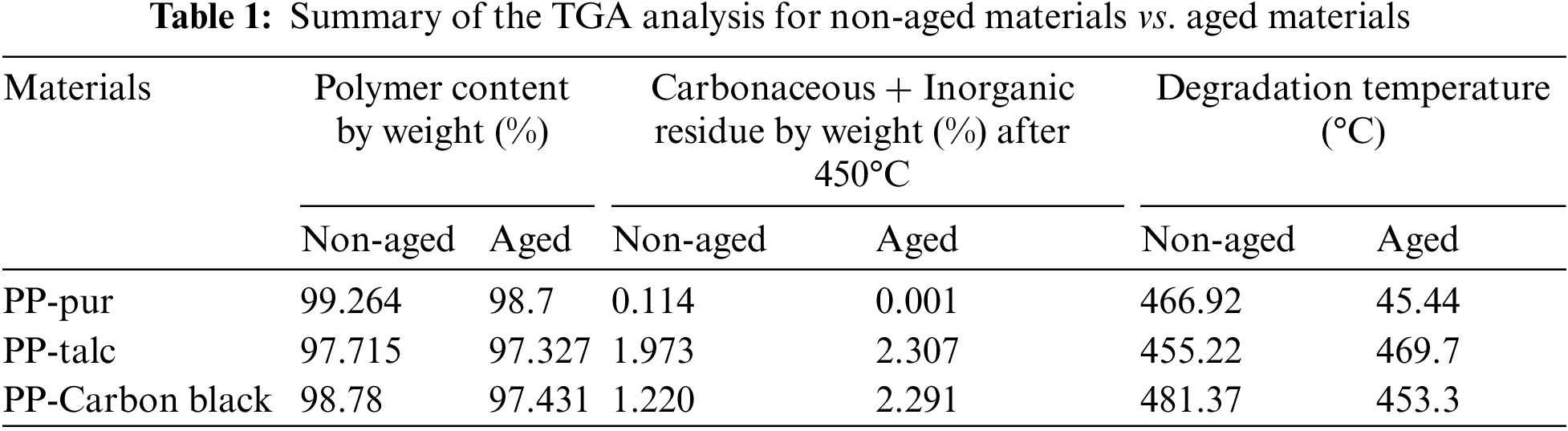

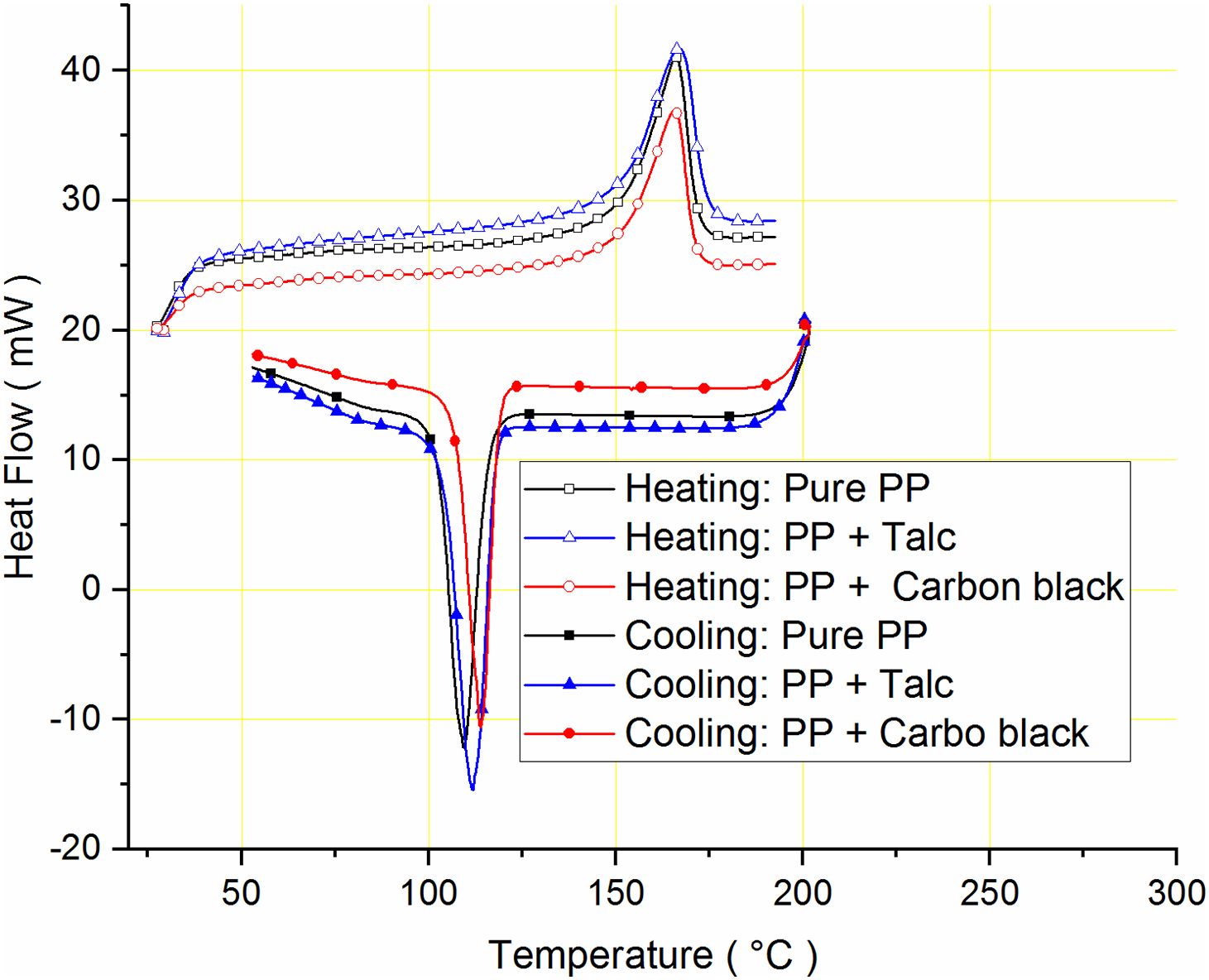

Thermogravimetric curves for pure unaged PP, unaged PP + 4% of talc and unaged PP + 4% of carbon black are shown in Fig. 5. All three curves show a one-step degradation attributed to the random fractionation of radicals leading to polyolefin degradation. We can see from this figure that the presence of talc leads to a reduction in the degradation temperature of PP. In contrast, the presence of CB has the opposite effect, with the degradation temperature of PP increasing with the addition of carbon black particles. The degradation temperature of unaged PP is around 466.92°C, decreasing to 455.22°C when 4% talc is added to PP. For CB particles, the degradation temperature is 481.37°C. It can, therefore be said that the presence of carbon black in PP improves its thermal stability. However, the presence of talc slightly reduces this stability. At a temperature of 700°C, the residual weight of the PP + talc composite is around 1.97%, whereas for PP + CB, the residual weight is around 1.22%. This shows that small quantities of talc and CB were lost during the compounding and extrusion operations. Table 1 summarizes the results of TGA tests on aged andnon-aged materials. Our results are in concordance with those of Espinosa et al. [26]. These authors showed that the degradation temperature of pure PP is about 461°C and that of PP + 2% of talc is about 458°C.

Figure 5: TG curves of non-aged PP, PP/talc and PP/CB

Fig. 6 shows the TGA curves for the three materials (pure PP, PP + 40% talc, and PP + 40% CB) after exposure in an oven at 50°C for 7 days. It can be seen that the degradation temperature is lower for all three materials than in the unaged case. This temperature is around 452.44°C for pure PP and the PP/NC composite and around 454.3°C for the PP/talc composite, at 469°C. We can, therefore, confirm that thermal ageing considerably affects the PP/CB composite since its degradation temperature drops from 481°C to 454°C, with a relative reduction of 6%. At the same time, for PP/talc, we have an improvement in degradation temperature of around 3%. We can conclude that after thermal ageing, talc offers better thermal stability to PP than carbon black.

Figure 6: TG curves of aged PP, PP/talc and PP/CB

In summary, the decrease in the thermal stability of talc particles after ageing results from the breaking mechanisms of the polypropylene (PP) matrix chains during the mixing process [27]. Furthermore, the thermal conductivity of talc is higher than that of PP, allowing the temperature of the talc-containing sample to rise immediately. After ageing, the thermal stability of PP is improved by talc, which is chemically inert and does not affect the structure of PP modified by ageing. However, before ageing, carbon black enhances the thermal stability of unaged PP by delaying oxidative degradation thanks to the presence of its particles [28]. However, after thermal ageing, the degradation of PP molecular chains favors the reaction between carbon black and PP, leading to a reduction in thermal stability.

3.2 Effects of Minerals Particles on Thermal Properties

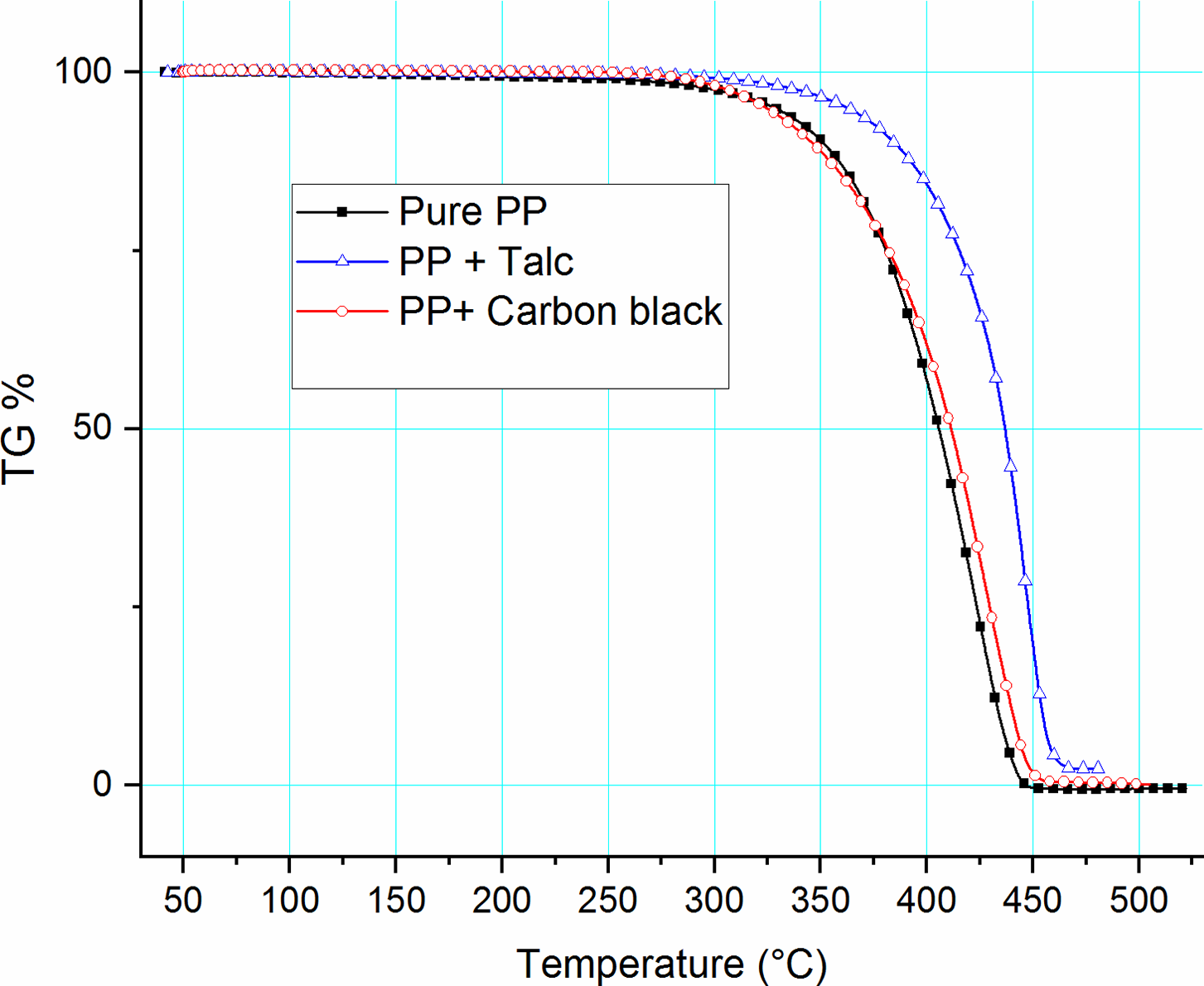

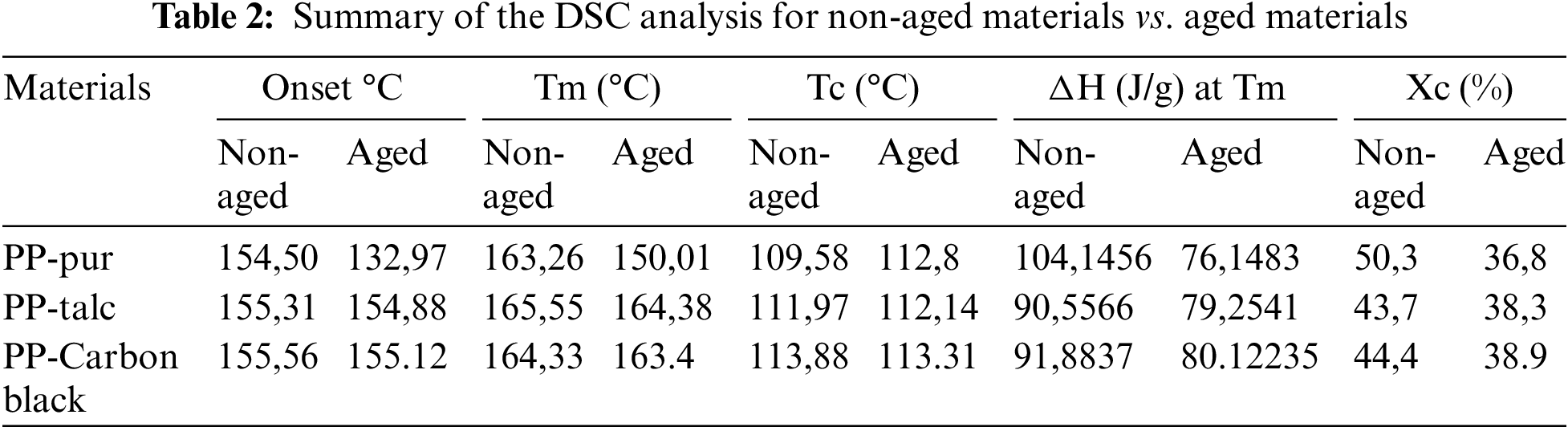

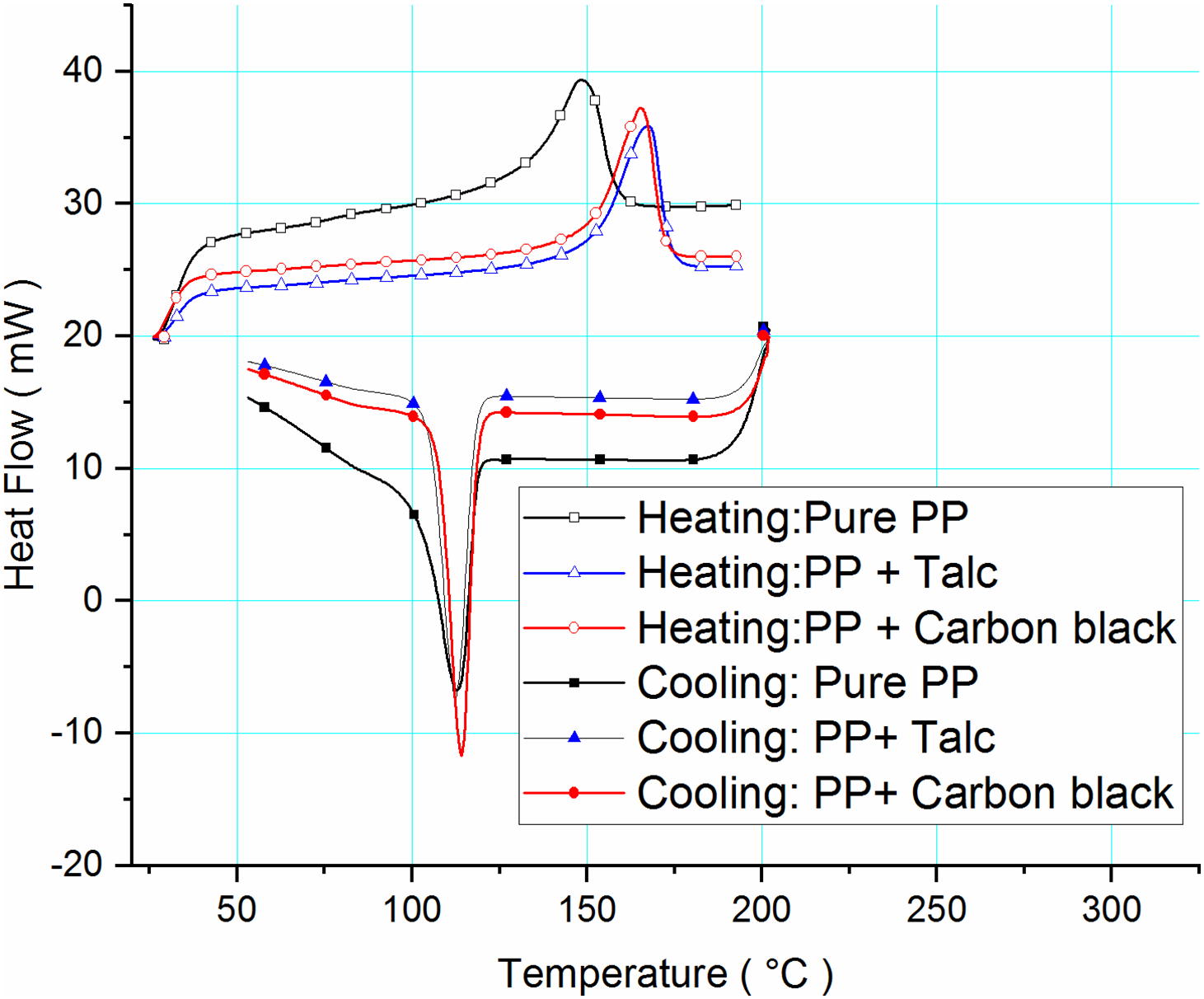

Fig. 7 presents the thermo grams of the DSC analysis for the unaged materials, and Table 2 summarizes the results. We note that adding talc or carbon black particles slightly increases the melting temperature (Tm). The crystallization temperature also increases for both composites, but this increase is not significant enough. On the other hand, the crystallinity index (Xc) is reduced by the addition of mineral particles. The crystallinity index was by calculating the ratio between the enthalpy of our polymer (at the temperature Tc) and that of 100% crystalline polypropylene. Hou et al. [29] confirmed that the melting Temperature of the PP/talc composite increases slightly compared with pure PP, which may be due to the thick formed wafers when crystallized at high temperatures. They also concluded that the crystallinity of PP in the composites is slightly less than that of pure PP. The high melting points of talc and carbon black will raise the melting and crystallization temperatures of PP. On the other hand, the addition of mineral particles to the PP matrix will disrupt the polymer’s molecular chain arrangement, reducing its crystallinity index.

Figure 7: DSC curves for the three materials before ageing: heating vs. cooling

After exposure to a temperature of 50°C for 8 days (Fig. 8 and Table 2), the melting temperature is reduced for PP and both composites. This reduction is more pronounced for pure PP. In contrast, for the two composites (PP/talc and PP/CB), the effect of thermal ageing on the crystallization temperature (Tc) is not noticeable. The crystallinity index (Xc) is clearly deteriorated by thermal ageing. This index is reduced by 36% for pure PP, 14.1% for PP/talc, and 13.2% for PP/CB. Adding mineral particles to PP attenuates the negative effects of thermal ageing on polymer crystallinity.

Figure 8: DSC curves for the three materials after ageing: heating vs. cooling

3.3.1 Variation of Elongation Storage Modulus

Fig. 9 shows the variation curves of the elongation storage modulus (E′) as a function of temperature for the three unaged materials (PP, PP/talc, and PP/CB). This modulus represents the elastic stiffness of the material. It represents the capacity of the material to restore the stored mechanical energy in the form of elastic deformation (the notion of reversibility). According to Fig. 9, we notice that the presence of mineral filler in the PP improves the modulus of conservation for low temperatures. The modulus E′ values are higher for PP/talc compared to PP/CB, which allows us to confirm that talc gives a better elastic rigidity compared to carbon black. When the temperature increases, the E′ modulus values of the three materials drop considerably and get closer; this is due to the fact that the stiffness of the three materials deteriorates considerably when the temperature increases. Our Results confirm those of Bouakkaz et al. [23] whom showed that the addition of talc particles in PP increases the storage modulus even at high temperature.

Figure 9: Storage modulus vs. temperature for non-aged materials

Fig. 10 presents the variation curves of the elongation conservation modulus (E′) as a function of temperature for pure PP, PP/talc, and PP/CB after exposure at the temperature of 50°C for 7 days. It can be seen that the modulus E′ drops significantly for all three materials after thermal ageing compared to the cases of unaged materials (Fig. 7). Even if the temperature is not high, its effect over time is significant. At a temperature of 0°C and for pure PP, this modulus drops from 2200 MPa (before ageing) to 1900 MPa (after ageing), i.e., a relative reduction of 14%. This reduction is about 11% for the PP/CB composite and 8% for the PP/talc composite. This shows that adding mineral filler (especially talc) improves elastic rigidity.

Figure 10: Storage modulus vs. temperature for aged materials

3.3.2 Variation of Damping Factor

Fig. 11 shows the curves for the variation of the mechanical damping factor tang (δ) as a function of temperature for the three non-aged materials. The mechanical loss angle (or damping factor) tang (δ) expresses the ratio of the damping dissipation modulus (E″) to the elastic modulus (E′):

Figure 11: Damping factor vs. temperature for non-aged materials

It can be seen from Fig. 11 that for a temperature below 40°C, the damping factor of pure PP is higher than those of the two composites; the low E′ modulus of pure PP compared to its composites explains in part this trend for the damping factor. Above the temperature of 40°C, the three materials have almost the same damping factor.

Concerning the aged materials (Fig. 12), we notice that the damping factor remained practically unchanged for pure PP and decreased for the two composites (PP/talc and PP/CB). The stability of this factor for pure PP is explained by the fact that after ageing, the ductility of PP increases, leading to an increase in the modulus E″ and a decrease in E′, which will give an unchanged ratio. For both composites, the addition of rigid mineral particles reduces the decrease of the modulus E′ after ageing, which leads to an increase in the damping factor.

Figure 12: Damping factor vs. temperature for aged materials

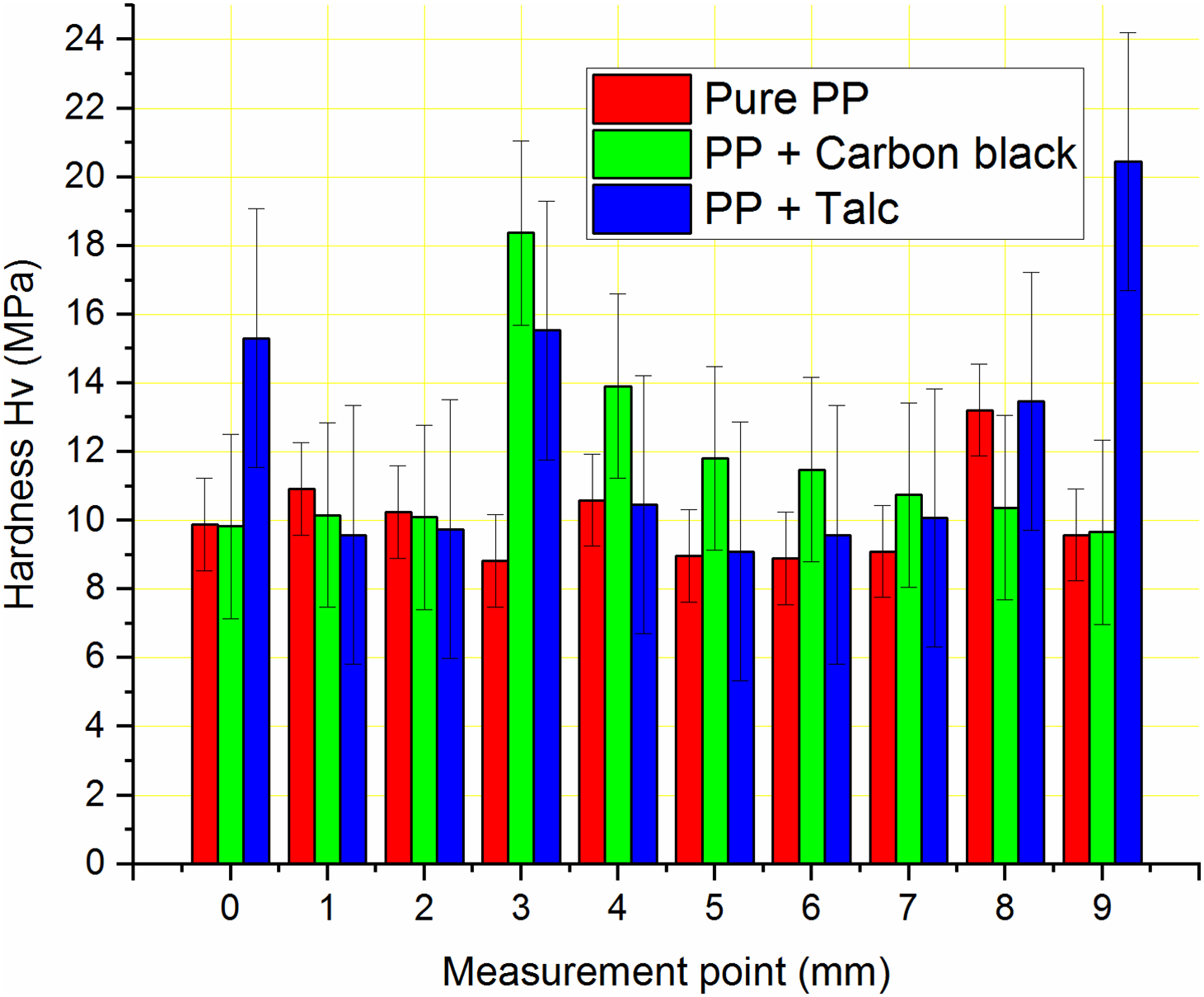

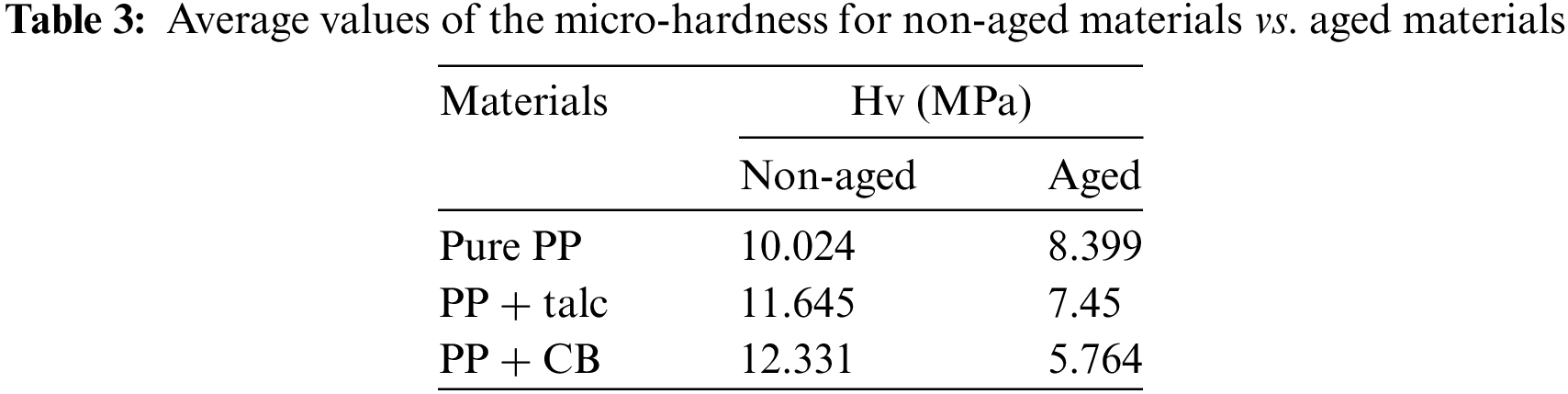

Vickers micro-hardness measurements were performed on non-aged flat specimens made of pure PP, PP/talc, and PP/CB of dimensions 100 × 6 × 0.5 mm. The measurements were carried out on ten positions of these specimens; the results are presented in Fig. 13. We notice a significant dispersion of the microhardness values, particularly for the composite’s PP/talc and PP/CB. This is due to the enormous differences in the hardness between the matrix PP and the microparticles constituting the reinforcements (talc and carbon black). We have consolidated these results by presenting the standard deviation of the microhardness values for the three materials, where we notice a relatively low standard deviation for pure PP. This standard deviation doubles for PP/CB and triples for PP/talc. The latter (PP/talc) presents a more significant heterogeneity than PP/CB. Table 3 shows the average values of the micro-hardness for the three non aged-materials. It can be seen that the Vickers hardness is around 10 MPa for pure PP, and it rises to 11.6 MPa for PP/CB and to 12.3 for PP/talc, which confirms that the mineral fillers increase the hardness of PP and its stiffness will also be increased.

Figure 13: Distribution of the micro-hardness for the three non-aged materials

To evaluate the effects of thermal ageing on the variation of the microhardness of the three materials, the exact Vickers microhardness measurements were performed on specimens exposed to a temperature of 50°C for 7 days; the results are presented in Fig. 14. We notice that the trend was completely reversed. Indeed, the dispersion of the micro-hardness values is more significant for pure PP compared to the two composites. The standard deviation of the values of the micro-hardness presented shows that this value is higher for the PP compared to the micro-composites; the pure PP presents a higher heterogeneity compared to the composites; this is explained by the fact that the thermally aged PP undergoes local hardening which will increase its hardness locally and thus makes it more fragile while the presence of hard mineral filler in the two composites minimizes the extent of this hardening. Table 3 confirms these results; this table presents the average values of the micro-hardness for the three aged materials. We notice a higher average hardness for pure PP than PP/talc and PP/CB, confirming that thermal ageing gives a more significant brittleness for pure PP. However, according to Table 3, we notice that globally, after exposure to the temperature of 50°C for 7 days, the average hardness value decreases from 10 MPa (unaged case) to 8.4 MPa, the relative reduction is about 16%. This reduction is about 53% for PP/CB and about 39% for PP/talc. The hardness of both composites is more affected by thermal ageing compared to pure PP. Bechikhi et al. [30] studied the ageing of pure PP and PP + 5% talc in benzene, and their results are in line with those of the present work. They showed that the addition of talc particles increases the average hardness of PP and attenuates polymer degradation in benzene. The high standard deviation observed in this study is attributable to differences in hardness between the PP and the reinforcements, resulting in significant variations in the measured hardness values of the composite. In addition, this high standard deviation suggests an irregular dispersion of mineral particles in the PP. Recently, Bechikhi et al. [30] have shown that the addition of mineral particles to PP results in a microhardness probability density following a Gaussian normal distribution. Average microhardness is achieved at a probability density of 0.3 for pure PP and 0.1 for PP containing 10% mineral particles. This difference may explain the high values of the microhardness standard deviation for PP loaded with mineral particles.

Figure 14: Distribution of the micro-hardness for the three aged materials

In conclusion, the findings of this study underscore the overall enhancement of polypropylene (PP) properties through the incorporation of mineral fillers, namely talc and carbon black. TGA analysis revealed that carbon black exhibited superior thermal stability compared to talc prior to ageing. The degradation temperature of unaged PP decreases by 11°C after addition of talc and increases by 14.45°C after addition of carbon black particles. For aged PP, the degradation temperature increases by 0.86°C for CB particles and by 17.26°C for talc particles. However, post-ageing, talc demonstrated a more pronounced ability to mitigate the adverse effects of thermal degradation on PP’s thermal stability. DSC analysis provided insights into the positive influence of both fillers on the melting temperature of PP, showcasing mitigation of thermal degradation effects on this crucial parameter. Although the crystallinity index of PP decreased with the introduction of both mineral fillers, their incorporation notably alleviated the negative impact of thermal ageing on this index. The crystallinity index is practically the same at around 38% for both types of composite after thermal ageing.

Remarkably, the storage modulus (E′) experienced a more substantial decrease after thermal ageing in pure PP, emphasizing the mineral fillers’ capacity to preserve elastic stiffness even post-ageing. The micro-hardness results presented a distinctive observation, with the average micro-hardness of pure PP surpassing that of the two composites after ageing. After ageing, the average microhardness value decreases by 21% for PP + talc and 32% for PP + CB compared with pure PP.

To further enrich our understanding, future endeavors will delve into additional mechanical tests, encompassing tensile, bending, impact, and wear analyses. This comprehensive exploration aims to unravel the nuanced interplay between mineral-filled composites and mechanical properties, providing valuable insights for the advancement and optimization of polypropylene-based materials.

Acknowledgement: The authors would like to thank Dr Mohamed Elmeguenni for his invaluable assistance in the realization of this work.

Funding Statement: This research received no specific grant from any public, commercial, or non-profit funding agencies.

Author Contributions: Rachid Bouregba: Methodology, writing review and results discussion. Bel Abbes Bachir Bouiadjra: Methodology, writing review and supervision. Mohamed Mokhtar Bouziane: Methodology and writing review. Mohamed Amine Belaili: Methodology. Mokadem Salem: Methodology after revision. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Takasuka S, Takahashi T. Reinforcing effect of compatibilizers containing oxazoline groups in liquid crystalline polymer/polypropylene blending material. J Polym Mater. 2021;38(1–2):1. [Google Scholar]

2. Zhu W, Yan C, Shi Y, Wen S, Liu J, Shi Y. Investigation into mechanical and microstructural properties of polypropylene manufactured by selective laser sintering in comparison with injection molding counterparts. Mater Des. 2015;82:37–45. doi:10.1016/j.matdes.2015.05.043. [Google Scholar] [CrossRef]

3. Suljovrujic E. The influence of molecular orientation on crosslinking/oxidative behaviour of iPP exposed to gamma radiation. Eur Polym J. 2009;45:2068–78. doi:10.1016/j.eurpolymj.2009.03.017. [Google Scholar] [CrossRef]

4. Keene B, Bourham M, Viswanath V, Avci H, Kotek R. Characterization of degradation of polypropylene nonwovens irradiated by-ray. J Appl Polym. 2014;131(4):1–10. doi:10.1002/app.39917. [Google Scholar] [CrossRef]

5. Cosnita M, Cazan C, Duta A. The influence of inorganic additive on the water stability and mechanical properties of recycled rubber, polyethylene terephthalate, high density polyethylene and wood composites. J Cleaner Prod. 2017;165:630–6. doi:10.1016/j.jclepro.2017.07.103. [Google Scholar] [CrossRef]

6. Oliani WL, Fermino DM, Lima LFCP, Lugao AB, Parra DF. Effects of accelerated thermal aging on polypropylene modified by irradiation process. In: Carpenter JS, Bai C, Escobedo JP, Ikhmayies JHS, Li B, Li J, Monteiro SN, Peng Z, Zhang M, editors. Characterization of minerals, metals, and materials 2015 Orlando, Florida: The Minerals, Metals & Materials Society; 2015. p. 651–8. [Google Scholar]

7. Thu Anh N, Shota I, Kenji K, Wataru S, Naoto T, Satoko O. Spin trapping analysis of the thermal degradation of polypropylene. Polym Degrad Stab. 2022;97:109871. [Google Scholar]

8. Wang K, Addiego F, Bahlouli N, Ahzi S, Rémond Y, Toniazzo V, et al. Analysis of thermomechanical reprocessing effects on polypropylene/ethylene octene copolymer blends. Polym Degrad Stab. 2012;97:1475–84. doi:10.1016/j.polymdegradstab.2012.05.005. [Google Scholar] [CrossRef]

9. Mat-Shayuti MS, Abdullah MZ, Megat-Yusoff P. Thermal properties and morphology of polypropylene/polycarbonate/polypropylene-graft-maleic anhydride blends. MATEC Web Conf. 2016;69:3001. doi:10.1051/matecconf/20166903001. [Google Scholar] [CrossRef]

10. Esmizadeh E, Tzoganakis C, Mekonnen TH. Degradation behavior of polypropylene during reprocessing and its biocomposites: thermal and oxidative degradation kinetics. Polymers. 2020;12(8):1627. doi:10.3390/polym12081627. [Google Scholar] [PubMed] [CrossRef]

11. Mandal DK, Bhunia H, Bajpai PK, Bhalla VK. Thermal degradation Kinetics and estimation of lifetime of radiation grafted polypropylene films. Radiat Phys Chem. 2017;136:1–8. doi:10.1016/j.radphyschem.2017.03.036. [Google Scholar] [CrossRef]

12. Aridi NAM, Sapuan SM, Zainudin ES, AL-Oqla FM. Mechanical and morphological properties of injection-molded rice husk polypropylene. Int J Polym Anal Ch. 2016;21:305–13. [Google Scholar]

13. Yano A, Akai N, Ishii H, Satoh C, Hironiwa T, Millington KR, et al. Thermal oxidative degradation of additive-free polypropylene pellets investigated by multichannel Fourier-transform chem-iluminescence spectroscopy. Polym Degrad. 2013;98:2680–6. [Google Scholar]

14. Wee JW, Choi MS, Hyun HC, Hwang JH, Choi BH. Effect of weathering-induced degradation on the fracture and fatigue characteristics of injection-molded polypropylene/talc composites. Int J Fatigue. 2018;117:111–20. [Google Scholar]

15. Shiravi H, Movahedi M, Ozlati A. Improving appearance and mechanical strength of aluminum-polypropylene/talc composite friction stir joint using a novel tool design. Int J Adv Manuf Technol. 2022;121:3717–30. [Google Scholar]

16. Shokrieh MM, Esmkhani M, Taheri-Behrooz F. A novel model to predict the fatigue life of thermoplastic nanocomposites. J Thermoplast Compos Mater. 2013;28:1496–506. [Google Scholar]

17. Fekih SM, Bouziane MM, Benyahia F, Mohammed SMAK. Optimization of the mechanical strength of PP/TALC micro-composite after immersion in benzene. Strength Mater. 2022;54(3):493–50. [Google Scholar]

18. Meneghetti G, Ricotta M, Lucchetta G, Carmignato S. An hysteresis energy-based synthesis of fully reversed axial fatigue behavior of different polypropylene composites. Compos Part B-Eng. 2017;65:17–25. [Google Scholar]

19. Lin TA, Lin JY, Lou CW, Lin JH. Impact-resistant polypropylene/thermoplastic polyurethane blends: compatible effects of maleic anhydride on thermal degradation properties and crystallization behaviors. J Mater Res Technol. 2019;8:3389–98. [Google Scholar]

20. Esthappan SK, Kuttappan SK, Joseph R. Thermal and mechanical properties of polypropylene/titanium dioxide nanocomposite fibers. Mater Des. 2012;37:537–42. [Google Scholar]

21. Vidakis N, Petousis M, Velidakis E, Mountakis N, Grammatikos S, Tzounis L. Multi-functional medical grade Polyamide 12/Carbon black nanocomposites in material extrusion 3D printing. Compos Struct. 2023;311:116788. [Google Scholar]

22. Shirvanimoghaddam K, Balaji KV, Yadav R, Zabihi O, Ahmadi M, Adetunji P, et al. Balancing the toughness and strength in polypropylene composites. Compos Part B-Eng. 2021;223:109121. [Google Scholar]

23. Bouakkaz AO, Albedah A, Bouiadjra BB, Khan SMA, Benyahia F, Elmeguenni M. Effect of temperature on the mechanical properties of polypropylene-talc composites. J Thermoplast Compos Mater. 2018;31(7):896–912. [Google Scholar]

24. Fabiyi JS, Mcdonald AG. Degradation of polypropylene in naturally and artificially weathered plastic matrix composites. Maderas-Cienc Tecnol. 2014;16:275–90. doi:10.4067/S0718-221X2014005000021. [Google Scholar] [CrossRef]

25. Ammar O, Bouaziz Y, Haddar N, Mnif N. Talc as reinforcing filler in polypropylene compounds: effect on morphology and mechanical properties. J Polym Sci. 2017;3:1–8. [Google Scholar]

26. Espinosa KR, Castillo LA, Barbosa SE. Blown nanocomposite films from polypropylene and talc. Influence of talc nanoparticles on biaxial properties. Mater Des. 2016;111:25–35. doi:10.1016/j.matdes.2016.08.045. [Google Scholar] [CrossRef]

27. Yang H, Gong J, Wen X, Xue J, Chen Q, Jiang Z, et al. Effect of carbon black on improving thermal stability, flame retardancy and electrical conductivity of polypropylene/carbon fiber composites. Compos Sci Technol. 2015;113:31–7. doi:10.1016/j.compscitech.2015.03.013. [Google Scholar] [CrossRef]

28. Wang K, Bahlouli N, Addiego F, Ahzi S, Rémond Y, Ruch D, et al. Effect of talc content on the degradation of re-extruded polypropylene/talc composites. Polym Degrad Stab. 2013;98:1275e128. doi:10.1016/j.polymdegradstab.2013.04.006. [Google Scholar] [CrossRef]

29. Hou J, Zhao G, Wang G. Polypropylene/talc foams with high weight-reduction and improved surface quality fabricated by mold-opening microcellular injection molding. J Mater Res Technol. 2021;12:74–86. doi:10.1016/j.jmrt.2021.02.077. [Google Scholar] [CrossRef]

30. Bechikhi Y, Bachir Bouiadjra B, Bouziane MM, Bachir Bouiadjra BA, Benbarek S. Distribution of microhardness in polypropylene/talc microcomposite. Compos Theory Pract. 2021;21:141–8. [Google Scholar]

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools