Open Access

Open Access

ARTICLE

Study of Ultraviolet Radiation Effect on the Mechanical Properties of Jute and Montmorillonite Nanoclay Reinforced Polyester Nanocomposites

a Mechanical Engineering Department, Rajalakshmi Engineering College, Tamil Nadu, India

* Corresponding Authors: e-mail: ;

Journal of Polymer Materials 2023, 40(1-2), 83-91. https://doi.org/10.32381/JPM.2023.40.1-2.7

Abstract

In this research, the effect of UV light on the mechanical properties of jute polymer nanocomposites was evaluated. Due to the fact that photodegradation is a surface process and is confined to the degradation of the mechanical characteristics of polyester resin, this study focuses on the resin quality. Therefore, test samples comprised of fibre-reinforced polyester nanoclay composites were fabricated different weight ratios of nanoclay. They were put through UV exposure in an Ultraviolet (UV) chamber. Tensile testing samples were made in accordance with ASTMD638 and had a minimum thickness of 3 mm. Additionally, specimens for Flexural and Impact testing were also produced. Samples were treated at various time intervals under UV radiation and their mechanical properties were determined. The effect of nano additives in preventing the deterioration of polyester’s mechanical qualities was also investigated, and it was found that the addition of clay to polyester resin reduces the deterioration level by 19.86%, 9.38%, and 13.53% when compared to pure polyester resin’s tensile, flexural, and impact properties, respectively. The results demonstrated that samples containing nano additives were less susceptible to UV damage than that of the samples without nanoclay. This is because of the fact that when clay was added to the polymer, its platelets totally exfoliated and acted as barriers against the entry of UV radiation.Keywords

Fiber reinforced composites are substances that strong fibres are embedded with a lighter weight matrix resin, resulting in excellent specific characteristics. A wide variety of technical materials may be produced by tailoring the fibre length, fibre type, fillers and matrices. Like other natural fibres, jute fibers can be made which are biodegradable, and are cost effective than synthetic fibers like glass, aramid, and carbon. The establishment of diverse processing methods and innovative nanoclay polymer hybrid fiber composite applications have been facilitated by recent breakthroughs in material technology. Novel polymer-nanoclay composites with better characteristics have been produced by creative synthesis methods and are effectively used in a variety of industries, including wastewater treatment, aerospace, automotive, construction, and oil and gas. The long-term durability performance and degradation behaviour of commercially relevant biobased composites were studied in diverse ageing conditions (thermo-oxidative ageing, ultraviolet ageing, hydrolytic degradation, etc.). With suitable biofiller selection and surface modification, the durability performance of biocomposites may be significantly improved[1].

UV has been a major factor in the material’s strength degradation. It was discovered that the length of UV exposure time caused the fiber’s tensile strength to diminish. Composite materials have been related to UV radiation-induced deterioration, with the rate of degradation depending on certain important factors including UV wavelength, exposure period, and UV intensity[2]. Various methodologies were used to investigate the effects of different montmorillonite nanoclays on the characteristics of DGEBA epoxy resin. The curing of epoxy resin to generate nanoclay nanocomposites are affected differently by distinct montmorillonite nanoclays. Surface treatment can influence the interaction of clay/epoxy molecules with UV radiation, resulting in enhanced mechanical property retention after UV exposure[3]. The influence of UV absorbers on the stability of polyester mechanical characteristics is investigated. The mechanical characteristics of polyester resin were tested using an artificial UV exposure chamber at three distinct time intervals, corresponding to 3, 6, and 12 months. The results demonstrated that UVA additions did not damage the samples following UV exposure[4]. Research into the characteristics of composites made from recycled high density polyethylene and rice husk that had been treated with ultraviolet-ozonolysis was conducted. Surface-treated rice husk had rougher surfaces and better rHDPE matrix adherence than untreated RH. UV treatment yielded the best results and may be utilised as an alternative surface modification technique for rice husk composites to improve their mechanical characteristics[5]. Investigation into the ageing of polypropylene composites that were mixed with date palm nanofiber was conducted to predict the performance of these hybrid composites. Dry-melt blending was used to combine the palm fibers with polypropylene in the range of 1- 5 wt% loading such that the composites could be made. After that, these biocomposites were exposed to UV light for an accelerated weathering process for a period of 250 and 500 hours in accordance with a conventional approach. The exceptional durability of these composites is demonstrated by a small drop in tensile strength, degradation, and weathering-induced oxidation[6]. The Physical and ageing properties of E-glass fibre reinforced by jute fibre composites are investigated. The harmful effects of weather conditions are simulated and used to forecast the durability of the outdoor products. The results reveal that polymer has a longer life when exposed to a mix of UV radiation and water spray[7]. Nonwoven fabrics made of polyethylene terephthalate were given a coating of TiO2, ZnO, and SiO2 respectively. Chitosan and polyvinylidene fluoride polymers were utilised in order to make certain that the final composite PET-PVDF-OM-CT possessed excellent surface compatibility. Metallic oxides formed robust cross-linked chitosan networks. The modified PET nonwovens block the UV rays and have a high UV protection factor[8]. Properties of coir-epoxy infused particle composites were investigated after being subjected to accelerated UV-aging. The QUV weatherometer was used to accelerate the ageing process of composites with 15% particulates for a period of twenty-four hours. According to the findings, coir-epoxy injected particle composites exhibited a high degree of UV resistance while maintaining their mechanical characteristics[9]. UV light has been shown to be a sustainable and cost-effective approach for improving the mechanical characteristics of banana fibers in order to produce composites with enhanced mechanical and thermal qualities. The research may potentially contribute to the scientific manufacture of lignocellulosic fibres based on photochemical processes and phenomena[10].

The maximum UV stability is seen in plain HDPE and nanocomposites including multiwall carbon nanotubes, while untreated montmorillonite has little influencing impact[11]. As a result, in the current work, nanocomposites of polyester with montmorillonite nanoclay and jute fibres were synthesised in varied ratios with the goal of evaluating the influence of these nanoparticles on the UV stability of the polyester matrix and fiber.

Jute yarn fibres were obtained from the National Jute Board in Chennai. Biocorporals in Chennai provided the montmorillonite nanoclay (filler). The unsaturated polyester resin, Cobalt napthanate, and Methyl Ethyl Ketone Peroxide were acquired from the Biocorporals in Chennai. The physical and chemical properties of montmorillonite nanoclay, as well as its composition, are as follows:

The chemical formula of Montmorillonite nanoclay is H2Al2O6Si and its formula weight is 180.1 g/mol. It appears physically in powder form with particle sizes less than 20 microns. Its bulk density is in the range of 650 - 1150 kg/m3. The product has a pH range of 3.0 to 4.0 and a relative density of 2500 g/cm3. The product is off-white to faint grey in colour, with a moisture level of 1-2%.

Unsaturated isophthalic polyester resin and natural filler montmorillonite nanoclay were mixed together to make the final product. The different amounts of nanoclay (1, 3, 5, and 7 wt%) and polyester resin are mixed together using the ultrasonication method[12–14] in which the optimum 5 wt% (i.e. even dispersion of nanoclay without agglomeration) nanoclay[12] is considered for this work. Similarly in the polyester resin, primary reinforcement takes the form of jute fibres with different fibre contents (5%, 10%, 15%, 20%, 25%, and 30% wt.%), while secondary reinforcement takes the form of montmorillonite nanoclay[15,16] in which the optimum 15wt% jute fiber[15] is considered for this work. Figure 1 shows the hand layup fabricated specimens of neat polyester, optimum 5wt% nanoclay, 15wt% jute fiber and optimum 15wt% jute fiber + 5wt% nanoclay.

Fig. 1: Composite plates of (a) Neat polyester; (b) 5wt% clay polyester; (c) 15wt% jute fiber; (d) 15wt% jute fiber + 5wt% nanoclay

The controlled deterioration of a material sample caused by light, oxidation, moisture, etc. is measured using a weatherometer. A substance or product will weather when it reacts negatively with the environment, frequently leading to unintended and early failures[21]. In order to evaluate specimens under regulated circumstances, it may produce UV and other light frequencies. The components used for the fabrication of the UVB Weatherometer are as follows: 20 W fluorescent UV-B lamps – 2 nos; reflector – 2 nos; UV Sensor ML8511 & Arduino board – 1 nos; Enclosure – 1 nos.

From microlites, Chennai, 20 W fluorescent UV bulbs emitting UV-B light with a wave length between 305 and 315 nm were purchased. The two lights were placed on the enclosure’s upper and lower sides. The UV light is directed onto the test specimen using a reflector. In this work, used an Arduino interface to measure the ultra violet light intensity in mW/cm2. The UVB-burning rays range in wavelength from 280 nm to 390 nm, which is better detected by the ML8511 UV sensor. The accelerated weathering tester with an irradiance level of 0.15 mW/cm2 at 315/ nm wavelength was used in the UV testing[22].

2.4 Tensile, Flexural and Impact Testing

A Zwick/Roell universal testing equipment was utilised for both the flexural and tensile tests. The tensile test was performed at a rate of 2 mm/min in accordance with ASTM D-638. ASTMD-790 mandated a flexural three-point bending test, which was performed. The Izod technique was used to calculate the impact strength in accordance with ASTMD-256. All analyses were performed on sets of five samples, and their averages were recorded.

The pure polyester resin, polyester nanoclay, jute fibre reinforced polyester nanoclay composites that are fabricated are cut into the required dimension using an abrasive water jet cutting machine located in Alind, Chennai.

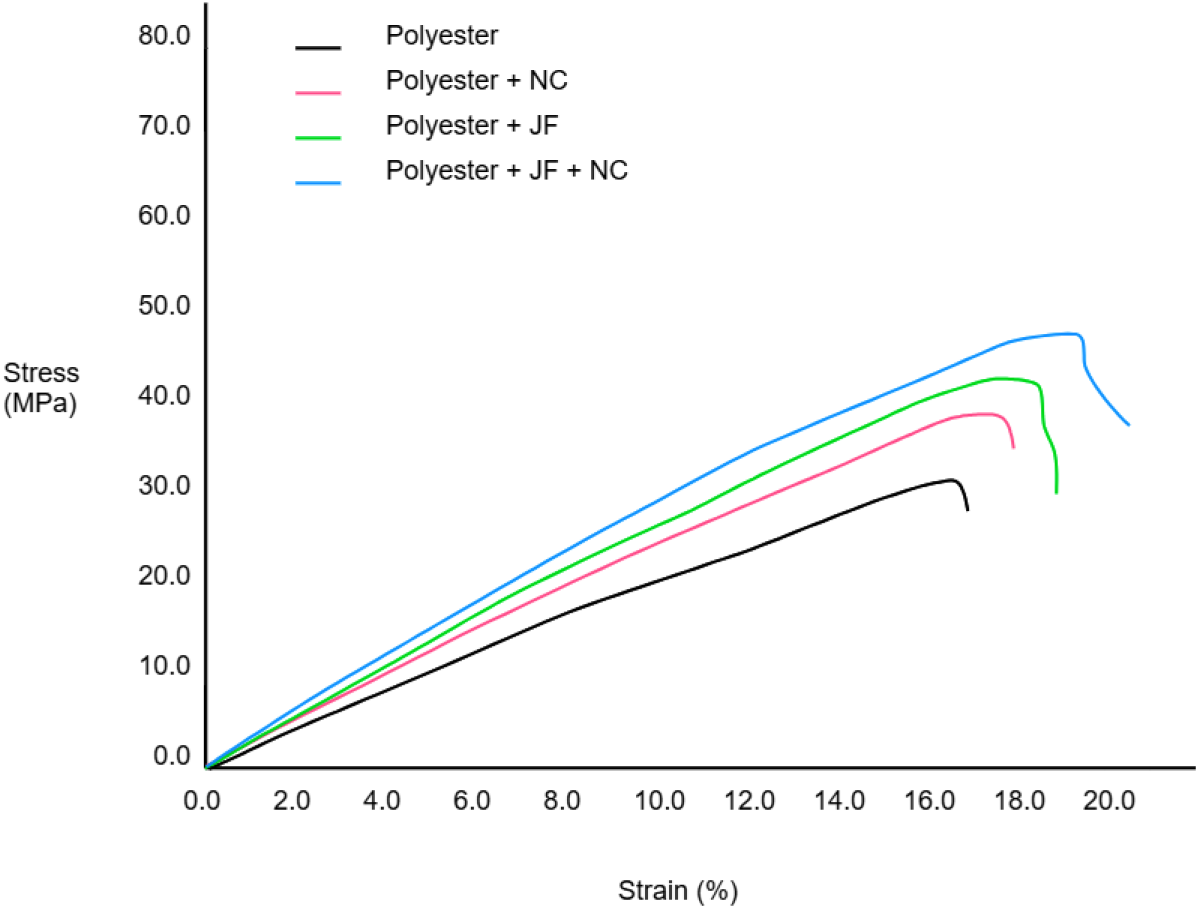

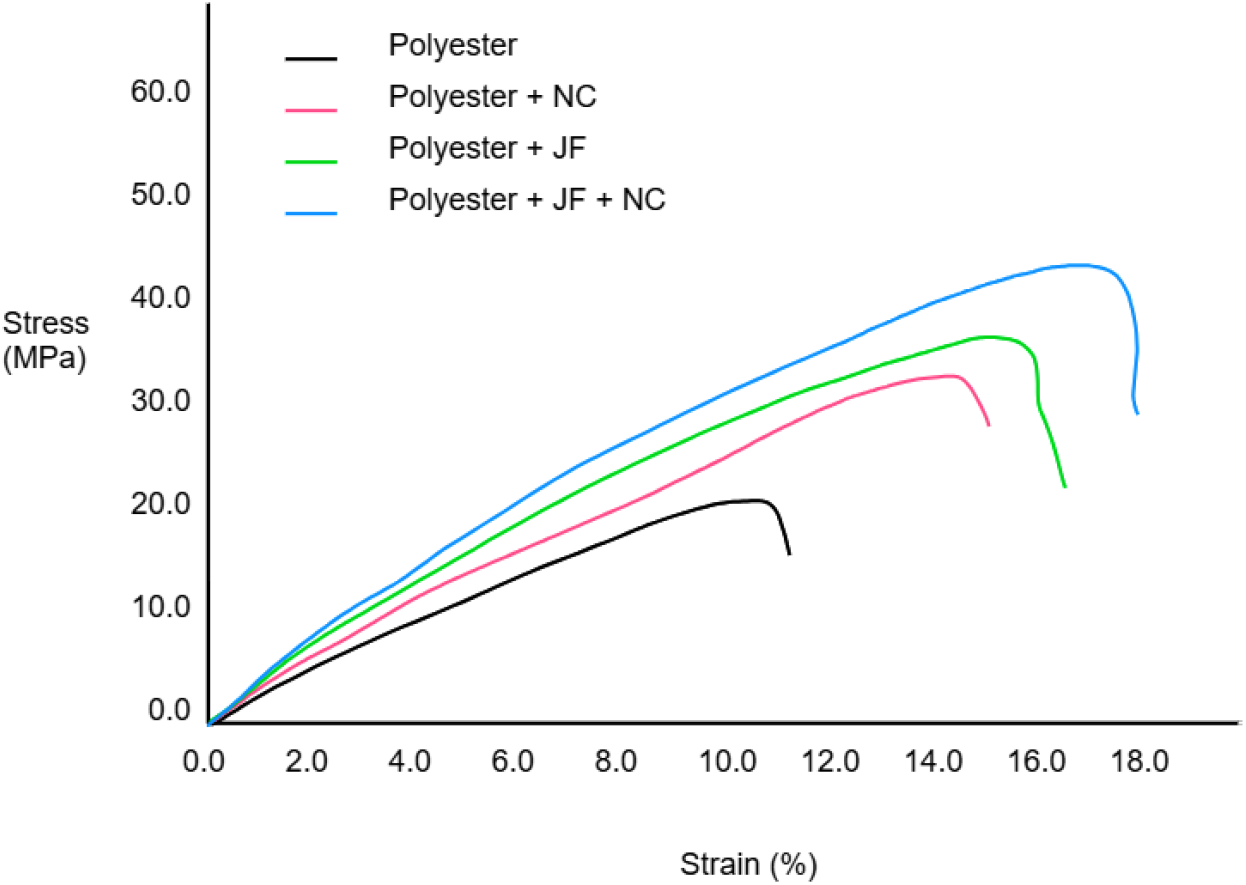

All the samples were treated to UV ageing utilising a UV accelerated weathering chamber in order to investigate the possibilities of montmorillonite nanoclay reducing the damaging effects of UV and thermal stability. Throughout the course of 100 hours (nearly equals a year) of exposure[4], UV rays produced by 315 nm fluorescent were permitted to continually incident on the surfaces of the various nanocomposite samples. Figure 2 and 3 represent the stress strain curves of composite specimens before and after exposure to UV radiation.

Fig. 2: Stress strain curve of composite specimens before exposure

Fig. 3: Stress strain curve of composite specimens after exposure

During exposure to UV light, composite materials lose tensile, flexural and impact strength. It was discovered that the tensile, flexural and impact strengths dropped from 32.14 to 21.64MPa, 58.08 to 46.41MPa, and 37.74 to 27.21, respectively for neat polyester resin.

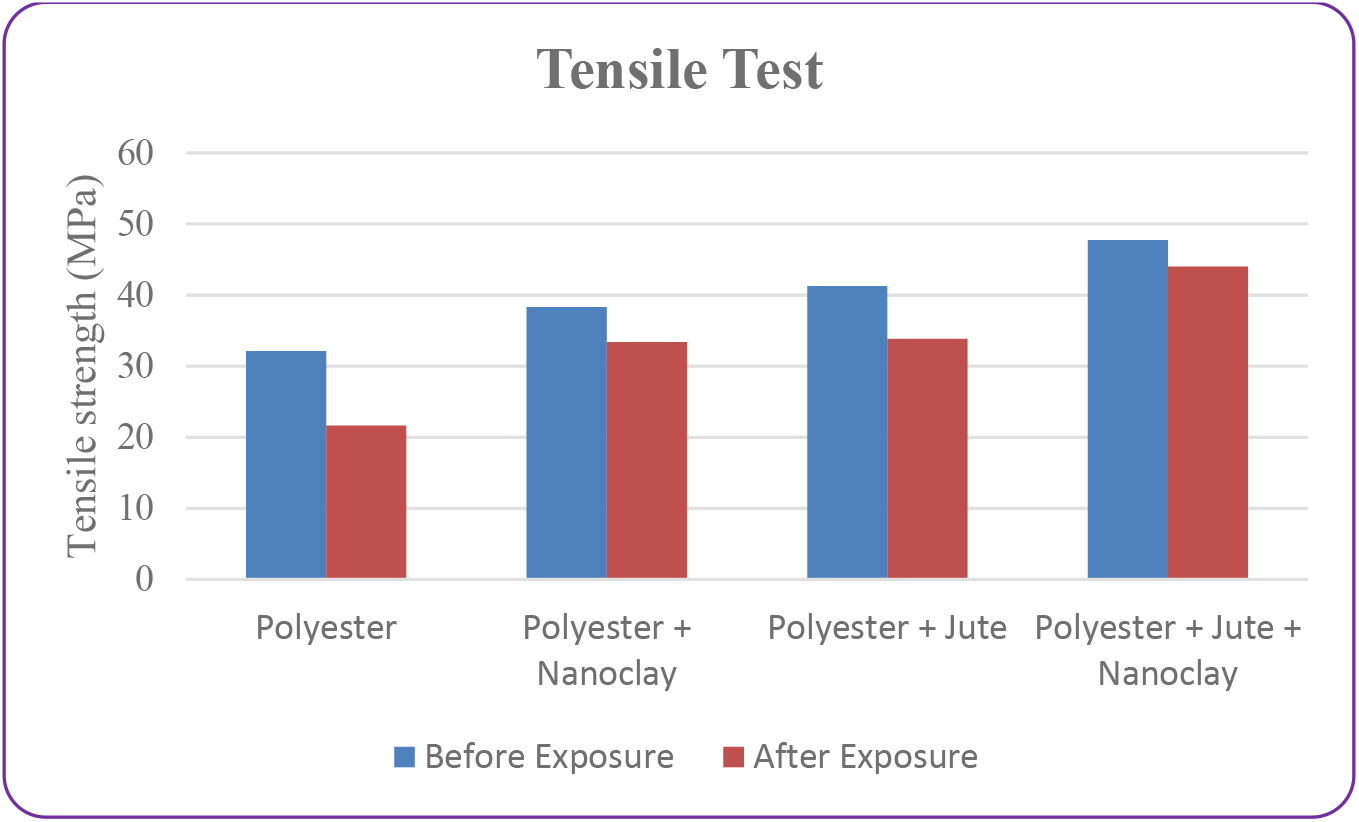

Figure 4 demonstrates that the addition of clay to polyester resin raises the tensile property by 19.22%, from 32.14 to 38.32 MPa. As indicated in Figure 3, when pure polyester and polyester nanoclay samples were subjected to UV radiation, the percentage drop was 32.67 and 12.81 percent, respectively, compared to the unconditioned sample. Similarly, the addition of clay to jute polyester resin raises its tensile property by 15.65%, from 41.27 to 47.73 MPa. As indicated in Figure 4, when the jute polyester and jute polyester nanoclay samples were subjected to UV radiation, the percentage drop was 18 and 7.77 percent, respectively, compared to the unconditioned sample. It is evident from the data that the percentage increase in polyester and jute fibres after the addition of nanoclay was attributable to improved clay dispersion and robust fibre-matrix adhesion[12,15]. In contrast, the percentage loss was reduced in response to UV exposure without clay and clay addition in relation to polyester and fibre addition. This decrease in percentage was attributable to the fact that when clay was added to the polymer, its platelets totally exfoliated and acted as barriers against the entry of UV radiation[17].

Fig. 4: Tensile properties of untreated and UV treated specimens

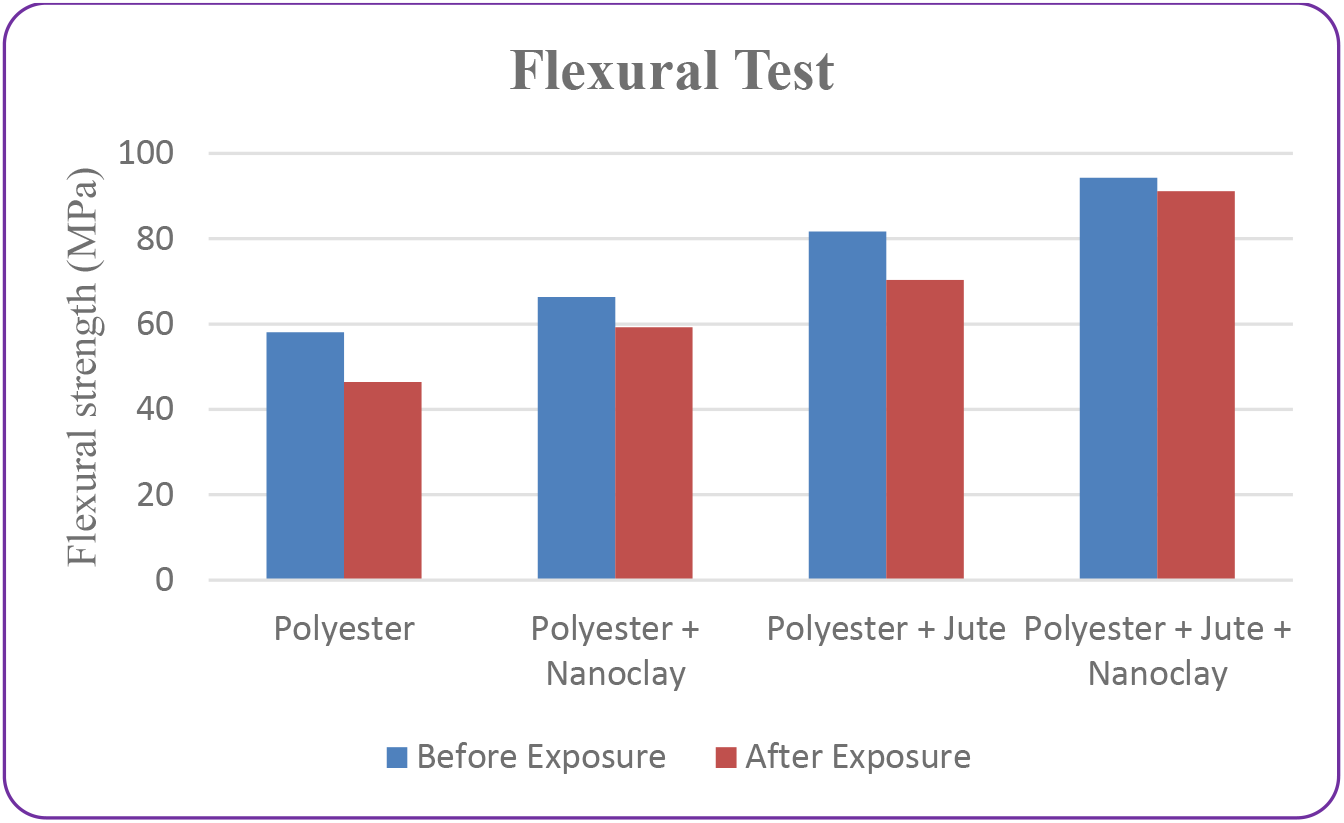

The addition of clay to polyester resin increases the flexural property by 14.26%, from 58.08 to 66.36 MPa, as shown in Figure 4. As shown in Figure 5, when samples of pure polyester and polyester nanoclay were exposed to UV light, the percentage decrease was 20.09 and 10.71 percent, respectively, as compared to the unconditioned sample. Likewise, adding clay to jute polyester resin increases its flexural property by 15.43%, from 81.71 to 94.32 MPa. As shown in Figure 5, when jute polyester and jute polyester nanoclay samples were exposed to ultraviolet light, the percentage decrease was 13.94 and 3.39 percent, respectively, compared to the unconditioned sample. The percentage increase in polyester and jute fibres with the addition of nanoclay is clearly attributed to enhanced clay dispersion and strong fibre-matrix adhesion, as indicated by the statistics[14]. In contrast, the percentage loss decreased in response to UV exposure without clay and with clay addition in comparison to polyester and fibre addition. The reason for the drop in % is that nanophased samples retained their characteristics better than neat samples after being exposed to UV light. There was some evidence that the nanoclay infusion helped reduce the UV deterioration of the composites[18].

Fig. 5: Flexural properties of untreated and UV treated specimens

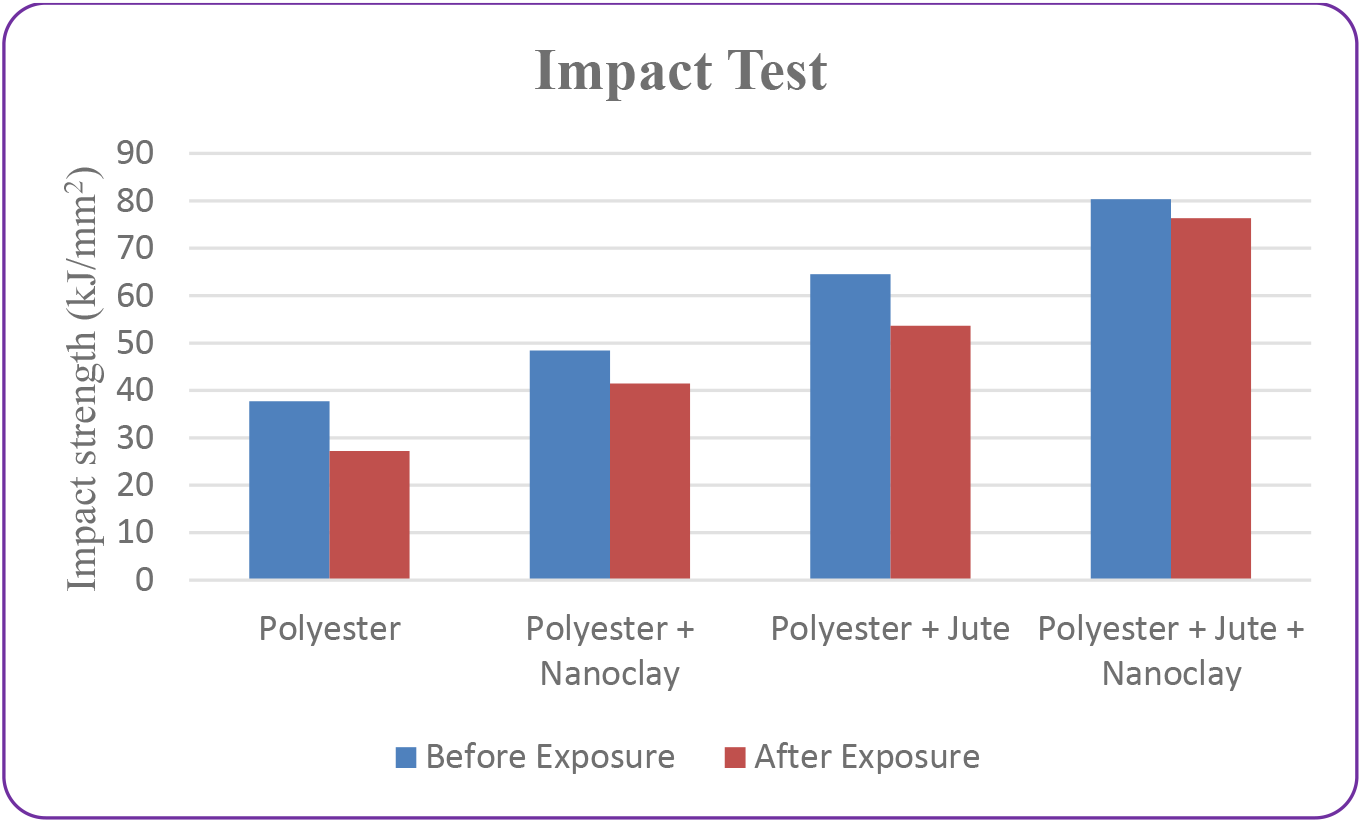

Figure 6 indicates that incorporating clay into polyester resin increases the impact property by 28.30%, from 37.74 to 48.42 kJ/mm2. This shows that the percentage reduction in pure polyester and polyester nanoclay exposed to UV light was 27.90 and 14.37 percent, respectively, as compared to the unconditioned sample. Similarly, adding clay to polyester resin made from jute improves its impact property by 15.43%, from 64.51 to 80.35 kJ/mm2.

Fig. 6: Flexural properties of untreated and UV treated specimens

Figure 6 shows that the UV-exposed jute polyester and jute polyester nanoclay samples saw a 16.88% and 4.99% reduction in weight, respectively, as compared to the unconditioned sample. Improved clay dispersion and strong fibre-matrix adhesion can be directly attributed to the observed percentage increase in polyester and jute fibres following the use of nanoclay. In contrast, the percentage loss was mitigated by UV exposure combined with either polyester or fibre, but not both. The addition of clay to the polymer caused the platelets to completely exfoliate, creating a barrier that reduced the amount of UV light that penetrated the material by a significant proportion[19,20].

The impact of montmorillonite nanoclays on the properties of jute fibre reinforced polyester composites was examined using a UVB weatherometer. The findings allow for the following inferences:

• In comparison to neat samples, nanophased materials following UV exposure exhibited a good preservation of characteristics. a sign that the UV deterioration of the composite materials was reduced as a result of the nanoclay infusion.

• The addition of clay to polyester resin reduces the deterioration level by 19.86%, 9.38%, and 13.53% when compared to pure polyester resin’s tensile, flexural, and impact properties, respectively. Similarly, the addition of clay to jute fibre reinforced polyester resin reduces the deterioration level by 10.23%, 10.55% and 11.89% when compared to jute fibre reinforced polyester resin’s tensile, flexural, and impact properties, respectively.

• Clay platelets formed a barrier to block UV light as it passed through webs after being exfoliated in the matrix. Due to the clay’s contribution to aggregation, there is a limitation in the clay content application, and in the current study, only 5% of clay served the primary goal and acted as a superior barrier.

• The sample’s mechanical capabilities were retained when it was exposed to UV radiation, demonstrating that it is conceivable to add nanoclay to the polyester matrix, which has potential uses in a variety of industries including the textile, military, medical, and biological domains.

References

1. B. P. Chang, A. K. Mohanty and M. Misra. (2020). RSC adv. 10: 17955. [Google Scholar]

2. S. Mahzan, M. Fitri and M. Zaleha. (2017). IOP Conf. Ser.: Mater. Sci. Eng. 165: 012021. [Google Scholar]

3. A. Tcherbi-Narteh, M. Hosur, E. Triggs and S. Jeelani. (2013). Polym. Degrad. Stab. 98: 759. [Google Scholar]

4. M. M. Shokrieh and A. Bayat. (2007). J. Compos. Mater. 41: 2443. [Google Scholar]

5. N. R. Rajendran Royan, A. B. Sulong, N. Y. Yuhana, R. S. Chen, M. H. Ab Ghani and S. Ahmad. (2018). PloS one. 13: e0197345. [Google Scholar]

6. B. A. Alshammari, O. Y. Alothman, A. Alhamidi, M. Jawaid and H. M. Shaikh. (2022). Materials. 15: 6053. [Google Scholar]

7. B. Sudhabindu and P. V. Rama Rao. (2017). Int. J. Chemtech Res. 10: 487. [Google Scholar]

8. N. Bouazizi, A. Abed, S. Giraud, A. El Achari, C. Campagne, M. N. Morshed, O. Thoumire, R. El Moznine, O. Cherkaoui, J. Vieillard and F. Le Derf. (2020). Physica E Low Dimens. Syst. Nanostruct. 118: 113905. [Google Scholar]

9. S. Dixit. (2014). Am. J. Polym. Sci. Eng. 2: 1. [Google Scholar]

10. R. M. Benedetto, M. V. Gelfuso and D. Thomazini D. (2015). Mater. Res. 18: 265. [Google Scholar]

11. I. Grigoriadou, K. M. Paraskevopoulos, K. Chrissafis, E. Pavlidou, T. G. Stamkopoulos and D. Bikiaris. (2011). Polym. Degrad. Stab. 96: 151. [Google Scholar]

12. A. Seetharaman and V. Narayanan. (2022). Polym. Compos. 43: 7290. [Google Scholar]

13. S. Arulmurugan and N. Venkateshwaran. (2021). Surf. Rev. Lett. 28: 2050040. [Google Scholar]

14. S. Arulmurugan and N. Venkateshwaran. (2016). Polym. Polym. Compos. 24: 507. [Google Scholar]

15. S. Arulmurugan and N. Venkateshwaran. (2020). Polimeros. 29: e2019054. [Google Scholar]

16. S. Arulmurugan and N. Venkateshwaran. (2019). Surf. Rev. Lett. 26: 1950050. [Google Scholar]

17. M. Elhami and S. Habibi. (2021). J. Vinyl Addit. Technol. 27: 89. [Google Scholar]

18. A. Tcherbi-Narteh, M. V. Hosur, S. Zainuddin and S. Jeelani. (2010). Int Mech Eng Congress Expo. 44274: 163. [Google Scholar]

19. Y. Zheng and R. Ning. (2003). Mater. Lett. 57: 2940. [Google Scholar]

20. B. K. Deka, M. Mandal and T. K. Maji. (2012). Ind. Eng. Chem. Res. 51: 11881. [Google Scholar]

21. E. Yousif and R. Haddad. (2013). Springerplus. 2: 1. [Google Scholar]

22. T. Lu, E. Solis-Ramos, Y. Yi and M. Kumosa. (2018). Polym. Degrad. Stab. 154: 203–210. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools