Open Access

Open Access

ARTICLE

Studies on Compressive Loading-characteristics of PU Foam Materials Used in Footwear for Obese

CSIR-Central Leather Research Institute, Chennai-600020, India.

1

Department of Mechanical Engineering, Anna University, Chennai-600025, India.

* Corresponding Author: e-mail:

Journal of Polymer Materials 2022, 39(3-4), 195-204. https://doi.org/10.32381/JPM.2022.39.3-4.2

Abstract

Optimum-designed footwear with polyurethane (PU) material for comfort is an important requirement for obese. Investigations on compressive behavior of varied designed footwear using 120 D PU material have been carried out. The energy absorption primarily depends on heel height, slope angle and load applied or body mass index of obese. Statistical analysis has been used to formulate the prediction of absorbed energy wherein a heel height of 30 mm with 20-degree angle provides optimum value with the incorporation of 120 D PU material. A coefficientof-determination (R2 ) value of 0.9406 confirms the suitability of the statistical regression model. Hence, the optimally designed footwear for higher energy absorption with 120 D PU foam material is recommendable for obese.Keywords

Overweight and obesity are defined as abnormal or accumulation of excessive fat resulting in a risk to health. A person with a BMI of 30 or more is generally considered obese whereas a person with a BMI equal to or more than 25 is considered overweight. The overweight and obesity are now rising intensely in low and middle-income countries, particularly in urban settings. It is commonly known that the reality of obesity has a negative impact on human health and its primary effect due to bodyweight on feet is largely overlooked. Obesity is a major threatening factor for problems related to foot and ankle pain, musculoskeletal disorders, plantar fasciitis, arthritis, and other foot complications where the pain is a common presentation. It also destabilizes the stability of a person in standing / walking conditions. It has been revealed from literature studies that the quantum of research on footwear for the obese carried out to date stands to the least possible extent. Hence, the design and development of footwear with foot comfort especially for the beneficiaries warrants scientific insights and research interventions.

The materials for the foot-comfort of the foot play a significant role in the design of footwear. To provide a better solution for the comfort of the foot, foot orthoses (FO) were felt as ideal materials of choice for the beneficiaries. The Foot-orthoses impart comfort advantages for the end-users in footwear. FOs made of materials such as plastics, metals, leather, and others are helpful in improving the foot function of people with lower-limb pathologies [1] FOs reduce the symptoms of plantar fasciitis by reducing strain in the fascia during standing and ambulation [2]. Soft FOs aids improve both forefoot and general foot pain. Cadaveric research explored that orthoses reduce foot pronation, the collapse of the longitudinal arch, and elongation of the foot [3]. FOs are commonly used in non-surgical treatment for improving the well-being of heavy people while using footwear. However, these FOs pose difficulties as the materials are relatively difficult to adjust, relatively firm, and less cushiony. Elastomeric foam materials are capable of providing protection against impact as they absorb energy. [4, 22] These materials have been characterized for their sensitivity toward strain, which can significantly affect their cushioning and shock absorption capabilities during activities such as running.[5, 23] Although, previous research has demonstrated reductions in plantar pressure using orthotic insoles completely made of cushioning materials [6], there has been minimal quantum of research attempted on orthotic insoles made with materials of different densities. Polymeric urethanes (PU) are elastomers that show good load-bearing capacity, flexibility, abrasive & impact resistance, and water oil-grease repellant over metal and plastics [7, 8]. Due to the characteristic porosity of sized foams, PU exhibits tensile, tear & elongation properties. PU can be formulated as bio-degradable materials [9]. There are two types of PU foams, namely open & closed cells. The latter variety, due to its higher water resistance, rigidity and strength, is under the scope of the present investigation. Due to wide applicability, like in the areas of preparation of ink, coating, elastomers, foam, footwear, sportswear etc. [10, 11], PU foams are still under research.[12] Expanded poly-styrene of higher density showed higher energy-absorption capability than the lower dense type[13]. With the increase in stress value, the capability of carrying load increases[14]. If the foam density is increased to 20%, the yield strength becomes double [15]. The elasticity also depends on relative density, size, young's modulus and Poisson's ratio of foam [16]. Young's modulus and density can be related by the following relation [17]

Where Y* is Young's modulus for the testing material, Ys is the cell wall of material; ρ* be the density of test material and rs be the density of cell-material of foam, C1 is a constant. These beneficial characteristics of PU foams can be explored in the application or preparation for rendering comfort advantages for obese.

Hence, polyurethane foams are selected as a more promising material in the design of foot orthoses. Polyurethane (PU) foam-based materials are predominantly used in footwear and leather-product-industries for imparting extra comfort advantages for the beneficiaries. PU foam material of 120 D was analyzed and recommended for alleviating foot and ankle pain-related problems and providing therapeutic benefits for high-BMI people. In this work, the polyurethane foam materials possessing varied densities (D) have been characterized by properties like density, hardness, the compression set of static and dynamic conditions.

To the best of our knowledge, the present studies on the compressive characteristics of PU foam materials used in footwear designed with varied slope angle configurations have not been explored in the domain of footwear. Hence, this study has been proposed to bring a novel approach to exploring the use of PU foam materials for the design and development of footwear.

The objective of this study is to determine whether the external design intervention of footwear signifies the impact of energy absorption through compressive loading analysis thereby easing foot pain for obese individuals. The energy absorption characteristics are studied using Universal Instron Device on varied external configured shoes with the composition of 120 D PU foam material.

The findings from compressive loading analysis of PU foam materials versus design angle footwear would help reveal the identity of superior density PU foam material and appropriate slope angle footwear to render therapeutic outcomes for obese individuals.

2.1. Compressive loading characteristics of PU foam materials used in the footwear of varying slope angle configurations

It is imperative to determine the effectiveness of compressive loading characteristics of PU foam materials with the composition of footwear designed with slope angles being prioritized as the promising field of interest in footwear. To carry-forward this research initiative, PU foam materials of varied densities were procured from the local market, and footwear configured with different slope angles including standard design footwear was fabricated for scientific evaluation and analysis.

The PU foam materials possessing density indices: 55D, 75D, 90D, 120D, and 140D with 4 mm thickness were considered for evaluation. The Shoe Allied Trade Research Association (SATRA) standards and methods have been employed for assessing the physical characteristics of PU foam materials such as hardness, density, compression set (Static and Dynamic), and cushion energy. The superior PU foam material suitable for the foot-comfort needs of obese individuals has been identified in the initial phase of evaluation. The device Universal Instron Testing Machine (3369) has been employed to ascertain the compressive loading characteristics of PU foam materials incorporated as shoe comfort inserts in footwear. The assessment of footwear designed with slope angles 5°, 10°, 15°, 20° including standard design on the heel region under the loading conditions: 700 N, 800 N, 900 N, and 1000 N have been proposed to be carried out primarily to understand the energy absorption characteristics of PU foam materials in this research.

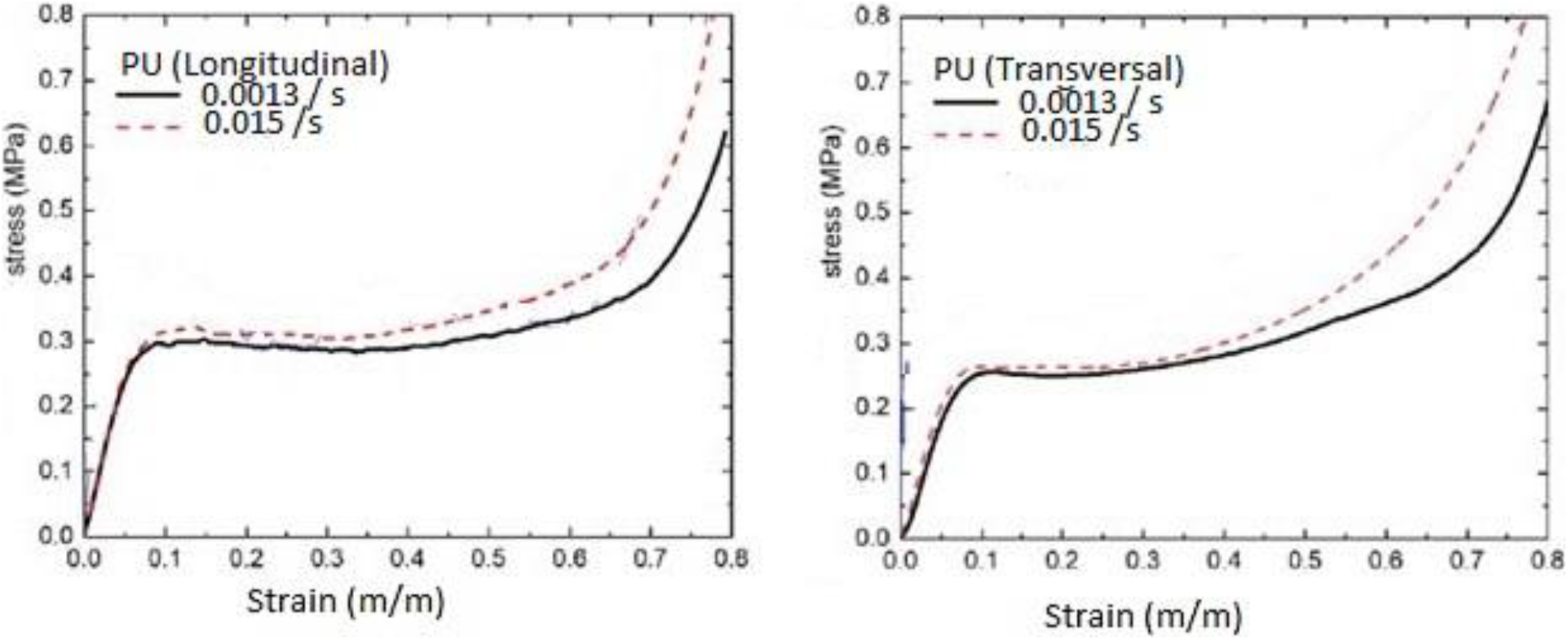

Burr DB et al., [18] informed that during Walking, Jogging, Sprinting, and Zigzag running, human being exerts a compressive strain rate of 700-1300 μɛ and a peak compressive strain rate of 7000-30000 μɛ. Hence, we consider two strain rates at 0.0013 s-1 and 0.015 s-1 to show the compressive loading experiments (Figure 1). However, forces ranging from 700 N to 1000 N have been tested as described below. The PU foam materials have been evaluated on compressive loading characteristics: 700N, 800N, 900N, and 1000N on footwear designed of slope angles, as mentioned earlier including standard design using Universal Instron Device.[19-20]

Figure 1. Stress-Strain relation for PU foam material (a) longitudinal (b) transversal position

The footwear was placed on the steel base of the Universal Testing Machine (UTM). The test punch, a component of the UTM, is the rear section of a standardized shoe last made up of polyethylene. The shoe last was sectioned on a plane vertical to the feather edge and at 90° to the axis of the back part. The shoes developed with a heel height of 30 mm with external design angles ranging from 0° to 20° were experimented with using this equipment. The test punch was pressed against various design configured shoes with the composition of PU foam materials at the center of the heel area at a test rate of 10 ± 3 mm/min until a force of 700 to 1000 N is obtained.

The load and compression values drawn for each test are plotted using MS-excel and subsequently, the energy absorption E in joules is deter-mined using the equation: E = F ds where, F is the compressive force applied in Newtons and s is the distance in mm. The energy absorption values of footwear appear on the display of the UTM, from which the readings are measured. The density of foam material was calculated by dividing the mass of material by volume, assuming the foam layer has a uniform consistency. The hardness of foam material was measured by X-F durometer. The tester was placed on the sample when the pressure exerted on it by the sample for moving the indentor was measured. The depth of the indentor gives a measure of hardness.[21-22] Cushion energy is related to energy absorption by the material whereas absorbed energy is the work done by the force. As has been mentioned earlier the formula used for calculating E = F ds Where F, the stress (σ) is a function of strain (s).

3.1. Physical Parameters on PU foam Materials

The physical test methods such as hardness, density, and percentage of compression set (static and dynamic) were conducted on PU foam materials of varying densities, (as mentioned earlier section) and the data are presented in Table 1.

The term “D” represents the density characteristic of PU foam materials and it is observed that out of the varied PU foam materials,140 D possesses the highest density value of 0.146 g/cm3 and hardness value of 61 while compared to other PU inserts. The hardness values ranging between 31 and 61 were determined for PU inserts with densities ranging between 55D and 140D. The tests on compression set for static and dynamic conditions were carried out by the test method SATRA TM 64. This method was intended to determine the compression set which is a measure of retention of shape and elastic properties of PU foam materials. The compression set is a measure of retention of shape and elastic properties. The basic phenomenon of the compression set is the percentage change in thickness calculated after the compression with a predefined pressure for a set of time and allowed to recover for a set of time on PU foam materials. The results obtained are furnished as in the above. The compression set values of 55D, 75D, 95D, 120D, and 140D materials with respect to static conditions resulted in terms of percentage to values of 12.0, 9.33, 6.74, 6.17, and 18.58 respectively, wherein 120 D possesses the lowest percentage value of 6.17 among the materials assessed in the laboratory. Subsequent to this evaluation, the compression set values of the 55D, 75D, 95D, 120D, and 140D materials with respect to dynamic conditions resulted in the values of 3.82, 5.9, 4.8, 2.3, and 0.38 respectively, wherein 140 D has been observed to be the lowest value of 0.38 percentage among the materials assessed in the laboratory. The rapid downward fall in the case of 140 D PU foam material is primarily due to higher values of density and hardness characteristics.[23] The lowest value of 140 D exhibits the highest recovery character when compared to all other PU foam materials. The compressibility in the case of 140 D PU foam is not much significant primarily due to the highest density and hardness characteristics under the dynamic conditions.

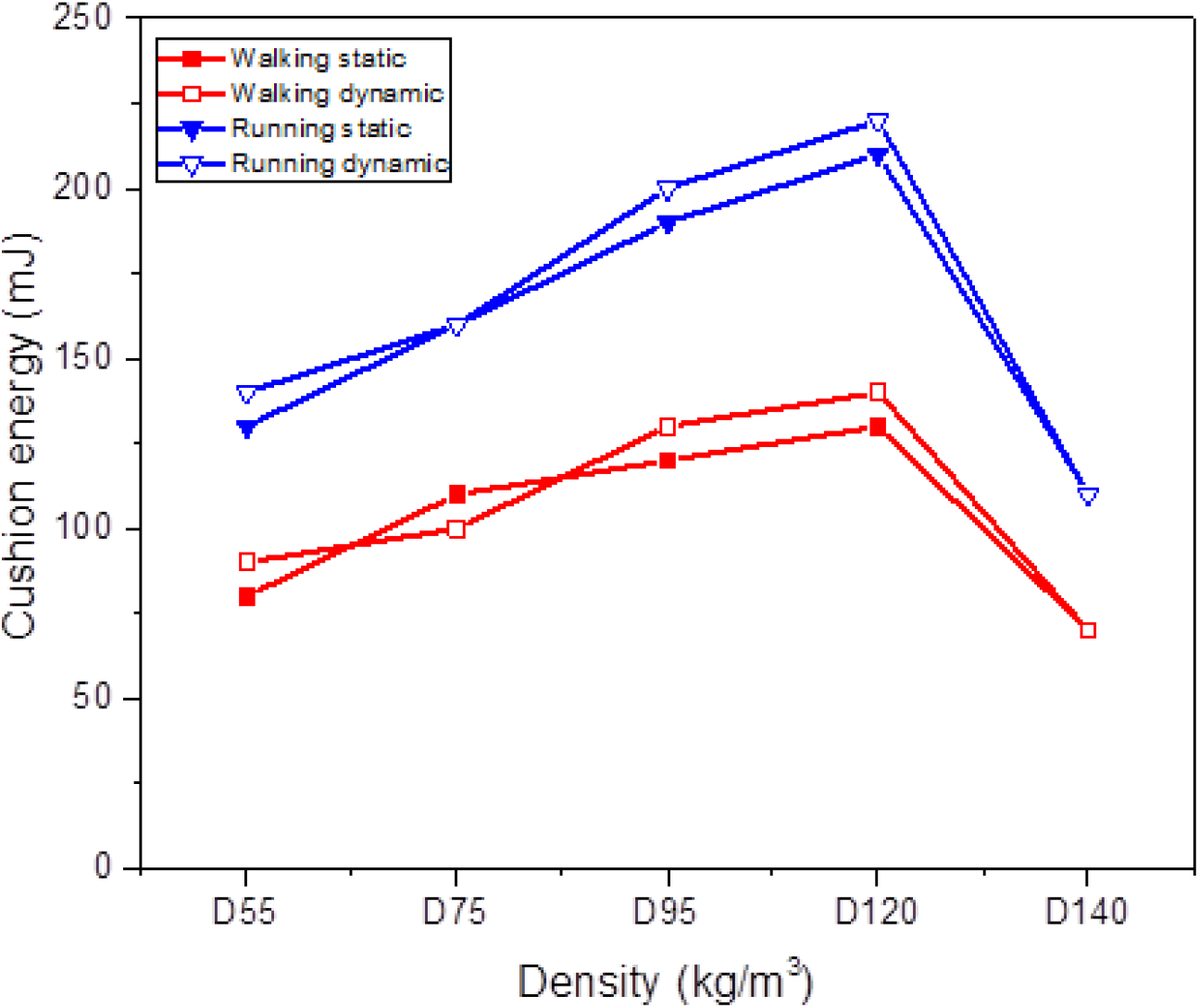

The cushion energy (CE) characteristics on 55D, 75D, 95D, 120D and 140D PU foam materials were conducted. The direction of curves in respect of walking and running conditions of PU foam materials is linearly progressing from 55 to 120 D and further, the curve is sloping downwards in respect of 140 D PU foam material. The cushion energy characteristics of all density PU foam materials and their trends are represented in the graphical presentation shown in the Figure 2.

Figure 2. PU foam materials versus Cushion Energy behaviors (Walking and Running Conditions)

Of the five densities evaluated, 120 D PU foam material has the highest resilience in static and dynamic conditions. The CE values of 120 D PU foam material with respect to walking–static condition possesses around 7 % higher value than of 95 D PU foam material and 46 % higher CE value while comparing 140 D PU foam material. The CE values of 120 D PU foam material with respect to walking – dynamic condition possesses around 7 % higher value than of 95 D PU foam material and 50 % higher CE value than 140 D PU foam material. The CE values of 120 D PU foam material with respect to running–static conditions possess just above 5 % higher value than 95 D PU foam material and around 47 % higher CE value than 140D PU foam material. The CE values of 120 D PU foam material with respect to running – dynamic condition possesses around 9 % higher value than 95D PU foam material and around 50 % higher CE value than 140 D PU foam material. These results clearly indicate that 120 D PU foam material possesses a higher percentage of compression set behaviors on static and dynamic conditions which further means that this material exhibits superior recovery and elastic characteristics to attain improved mechanical properties. It is clearly evident that the CE behaviors of 120 D PU foam material with respect to walking/running on static and dynamic conditions were superior, as they possess better-cushioning performance on footwear applications.[24] Hence, the 120 D PU foam material is concluded to be the best material for footwear insert for alleviating foot and ankle pain-related problems and for providing therapeutic benefits to high-BMI individuals.

3.2. Energy absorption characteristics of PU foam materials used in footwear designed with varying slope angles

The footwear was designed with varied slope angles: standard design, 5°, 10°, 15°, and 20° were assessed on the compressive loading characteristics using Universal Instron Device. As it was revealed that 120 D PU foam stands superior characteristics to all other PU foam materials, it deserved merit being used as foot-comfort insert material in footwear designed in different configurations.[25-27] The energy absorption characteristics of PU foam materials used in footwear were carried out.

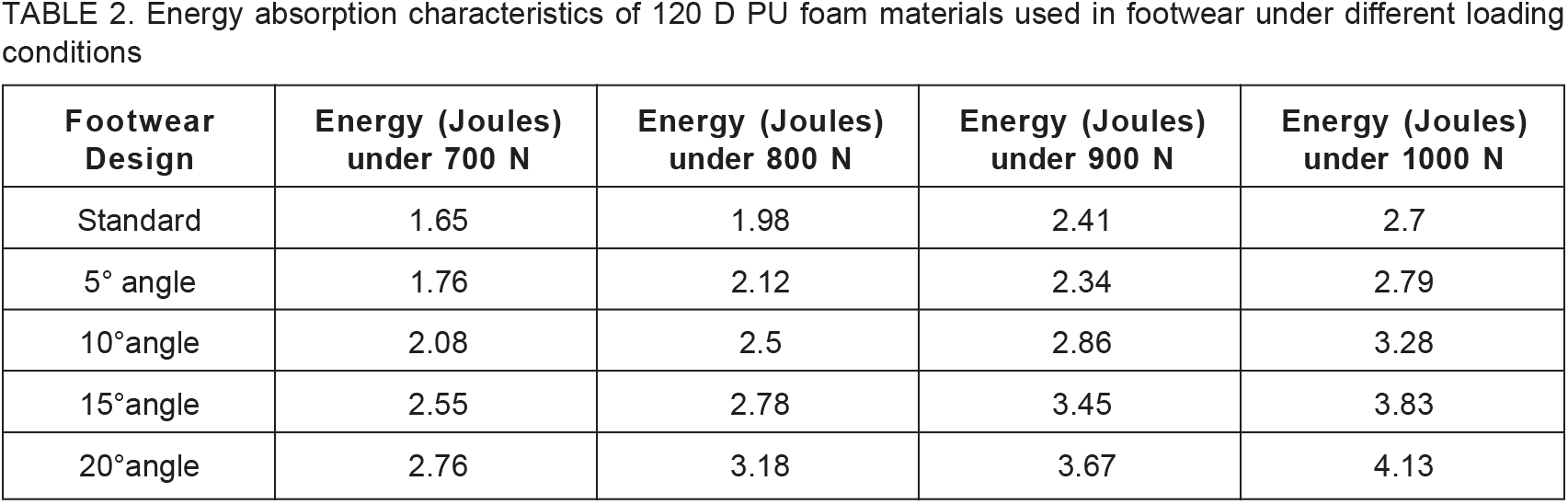

The data pertaining to energy absorption characteristics of 120 D PU foam materials used in composition with varying slope angle footwear under the loading conditions from 700N to 1000N are presented in the Table 2.

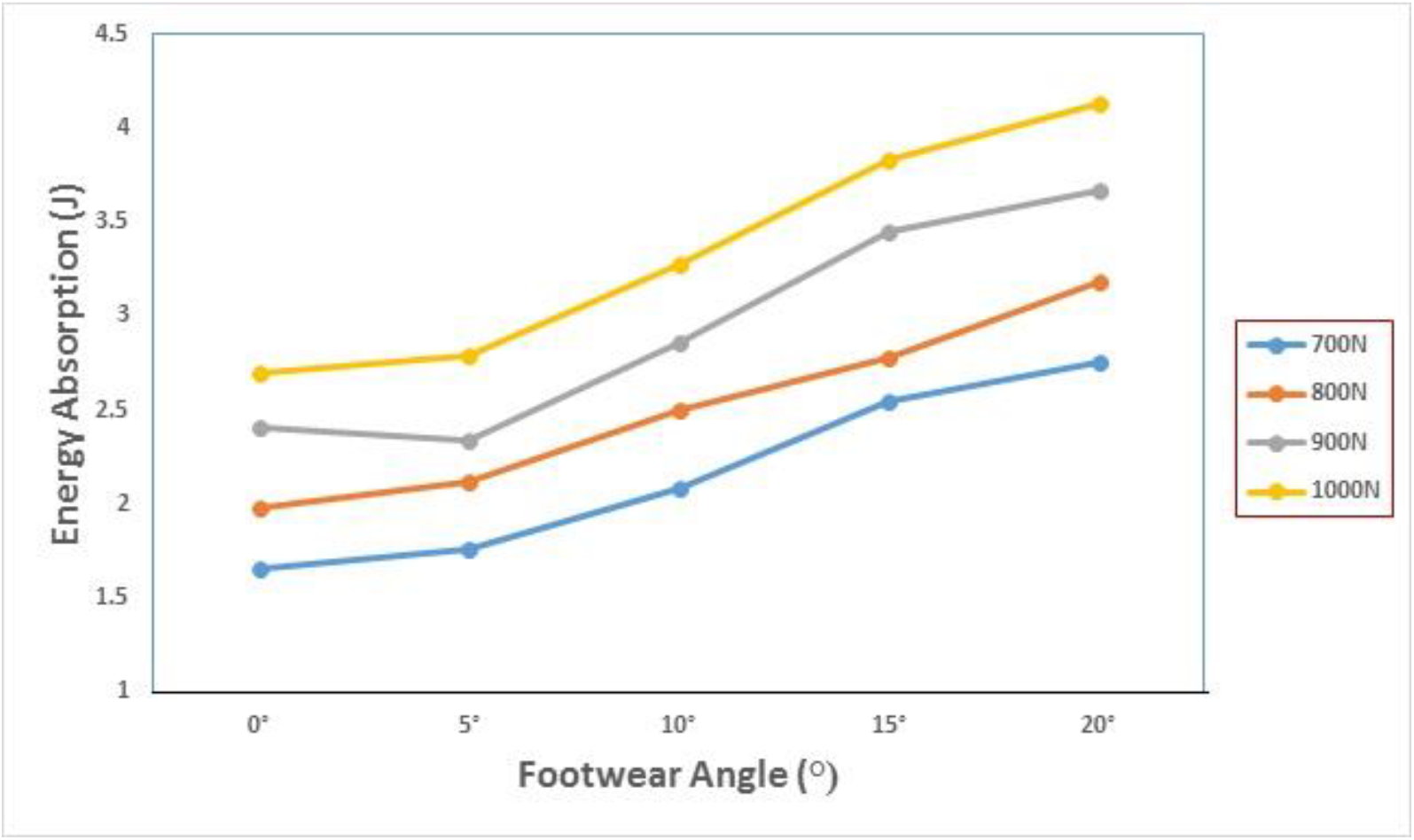

It is observed from Figure 3 that the standard design footwear under the loading conditions; 700N, 800N, 900N, and 1000N exhibits energy absorption values of 1.65J, 1.98J, 2.41J, and 2.7J respectively. The energy absorbed values demonstrate linear progression positively in respect of different loading conditions ranging from 700N to 1000N. In the case of 5° angle footwear, it presents the energy values: 1.76J, 2.12J, 2.34J and 2.79J under the loading conditions from 700N up to 1000 N followed by 10° angle footwear demonstrates the energy values 2.08 J, 2.5 J, 2.86J and 3.28J respectively. Further, 15° angle footwear demonstrates the energy values of 2.55J, 2.78J, 3.45J, and 3.83J and 20° angle footwear exhibits the energy values: of 2.76J, 3.18J, 3.67J, and 4.13J. The energy values of 20° angle footwear are higher than all other design angle footwear including standard design footwear. The slope angle of 20° footwear facilitates the reduction of impact force exerted by obese individuals during the heel strike phase and is further helpful for protecting the heel bone and ligaments. It also ensures smooth progression significant for diffusing ground reaction forces and aiding in the harmony of movement during the phases of locomotion.[28-31] Besides, its longest slope distance aids in improving faster cadence to acquire the increased speed of walking to restore health and fitness to obese individuals.[32] It is understood that the footwear designed with a specially curved outer sole eases reduces the bending of foot joints and the local impacts and stresses on the feet. Besides, 20° angled footwear facilitates the foot to roll faster off the heel to acquire the advantages of foot comfort for obese individuals. However, if the angle becomes more than 20°, there is an instability and balance problem faced by the user. Hence, there are practical limitations. The heel height with a 20° angle has been chosen as optimum.

Figure 3. Energy absorption characteristics 120 D PU foam materials under different loads

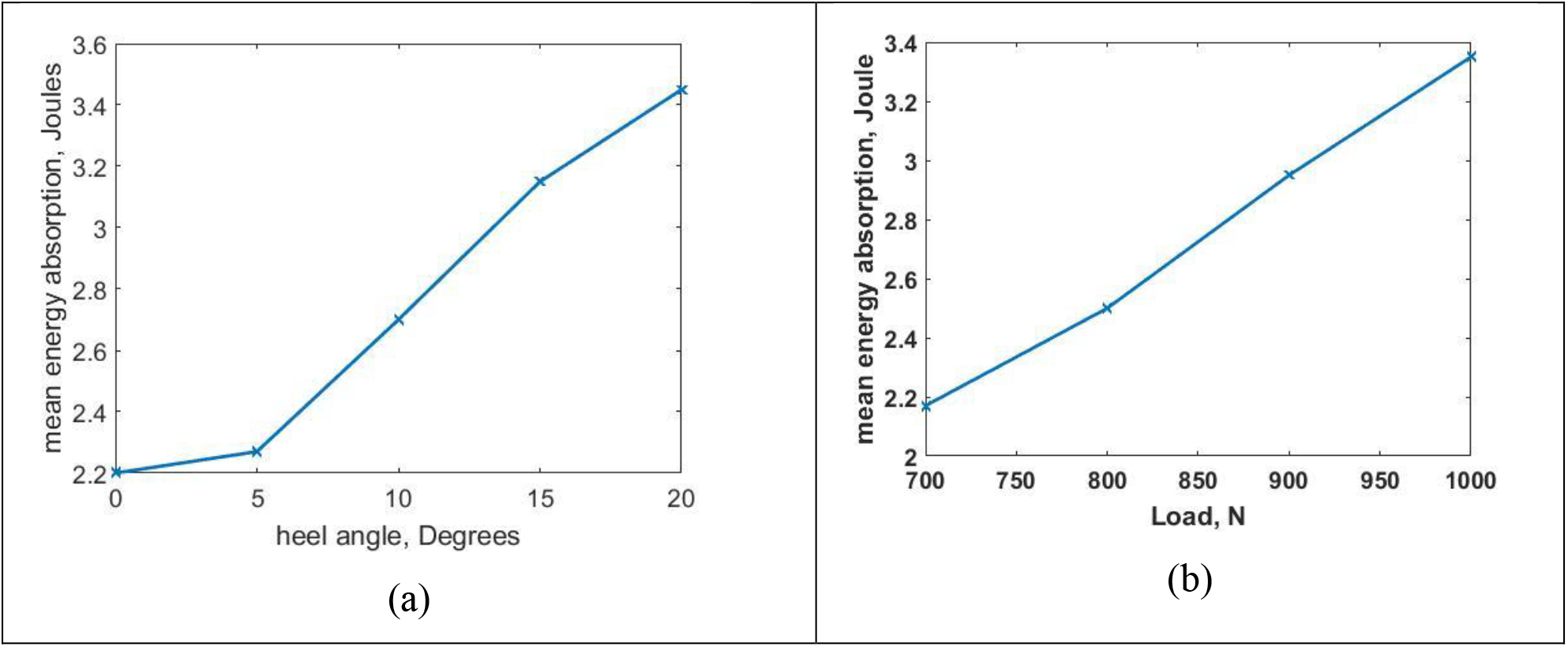

The two-way normal ANOM statistical method was employed to relate heel angle and load for energy absorption characteristics of footwear. From the main effects plot for energy absorption presented in Figure 4, it can be observed that the mean energy absorption increases with an increase in both heel angle and load and is statistically significant.

Figure 4. Mean of energy absorption for PU foam under (a) different heel angles (b) different loads

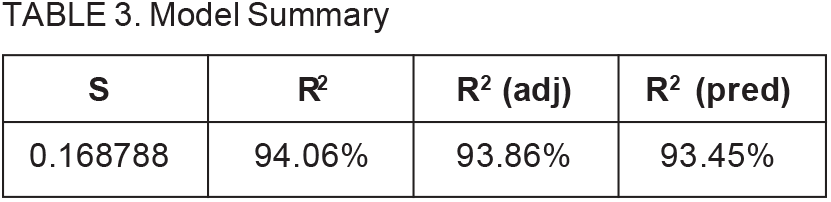

The observations on absorbed energy for all the slope angle degrees of footwear were subjected to statistical analysis to formulate a predictive regression equation for energy.[33-35] The independent variables, in this case, are the angle and load exerted by the obese, while the dependent variable is the absorbed energy. The coefficient of determination (R Square) was found to be 0.9406, (Table 3) which indicates that the model confirms fit and suitability. Hence, the energy absorbed can be related to heel angle and load by formulating first-order linear regression equation.

The significance of dependent variables: heel angle and load and their impact on the dependent variable (energy absorbed) can be understood clearly from the analysis of variance. It is observed that P-value stands at 0.013 which supports the fitness of the model. From the regression equation, it can be found that the angle contributes more significantly (0.067) than the other parameter to the energy absorbed.

From the regression equation, it is given as a constant term – 1.338 and the other coefficients for heel angle are 0.06753 and for the load is 0.004008 respectively. It can be found that the angle contributes more significantly (0.067) than the other parameter to the energy absorbed.

The research undertaken here primarily focuses on studying compressive loading characteristics of PU foam materials used in the design of footwear with different slope angles such as 5°, 10°, 15°, and 20° including standard design footwear. The results of energy-absorption characteristics of varied external designed footwear interposing with 120 D PU foam materials were obtained using Universal Testing Machine. The energy-absorption capacity of 20° angled footwear exhibited 2.76J, 3.18J, 3.67J, and 4.13J under varied loading conditions of 700N, 800N, 900N, and 1000N respectively. It has been observed that the value of energy absorption increased ranging from 59% to 65% for the varied loading conditions. Hence, it is ideally suitable, especially for the people with higher BMI values for foot-comfort benefits. The study concludes that 20° angled footwear is the optimum design demonstrating a higher energy absorption feature followed by a higher dissipation of energy. The slope configuration eases smoother dissipation of energies on the heel region across the surface of the footwear. The heel geometry profile of 20° angled footwear with the composition of 120 D PU foam possess improved cushion energy as well as compression set and resiliency property and is ideally recommendable for rehabilitation and therapeutic advantages for obese individuals.

Acknowledgement: The authors are willing to acknowledge the support of CSIR-CLRI for providing infrastructure and facilities for carrying out this research. There is no conflict of interest in this publication.

References

1. D.I. Brown, J.J. Wertsch, G.F. Harris, J. Klein and D. Janisse, Archives of Physical Medicine Rehabilitation. 85(2004): 81. [Google Scholar]

2. J.D. Chapman, S. Preece, B. Braunstaien and S. Hohne, Clinical Biomechanics. 28 (2013): 679. [Google Scholar]

3. S. Forghany, C. Nester, B. Richards and A. Hatton, Journal of Foot and Ankle Research. 5(2012): 24. [Google Scholar]

4. E. Fuller, S. Schroeder and J. Edwards, Journal of the American Podiatric Medical Association. 91(2001): 501. [Google Scholar]

5. S. Hutchins, P. Bowker, N. Geary and J. Richards, Foot (Edinburgh, Scotland). 19 (2009): 165. [Google Scholar]

6. A. Healy, D.N. Dunning and N. Chockalingam, Prosthetics and Orthotics International. 36(2012): 53. [Google Scholar]

7. Z. Rafiee, Progress in Organic Coatings. 86 (2015): 190. [Google Scholar]

8. C. Prisacariu, “Structural studies on polyurethane elastomers” Springer, Vienna. (2011). [Google Scholar]

9. M. Moumita, A. Senthil, T. Gurusamy, C. Dinesh Kumar, A. Ananthan, B.N. Das, N. Jaisankar, A.B. Mandal, Applied Surface Science. 499(2020): 143966. [Google Scholar]

10. J.O. Akindoyo, M.D.H. Beg, S. Ghazali, S, M.R. Islam, N. Jeyaratnam and A.R. Yuvaraj, RCS Advances. 213(2016): 115. [Google Scholar]

11. H.W. Engels, H.G. Pirkl, R. Albers, R.W. Albach, J. Krause, A. Hoffmann, H. Casselmann, and J. Dormish, J, Angewandte Chemie International Edition. 52(2013): 9422. [Google Scholar]

12. K.M. Zia, S. Anjum, M. Zuber, M. Mujahid and T. Jamil, International Journal of Biological Macromolecules. 66(2014): 26. [Google Scholar]

13. W. Chen, H. Hao, D. Hughes, Y. Shi, J. Cui, Z.X. Li, Materials & Design. 93 (2015): 170. [Google Scholar]

14. QFP, Polyurethane Glossary. 52 (2019): 249. [Google Scholar]

15. K. Lu, X.L. Gao and A.K. Roy, Composites Science and Technology. 63(2003): 1769. [Google Scholar]

16. M.F. Alzoubi, S. Al-Hallaj and M. Abu-Ayyad, Journal of Solid Mechanics. 6(2014): 82. [Google Scholar]

17. I.J. Gibson and M.F. Ashby, Proceedings of Royal Society of London. 382(1982): 43. [Google Scholar]

18. D.B. Burr, C. Milgrom, D. Fyhrie, M Forwood, M. Nyska, A. Finestone, S. Hoshaw, E. Saiag and A. Simkin, Bone. 18(1996): 405. [Google Scholar]

19. F. Saint-Michel, L. Chazeau, J.Y. Cavaillé and E. Chabert, Composites Science and Technology. 66(2006): 2700. [Google Scholar]

20. D.J. Janisse. Clinics in Podiatric Medicine and Surgery. 12(199541. [Google Scholar]

21. H.B. Kitaoka, Z.P. Luo, and K.N. An, Clinical Orthopaedic Related Research. 339 (1997): 250. [Google Scholar]

22. L. Stewart and J. Gibson. Gait & Posture. 25(2007): 648. [Google Scholar]

23. N.A. Maffiuletti, D. Malatesta, F. Agosti and A. Surtorio, The American Journal of Medicine. 125(2012): 513. [Google Scholar]

24. P. Marcelo. De Castro, C. Sofia. Abreu, Helena Sousa, Leandro Machado, Ru-bim Santos and Joao Paulo Vilas – Boas, Research Quarterly for Exercise and Sport. 85(2014): 188. [Google Scholar]

25. D.A. Nawoczenski, J.A. Birke and W.C. Coleman, Journal of American Podiatric Association. 78 (1988): 455. [Google Scholar]

26. K. Rome, M. Frecklington, P. McNair, P. Gow and N. Dalbeth Arthritis Care & Research. 63(2011): 1599. [Google Scholar]

27. K. Rome, Journal of American Podiatric Association. 81(1991): 73. [Google Scholar]

28. D.A. Seligman, Archives of Physical Medicine and Rehabilitation. 84(2003): 1564. [Google Scholar]

29. S. Mathivanan, R. Mohan and P. Balachander, Fibres and Textiles in Eastern Europe. 27 (2019): 76. [Google Scholar]

30. S. Mathivanan, R. Mohan, B.N. Das. Journal of Polymer Engineering. 36(2015): 253. [Google Scholar]

31. M. Steffen, A. Carlsohn, J. Mueller, H. Baur and F. Mayer, Plos One. 11(2016): e0149924. [Google Scholar]

32. M. Taniguchi, H. Tateuchi, T. Takeola and N. Ichihashi, Gait & Posture. 35(2012): 567. [Google Scholar]

33. A. Williams and C. Nester, The Pocket Podiatry Guide Edinburgh: Churchill Livingstone. Edinburgh. (2010). [Google Scholar]

34. H. Xu, M. Akai, S. Kakurai, K. Yokota and H. Kaneko, American Journal of Physical Medicine & Rehabilitation. 78 (1999): 516. [Google Scholar]

35. N. Mills, Polymer Foams Handbook. Elsevier B.V. (2007). [Google Scholar]

Cite This Article

Copyright © 2022 The Author(s). Published by Tech Science Press.

Copyright © 2022 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools