Open Access

Open Access

ARTICLE

Sustainable Composite of Cardanol Based Phenalkamine Cured Epoxy Systems: Fabrication, Characterization and Mechanical Performance Evaluation for Emerging Applications

1 Department of Rubber & Plastics Technology, MIT Campus, Anna University, Chennai, 600044, India

2 Department of Chemistry, Madras Christian College (Autonomous), Affiliated to University of Madras, Tambaram East, Chennai, 600059, India

* Corresponding Author: Jayakumari Lakshmanan Saraswathi. Email:

Journal of Polymer Materials 2024, 41(4), 299-313. https://doi.org/10.32604/jpm.2024.056261

Received 18 July 2024; Accepted 20 September 2024; Issue published 16 December 2024

Abstract

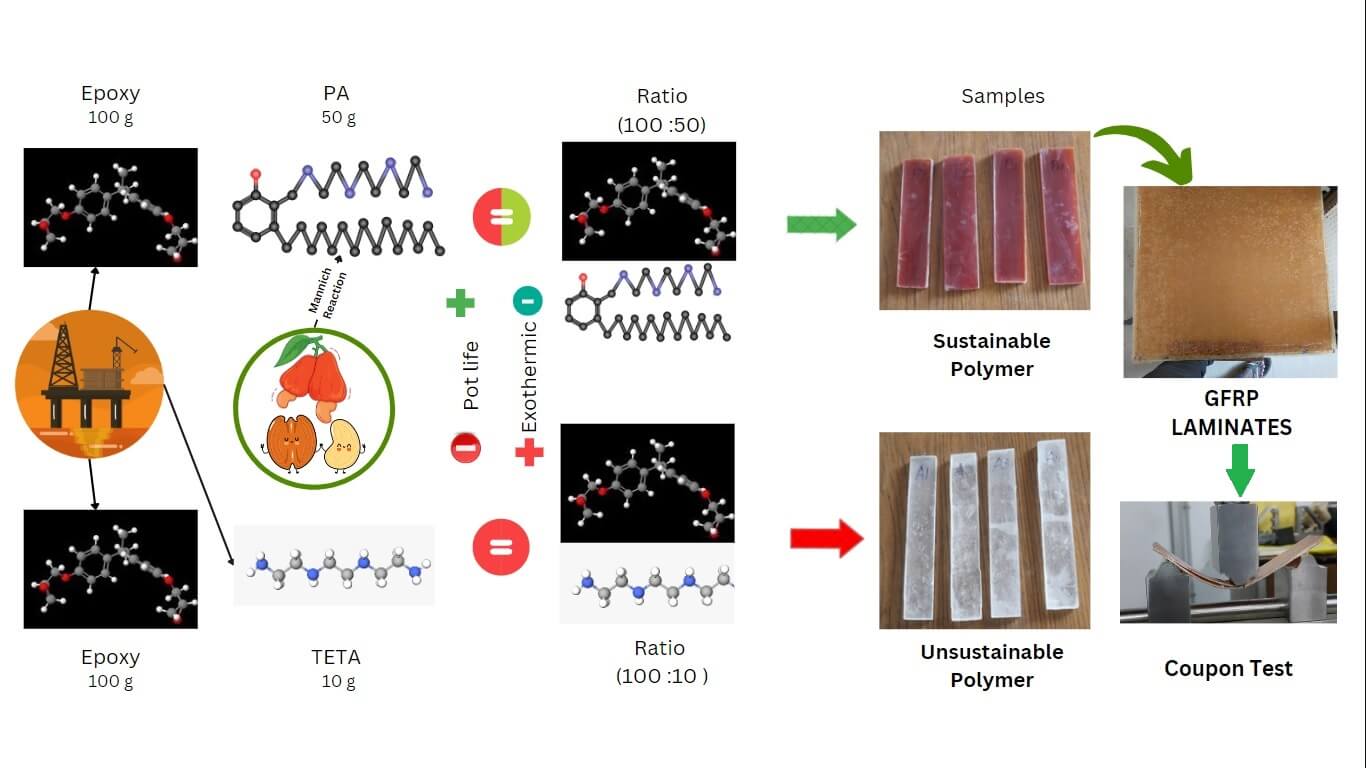

Petroleum-based cured epoxy polymers, used widely in aerospace, marine, and automotive industries, pose environmental threats due to their toxicity. Therefore, developing alternative curing systems for epoxy resin is crucial. This study explores the use of bio-based phenalkamines as curing agents for epoxy resin to enhance the mechanical properties of polymer composites and fiber-reinforced laminates. The functional groups, morphology, and thermal properties of the composites were analyzed using Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and thermogravimetric analysis (TGA). Mechanical properties of two epoxy systems—EP-TETA (triethylenetetramine-cured) and EP-PA (phenalkamine-cured)—were evaluated according to ASTM standards. EP-PA exhibited approximately 318% greater elongation, indicating improved ductility, and 16% higher ultimate force and stress compared to EP-TETA, suggesting its suitability for load-bearing applications. Additionally, phenalkamine-cured epoxy resin composites with adequate thickness demonstrated excellent performance. Glass fiber-reinforced GEP-PA showed 5.3 times greater toughness and adhesion in end notch tests compared to GEP-TETA. These results offer valuable insights for material selection in aerospace and automotive applications.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools