Open Access

Open Access

PROCEEDINGS

Machining Learning Enhanced Shape Morphing Design of 4D Printed Microplatelet Composites

1 School of Mechanical and Aerospace Engineering, Nanyang Technological University, 50 faculty avenue, 639798, Singapore

2 School of Materials Science and Engineering, Nanyang Technological University, 50 faculty avenue, 639798, Singapore

* Corresponding Author: Hortense Le Ferrand. Email:

The International Conference on Computational & Experimental Engineering and Sciences 2024, 31(1), 1-2. https://doi.org/10.32604/icces.2024.011119

Abstract

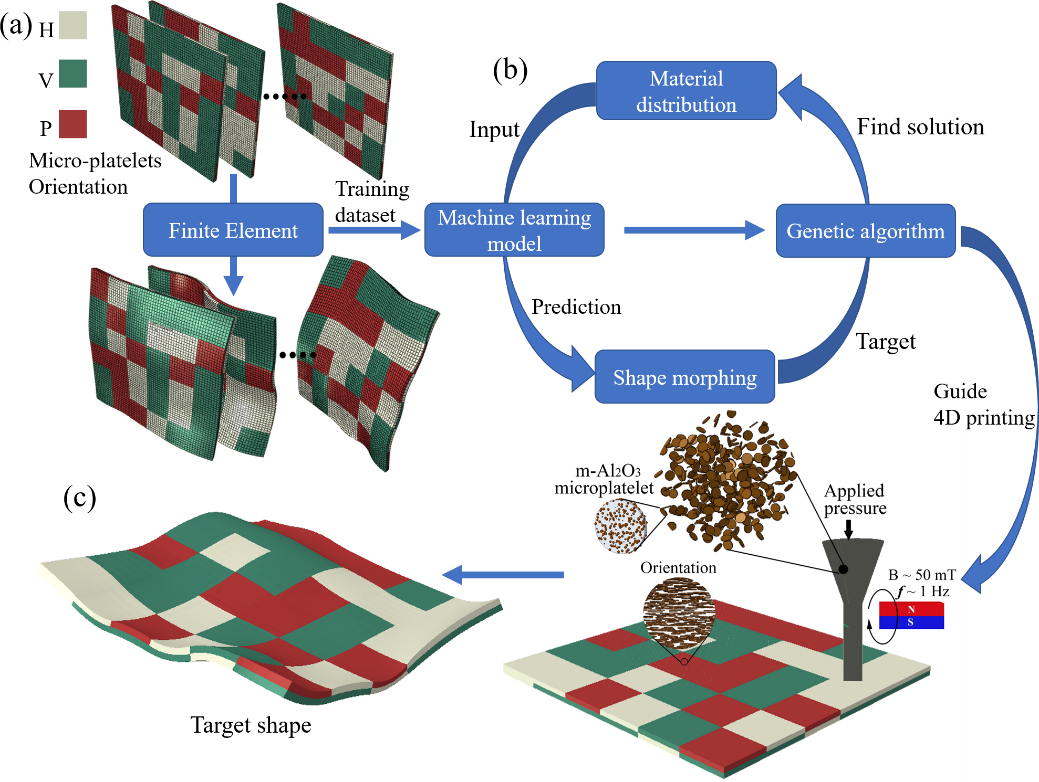

Natural structural materials have undergone extensive evolution, resulting in intricate microstructural designs over billions of years. These designs have given rise to a diverse array of hierarchical microstructures that exhibit exceptional performance in terms of strength, resilience, toughness, and adaptability [1]. Among these natural microstructures, the microplatelet-based brick-and-mortar arrangement found in the nacreous layers of seashells has been the subject of extensive study. Additionally, more complex microstructural alignments exist, and these mineral orientations showcase varying properties, such as the shrinkage deformations. Inspired by the observed expansion deformation characteristics in nature, this study delves into the potential of 4D printing to achieve designed material or property distributions by utilizing a pre-designed complex material on numerous small voxels. Despite offering significant design flexibility, this expansive design possibilities poses the challenge of efficiently identifying suitable designs to attain a target shape change [2]. To address this challenge, the study introduces an innovative machine learning (ML)-based approach to guide the design process. Drawing on the 2D plate deformation characteristics, a coordinate-based convolutional neural network (CNN) ML model is developed. This model predicts shape morphing based on a training dataset acquired from finite element simulations. Additionally, an inverse genetic algorithm with an ML model is devised to find solutions for the targeted shape. The study concludes by transforming hand-drawn 2D shapes into drawn profiles and determining the corresponding material distributions for 4D printing, ultimately achieving the desired shape.

Fig. 3. Schematic Illustration of the Desired Design for a 4D Printed 2D Plate Composite. Complete Design Process: (a) Dataset Generation through Finite Element Simulations. H, V and P indicate the expansion properties of horizontal, vertical, and perpendicular microplatelets, respectively. (b) Shape Morphing Prediction by Machine Learning (ML) Model, and Material Distribution Design by ML and Genetic Algorithm, (c) 4D Printing Design for Achieving the Target Shape.

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools