Open Access

Open Access

PROCEEDINGS

Study on the Effect of Welding Sequence on Residual Stress in Post Internal-Welding Joint of Bimetal Composite Pipe

1 School of Materials Science and Engineering, China University of Petroleum, Qingdao, 266580, China

* Corresponding Author: Bin Han. Email:

The International Conference on Computational & Experimental Engineering and Sciences 2024, 30(3), 1-4. https://doi.org/10.32604/icces.2024.013339

Abstract

With the rapid development of industry and globalization, the demand and strategic importance of oil and natural gas have become increasingly significant, leading to energy extraction in more complex corrosive environments [1, 2]. Bimetallic composite pipes, which offer strength and corrosion resistance, exhibit promising potential. For the welding of bimetallic composite plates, it is optimal to follow the welding sequence of the base layer, transition layer, and inner layer [3, 4]. For the welding of bimetal composite pipes, due to the diameter limit, the inner layer is usually welded first, followed by the transition layer, and the base layer finally, which is referred to as the single-side welding process. There is a significant martensitic layer in the fusion zone when using less costly mixed welding material in the single-side welding process, resulting in cracks in the bending specimen and a deterioration in mechanical properties.With the application and miniaturization of internal welding machines, the welding of bimetal composite pipes can be accomplished by first welding the base layer, followed by using an internal welding machine to weld the inner layer, which is known as the post internal-welding process proposed by Han and Li [5, 6]. Studies have shown that the properties of the post internal-welding joints meet the required standards, especially the bending properties. The post internal-welding process diversifies the welding sequence, significantly influencing the residual stress in welding [7]. Therefore, it is necessary to explore the effect of the welding sequence on residual stress.

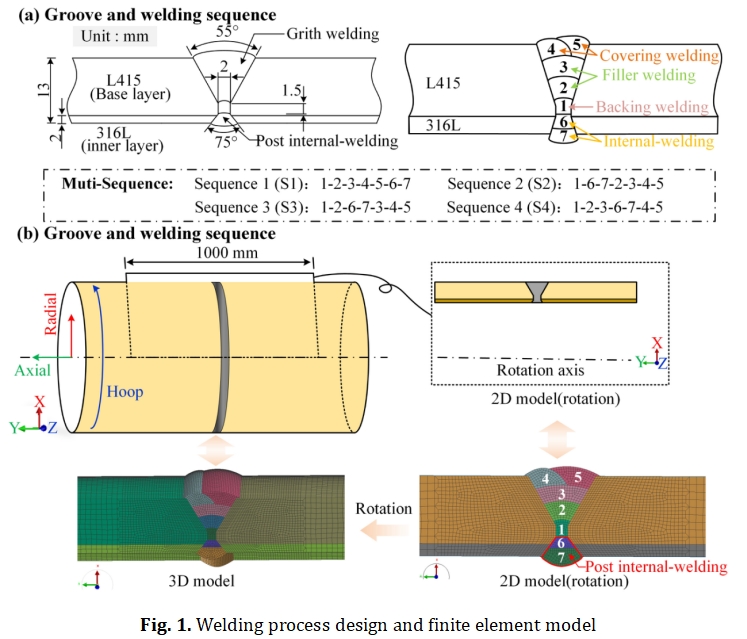

The bimetal composite pipe of L415/316L with specifications of φ355×(11+2) is used in this work, where the base material is L415 (thickness of 11 mm) and the inner layer is 316L (thickness of 2 mm). The welding groove is an asymmetric double V-groove, divided into 7 weld layers. The weld beads with names 6 and 7 are formed in the internal weld layer using an internal welding machine. By adjusting the internal welding sequence throughout the entire welding process, the welding sequence is categorized into four types. Fig. 1 (a) shows the groove and sequence division. The 1:1 scale model with actual dimensions is built by a combination of 2D and 3D models (Fig. 1 (b)). Transition meshes are used to balance computational efficiency and accuracy. To ensure the accuracy of the calculation, the length of the single side is 1000 mm, and the minimum grid is 0.3 mm×0.3 mm. The mesh size gradually increases in regions away from the welding joint to improve computational efficiency [8].

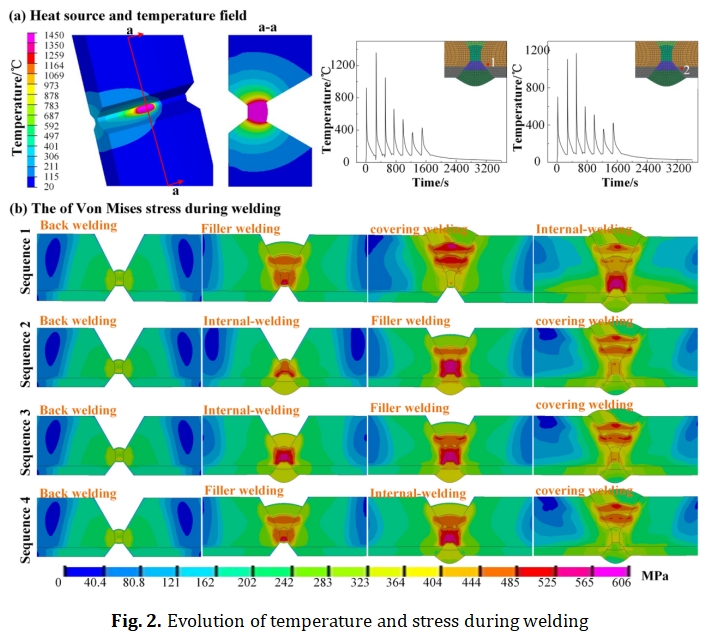

As shown in Figure 2(a), the heat source loading of the backing weld layer in the 3D model is primarily used for determining the welding heat source parameters. The thermal cycle of the entire welding process is extracted, with point 1 (L415 material) and point 2 (316L material), which are adjacent positions. During the internal welding process, the thermal cycle of the two materials differs significantly, because their thermophysical parameters are not the same. This difference in the thermal process also leads to variations in residual stress.

The evolution of Von Mises stresses during the welding process is shown in Fig. 2(b). The high-stress region begins to appear during internal welding or filler welding. With the change in the welding sequence, the high-stress region transfers between the backing weld layer and the filler layer, and the stress in the backing weld layer undergoes a process of increase and decrease. Reasonable adjustment of the welding sequence can transfer the high-stress region in the backing weld layer to the filler layer, reducing the stresses in the root weld layer and the inner surface.

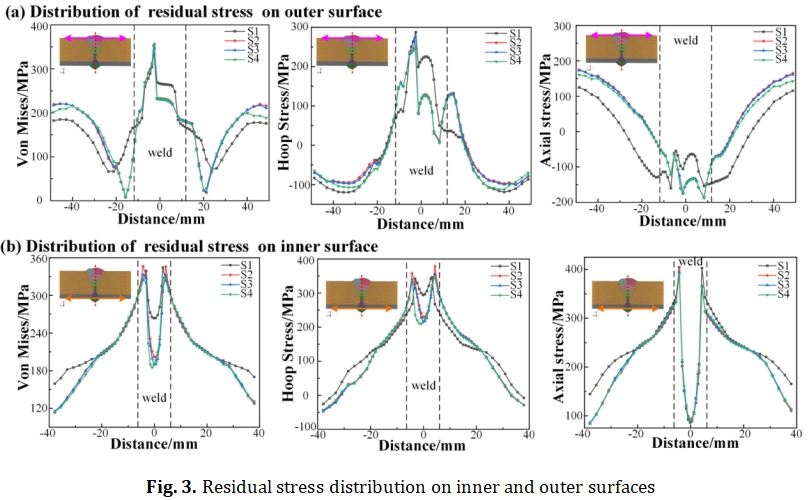

The residual stress distribution on the inner and outer surfaces under different welding sequences is shown in Fig. 3. The stress distribution of four sequences is approximately as same on the outer surface. However, the difference is mainly reflected in the stress levels between S1 and the other three sequences. For the stresses of the inner surface, the stresses of the four sequences are different, which is mainly reflected in the hoop stresses and Von Mises stresses.

The welding sequence mainly affects the level of residual stresses but has little effect on the distribution. Changing the welding sequence, the residual stresses on the inner surface change more significantly than that of the outer surface. The welding between the inner welding layer and the backing welding layer involves dissimilar metals, leading to the brittle hard layer of martensitic inevitably [9]. The combination of this structure and stress causes cracks. The S4 welding is the best sequence and the residual stresses in weak positions are effectively reduced.

Through the reasonable adjustment of the welding sequence, the residual stress in weak positions such as the backing welding layer and the inner welding layer can be reduced, thereby improving the safety of the joints. This provides theoretical guidance for optimizing the welding process of bimetal composite pipes. The mechanical composite pipe needs to consider the effect of pipe end overlay welding on residual stress. Therefore, the welding sequence planning for mechanical composite pipes and metallurgical composite pipes in the post internal-welding process needs to be considered separately.

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools