Open Access

Open Access

ARTICLE

Deep Learning-Based Swot Analysis in Construction and Demolition Waste Management

Department of Civil Engineering, Noorul Islam University, Thuckalay, 629180, Tamilnadu, India

* Corresponding Author: R. Rema. Email:

Intelligent Automation & Soft Computing 2023, 36(2), 1497-1506. https://doi.org/10.32604/iasc.2023.032540

Received 21 May 2022; Accepted 28 June 2022; Issue published 05 January 2023

Abstract

Researchers worldwide have employed a varied array of sources to calculate the successful management of Construction and Demolition (C&DW). Limited research has been undertaken in the domain of Construction and Demolition Waste Management (C&DWM) and consequently leaving a large gap in the availability of effective management techniques. Due to the limited time available for building removal and materials collection, preparing for building materials reuse at the end of life is frequently a challenging task. In this research work Convolutional Neural Network-Long Short-Term Memory (CNN-LSTM) is proposed to predict the number of waste materials that are obtained from a building at the end of its useful life. As a result, an effective Waste Management (WM) plan has been established through SWOT analysis. The results of the study reveal that, given fundamental building characteristics, it is possible to predict the number of materials that would be collected with high precision from a building after demolition. The proposed deep learning models achieved an average R-squared value of 0.98 and a Mean Absolute Error of 18.1 and 20.14 better than existing methods such as random forest, CNN, and DBN (Data Bus Network).Keywords

The management of C&DW is a serious environmental problem and a burden on developing countries. Similarly, it is a major environmental challenge and threat which draws the concern and responsibility of individuals towards enabling a sustainable environment. C&DW contains building materials and waste deriving from construction, renovation, and destruction of any type of structure as mentioned by, the Ministry of Environment, Forests & Climate Change [1]. Entering the waste stream with contaminants and decontaminating other building components during reconstruction, renovation, or demolition poses a task to the building sector [2,3]. To assist in the waste disposal process, assessments of building waste are currently performed during pre-demolition audits for individual buildings [4].

One of the fundamental needs for sustainability in the construction and demolition (C&D) industry is determining the greatest derivable economic and environmental values from a building at the end of life before deconstruction and demolition [5]. Pre-demolition audits have been highlighted as a useful tool for stakeholders in the C&D industry (clients, architects, engineers, contractors, planners, and so on). It is critical to be able to access information on the material type created by the process to support sufficient materials recovery and reuse. In Europe, this information is currently gathered through pre-demolition audits [6]. Performing a pre-demolition audit can be difficult, especially when there is little or no information available.

Before the construction of a new building, a limited amount of time is normally set aside for the removal of old structures from the site. The demolition engineers don’t have enough time to do a complete pre-demolition audit [7]. This research is unique in that it uses a selected deep learning method to handle the issues of calculating building end-of-life values. The research is different in using chosen deep learning technique to handle the issues of calculating building end-of-life values.

The Convolutional Neural Network-Long Short-Term Memory (CNN-LSTM) technique is used in this study to create a computer programme for estimating the number of construction materials available from demolition. The specific goal is to create CNN-LSTM models that can predict how many tonnes of building materials will be generated once a building is demolished. Finally, the current situation is evaluated, and waste management strategies were developed using a Strengths, Weaknesses, Opportunities, and Threats (SWOT) analysis to avoid environmental management difficulties.

The remainder of the paper is carried out as follows: In part 2, the literature review is presented, along with methodologies for C&D waste prediction and estimation, as well as their limitations. Section 2 also discusses several uses of deep learning models. Section 3 presents the material and model for this research. Section 4 explains the technique used in this study, including data description and model construction. Section 4 also discusses model testing and evaluation. Sections 5 and 6 include the results and conclusions.

Different approaches for calculating construction wastes and demolition risings are described in this section. The present method’s limitations are also discussed.

Wang et al. [8] presented an innovative robotic system for collecting and sorting construction and demolition trash. The robot patrols the construction site using an RGB-D (Red Green Blue-Depth) camera and Simultaneous Localization And Mapping (SLAM). The outcome demonstrates the technique for improving robot reliability in real engineering. The major drawback is the poor performance of the RGB camera.

Abulebdah et al. [9] presented the SWOT analysis is being used to assess the existing state of CDWM practices in Qatar, identify issues of concern, and provide strategies for building sound CDWM practices that can effectively decrease the effects of C&D waste generation and accumulation.

Ding et al. [10] presented Agent Based Modelling (ABM) as a useful tool for assessing and measuring the environmental impact of Demolition Waste Management (DWM). According to the simulation results, increasing the level of green DWM has the greatest positive impact on overall DWM. The findings show that the negative environmental impacts of DW can be reduced by at least 50%.

Xu et al. [11] presented a multiperiod optimization based on a Reverse Logistics Network (RLN) to reduce pollution and waste disposal costs. The result shows that the introduced method efficiently regulates Construction and Demolition Waste (CDW) recycling and reduces environmental damage.

Davis et al. [12] presented the deep convolutional neural network to identify the construction and demolition waste. This method simulated real-world building site circumstances when sorting is difficult on-site. The experimental result has high accuracy and reduces the CDW diversion from landfills.

Ku et al. [13] presented the deep learning method for grasping detection to improve the level of resource utilization of CDW. The experiment revealed that robotic grasping accuracy is just 70% at the time of the experiment. The accuracy of grasping detection after deep learning is well above 90%, which fully meets the requirements of efficiency and accuracy for sorting CDW under real-world settings. The major drawbacks are low recycling purity and low efficiency.

You et al. [14] presented an informatization scheme for C&D waste supervision and management in China, which will contribute to real-time monitoring of the waste disposal process for identifying potential illegal behaviors, accurate data collection for stakeholder performance evaluation, and data sharing between supervision departments for better coordination.

The existing method for calculating C&D wastes are significantly superior but are limited in their applicability to older building stocks. This research aims to close this gap by creating CNN-LSTM models that calculate the materials output from buildings based on the building’s basic features.

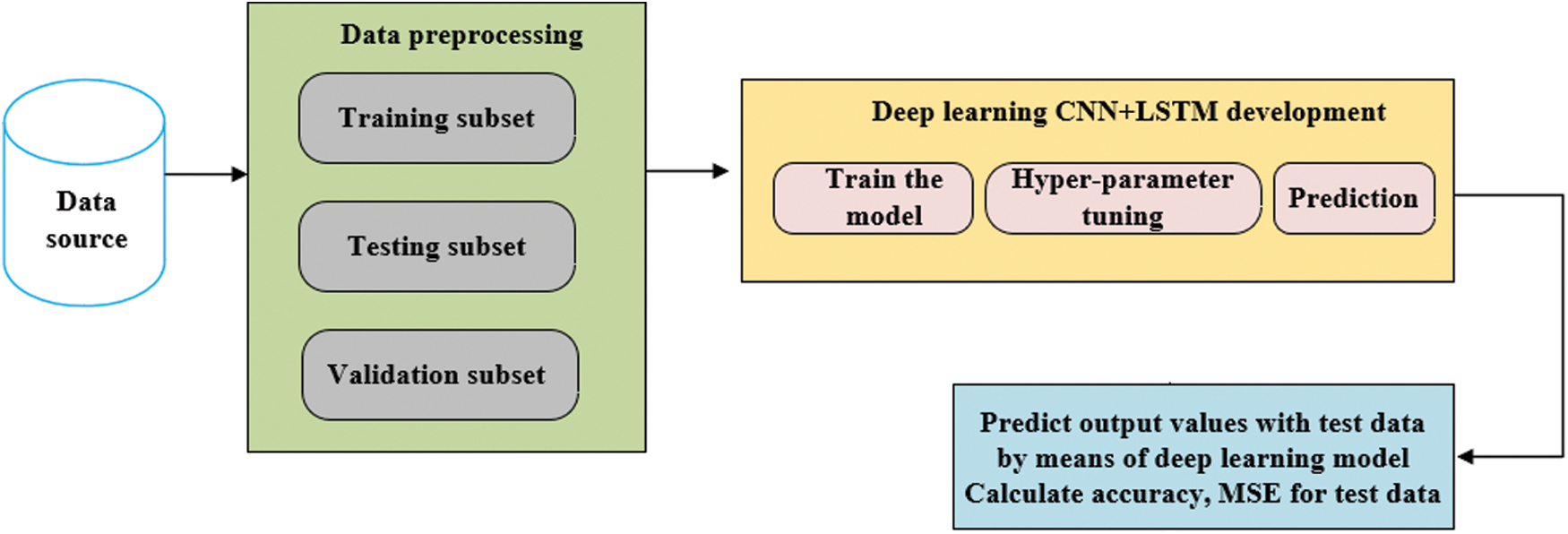

This section describes the data collecting, pre-processing, feature selection, and deep learning model development processes. CNN-LSTM based models are used to predict the end-of-life use case of building materials. Fig. 1 shows the proposed deep learning CNN-LSTM method for predicting waste generation rates. The CNN-LSTM was created to develop a link between the dependent and independent variables. The dependent variables are recyclable, reuse, and landfill components of building materials, while the independent variables are variables chosen from the dataset. Finally, evaluation metrics such as MAE, Accuracy and R^2 on test data are used to assess the model prediction accuracy.

Figure 1: Proposed deep learning CNN-LSTM method for predicting waste generation rates

The information used in this research comes from building demolition records gathered in India. Our sources are key figures in India’s demolition sector. The WTS (Waste Transfer Stations) combines building rubble from several demolition sites before further processing. A total of 2,280 demolition records were obtained. The collection includes building information as well as the number of different construction materials recovered during demolition. Five essential elements of structures are recognized as primary predictors of the number of building materials recovered after demolition work with the help of our informants. GFA (Gross Floor Area), volume, number of floors, building archetype, and usage are some of these characteristics. Each of the waste categories is also included in the dataset (reusable, recyclable, and landfill). The dataset contains missing data at a negligible amount (9 records, or 0.004%).

4 Proposed CNN-LSTM Model Development

This section describes the CNN-LSTM technique for predicting the number of building materials in tonnes depending on the buildings. The number of recycled, reused, and landfill materials are predicted using the CNN-LSTM technique. The CNN-LSTM architecture used to predict demolition waste and its classifications are shown in Fig. 2. One input layer, one convolutional layer, one LSTM layer, one attention layer, and one output layer make up the model. After pre-processing, the dataset has three sections: 90% for training, 12% for testing, and 12% for validation. The sensitivity of CNN-LSTM can be used to calculate the best network structure. The best validation results for CNN-LSTM models include determining the best neural network topology and controlling hyper-parameters. A random search was used to determine the control hyper-parameter. The CNN-LSTM architecture is in charge of improving classification and prediction accuracy. The data is first incorporated into the model, after which the characteristics are extracted using CNN layers. Second, the CNN layers outputs are fed into the LSTM layer, which captures long-term variables’ dependencies. Finally, all of each LSTM layer’s hidden states are fed into the attention layer, which can learn the importance of these hidden layer states. Finally, a weighted total is used to calculate the output.

Figure 2: The framework of the CNN-LSTM model

The input data flow through the input layer before entering the one-dimensional convolutional layer, where the kernel only moves in time. The A = {

where

4.2 Long Short-Term Memory (LSTM) Layer

The outputs of the convolutional layers are passed into the LSTM layer. A forget gate, an input gate, and an output gate, as well as a cell state, are all present. Because of its unique cell state and three gates, LSTM overcomes RNN’s vanishing gradient and expanding gradient issues. After the forget gate rejects some information in the first phase, the input gate decides what kind of information is saved in the cell state. The following are the equations:

where, M for weight matrix of corresponding gate,

In the last several years, awareness of the WM in India has increased considerably. Some attendees at the Focus Group meeting were surprised by the growth of waste generation in the Indian construction industry in the last 30 years. They considered it part of the cultural deterioration, which caused enormous waste to C&D activities. In the construction industry, extensive use of recycled and prefabrication materials has been made (doors, windows, and partition walls), which leads to a significant decrease in waste generation. However, waste management practices have failed to keep pace with the building industry. The results show that C&DWM is not related to other waste management activities. The measures of C&DWM should be collective, not inherently individual behavior equivalent. Thus, the SWOT analysis of C&DWM helps comprehend Chennai’s situation when developing C&DWM. From the focus group meetings, the internal and external factors are summarized in Tab. 1.

The results section gives the construction material dataset before comparing the models’ predictions. The influence of data size on simulation results is explored with the most important characteristics emphasized.

5.1 Performance Metrics for the CNN-LSTM Model

The prediction accuracies of the CNN-LSTM models were assessed to determine their generalization on the test dataset. The metrics MAE (Mean Absolute Error) and R-squared are scale-dependent and can be used to calculate prediction error. The goal is to reduce these indicators to achieve the maximum model prediction accuracy. Eqs. (5) and (6) define these measures, where

The validation procedure in deep learning model development eliminates overfitting by comparing the prediction models produced using training data and choosing the method with the greatest function metric. Figs. 3a and 3b shows the accuracies of various CNN-LSTM network architectures for reusable materials in terms of MAE and R-Squared. The MAE value of 18.1 and the R-Squared value of 0.98 are the lowest for this structure.

Figure 3: (a) Accuracy of CNN-LSTM for reusability with MAE metric (b) Accuracy of CNN-LSTM for reusability with

R-Squared metrics are used to evaluate the CNN-LSTM models accuracy. R-Squared is a performance indicator for regression problems that illustrates how near the predicted values are to the actual values. Tab. 2 shows the accuracies of the CNN-LSTM models, which include recyclable, reuse, and landfill models. The CNN-LSTM model for recyclable materials has a prediction accuracy of 95%, the CNN-LSTM model for reusable materials has a prediction accuracy of 98%, and the CNN-LSTM model for landfill materials has a prediction accuracy of 99%. Based on R-squared performance metrics, the overall average performance of the proposed models is 98%.

The results of the CNN-LSTM models’ evaluation on the case study building are shown in Tab. 3. The evaluation uses four different combinations of building features to produce four different architypes for a building. The analysis of the predicted end-of-life arisings is shown in Tab. 4. According to the analysis, the concrete building includes recyclable, 12% reusable, and 18% landfill materials. The masonry building, on the other hand, has 58% recyclable, 41% reusable, and 3.60% landfill materials. Steel construction created 38%, 66%, and 0.98% recyclable, reusable, and landfill materials, respectively. The timber frame construction generates 18% recyclable, 85% reusable, and 0.55% landfill waste, respectively. According to the findings, the timber frame building creates the most reusable end-of-life arisings, obtained the steel frame building. The concrete-framed building produces the least reusable arisings, obtained by the masonry-framed building. Similarly, timber frame construction produces the least waste, followed by steel frame construction.

The deep learning models developed in this research using CNN-LSTM to develop a meaningful relationship between independents factors are building usage, building architypes, number of floors, gross floor area, and volume and the dependent variables are recyclable materials, reusable materials and landfill materials. The CNN-LSTM model proposed has an average accuracy of 98%. According to CNN-LSTM method, the most important factor is building usage type (1.00), gross floor area (0.97), number of floors (0.95), architype (0.80), and volume (0.65), are displayed in Fig. 4. Fig. 4b depicts the independent variable relevance levels for the reusability DNN model. The relevance levels of the independent variables for the landfill CNN-LSTM model are shown in Fig. 4c. The value of the number of floors in a building is highest (1.00), the importance of the gross floor space, which is 0.89. Volume, with a 0.23 relevance level, is the least important variable in the model.

Figure 4: (a) Recyclable CNN-LSTM model (b) Reusable CNN-LSTM model (c) Landfill CNN-LSTM model

A balance between correct retrieval of true positives from all observations and relevant observations within each classifier’s comparable accuracy and recall rates shown in Fig. 5. The waste materials predicted to 98% and 95% of average accuracy and recall rates for CNN-LSTM model.

Figure 5: Comparison of proposed method with existing methods

The study demonstrates the possibility of applying deep learning in predicting building materials based on selected building features. Determining the real number of materials generated by demolition and deconstruction activity can help with material reuse planning. Current methods for predicting end-of-life situation are time-consuming, and they almost always result in higher disposal costs. The CNN-LSTM models generated achieved an overall average accuracy of 98% on all datasets using R-squared as a performance metric. The model for recyclable materials was 95% accurate, while the reusable materials model is 98% accurate, and the landfill materials model is 99% accurate. The study found that the number of floors in a building has the greatest impact on the CNN-LSTM performance levels, while the volume of the building has the least impact.

Acknowledgement: The Author with a deep sense of gratitude would thank the supervisor for his guidance and constant support rendered during this research.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. A. Barbudo, J. Ayuso, A. Lozano, M. Cabrera and A. López-Uceda, “Recommendations for the management of construction and demolition waste in treatment plants,” Environmental Science and Pollution Research, vol. 27, no. 1, pp. 125–132, 2020. [Google Scholar]

2. C. Bodar, J. Spijker, J. Lijzen, S. Waaijers-van der Loop, R. Luit et al., “Risk management of hazardous substances in a circular economy,” Journal of Environmental Management, vol. 212, no. 16, pp. 108–114, 2018. [Google Scholar]

3. G. Zharkova, Construction and Demolition Waste Management. Finland: Metropolia University of Applied Sciences, 2021. [Google Scholar]

4. Y. Song, Y. Wang, F. Liu and Y. Zhang, “Development of a hybrid model to predict construction and demolition waste: China as a case study,” Waste Management, vol. 59, pp. 350–361, 2017. [Google Scholar]

5. M. Spišáková, P. Mésároš and T. Mandičák, “Construction waste audit in the framework of sustainable waste management in construction projects—Case study,” Buildings, vol. 11, no. 2, pp. 6, 2021. [Google Scholar]

6. C. Rose, “Systems for reuse, repurposing and upcycling of existing building components,” (Doctoral dissertationUniversity College London, United Kingdom, 2019. [Google Scholar]

7. A. Ajayi, L. Oyedele, H. Owolabi, O. Akinade, M. Bilal et al., “Deep learning models for health and safety risk prediction in power infrastructure projects,” Risk Analysis, vol. 40, no. 10, pp. 2019–2039, 2020. [Google Scholar]

8. Z. Wang, H. Li and X. Yang, “Vision-based robotic system for on-site construction and demolition waste sorting and recycling,” Journal of Building Engineering, vol. 32, no. 5, pp. 101769, 2020. [Google Scholar]

9. A. T. Abulebdah and F. Musharavati, “A SWOT analysis of the construction and demolition waste management practices in Qatar,” WIT Transactions on Ecology and the Environment, vol. 210, pp. 749–759, 2017. [Google Scholar]

10. Z. Ding, Y. Wang and P. X. Zou, “An agent based environmental impact assessment of building demolition waste management: Conventional versus green management,” Journal of Cleaner Production, vol. 133, pp. 1136–1153, 2016. [Google Scholar]

11. J. Xu, Y. Shi and S. Zhao, “Reverse logistics network-based multiperiod optimization for construction and demolition waste disposal,” Journal of Construction Engineering and Management, vol. 145, no. 2, pp. 4018124, 2019. [Google Scholar]

12. P. Davis, F. Aziz, M. T. Newaz, W. Sher and L. Simon, “The classification of construction waste material using a deep convolutional neural network,” Automation in Construction, vol. 122, no. 3, pp. 103481, 2021. [Google Scholar]

13. Y. Ku, J. Yang, H. Fang, W. Xiao and J. Zhuang, “Deep learning of grasping detection for a robot used in sorting construction and demolition waste,” Journal of Material Cycles and Waste Management, vol. 23, no. 1, pp. 84–95, 2021. [Google Scholar]

14. Z. You, C. Wu, L. Zheng and L. Feng, “An informatization scheme for construction and demolition waste supervision and management in China,” Sustainability, vol. 12, no. 4, pp. 1672, 2020. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools