DOI:10.32604/iasc.2022.019848

| Intelligent Automation & Soft Computing DOI:10.32604/iasc.2022.019848 |  |

| Article |

Hysteresis Compensation of Dynamic Systems Using Neural Networks

Department of Software Engineering, Uiduk University, Gyeongju City, 380004, Korea

*Corresponding Author: Jun Oh Jang. Email: jojang@uu.ac.kr

Received: 28 April 2021; Accepted: 11 June 2021

Abstract: A neural networks(NN) hysteresis compensator is proposed for dynamic systems. The NN compensator uses the back-stepping scheme for inverting the hysteresis nonlinearity in the feed-forward path. This scheme provides a general step for using NN to determine the dynamic pre-inversion of the reversible dynamic system. A tuning algorithm is proposed for the NN hysteresis compensator which yields a stable closed-loop system. Nonlinear stability proofs are provided to reveal that the tracking error is small. By increasing the gain we can reduce the stability radius to some extent. PI control without hysteresis compensation requires much higher gains to achieve similar performance. It is not easy to guarantee the stability of such highly nonlinear dynamical system if only a PI controller is used. Initializing the NN weights is simple. The initial weights of hidden layer are randomly selected and initial weights of output layer are set to zero. A PI loop with integerted an unity gain feedforward path keeps the system stable until the NN starts learning. Simulation results show its efficacy of the NN hysteresis compensator on a system. This work is applicable to xy table-like precision control system and also shows neural network stability proofs. Moreover, the NN hysteresis compensation can be further extended and applied to dead-zone, backlash, and other actuator nonlinear compensation.

Keywords: Hysteresis compensation; neural networks; dynamic inversion; velocity control

Industrial dynamical control systems have generally the structure of a nonlinear system in front of some nonlinearity in the actuator, for example, dead-zone, backlash, and hysteresis, etc. Hysteresis phenomena caused by magnetism, stiction or gear with backlash generally exist in control system [1–3] and often severely reduce system performance such as giving rise to oscillations and/or undesirable inaccuracy, even leading to instability. Hysteresis characteristics are usually unknown and/or generally non-differentiable nonlinearities. Most results of adaptive control system are for differentiable nonlinear or linear systems, and are not applicable to control systems with non-differentiable nonlinearities. Developing an adaptive control scheme for systems with unknown hysteresis is a challenge of practical primary concern. The controlled plant may or may not have been known and the hysteresis is considered unknown. The goal is to achieve tracking and stabilization under influence of unknown hysteresis. In recent years, several rigorously guided adaptive schemes for compensation of actuator nonlinearities have been provided in detailed studies [4]. Backlash compensation with dynamic inversion is shown in [5,6], where NN is used to eliminate the inversion error. Adaptive control of plants with unknown hysteresis was developed using an adaptive inverse scheme [7]. In [8–10], NN compensation of gear backlash-like hysteresis in the position control mechanism was proposed.

In this paper, the author presents a NN hysteresis compensation design for a system. A rigorous design procedure with validation is provided to generate a PI tracking loop using an adaptive neural network system in a feed-forward loop for hysteresis compensation. The authors derive practical limits for tracking errors through tracking error dynamics analysis, and investigate the performance of NN hysteresis compensator in the system from computer simulations.

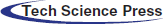

NN has been used widely in feedback control systems [11–14]. Most applications are temporary, with no proven stability. The proof of stability that exists almost invariably relies on the property of a universal approximation to NN [15,16]. The three-layer NN in Fig. 1 is composed of an input, a hidden, and an output layer. There are L neurons in the hidden layer and m neurons in the output layer. Multilayer NN is a nonlinear function from input space Rn to output space Rm. The NN output y is a vector with m components determined by the equation as the n components of the input vector x.

where σ(∙), the hyperbolic tangent functions, vkj the weight of the interconnection from the input layer to the hidden layer, and wik the weight of the interconnection from the hidden layer to the output layer. The threshold offsets are described as vk0, wi0.

Figure 1: Three-layer neural networks

By gathering all the NN weights vkj, wik into matrices VT, WT, we can write the NN equation as vector as follows:

The threshold is placed as the first column of the weight matrix WT, VT. In other words, the vector x and σ(∙) needs to be incremented by placing ‘1’ as their first element. That is , x = [1 x1 x2 · · · xn]T. To express (1) in this equation, there is sufficient generality σ(∙) to take as a diagonal function from RL to RL, which is σ(z) = diag{σ(zk)} for a vector z = [z1 z2 · · · zL]T ∈ RL.

For the convenience of notation, the matrix of all weights is defined as follows.

According to many well-known results, a sufficiently smooth function

Here, it is the NN approximation error ε(x), and ||ε(x)|| ≤ εN on a compact set S [17,18]. The approximating weights V and W are ideal target weights, and are assumed to be bounded, such that ||V||F ≤ VM, ||W||F ≤ WM, or ||Z||F ≤ ZM.

In this section, the author presents a hysteresis model and a hysteresis inverse model. The implementation of hysteresis inverse is provided in the following sections to develop an NN hysteresis compensation scheme for unknown hysteresis systems. Hysteresis compensation is performed using dynamic inversion compensation, which uses NN for dynamic inversion compensation [19]. Other types of hysteresis models, including backlash and electronics, can be identified from references [1–3]. However, general history models will not be convenient because they are complex. Here, we will use a simplified hysteresis model with most hysteresis properties.

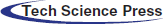

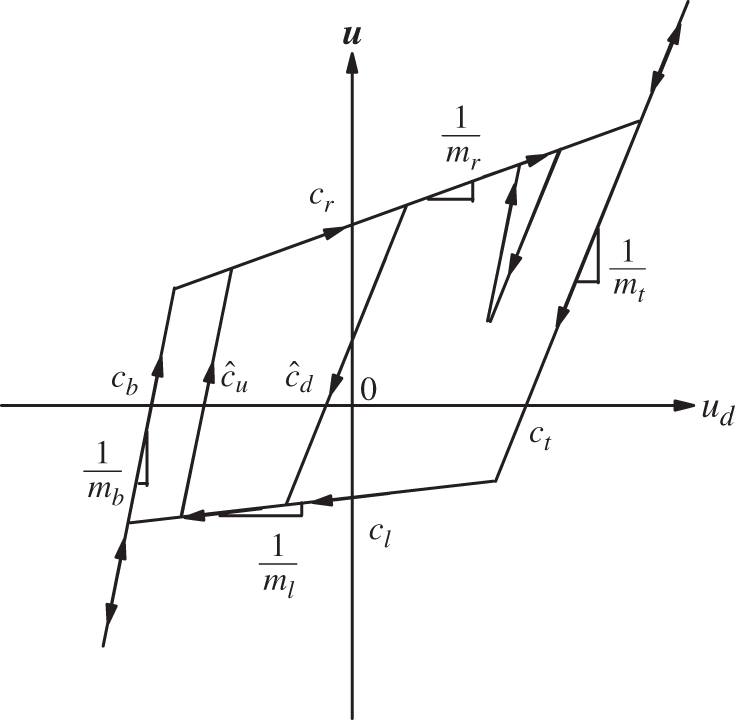

Fig. 2 shows a hysteresis model. The hysteresis properties H(∙) with input u(t) and output T(t): T(t) = H(u(t)) are described by the constants mt, ct, mb, cb, mr, cr, ml, cl and two half-lines:

and two line segments:

where u1, u2, u3, u4 are the values of u(t) at the four opposite “conners” of the quadrilateral.

Figure 2: Hysteresis nonlinearity

Along the segments, the time derivatives of T(t), u(t) are of constant sign, namely,

The hysteresis phenomena occur inside the loop formed by the half-lines (5) and (6) and the segments (7) and (8). Within the hysteresis loop, the relationship between T(t) and u(t) is

where cd(t), cu(t)are partial constant function that depends on the point where

The motion of T(t) and u(t) inside the half-line (5) and (6) and the segments (7) and (8) and the hysteresis loop can be mathematically described as

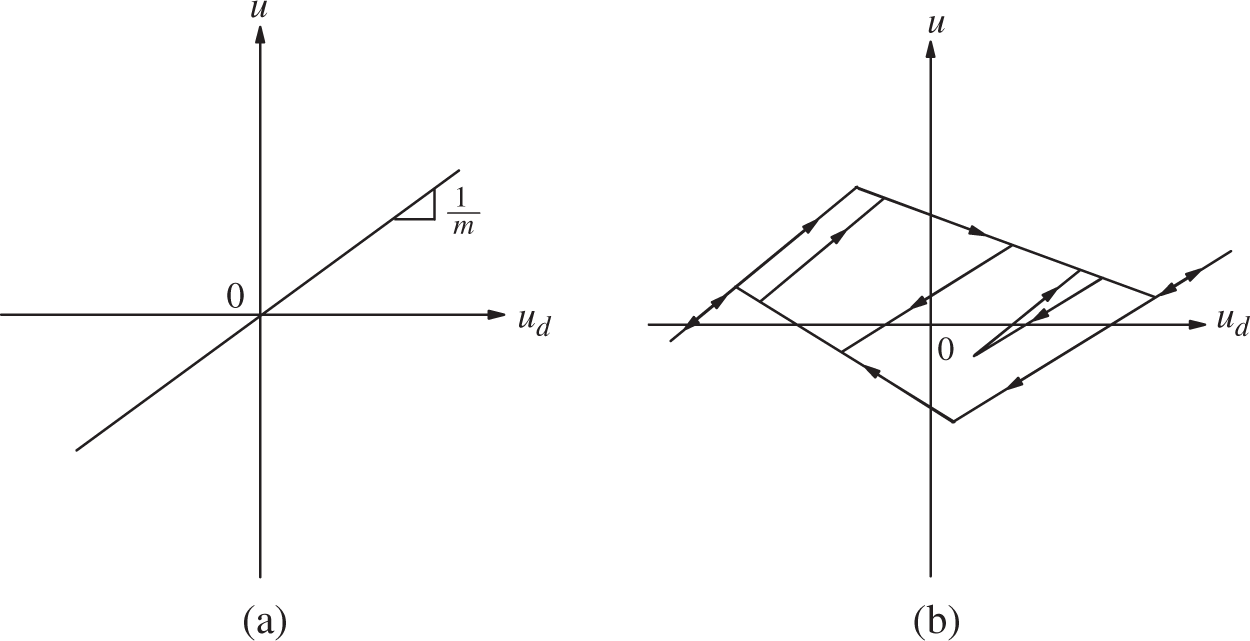

Fig. 2 shows a hysteresis model and two typical minor loops. To cancel the hysteresis effect in the system, the pre-compensator must generate the reciprocal of the hysteresis nonlinearity. Fig. 3 shows the hysteresis inverse function. The dynamics of the NN hysteresis compensator is as follows

Figure 3: Hysteresis inverse

Also, Fig. 3 shows that hysteresis inverse properties can be decomposed into two functions. Fig. 4 shows the direct feed forward term and the further modified hysteresis inverse. This decomposition allows us to design compensator with better structure when NN is used in feed forward paths.

Figure 4: Hysteresis inverse decomposition (a) feed forward term (b) modified hysteresis inverse

4 NN Hysteresis Nonlinearity Compensation of Dynamic Systems

In this section, the author shows how to design an NN hysteresis compensator using back-stepping techniques [20]. It also shows how to weight or learn NN online, with small tracking errors and boundaries for all internal states (such as NN weights). Assume that actuator output can be measured. The system dynamics without vibration mode can be describes as follows.

where

with the nonlinear plant function

The term x includes all the time signals required for calculation f(∙), for example it can be defined as

with

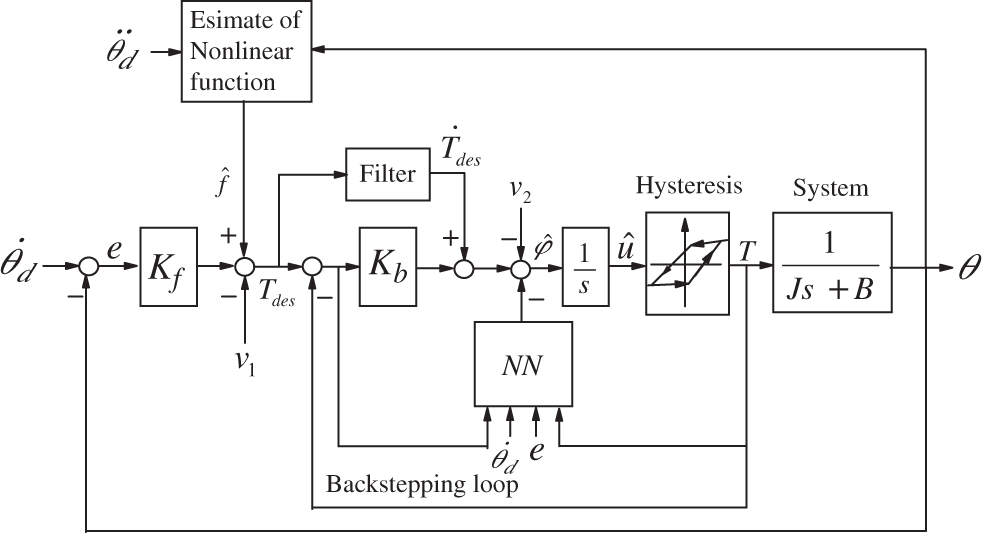

Fig. 5 illustrates the control structure implied by this scheme. The controller consists of a proportional and integral tracking loop with gains

Figure 5: NN hysteresis compensation of systems

The following theorem is the first step in the backstepping design, which shows that the desired control law (15) keeps the tracking error small.

Theorem 1 : Under the system (12), use the tracking control law (15). Select the robustifying signal v1 as follows

the tracking error is then bounded and can be kept as desired by increasing the gains Kf.

Proof : Choose the Layapnov function candidate

Differentiating L1 and using the assumption

Using the tracking control law (15) one has

Eq. (20) can be bounded as

For as long as |e| ≠ 0, one can conclude that

Theorem 1 demonstrates a control law that guarantees stability in terms of tracking errors. If there is unknown hysteresis nonlinearity, the desired control signal and the actual value are different. According to the dynamic inversion concept, NN is used to compensate for the inversion error originally provided by Calise et al. [19], the author gives a rigorous analysis of closed-loop system stability. The actuator output provided in (15) is a desirable signal. To find the overall system error dynamics, define the error between the desired actuator output and the actual actuator output as follows:

Differentiating one has

which (13) and related (15) represent complete system error dynamics.

The dynamics of the hysteresis nonlinearity can be written as

where ϕ(t) is pseudo-control input [19]. For known hysteresis, the ideal hysteresis inverse is given by

Since hysteresis and thus its inverse are unknown, only the inverse of hysteresis can be approximated as

We can now write the hysteresis dynamics as follows

where

Introducing the NN approximation property, the hysteresis inversion error can be expressed as

where the NN input vector is selected as

We define

and the hidden layer output error for a given xnn as

To design the stable closed-loop system with hysteresis compensation, nominal hysteresis inverse

where v2(t) is a robustifying term detailed later.

The closed loop system with NN hysteresis compensator is shown in Fig. 5. The proposed hysteresis compensation scheme follows the hysteresis inverse decomposition in Fig. 4. That is, the exact hysteresis inverse consists of a direct feed term and the error term in Fig. 4b estimated by NN.

The propod controller (32) allows to write the error dynamics (23) as

Taylor series expansions can be used to overcome the strong restriction of linearity in the tunable parameters. The weights V appear in nonlinear way. Applying the method developed in [15,16] yields the error dynamics

where the disturbance term is given by

Here,

Assuming that the approximation property of the neural network are maintained, the norm of the disturbance term can be bounded as [15,16]

where c1 and c2 are positive constants. The NN input is bounded by

Combination of the inequalities (36) and (37) one has

where Ci are computable positive constants.

The following theorem explains how to adjust the neural network weights so the tracking error e(t) and

Theorem 2. Let the desired trjectories be restricted. Choose the control input as (27). Select the robustifying signal v2 as

where

with any constant matrices S = ST > 0, Q = QT > 0, and k > 0 small scalar deign parameter. The tracking error e(t), error

Proof : Select the Lyapnov function candidate

which weights both errors e(t) and

and applying (13) and (34) one has

Using (15) and tuning rules yields

Applying the same inequality as for (20), expression (47) can be bounded as

Intorducing (39) and applying some norm properties, one can has

Taking

Choosing

Completing the square yields

Therefore, the

or

From the standard Layapnov theorem, the error,

Similarly, Eq. (56) gives

Notice that by increasing the gain Kb we can reduce the stability radius to some extent. Also, note that PI control without hysteresis compensation requires much higher gains to achieve similar performance. Moreover, it is not easy to guarantee the stability of such highly nonlinear dynamical system if only a PI controller is used. NN hysteresis compensation demonstrates the stability of the system and can increase gain Kb to keep the tracking error arbitrary small. The NN weight errors are essentially constrained in terms of VM, WM. Due to the form of the feedforward compensator with integreted an unity feedforward path and a NN parallel path, initializing the NN weights is simple. The initial weights Vare randomly selected and initial weights W are set to zero. Then, a PI loop with integerted an unity gain feedforward path keeps the system stable until the NN starts learning.

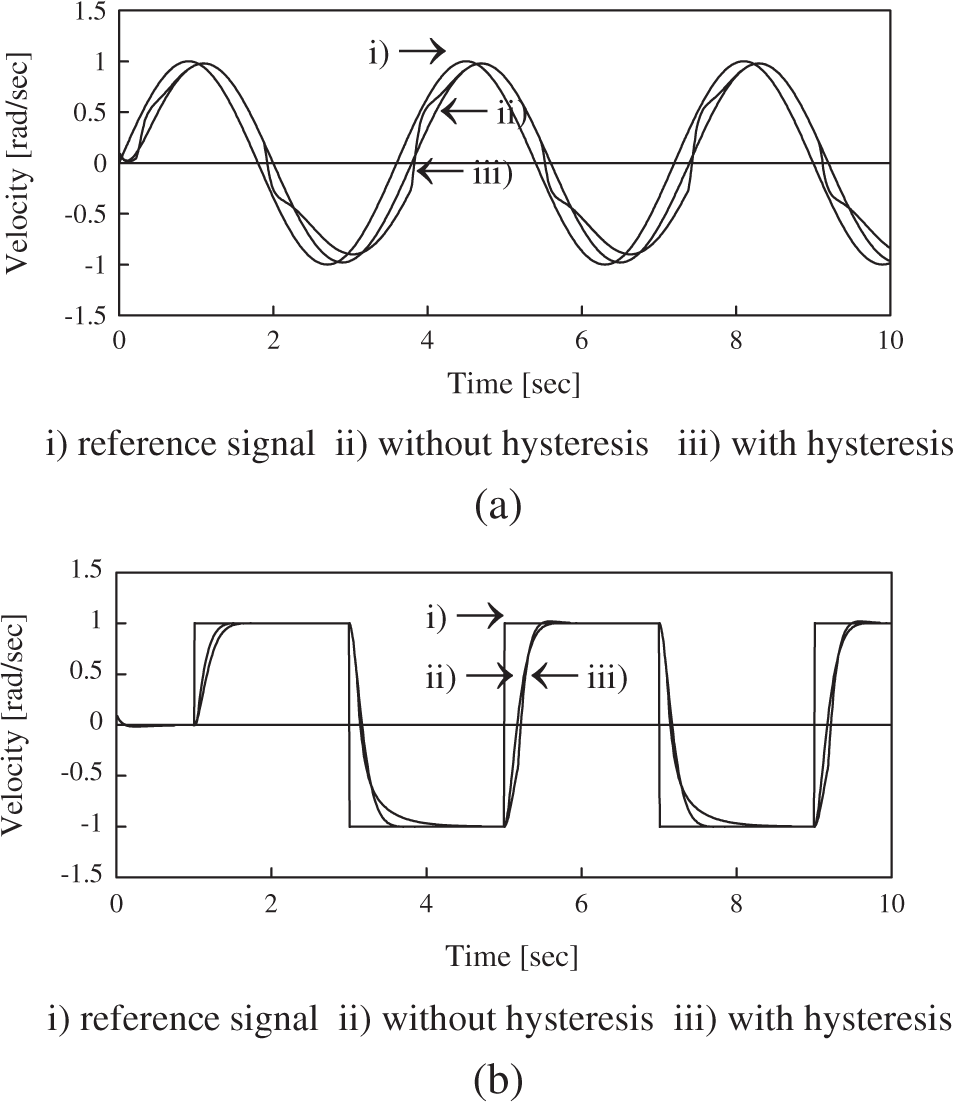

In this section, the author described the effective of a NN hysteresis compensator through computer simulations. One consider a plant with linear parts [21]:

and the hysteresis characteristic H(mt, ct, mb, cb, mr, cr, ml, cl; ·) where mt = 1, mb = 0.5, mr = 4.0, ml = 5.5, ct = 0.5, cb = −0.5, cr = 0.3, cl = −0.3. The NN weight tuning parameters are chosen as S = 8I9, Q = 9I4, and k = 0.002, when IN is N × N identity matrix. The robustifying signal gains are

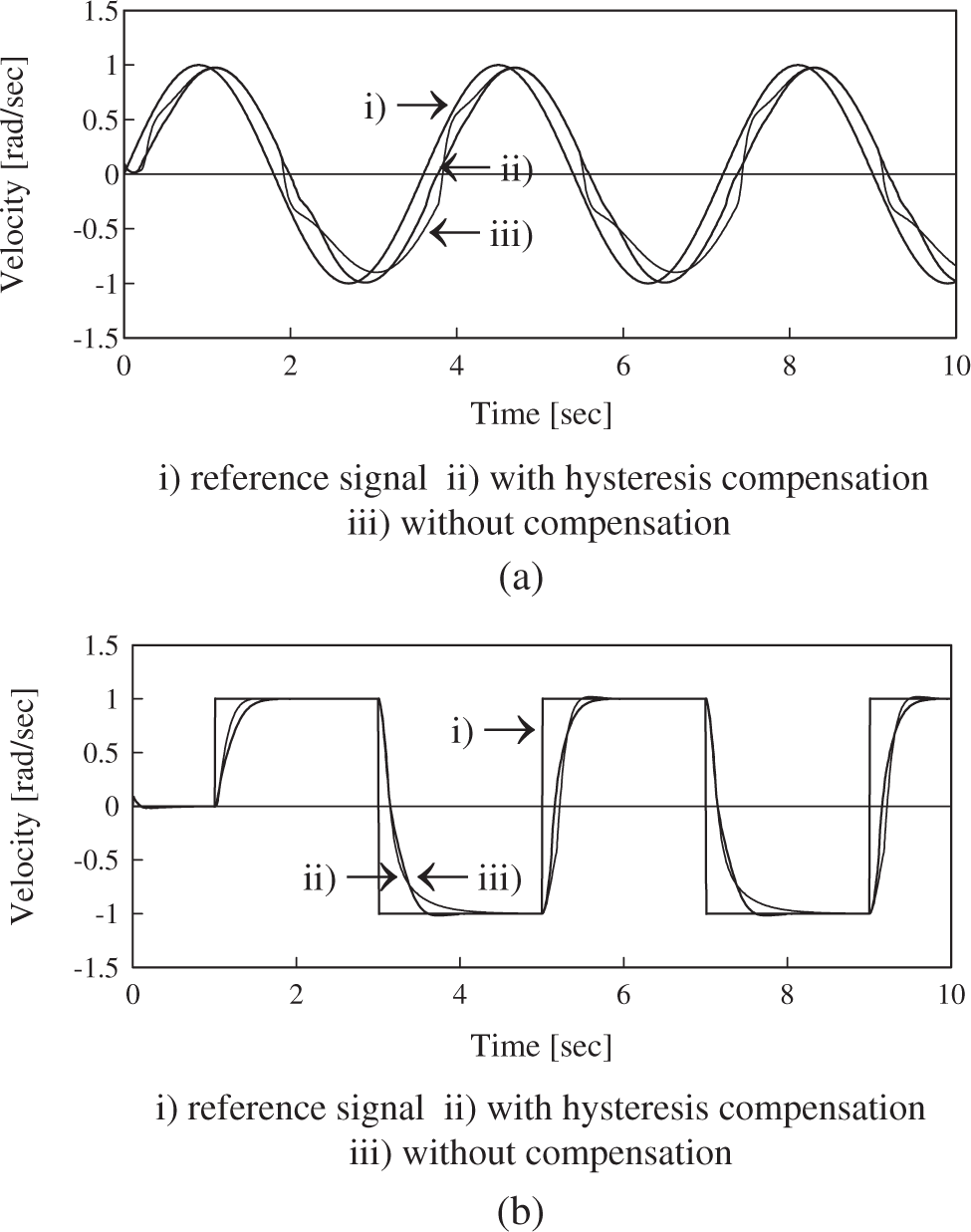

Figure 6: Velocity of a plant with/without hysteresis (a) sinusoidal reference signal (b) rectangular reference signal

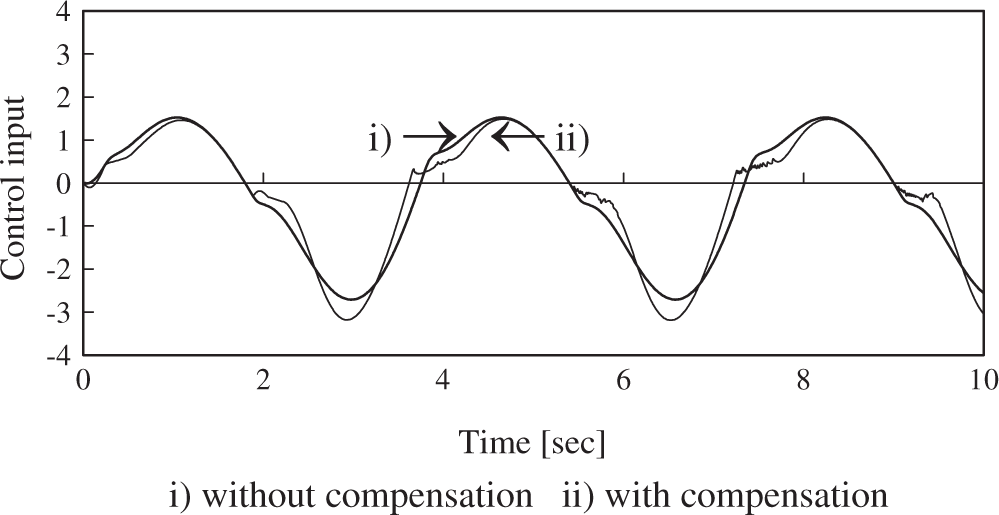

Hysteresis causes a loss of information about the signal each time u(t) change direction, indicating that system performance is degraded. Applying the NN hysteresis compensator significantly reduces the tracking error. Fig. 7 shows the velocity of a plant when a NN compensator is included. Fig. 8 shows the control signal u(t) in both cases when NN is applied and when NN is not present. In the simulation it is clear that the proposed NN hysteresis compensation is an efficient method to compensate for hysteresis nonlinearities.

Figure 7: Velocity of a plant with/without hysteresis compensation (a) sinusoidal reference signal (b) rectangular reference signal

Figure 8: Control signal u(t) with/without NN hysteresis compensation

A new technique for the hysteresis compensation has been proposed for systems. The compensator scheme has a dynamic inversion structure, and the NN of the feed-forward path approximating the hysteresis inversion error and filter dynamics required for back-stepping design. We show how to adjust the NN weights so that the hysteresis inversion error is learned on line. Using nonlinear stability techniques, the boundaries for tracking error are derived from the tracking error dynamics. Through simulation, we show the significant improvement in system performance by NN hysteresis compensation scheme.

Acknowledgement: Author thank to anonymous reviewers for paper improvement.

Funding Statement: The author received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Y. Yu, C. Chang and M. Zhou, “NARMAX Model-based hysteresis modeling of magnetic shape alloy actuators,” IEEE Transactions on Nanotechnology, vol. 19, pp. 1–4, (Early Acess2021. [Google Scholar]

2. B. Ding and Y. Li, “Hystresis compensation and sliding mode control with perturbation estimation for piezoelectric actuators,” Micromachines, vol. 9, no. 5, 241, pp. 1–13, 2018. [Google Scholar]

3. D. An, Y. Li, Y. Xu, M. Shao, J. Shi et al., “Compensation of hysteresis in the piezoelectric nano positioning stage under reciprocating linear voltage based on a mark-segmented PI model,” Micromachines, vol. 11, no. 1, 9, pp. 1–18, 2020. [Google Scholar]

4. Z. Mao, G. Tao, B. Jiang and X. Yan, “Adaptive actuator compensation of position tracking for high speed trains with disturbances,” IEEE Transactions on Vehicular Technology, vol. 67, no. 7, pp. 5706–5717, 2018. [Google Scholar]

5. R. R. Selmic and F. L. Lewis, “Backlash compensation in nonlinear systems using dynamic inversion by neural networks,” in Proc. of IEEE Conf. on Control Applications, Kohala Coast, HI, USA, pp. 1163–1168, 1999. [Google Scholar]

6. J. Campos, F. L. Lewis and R. R. Selmic, “Backlash compensation in discrete time nonlinear systems using dynamic inversion by neural networks,” in Proc. of IEEE Conf. on Robotics and Automation, Sanfrancisco, CA, USA, pp. 1289–1295, 2000. [Google Scholar]

7. G. Tao and P. V. Kokotovic, “Adaptive control of plants with unknown hysteresis,” IEEE Transactions on Automatic Control, vol. 40, no. 2, pp. 200–212, 1995. [Google Scholar]

8. C. Fu, Q. Wang, J. Yu and C. Lin, “Neural network-based finte time command filtering control for switched nonlinear systems with backlash-like hysteresis,” IEEE Transactions on Neural Networks and Learning Systems, vol. 31, pp. 1–6, (Early Acces2021. [Google Scholar]

9. Y. Qin and H. Duan, “Single-neuron adaptive hysteresis compensation of piezoelectic actuator based on hebb leaing rules,” Micromachines, vol. 11, no. 1, 84, pp. 1–14, 2020. [Google Scholar]

10. J. Wang, Z. Liu, Y. Zang and C. L. Chen, “Neural adaptive event-triggered control for nonlinear uncertain stochastic systems with unknown hysteresis,” IEEE Transactions on Neural Networks and Learning Systems, vol. 30, no. 11, pp. 3300–3312, 2019. [Google Scholar]

11. K. Liu, Z. Liu, C. L. Chen and Y. Zhang, “Event-triggered neural control of nonlinear systems with rate-dependent hysteresis input-based on a new filter,” IEEE Transactions on Neural Networks and Learning Systems, vol. 31, no. 4, pp. 1270–1284, 2020. [Google Scholar]

12. Z. Namadchian and M. Rouhani, “Adaptive neural tracking control of switched stochastic pure-feedback nonlinear systems with unknown bouc-wen hysteresis input,” IEEE Transactions on Neural Networks and Learning Systems, vol. 29, no. 12, pp. 5859–5869, 2018. [Google Scholar]

13. L. Kong, Q. Lai, Y. Quang, Q. Li and S. Zhang, “Neural leanning of a robotic manipulator with finite time convergence in the presence of unknown backlash-like hysteresis,” IEEE Transactions on Systems, Man, and Cybernetics: Systems, vol. 51, pp. 1–12, (Early Acces2021. [Google Scholar]

14. Z. Yu, S. Li, Z. Yu and F. Li, “Adaptive neural feedback control for nonstrict-feedback stochastic nonlinear systems with unknown backlash-like hysteresis and unknown control directions,” IEEE Transactions on Neural Networks and Learning Systems, vol. 29, no. 4, pp. 147–1160, 2018. [Google Scholar]

15. L. B. Wu, J. H. Park, X. P. Xie and Y. J. Liu, “Neural network adaptive tracking control of uncertain MIMO nonlinear systems wirh output constraints and event-triggered inputs,” IEEE Transactions on Neural Networks and Learning Systems, vol. 32, no. 2, pp. 695–707, 2021. [Google Scholar]

16. J. O. Jang, “Adaptive NFN nonlinearity compensation for mobile manipulator,” Journal of Next Generation Information Technology, vol. 4, no. 2, pp. 59–75, 2013. [Google Scholar]

17. G. Cybenko, “Approximation by superpositions of a sigmoidal function,” Mathematics of Control, Signals, and Systems, vol. 2, no. 4, pp. 303–314, 1989. [Google Scholar]

18. K. Hornik, M. Stinchombe and S. H. White, “Multilayer feedforward networks are universal approximator,” Neural Networks, vol. 2, pp. 359–366, 1989. [Google Scholar]

19. J. Leitner, A. Calise and J. V. R. Prasad, “Analysis of adaptive neural networks for helicopter flight control,” Journal of Guidance, Control, and Dynamics, vol. 20, no. 5, pp. 972–979, 1997. [Google Scholar]

20. M. Krstic, I. Kanellakopoulos and P. V. Kokotovic, in Nonlinear and Adaptive Control Design, John Wiley & Sons, Newyork, NY, 1995. [Google Scholar]

21. J. O. Jang, “Deadzone compensation of an xy positionings table using fuzzy logic,” IEEE Transactions on Industrial Electronics, vol. 52, no. 6, pp. 1696–1671, 2005. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |