Open Access

Open Access

ARTICLE

Nanofluid Heat Transfer in Irregular 3D Surfaces under Magnetohydrodynamics and Multi-Slip Effects

1 Faculty of Science, Jiangsu University, Zhenjiang, 212013, China

2 Department of Mathematics, University of Jhang, Jhang, 35200, Pakistan

3 College of Humanities and Science, Ajman University, Ajman, 346, United Arab Emirates

4 Department of Mathematics, School of Science and Engineering, Lahore University of Management Sciences, Lahore Cantt, 54792, Pakistan

* Corresponding Author: Mumtaz Khan. Email:

(This article belongs to the Special Issue: Advances in Computational Thermo-Fluids and Nanofluids)

Frontiers in Heat and Mass Transfer 2024, 22(5), 1399-1419. https://doi.org/10.32604/fhmt.2024.056597

Received 25 July 2024; Accepted 13 September 2024; Issue published 30 October 2024

Abstract

This study employs the Buongiorno model to explore nanoparticle migration in a mixed convection second-grade fluid over a slendering (variable thickness) stretching sheet. The convective boundary conditions are applied to the surface. In addition, the analysis has been carried out in the presence of Joule heating, slips effects, thermal radiation, heat generation and magnetohydrodynamic. This study aimed to understand the complex dynamics of these nanofluids under various external influences. The governing model has been developed using the flow assumptions such as boundary layer approximations in terms of partial differential equations. Governing partial differential equations are first reduced into ordinary differential equations and then numerically solved using the Runge-Kutta-Fehlberg method (RK4) in conjunction with a shooting scheme. Our results indicate significant increases in Nusselt and Sherwood numbers by up to 14.6% and 23.2%, respectively, primarily due to increases in the Brownian motion parameter and thermophoresis parameter. Additionally, increases in the magnetic field parameter led to a decrease in skin friction coefficients by 37.5%. These results provide critical insights into optimizing industrial processes such as chemical production, automotive cooling systems, and energy generation, where efficient heat and mass transfer are crucial. Buongiorno model; velocity-slip effects; Joule heating; convective boundary conditions; Runge-Kutta-Fehlberg method (RK4).Keywords

Nomenclature

| Magnetic parameter | |

| Velocity power index parameter | |

| Second-grade fluid parameter | |

| Thermophoresis parameter | |

| Brownian motion parameter | |

| Velocity slip parameter | |

| Thermal Biot number | |

| Concentration Biot number | |

| Prandtl number | |

| Schmidt number | |

| Radiation parameter | |

| Internal heat generation parameter | |

| Heat transfer coefficient | |

| Mass transfer coefficient | |

| Frictional resistance coefficient | |

| Reference velocity | |

| Stefan-Boltzmann constant | |

| Absorption coefficient | |

| Eckert number | |

| Geometric scaling factor | |

| Dynamic viscosity of fluid | |

| Thermal conductivity of fluid | |

| Specific heat capacity at constant pressure | |

| Brownian diffusion coefficient | |

| Thermophoretic diffusion coefficient | |

| Slip coefficients | |

| Transport coefficients | |

| External temperature | |

| External concentration | |

| Boundary Temperature | |

| Boundary concentration | |

| Heat generation parameter | |

| Magnetic field strength | |

| Capacity ratio of particle to fluid |

Nanoparticles, such as particles or fibers dispersed in liquids such as water, oil, or ethylene glycol, belong to an advanced group of solid-liquid substances that have brought significant advancements in the field of thermal science. When mixed with nanoparticles that vary in size from 1 to 100 nanometers, these fluids display altered characteristics. These changes affect thickness, mass, heat transfer efficiency, and distribution patterns. As a result, they offer better rates of heat transfer compared to base fluids. This makes them fascinating in engineering disciplines, including biomechanics, the chemical and nuclear industries, and general engineering applications. However, despite the growing interest and range of applications of nanofluids, their dynamics are still poorly understood. This is especially true for the effects of magnetohydrodynamics (MHD) and surface irregularities on nanofluids. The lack of knowledge in this area is particularly critical for applications that require behavioral control. Our study focuses on bridging this gap in understanding by exploring the thermal transfer processes and three-dimensional movement patterns in a nanofluid that consists of a second-grade fluid. A nanofluid is a class of fluid consisting of a base liquid dispersed with nanoparticles exhibiting significant enhancement in heat transfer properties. Nanofluids were first postulated by Choi et al. [1] as an unprecedented class of fluids. Since then, considerable advances have been made to this basic notion, then in Eastman et al. [2] an exceptionally high effective thermal conductivity for nanofluids containing ethylene glycol and copper nanoparticles, which he suggested offered considerable potential for practical improvements in heat transfer applications. Ghalambaz et al. [3] reported that non-uniform magnetic fields can increase the rates of heat and mass transfer in MHD nanofluids inside a cavity. Rashid et al. [4] also found that nanoflow have the best behavior for thermal conductivity followed by lamina-shaped nanoparticles MHD applications in micro-nanotechnologies. Wahid et al. [5] studied hybrid nanofluids influenced by MHD and radiation case which presented significant improvement in heat transfer, whereas Swain [6] analyzed ternary-hybrid nanofluid problem considering viscous dissipation and Lorentz force for the convection flow of water with copper-alumina-silver nanoparticles. Ramzan et al. [7] investigated ternary hybrid nanofluids in kerosene oil and showed that their thermal conductivity can be significantly enhanced. Dash et al. [8] reported that copper kerosene nanofluids are superior compared to their water-based counterpart in terms of heat transfer enhancement. Bhandari et al. [9] optimized nanofluid flow over a shrinking surface, highlighting the impact of Biot and Grashof numbers on heat transfer. Kotha et al. [10] investigated bioconvection in MHD nanofluids with gyrotactic microorganisms, showing enhanced heat and mass transfer. Hussain et al. [11] compared heat transfer in water-based MHD nanofluids, finding Zn-water nanofluids superior to TiO2-water nanofluids.

Studies of non-Newtonian fluids are critical in fluid mechanics due to their unique rheological characteristics, different from the predictable viscosities observed in Newtonian fluids [12]. Davis et al. [13] reported that these fluids exhibit intricate responses to external forces. Therefore, they are essential in numerous industrial and scientific fields, such as biomedical engineering and manufacturing. Second-grade fluids constitute an intriguing subclass of non-Newtonian fluids with a wide variability ([14]). Khan et al. [15] studied the time fractional second-grade MHD dusty fluid flow, highlighting the impact of heat and mass transfer rates on fluid dynamics. Entropy generation in Williamson fluid flow was investigated by Qayyum et al. [16], considering that thermal radiation and magnetic effects have a remarkable impact on entropy generation. Ahmed et al. [17] conducted a study on heat and mass dynamics within the MHD boundary layer flow of a second-grade fluid, discovering that chemical reactions and fluid oscillations reduced concentration levels. Anwar et al. [18] explored the transient MHD behavior of Oldroyd-B fluids, factoring in slip conditions and Newtonian heating effects to assess their influence on shear stress and heat distribution. Concurrently, Hayat et al. [19] conducted a study on the dual transport phenomena and entropy effects in MHD-driven second-grade nanofluid flows along a Riga plate, examining their contributions to thermal efficiency and entropy-related heat transformation. Khan et al. [20] studied how activation energy and complex heating and cooling processes impact the flow of Carreau nanofluids in environments influenced by radiation, focusing on how these factors affect speed and temperature changes. Das et al. [21] looked into how fluid flows with complex fluid properties, influenced by magnetic fields, chemical reactions, and heat transfer, contribute to irreversible energy loss. Chu et al. [22] examined how energy transfers in magnetically influenced nanofluids showing second-grade characteristics impact speed and temperature, highlighting significant effects from intense radiation. Tanveer et al. [23] studied electroosmosis in the peristaltic activity of MHD non-Newtonian fluid and illustrated the applications in micro-fabrication and chemical industries. Heat and mass transport in MHD flow of a non-Newtonian viscoelastic over a stretched magnetized surface were investigated by Aloliga et al. [24] and observed how induced magnetization was affecting heat transfer and flow behavior.

Boundary layer flows over-stretching sheets of various thicknesses are a topic of significant interest owing to their numerous applications in material processing and industrial manufacturing. The requirements for a fundamental understanding of fluid dynamics in flows of the boundary layer over continuously extending surfaces were laid down in the pioneering work of Sakiadis [25]. This represents a theoretical guideline for what has been experimentally demonstrated Tsou et al. [26]. Recent research has significantly progressed the description of boundary layer flows over stretching sheets including fluid dynamics, heat and mass transfer mechanisms as well as the influence of non-uniform sheet thickness. Hussain et al. [27] analyzed the entropy generation in MHD convection flow of hybrid nanofluids within a wavy enclosure, focusing on the impacts of heat generation and thermal radiation on thermal efficiency. Lin et al. [28] examined the behavior of fractional nanofluids in a porous medium, assessing the impact of magnetohydrodynamics and heat modifications on convective flow and heat transfer efficiency. Sharma et al. [29] conducted a numerical study of fractional boundary layer flow over a stretching sheet with variable thickness using a finite difference approach. Flow of a nanoliquid with gyrotactic microorganisms through the boundary layer over a stretching sheet was examined computationally by Hosseini et al. [30]. The nanofluid flow of variable thickness sheet with non-uniform stretching and porous velocities was examined by Alam et al. [31]. Rehman et al. [32] considered the influence of flow distribution on heat and mass transfer in MHD thin liquid film flow over an unsteady stretching sheet with mixed convection. Fatunmbi et al. [33] analyzed convective heat transfer in hydromagnetic micropolar fluid flow past an inclined nonlinear stretching sheet with variable thermo-physical properties.

This study extends the application of the Buongiorno model to explore the dynamic interactions of nanoparticle migration in a mixed convection second-grade fluid over a variable thickness stretching sheet. A comprehensive range of external influences including Joule heating, slip effects, thermal radiation, heat generation, and magnetohydrodynamic forces considered in the current assessment. To the authors’ knowledge, applying the Buongiorno model to study nanoparticle migration in second-grade fluids over variable-thickness sheets with Joule heating and convective boundaries is unprecedented. The model was constructed based on flow assumptions, utilizing boundary layer approximations represented by partial differential equations. These equations were transformed into dimensionless form through appropriate scaling. Subsequently, the dimensionless equations were numerically solved using MATLAB software. The results of physical factors are deliberated through graphs as well as tables. This research not only broadens the theoretical framework but also enhances practical applications in industries where precise control of thermal and fluid dynamics is critical.

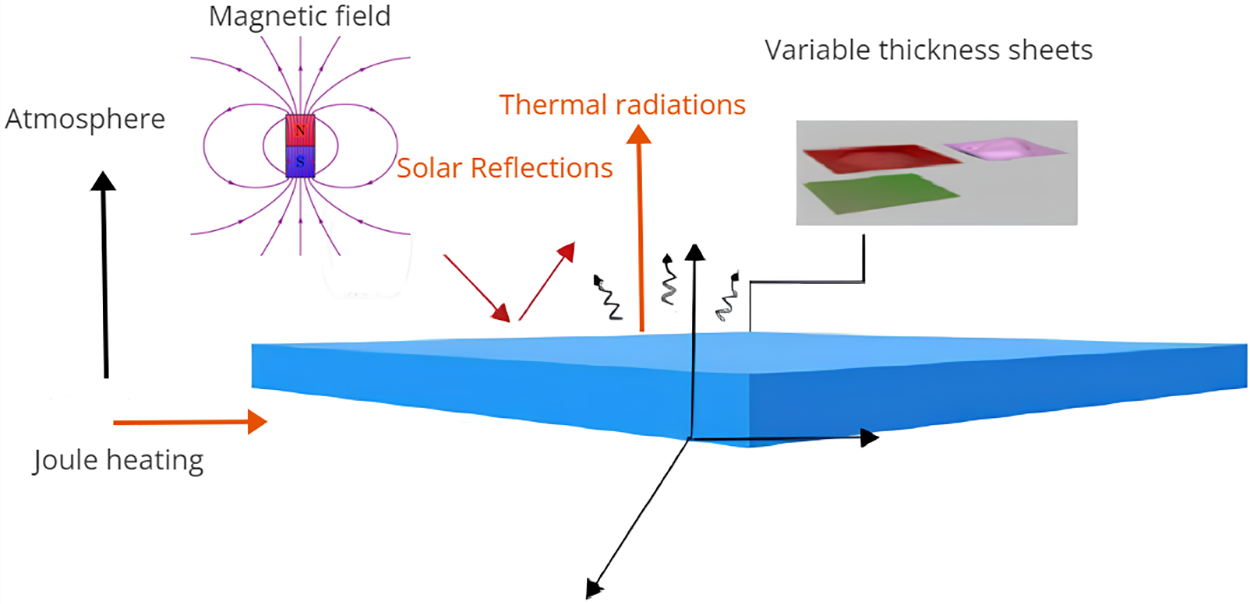

This study investigates the steady incompressible flow of a mixed convection second-grade fluid over a variable thickness stretching sheet, modeled by

Figure 1: Schematic of flow geometry

The velocity conditions at the surface, where the thickness is variable

whereas boundary conditions for concentration and temperature are detailed as follows:

The coefficients in the boundary conditions are defined as

The equation for energy as (4) describes how the radiative heat flow

Simply relying on the

We have implemented transformations to simplify the mathematical formulation [34,35].

Here,

The corresponding boundary conditions are

To make it easier to analyze the intricate differential Eqs. (12)–(15), and related boundary conditions (16) that were originally established across the range

The transformed differential equations are given by

The corresponding boundary conditions at the transformed domain are:

The following parameters are introduced to thoroughly analyzed the behavior of flow and heat and mass transfer effects in the systems:

Frictional resistance coefficient, mass transfer coefficient, and heat transfer coefficient are discussed below to determine the numerical solutions

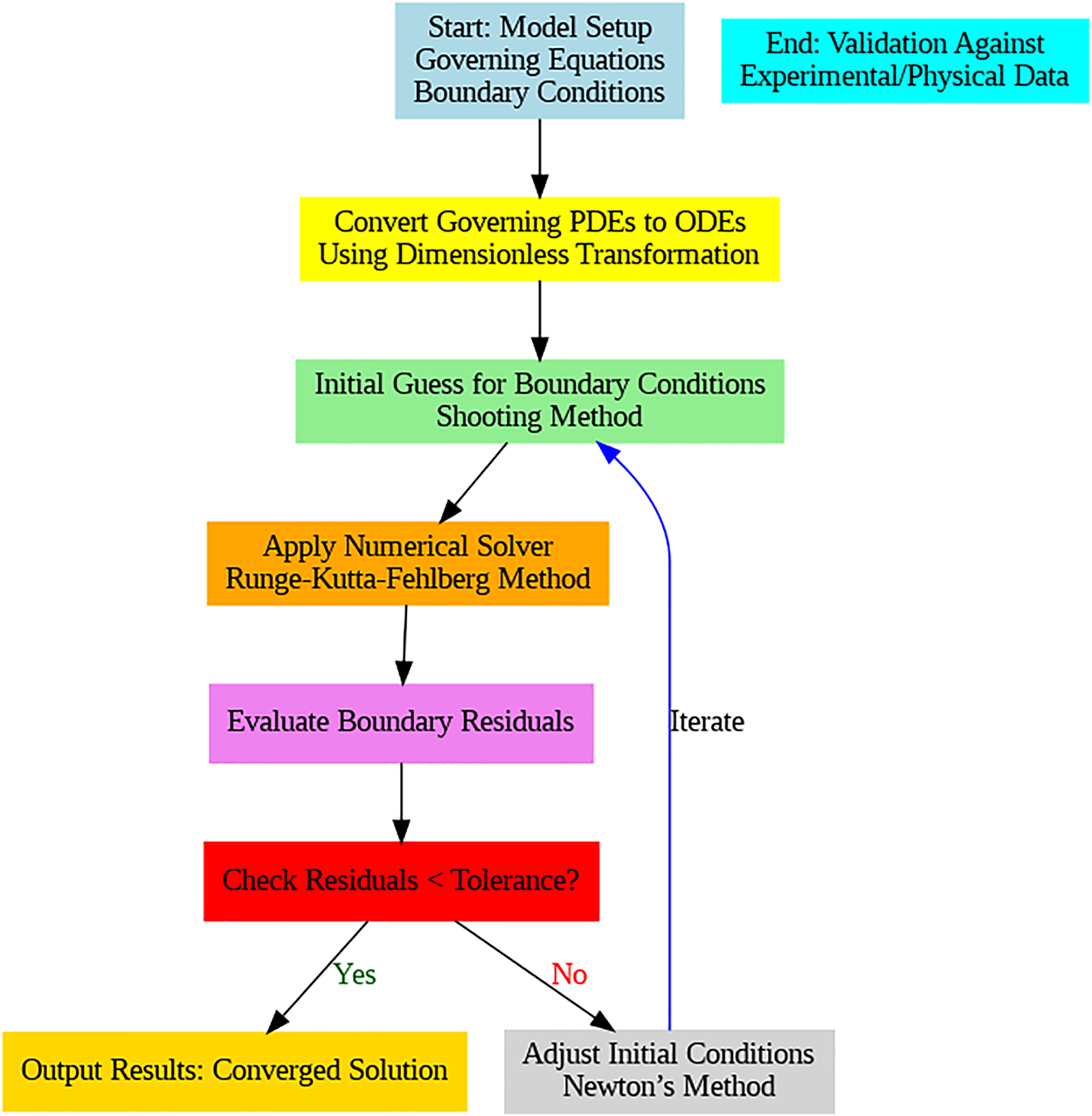

The dimensionless system, represented by ordinary differential equations (ODEs), is elucidated using numerical techniques. This method transforms higher-order nonlinear differential equations into first-order ones. The process is outlined below (refer to Fig. 2).

Figure 2: Schematic representation of the computational algorithm

Let’s introduce these variables: -

With boundary conditions

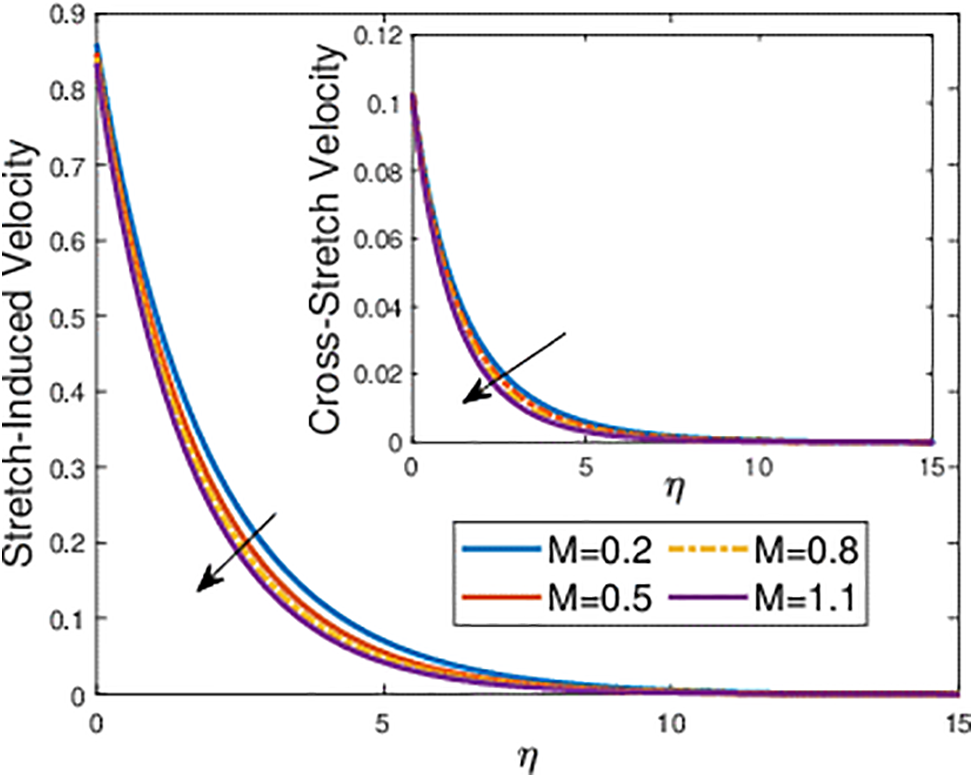

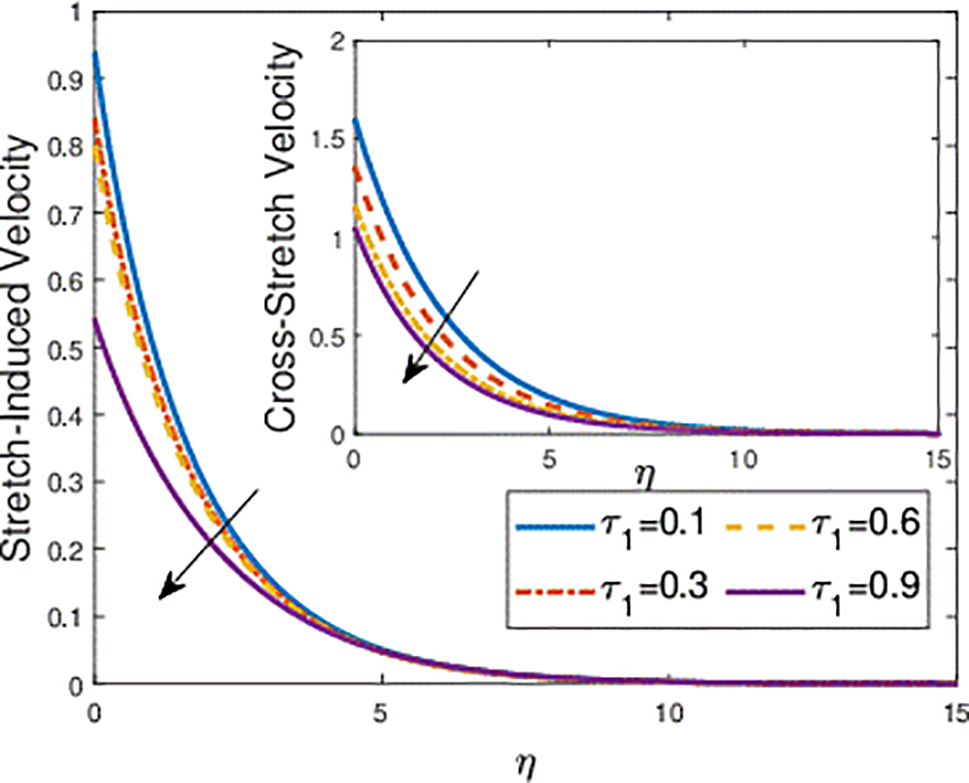

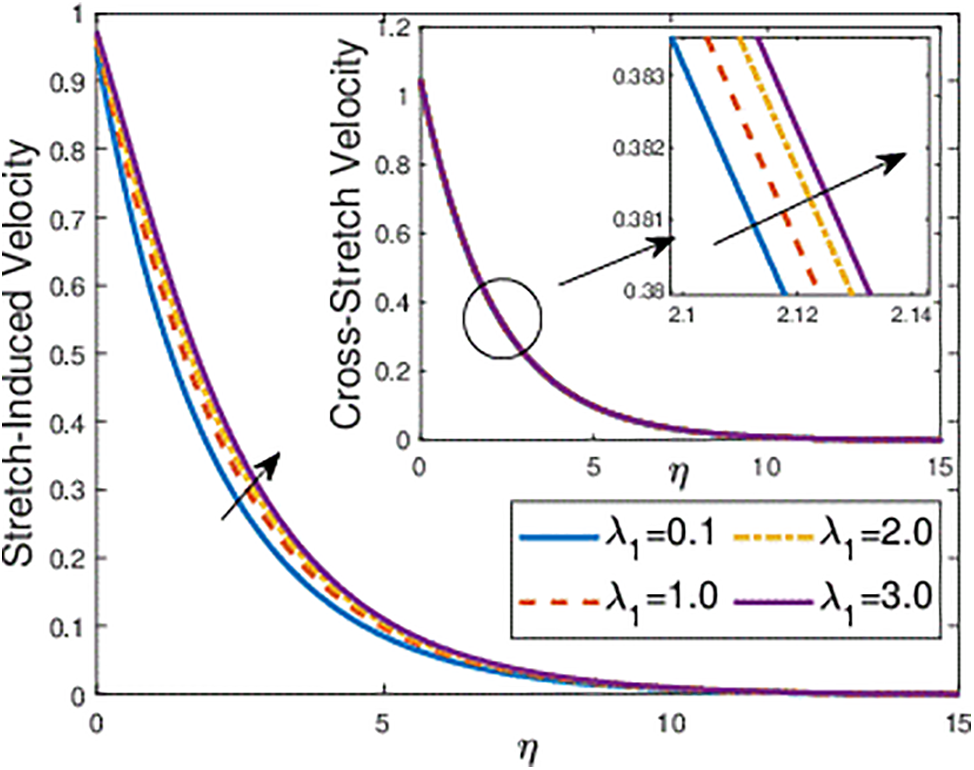

This investigation explores the complex behavior of nanofluid flow over a surface that is stretched in a manner affected by different factors. It examines the interaction between the nanofluid and irregular surface and the influence of external forces, such as magnetohydrodynamics (MHD) and thermophoresis. This section analyzes the impact of different critical parameters on the velocity, temperature, and concentration profiles. These parameters include the parameter

Figure 3: Effects of the magnetic parameter

Figure 4: Effects of the velocity slip parameter

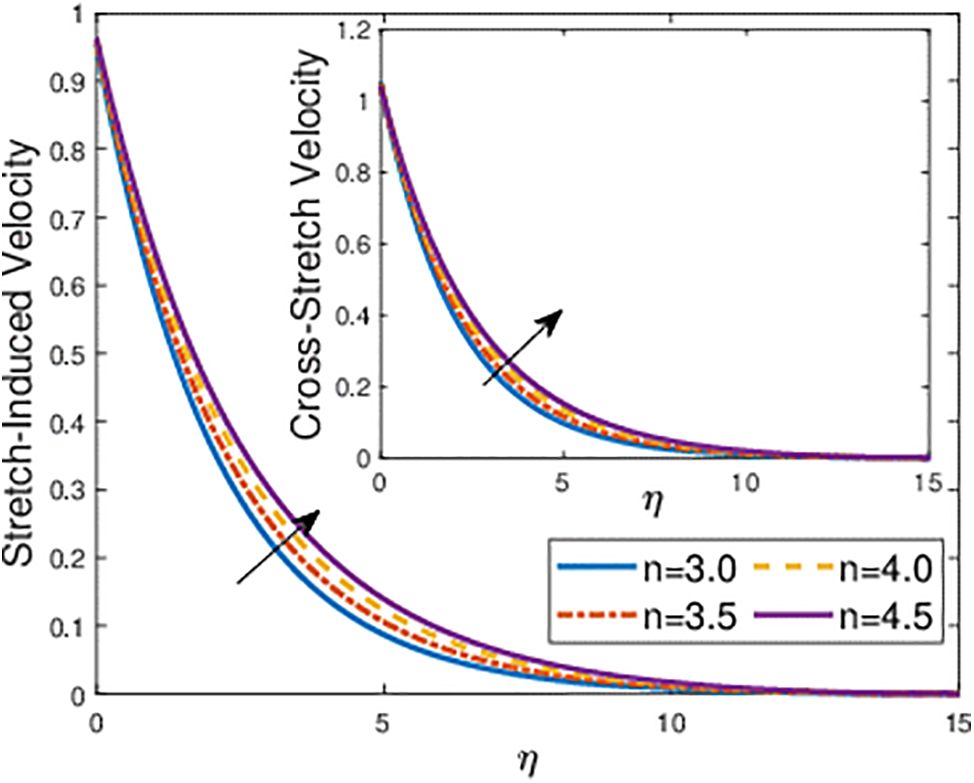

The impact of the velocity index parameter, denoted by

Figure 5: Effects of the velocity power index parameter

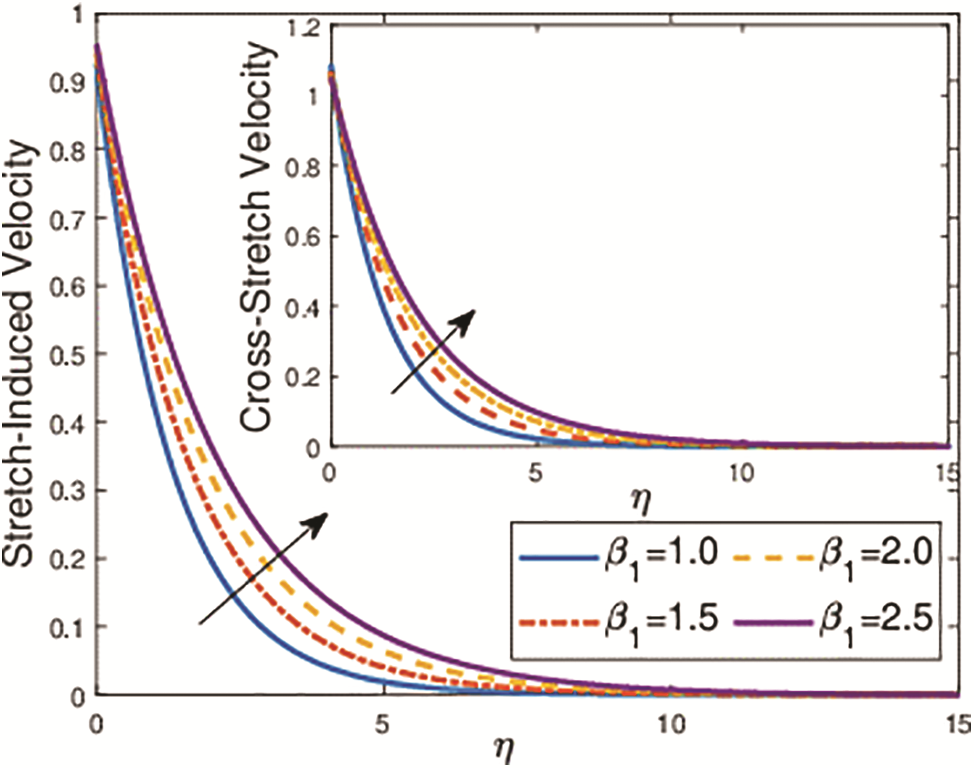

Figure 6: Effects of the second grade fluid parameter

Fig. 7 shows the effects of increasing the thermal Grashof number

Figure 7: Effects of the thermal Grashof number

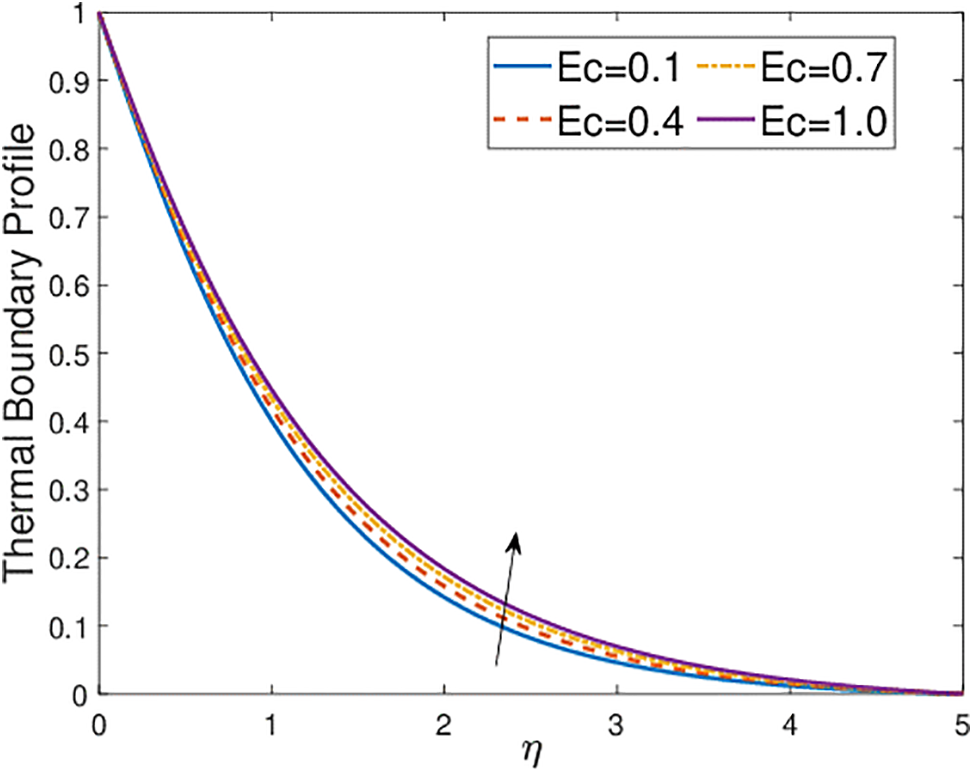

Figure 8: Effects of the Eckert number

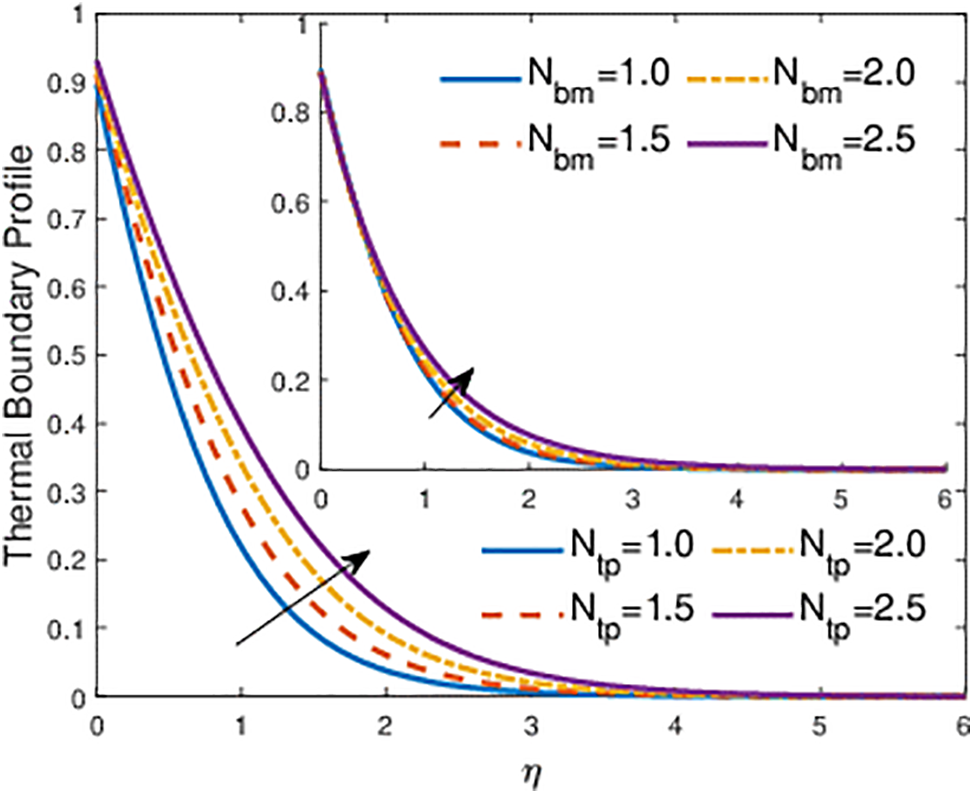

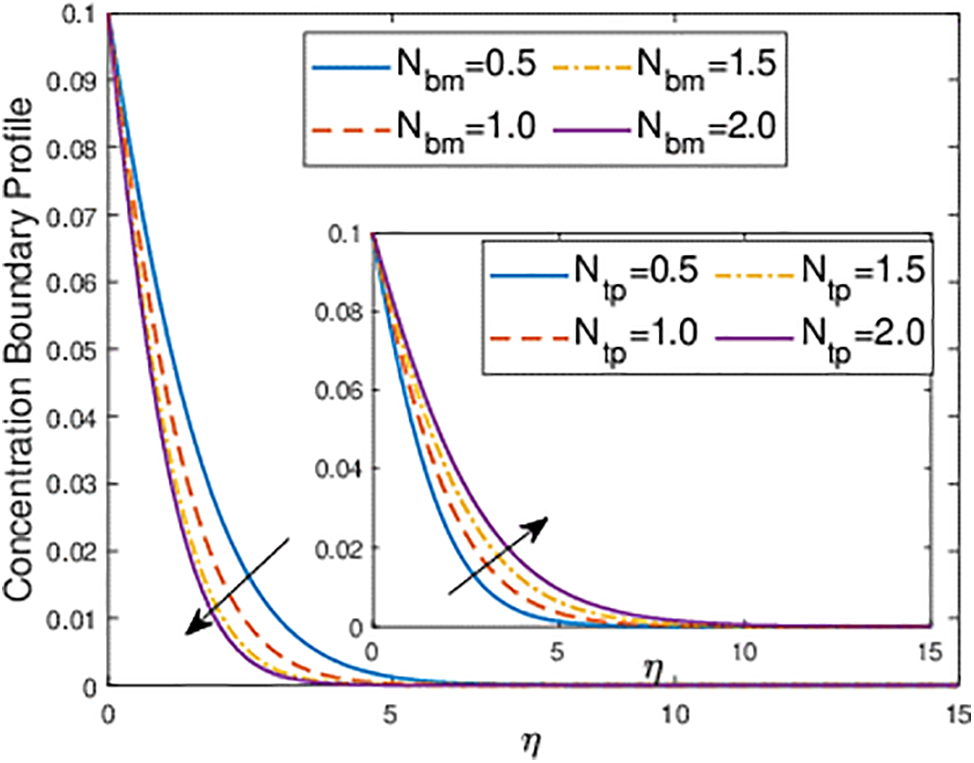

The Fig. 9 demonstrates how the thermophoresis parameter

Figure 9: Effects of the thermophoresis parameter

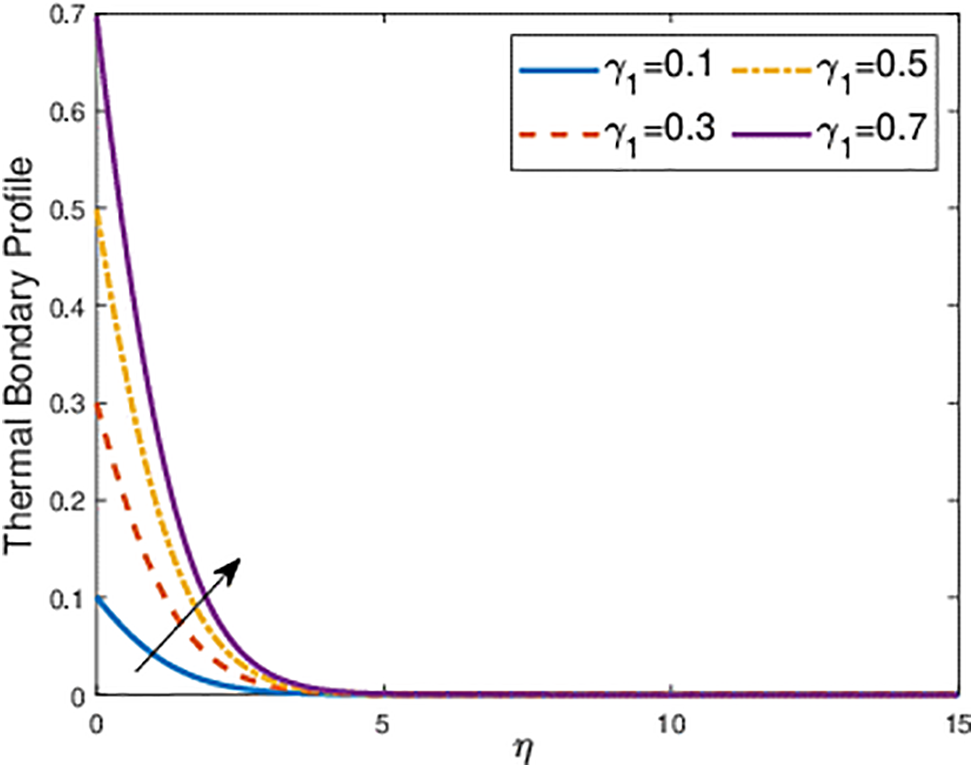

Figure 10: Effects of the thermal Biot number

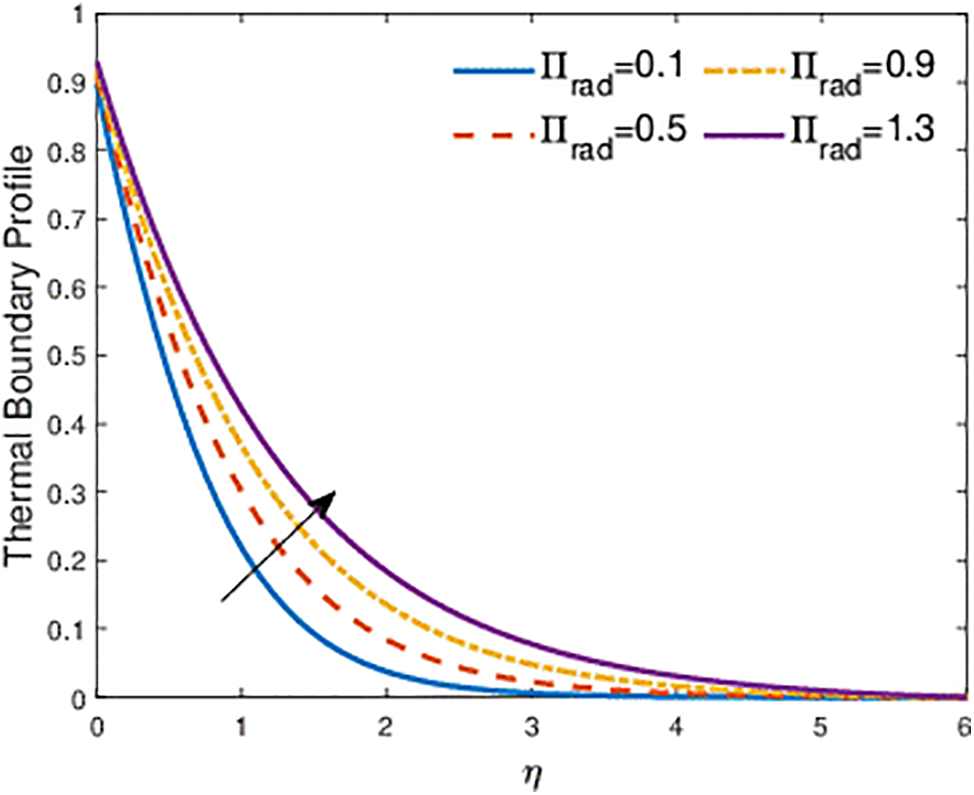

In Fig. 11, we observe the impact of the radiation parameter

Figure 11: Effects of the radiation parameter

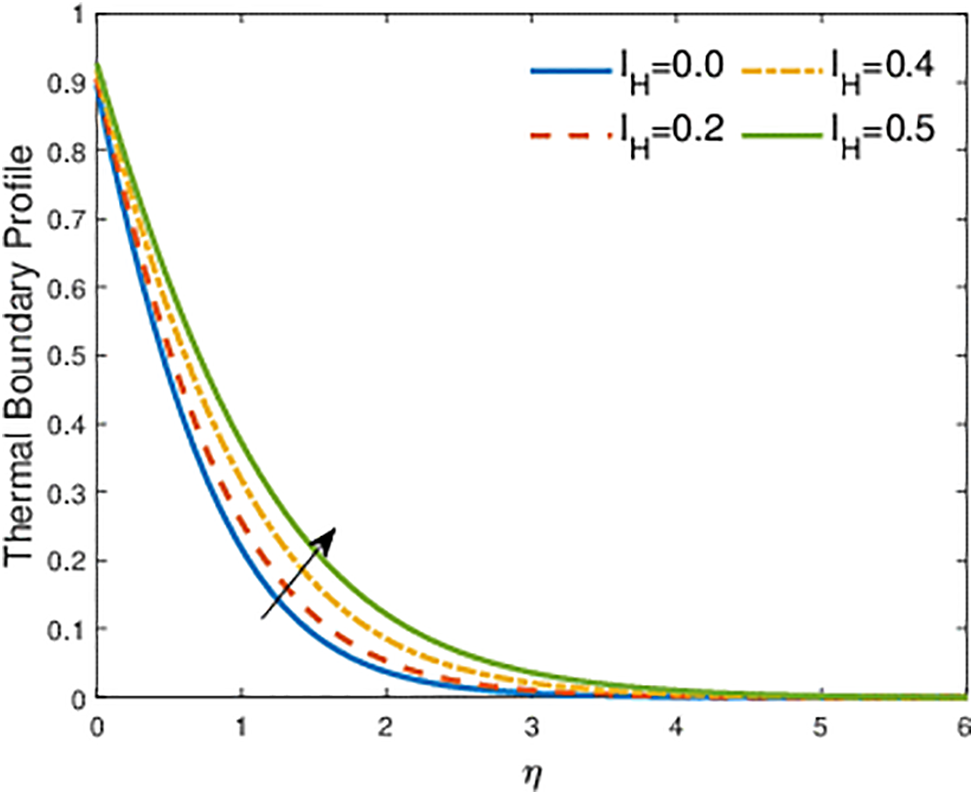

Figure 12: Effects of the internal heat generation parameter

Fig. 13 shows how changes in

Figure 13: Effects of the thermophoresis parameter

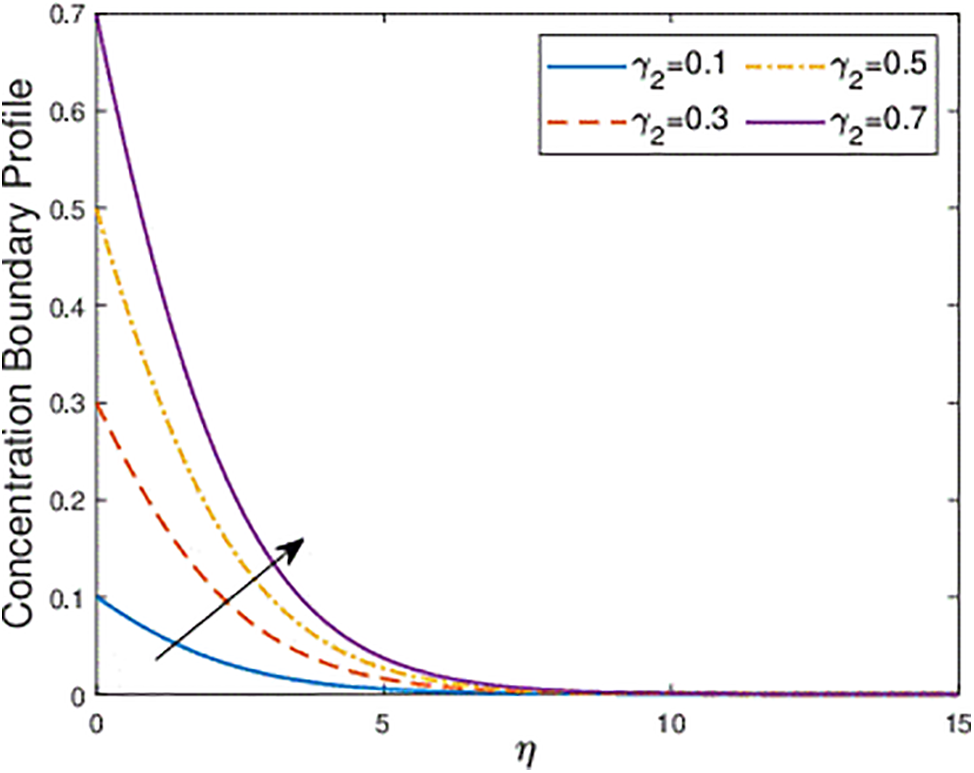

Figure 14: Effect of the concentration Biot number

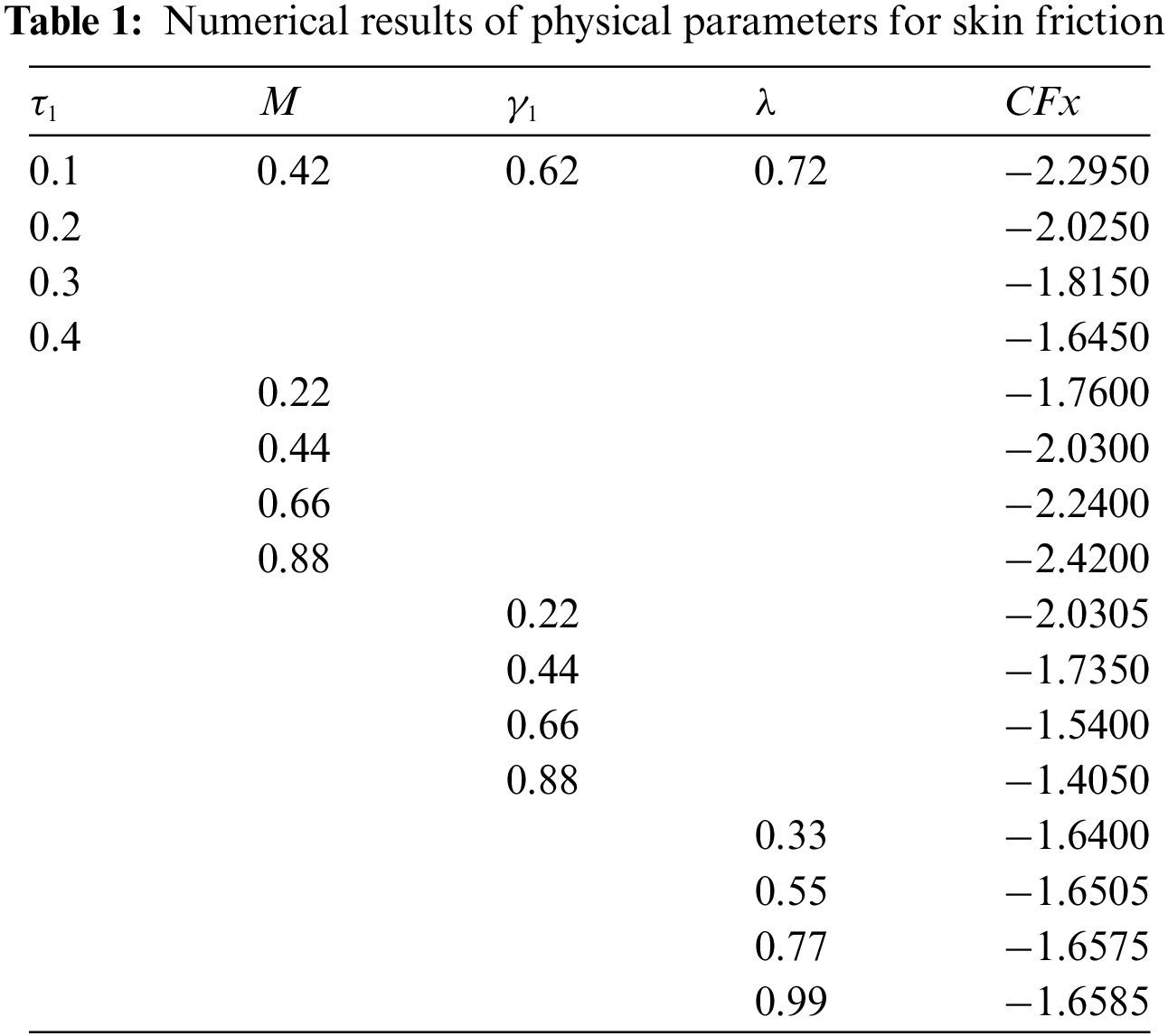

Our study examines the influence of various physical parameters on skin friction and heat and mass transfer in fluid flow, as detailed in Tables 1 and 2. Table 1 highlights the effects of parameters such as

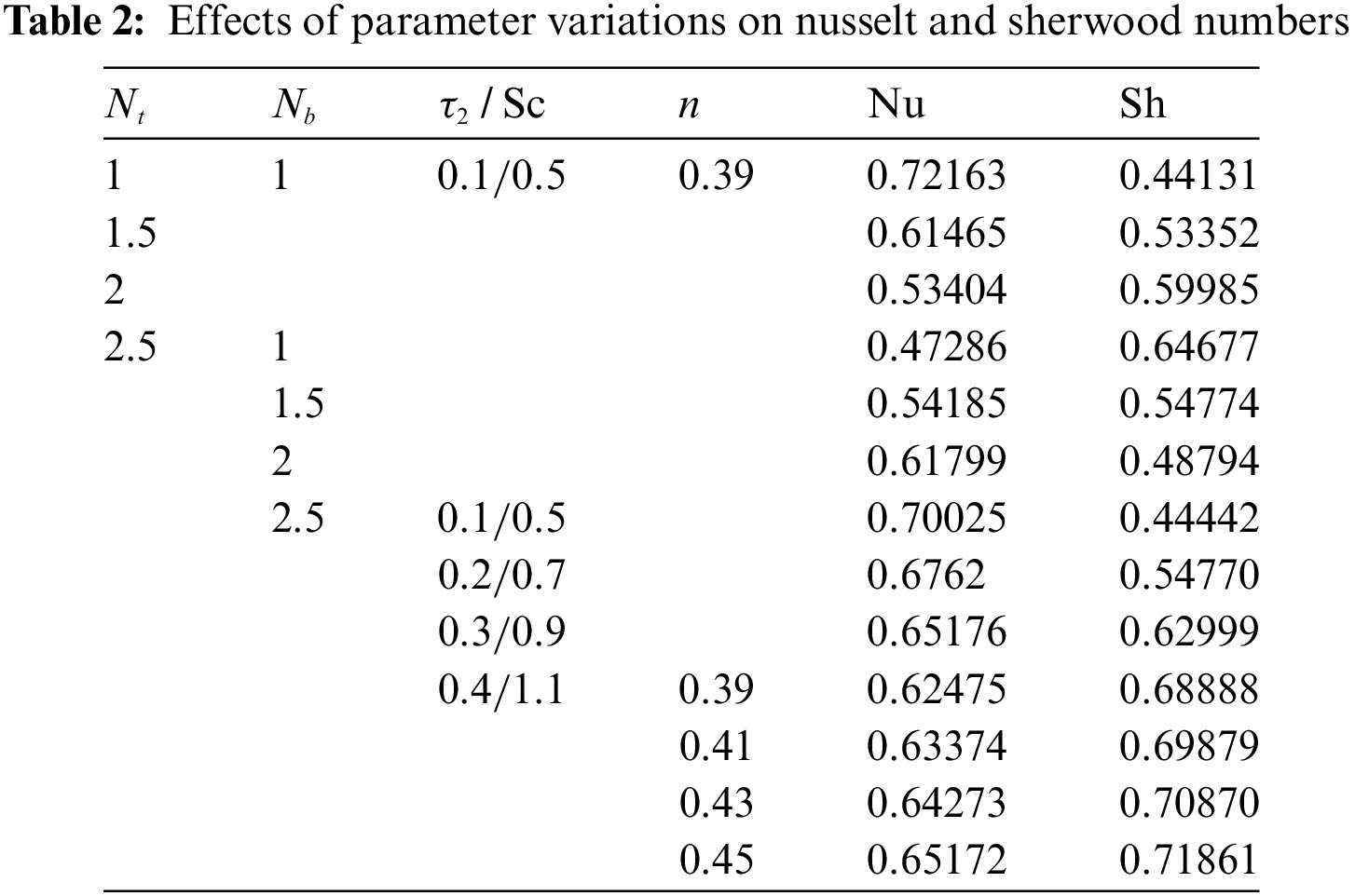

Table 2 analyzes the correlation between parameters

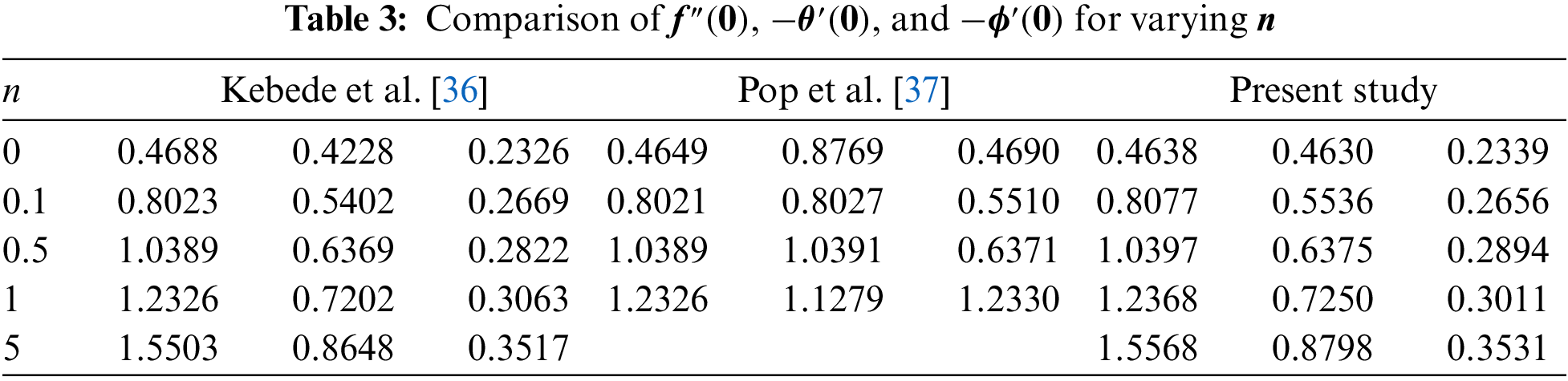

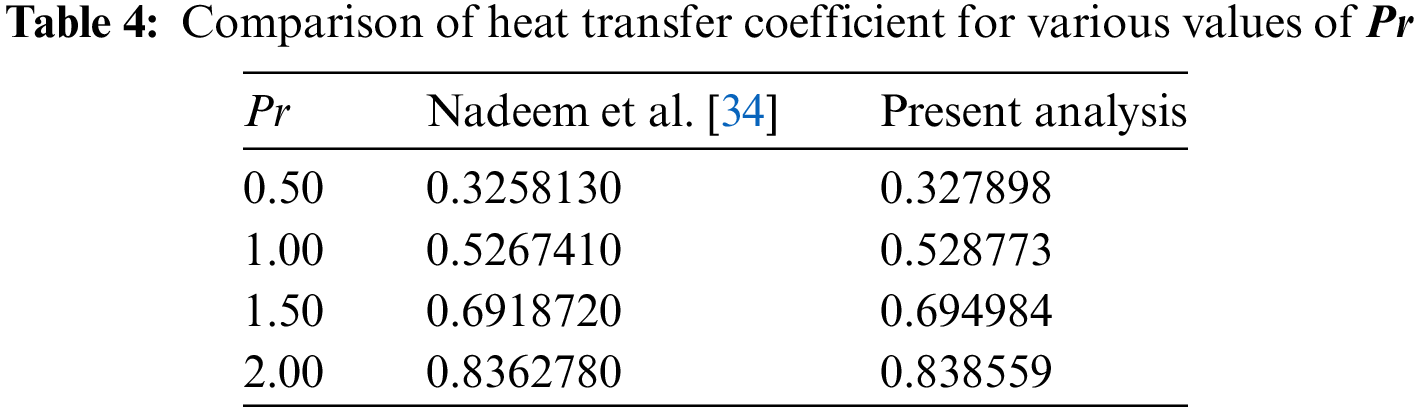

In Tables 3 and 4, we present a comparison of our study findings with the results from previous research by Nadeem et al. [34], Kebede et al. [36], and Pop et al. [37]. These comparisons specifically focus on the behaviors of

This research applies the Buongiorno model to investigate the behavior of nanoparticles in a mixed convection second-grade fluid flowing over a variable thickness stretching sheet. Key features such as Joule heating, slip effects, thermal radiation, heat generation, and magnetohydrodynamic forces are considered. The main findings of this study are as follows:

• Increasing

• Increasing the thermal Biot number enhances the temperature gradient at the boundary, while a rise in the concentration Biot number sharpens the concentration gradient at the boundary.

• Higher second-grade fluid parameters increase velocity profiles due to enhanced fluid elasticity.

• An increase in the velocity slip parameter reduces velocity gradients by lowering boundary resistance.

• Nusselt and Sherwood numbers increase by up to 14.6% and 23.2%, respectively, due to higher Brownian motion and thermophoresis parameters.

• Skin friction coefficients decrease by 37.5% with increasing magnetic field strength.

Investigating different fluid models such as Oldroyd-B and Sisko fluids on complex surfaces could provide further insights into non-Newtonian behaviors under stretching and magnetic influences. This research could enhance applications in industries that demand precise fluid dynamics control.

Acknowledgement: The authors would like to express their gratitude to the reviewers for their insightful and constructive comments, which have significantly contributed to enhancing the quality of this article according to the journal’s standards.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: The authors confirm their contributions to the paper as follows: study conception and design: Muhammad Shoaib Anwar; analysis and interpretation of results: Mumtaz Khan; draft manuscript preparation: Muhammad Shoaib Anwar, Mumtaz Khan. Mudassar Imran and Amer Rasheed contributed to addressing reviewer comments and the preparation of the revised manuscript. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: All data generated or analyzed during this study are included within this article.

Ethics Approval: This study did not involve human or animal subjects and, as such, ethical approval was not required.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Choi SUS, Eastman JA. Enhancing thermal conductivity of fluids with nanoparticles. ASME Fed. 1995;231:99–105. [Google Scholar]

2. Eastman JA, Choi SUS, Li S, Yu W, Thompson LJ. Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles. Appl Phys Lett. 2001;78:718–20. doi:10.1063/1.1341218. [Google Scholar] [CrossRef]

3. Ghalambaz M, Sabour M, Sazgara S, Pop I, Trambitas R. Insight into the dynamics of ferrohydrodynamic (FHD) and magnetohydrodynamic (MHD) nanofluids inside a hexagonal cavity in the presence of a non-uniform magnetic field. J Magn Magn Mater. 2020;497:166024. doi:10.1016/j.jmmm.2019.166024. [Google Scholar] [CrossRef]

4. Rashid U, Liang H, Baleanu D, Iqbal A, Abbas M. Shape effect of nanosize particles on magnetohydrodynamic nanofluid flow and heat transfer over a stretching sheet with entropy generation. Entropy. 2020;22(10):1171. doi:10.3390/e22101171 [Google Scholar] [PubMed] [CrossRef]

5. Wahid NS, Arifin N, Khashi’ie N, Pop I, Bachok N, Hafidzuddin E. MHD hybrid nanofluid flow with convective heat transfer over a permeable stretching/shrinking surface with radiation. Int J Numer Methods Heat Fluid Flow. 2021;32(5). doi:10.1108/HFF-04-2021-0263. [Google Scholar] [CrossRef]

6. Swain B. Dynamics of ternary-hybrid nanofluid of water conveying copper, alumina and silver nanoparticles when entropy generation, viscous dissipation, Lorentz force are significant. ZAMM. 2023;103(9):e202200254. doi:10.1002/zamm.202200254. [Google Scholar] [CrossRef]

7. Ramzan M, Dawar A, Saeed A, Kumam P, Sitthithakerngkiet K, Lone S. Analysis of the partially ionized kerosene oil-based ternary nanofluid flow over a convectively heated rotating surface. Open Phys. 2022;20:507–25. doi:10.1515/phys-2022-0055. [Google Scholar] [CrossRef]

8. Dash R, Mishra S, Pattnaik PK. Influence of radiative heat energy on the MHD flow of Cu-kerosene nanofluid over a vertical plate: laplace transform technique. Biointerface Res Appl Chem. 2021;12(5):6234–51. doi:10.33263/BRIAC125.62346251. [Google Scholar] [CrossRef]

9. Bhandari A, Pannala R. Optimization of heat transfer properties of nanofluid flow over a shrinking surface through mathematical modeling. Int J Appl Mech Eng. 2020;25(1):40–56. doi:10.2478/ijame-2020-0019. [Google Scholar] [CrossRef]

10. Kotha G, Kolipaula VR, Rao MVS, Penki S, Chamkha AJ. Internal heat generation on bioconvection of an MHD nanofluid flow due to gyrotactic microorganisms. Eur Phys J Plus. 2020;135(6). doi:10.1140/epjp/s13360-020-00606-2. [Google Scholar] [CrossRef]

11. Hussain A, Arshad M, Rehman A, Hassan A, Elagan S, Ahmad H et al. Three-dimensional water-based magneto-hydrodynamic rotating nanofluid flow over a linear extending sheet and heat transport analysis: a numerical approach. Energies. 2021;14(16):5133. doi:10.3390/en14165133. [Google Scholar] [CrossRef]

12. Smith AB, Johnson CD. Advanced rheology of non-Newtonian fluids. J Fluid Mech. 2018;123:45–67. [Google Scholar]

13. Davis LE, Lee MJ. Industrial applications of non-Newtonian fluids. Eng Appl. 2017;15(2):89–102. [Google Scholar]

14. Green P, Thompson K. Characteristics of Second-Grade Fluids. Rheol Today. 2021;20(4):210–25. [Google Scholar]

15. Khan Z, Ali F, Haq S, Khan I. A time fractional second-grade magnetohydrodynamic dusty fluid flow model with variable conditions: application of Fick’s and Fourier’s laws. Front Phys. 2022;10:1006893. doi:10.3389/fphy.2022.1006893. [Google Scholar] [CrossRef]

16. Qayyum S, Khan M, Masood F, Chu Y, Kadry S, Nazeer M. Interpretation of entropy generation in Williamson fluid flow with nonlinear thermal radiation and first-order velocity slip. Math Meth Appl Sci. 2020;44:7756–65. doi:10.1002/mma.6735. [Google Scholar] [CrossRef]

17. Ahmed NA, Krishna MV, Aljohani A. Heat and mass transfer in MHD boundary layer flow of a second-grade fluid past an infinite vertical permeable surface. Heat Transf. 2021;50:6022–42. doi:10.1002/htj.22160. [Google Scholar] [CrossRef]

18. Anwar T, Kumam P, Asifa, Thounthong P, Muhammad S, Duraihem FZ. Generalized thermal investigation of unsteady MHD flow of Oldroyd-B fluid with slip effects and Newtonian heating; a Caputo-Fabrizio fractional model. Alex Eng J. 2021;61(3):2188–202. doi:10.1016/j.aej.2021.06.090. [Google Scholar] [CrossRef]

19. Hayat T, Shah F, Alseadi A. Cattaneo-Christov double diffusions and entropy generation in MHD second grade nanofluid flow by a Riga wall. Int Commun Heat Mass Transf. 2020;119:104824. doi:10.1016/j.icheatmasstransfer.2020.104824. [Google Scholar] [CrossRef]

20. Khan M, Alzahrani F. Dynamics of activation energy and nonlinear mixed convection in Darcy-Forchheimer radiated flow of Carreau nanofluid near stagnation point region. J Therm Sci Eng Appl. 2021;13. doi:10.1115/1.4049434. [Google Scholar] [CrossRef]

21. Das S, Sarkar S, Jana R. Assessment of irreversible losses of non-Newtonian nanofluid flow underlying hall current, chemical reaction and thermal radiation. World J Eng. 2020;18(2):228–50. doi:10.1108/WJE-07-2020-0266. [Google Scholar] [CrossRef]

22. Chu Y, Shah F, Khan M, Kadry S, Abdelmalek Z, Khan W. Cattaneo-Christov double diffusions (CCDD) in entropy optimized magnetized second grade nanofluid with variable thermal conductivity and mass diffusivity. J Mater Res Technol. 2020;9:13977–87. doi:10.1016/j.jmrt.2020.09.101. [Google Scholar] [CrossRef]

23. Tanveer A, Mahmood S, Hayat T, Alsaedi A. On electroosmosis in peristaltic activity of MHD non-Newtonian fluid. Alex Eng J. 2021;60:3369–77. doi:10.1016/j.aej.2020.12.051. [Google Scholar] [CrossRef]

24. Aloliga G, Seini IY, Musah R. On MHD flow of non-Newtonian viscoelastic fluid over a stretched magnetized surface. Am J Appl Math. 2022;10(2):29. doi:10.11648/j.ajam.20221002.12. [Google Scholar] [CrossRef]

25. Sakiadis BC. Boundary-layer behavior on continuous solid surface: i. boundary-layer equations for two-dimensional and axisymmetric flow. J AIChe. 1961;7:26–8. doi:10.1002/aic.690070108. [Google Scholar] [CrossRef]

26. Tsou FK, Sparrow EM, Goldstain RJ. Flow and heat transfer in the boundary layer on a continuous moving surface. Int J Heat Mass Transf. 1967;10:219–35. doi:10.1016/0017-9310(67)90100-7. [Google Scholar] [CrossRef]

27. Hussain S, Parveen R, Katbar N, Rehman S, Abd-Elmonem A, Abdalla N, et al. Entropy generation analysis of MHD convection flow of hybrid nanofluid in a wavy enclosure with heat generation and thermal radiation. Rev Adv Mater Sci. 2024;63(1):20240037. doi:10.1515/rams-2024-0037. [Google Scholar] [CrossRef]

28. Lin Y, Rehman S, Akkurt N, Shedd T, Kamran M, Imran Qureshi M et al. Free convective trickling over a porous medium of fractional nanofluid with MHD and heat source/sink. Sci Rep. 2022;12:20778. doi:10.1038/s41598-022-25063-y [Google Scholar] [PubMed] [CrossRef]

29. Sharma R, Bisht A, Kumar A. Numerical study of fractional boundary layer flow over a stretching sheet with variable thickness: a finite difference approach. AIP Conf Proc. 2020;2253:020018. doi:10.1063/5.0018931. [Google Scholar] [CrossRef]

30. Hosseini Z, Abidi A, Mohammadi S, Mehryan S, Hulme C. A fully resolved computational fluid dynamics study of the boundary layer flow of an aqueous nanoliquid comprising gyrotactic microorganisms over a stretching sheet: the validity of conventional similarity models. Mathematics. 2021;9(21):2655. doi:10.3390/math9212655. [Google Scholar] [CrossRef]

31. Alam A, Marwat DNK, Ali A. Flow of nano-fluid over a sheet of variable thickness with non-uniform stretching (shrinking) and porous velocities. Adv Mech Eng. 2021;13. doi:10.1177/16878140211012913. [Google Scholar] [CrossRef]

32. Rehman S, Rehman S, Khan A, Khan Z. The effect of flow distribution on heat and mass transfer of MHD thin liquid film flow over an unsteady stretching sheet in the presence of variational physical properties with mixed convection. Physica A. 2020;551:124120. doi:10.1016/j.physa.2019.124120. [Google Scholar] [CrossRef]

33. Fatunmbi E, Okoya S, Makinde O. Convective heat transfer analysis of hydromagnetic micropolar fluid flow past an inclined nonlinear stretching sheet with variable thermo-physical properties. Diffus Found. 2020;26:63–77. doi:10.4028/www.scientific.net/DF.26.63. [Google Scholar] [CrossRef]

34. Abbas N, Tumreen M, Shatanawi W, Qasim M, Shatnawi TA. Thermodynamic properties of second grade nanofluid flow with radiation and chemical reaction over slendering stretching sheet. Alex Eng J. 2023;70:219–30. doi:10.1016/j.aej.2023.02.031. [Google Scholar] [CrossRef]

35. Cortell R. A numerical tackling on Sakiadis flow with thermal radiation. Chin Phys Lett. 2008;25(4):1340. doi:10.1088/0256-307X/25/4/048. [Google Scholar] [CrossRef]

36. Kebede T, Haile E, Awgichew G, Walelign T. Heat and mass transfer analysis in unsteady flow of tangent hyperbolic nanofluid over a moving wedge with buoyancy and dissipation effects. Heliyon. 2020;6:e03776. doi:10.1016/j.heliyon.2020.e03776 [Google Scholar] [PubMed] [CrossRef]

37. Pop I, Ingham DB. Convective heat transfer: mathematical and computational modelling of viscous fluids and porous media. 1st ed. New York: Pergamon; 2001. [Google Scholar]

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools