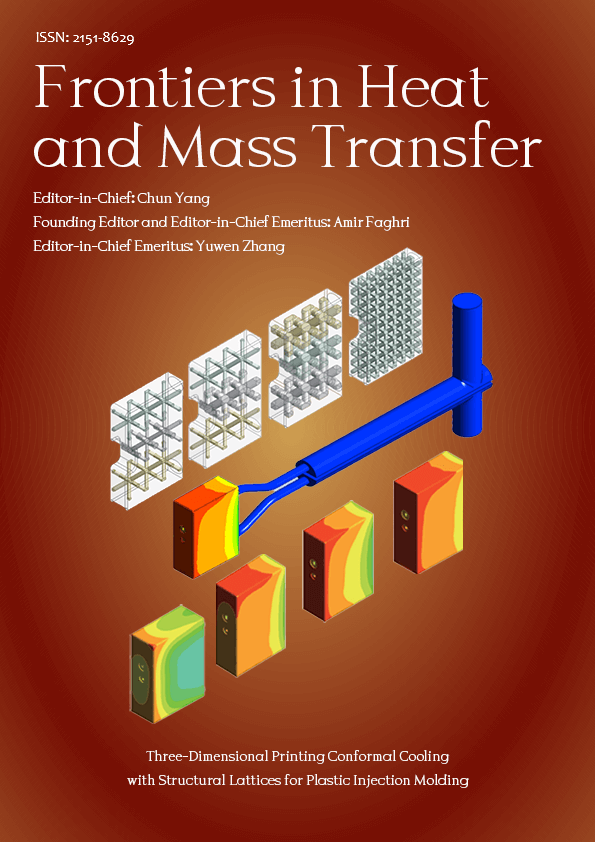

3D-printed conformal cooling cavities offer enhanced cooling efficiency by means of their large heat transfer surfaces and unique flow paths compared to traditional straight-drilled cooling channels in plastic injection molding process. However, their main limitation is low fatigue resistance. This study proposes original conformal cooling cavity designs supported by different lattice elements that aim to increase temperature uniformity on the mold, decrease the cooling time, and manage the pressure drop, as well as keep the mechanical performance above the minimum requested fatigue limits.

View this paper