Open Access

Open Access

ARTICLE

Cross-Diffusion Effects on an MHD Williamson Nanofluid Flow Past a Nonlinear Stretching Sheet Immersed in a Permeable Medium

1 Department of Mathematics, RGUKT, R.K. Valley, Kadapa (D), Andhra Pradesh, 516329, India

2 Department of Mathematics, Gitam University, Hyderabad, 502329, India

3 Department of Physics, Faculty of Sciences, University of 20 Août 1955-Skikda, Road El-Hadaeik, B.P. 26, Skikda, 21000, Algeria

4 Department of Mathematics, Anurag University, Hyderabad, Telangana, 500088, India

* Corresponding Author: F. Mebarek-Oudina. Email:

Frontiers in Heat and Mass Transfer 2024, 22(1), 15-34. https://doi.org/10.32604/fhmt.2024.048045

Received 26 November 2023; Accepted 23 January 2024; Issue published 21 March 2024

Abstract

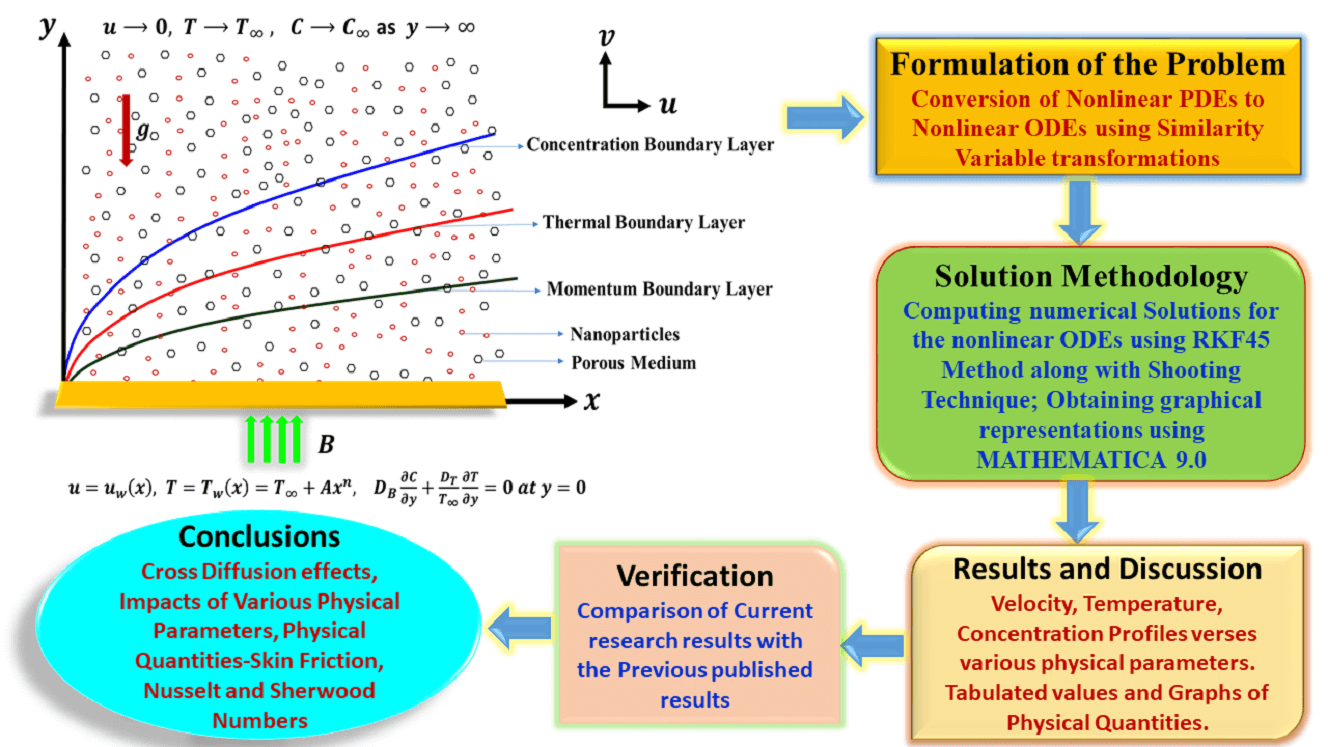

The primary aim of this research endeavor is to examine the characteristics of magnetohydrodynamic Williamson nanofluid flow past a nonlinear stretching surface that is immersed in a permeable medium. In the current analysis, the impacts of Soret and Dufour (cross-diffusion effects) have been attentively taken into consideration. Using appropriate similarity variable transformations, the governing nonlinear partial differential equations were altered into nonlinear ordinary differential equations and then solved numerically using the Runge Kutta Fehlberg-45 method along with the shooting technique. Numerical simulations were then perceived to show the consequence of various physical parameters on the plots of velocity, temperature, and concentration of the nanofluid flow. Boosting the magnetic, Williamson, porosity, and stretching sheet index parameters, the velocity of the fluid flow decreases. The temperature is enhanced as the Williamson and Brownian motion parameters upsurge, but it decreases as the Prandtl, thermophoresis, stretching sheet index, and Dufour parameters escalate. The concentration distribution decreases as the thermophoresis and magnetic parameters upsurge, but it escalates as the Soret, Schmidt, Brownian motion, and stretching sheet index parameters increase. Skin friction coefficient boosted as the stretching sheet index and magnetic parameters enhanced against the Williamson parameter. The findings from this study have been contrasted with earlier findings on local Nusselt numbers, which show substantial support and endorse the existing approach’s validity. The numerical values of the local Sherwood number gradually increase as the Schmidt, Soret, stretching sheet index, and thermophoresis parameters are upsurged.Graphic Abstract

Keywords

Nomenclature

| Concentration of the nanoparticles | |

| Concentration of the wall | |

| Stretching velocity | |

| Free stream temperature | |

| Temperature of the nanofluid | |

| Wall temperature distribution | |

| Free nanoparticle concentration | |

| Strength of the uniform magnetic field | |

| Acceleration due to gravity | |

| Coefficient of mass diffusivity | |

| Coefficient of Thermophoresis | |

| Brownian diffusion coefficient | |

| Dimensionless stream function | |

| Permeability of porous medium | |

| Ratio of thermal diffusion | |

| Concentration susceptibility | |

| Specific heat at constant pressure | |

| Williamson parameter | |

| Prandtl number | |

| Dufour parameter | |

| Schmidt number | |

| Soret parameter | |

| Porous parameter | |

| Stretching sheet index | |

| Magnetic field parameter | |

| Positive constants | |

| Intensity of the variable magnetic field | |

| Local skin friction coefficient | |

| Brownian motion parameter | |

| Thermophoresis parameter | |

| Local nusselt number | |

| Local Sherwood parameter | |

| Wall shear stress | |

| Heat flux | |

| Mass flux | |

| Cartesian coordinates along the plate and normal to it, respectively | |

| Velocity along | |

| Reference velocity | |

| Greek Symbols | |

| Dimensionless temperature | |

| Kinematic viscosity | |

| Positive time constant ( | |

| Coefficient of viscosity | |

| Density of the fluid | |

| Electrical conductivity | |

| Reynolds number | |

| Thermal conductivity | |

| Dimensionless concentration | |

| Ratio of effective heat capacity | |

| Similarity variable | |

| Thermal diffusivity | |

| Superscripts | |

| Wall condition | |

| Differentiation with respect to | |

| Free stream condition | |

Newton’s law of viscosity, which asserts that shear stress and shear rate must be inversely proportional, is infringed by non-Newtonian fluids. The viscosity of non-Newtonian fluids fluctuates with the rate of shear or shear stress. This demonstrates that the fluid’s resistance to flow varies depending on the conditions under which it flows. There are several types of non-Newtonian fluids, each with its distinct flow characteristics such as pseudoplastic fluids-toothpaste, ketchup, paints, dilatant fluids-a mixture of cornstarch and water, often called oobleck, Bingham plastic fluids-drilling muds, visco-elastic fluids-slime, polymer solutions, and human mucus. Magnetohydrodynamics (MHD) is an integrative discipline dedicated to investigating the properties of conducting fluids in the context of magnetic fields by combining fluid dynamics with electromagnetic concepts. It has several applications ranging from astronomy to engineering. Raju et al. [1] examined the flow of a chemically reacting fluid via an inclined vertical permeable moving plate in an unsteady MHD fluid flow. Many more studies have been drawn to this field of study [2,3].

In recognition of its many potential applications in industry, the boundary layer flow of such fluids is gaining prominence. The Naiver-Stokes equations alone are insufficient for determining and enhancing the rheological properties of materials. One of the most elegant non-Newtonian techniques for circumventing this hindrance is the Williamson fluid flow model (WFFM). The WFFM is based on a power-law relationship between the shear stress (

Nanofluids possess several characteristics that make them suitable for various industrial applications which include enhanced thermal conductivity, increased heat transfer efficiency, improved lubrication and wear resistance, stability and suspension of nanoparticles, tailored properties by selecting different nanoparticles and base fluids, compatibility with existing systems and potential for multi-functionality. The use of nanofluids in industrial applications offers several advantages due to the unique properties of nanoparticles at the nanoscale. Some key industrial applications of nanofluids are heat transfer and cooling systems, lubrication and wear resistance, oil and gas extraction, aerospace and rocket propulsion, solar thermal energy, electronic cooling, and biomedical applications, etc.

When nanoparticles are incorporated into the Williamson base fluid, their properties change, leading to improved heat transmission and other desired features. Williamson nanofluid flow (WNFF) has an extensive scope of industrial applications, encompassing heat transfer improvement, electronics cooling, solar thermal systems, lubrication and machining, biomedical applications, and so on. Nadeem et al. [8] illustrated the heat transfer analysis of a WNFF. Bhatti et al. [9] investigated the combined implications of thermo-diffusion and heat radiation on a porous stretched sheet filled with WNFF. Reddy et al. [10] investigated the MHD WNFF over a stretched sheet with variable thickness and diverse thermal conductivity to transfer mass and heat in the presence of radiation. Mabood et al. [11] used a finite difference approach to explore the MHD WNFF on a perpetually shifting heated surface to study the impacts of thermal radiation and heat source. Mebarek-Oudina et al. [12] analyzed the hydromagnetic flow of magnetite-water nanofluid utilizing an adapted Buongiorno model. Ramesh et al. [13] illustrated the computational analysis of the magnetic properties of a radiative nano Carreau fluid flow in a microchannel. Abbas et al. [14] explored the effects of heat generation and viscous dissipation of an MHD WNFF past a nonlinear stretching sheet immersed in a porous medium. Plenty of scholars enlightened their study on this globally vital problem in such a captivating manner [15–24].

Because of their unusual mechanical properties, nonlinear stretching sheets, also known as nonlinearly elastic membranes or nonlinearly deformable surfaces, offer a wide range of lucrative uses. A nonlinear stretching sheet is a mathematical model that describes the behavior of a stretching sheet or surface when the tension or stretching force is not exactly proportional to the displacement. This simulation is frequently employed for researching fluid dynamics and heat transport in a range of engineering processes. Das [25] addressed the partial slip of the boundary layer flow of a nanofluid at an ordained surface temperature across a nonlinear stretching sheet (NLSS). Bilal et al. [26] collaborated to detect the MHD 3D boundary layer flow of a Williamson fluid confined by a bidirectional nonlinear stretched membrane (NLSS). Abo-Dahab et al. [27] investigated the effect of suction/injection on an MHD Casson nanofluid flow over NLSS in a heated porous medium. The study carried out by Hayat et al. [28] explored the magnetohydrodynamic (MHD) boundary layer flow of Powell-Eyring nanofluid across a nonlinear stretching sheet with varying thickness. Qayyam et al. [29] sought an MHD third-grade nanofluid across a nonlinear stretching material that differed by thickness with effects of the heat radiation and chemical reaction. It has a broad spectrum of usages in industry, including stretching electronics, packing and wrapping, energy harvesting, robotics, and soft robotics. In recent decades, many more investigations have explored fascinatingly on this research area [30–36].

The implications of Soret and Dufour are two important transfers of mass and heat mechanisms in hydraulic systems. The Soret effect, popularly referred to as thermal diffusion, lays out how a species’ concentration in a mixture affects temperature dispersion. The Dufour effect, formerly referred to as thermal diffusion of momentum, is an aberration that stresses mass flow in the direction of a temperature gradient when there is a disparity in temperature in a fluid system. Hayat et al. [37] apparent the heat and mass transfer through natural convection to detect the impacts of the chemical reaction, Soret and dufour effects from vertical surfaces in a permeable medium. In the inclusion of magnetic nanoparticles, Postelnicu et al. [38] inquired about the effects of Soret and Dufour over fluid flow on a vertically stretched sheet due to multiple slips. Seid et al. [39] focused on the oscillatory flow of an elevated stress fluid due to a stretchy curved surface along the cross-diffusion impacts. Chemical engineering, combustion, isotope separation, biological sciences, geophysics, and energy conversion benefit substantially from the cross-diffusion effects. Understanding and accounting for these effects in relevant systems allow for improved process design, optimization, and performance research works [40–46].

The motivation for this study was gathered by studying the literature work existing in the references [4–6,14,27] to do the research on the WNFF. The novelty of this research work is to investigate the impacts of the cross-diffusions (Soret and Dufour effects) of an MHD Williamson nanofluid flow past a nonlinearly stretched sheet immersed in a permeable medium. A comprehensive examination of prior research that was published recognizes that no such attempt has ever been made, even though the current study’s range of views and phenomena may be anticipated to result in unusually dynamic interactions across disciplines. The subsequent section goes over the fluid flow model, flow regime, solution strategy, and results display.

2 Fundamental Formulation of the Williamson Fluid Flow

The corresponding equations of continuity and momentum associated with an incompressible Williamson fluid flow are provided using the references [4,6,8] as follows:

where

where

Here

where

called the strain tensor of the second invariant and the case

Using binomial series expansion:

Also,

The component form of the equations of continuity and momentum is represented as

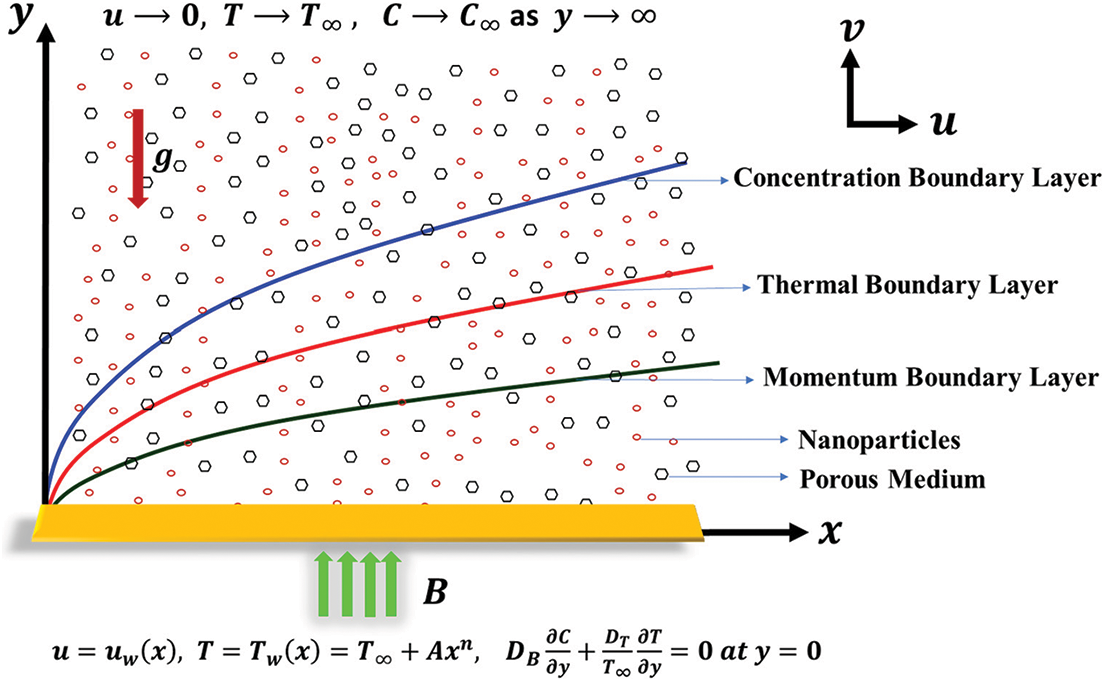

The current study examines the characteristics of a two-dimensional, viscous, and incompressible Williamson nanofluid flow past a nonlinear stretching sheet in the region

Figure 1: Physical interpretation of the fluid flow

The governing nonlinear partial differential equations of the considered fluid flow phenomena using the references [14,27] are given as

The pertinent boundary conditions for the defined fluid flow are given as

where

The following similarity variable transformations [27] are executed to switch the nonlinear PDEs (12) to (15) along their boundary conditions (16) to nonlinear ODEs:

where

After applying the above similarity transformations for the Eqs. (12) to (15), Eq. (12) satisfied identically; the transformed ODEs are provided below in the Eqs. (18) to (20):

The corresponding boundary conditions (16) for the proposed fluid flow becomes

In the Eqs. (18) to (21), the parameters are defined as Williamson nanofluid parameter

For the practical study, introducing the new quantities called the skin friction coefficient

where the wall shear stress

where

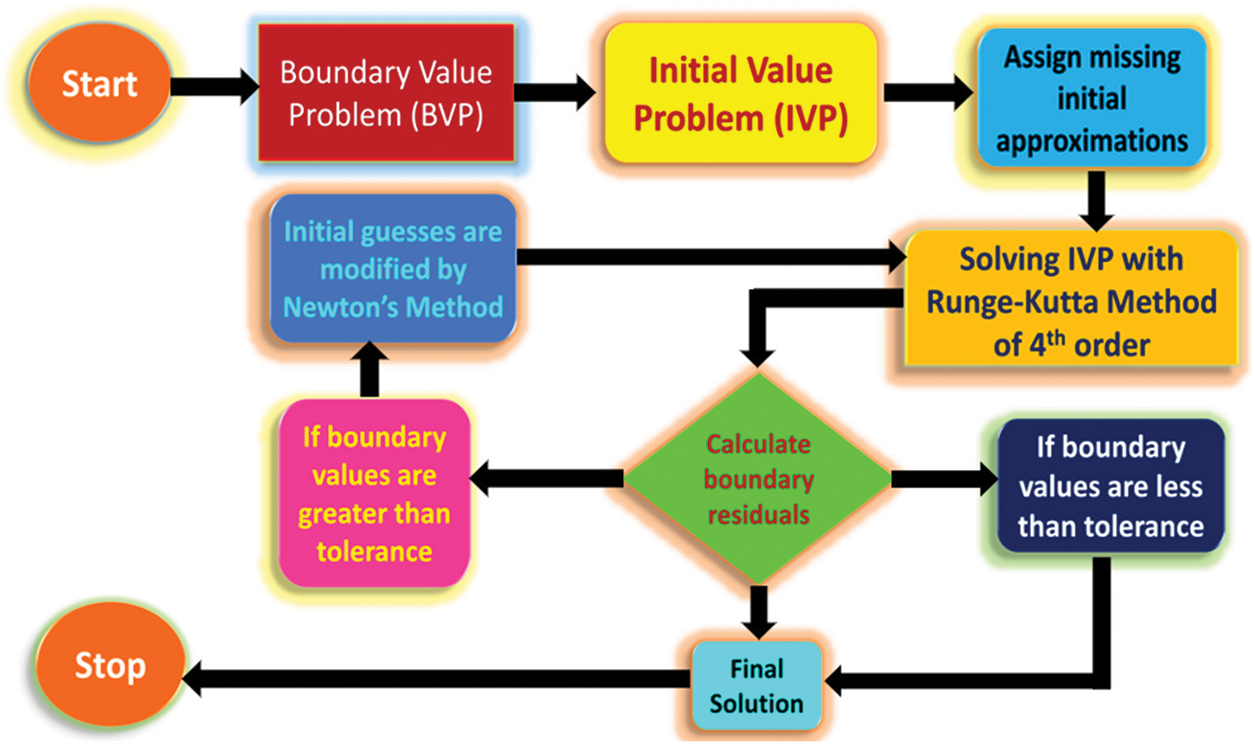

The system of interconnected differential Eqs. (18)–(20) presents a significant analytical obstacle, necessitating the utilization of a numerical approach for resolution. Although numerous numerical methods are available, the Runge Kutta Fehlberg-45 method proves to be particularly efficient when dealing with first-order first-value problems. Therefore, we have chosen to tackle Eqs. (18)–(20) and the corresponding boundary conditions (21) using the shooting technique in conjunction with the RKF-45 scheme. The Newton-Raphson method has been used for initial guesses. The resulting outcomes are subsequently verified by employing the MATHEMATICA-12.0. The procedure for implementing the RKF-45 method and the shooting strategy is outlined in Fig. 2. The fundamental procedures implicated in the conversion of the specified predicament into an initial value problem (IVP) of the first-order can be delineated as follows:

Figure 2: The flow chart for the shooting method

Eqs. (18)–(20) are converted into a system of ODEs by taking the following substitutions:

The formulated initial value problem is given by

The initial conditions are given as

The intricate and non-linear differential Eqs. (23)–(29) are efficiently addressed through the robust method of fourth-fifth order RKF. By attaining remarkable convergence, the numerical outcomes exhibit boundary residuals falling below the error threshold of

This section portrays the flow characteristics encountered throughout the flow regime for the computations of the velocity profiles

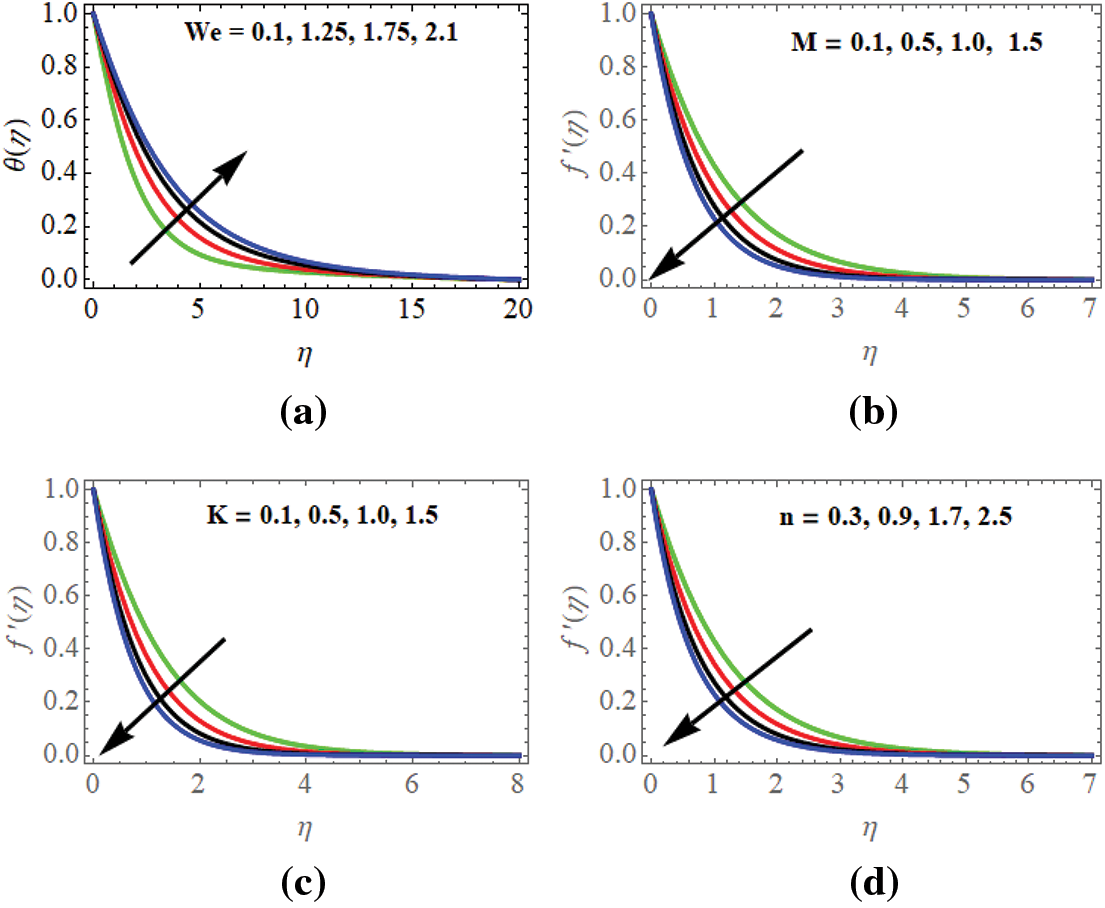

Fig. 3a depicts the effects of the Williamson parameter

Figure 3: (a) Velocity profiles w.r.t

The detrimental impact of the magnetic parameter

Fig. 3c illustrates the ramifications of the porosity parameter

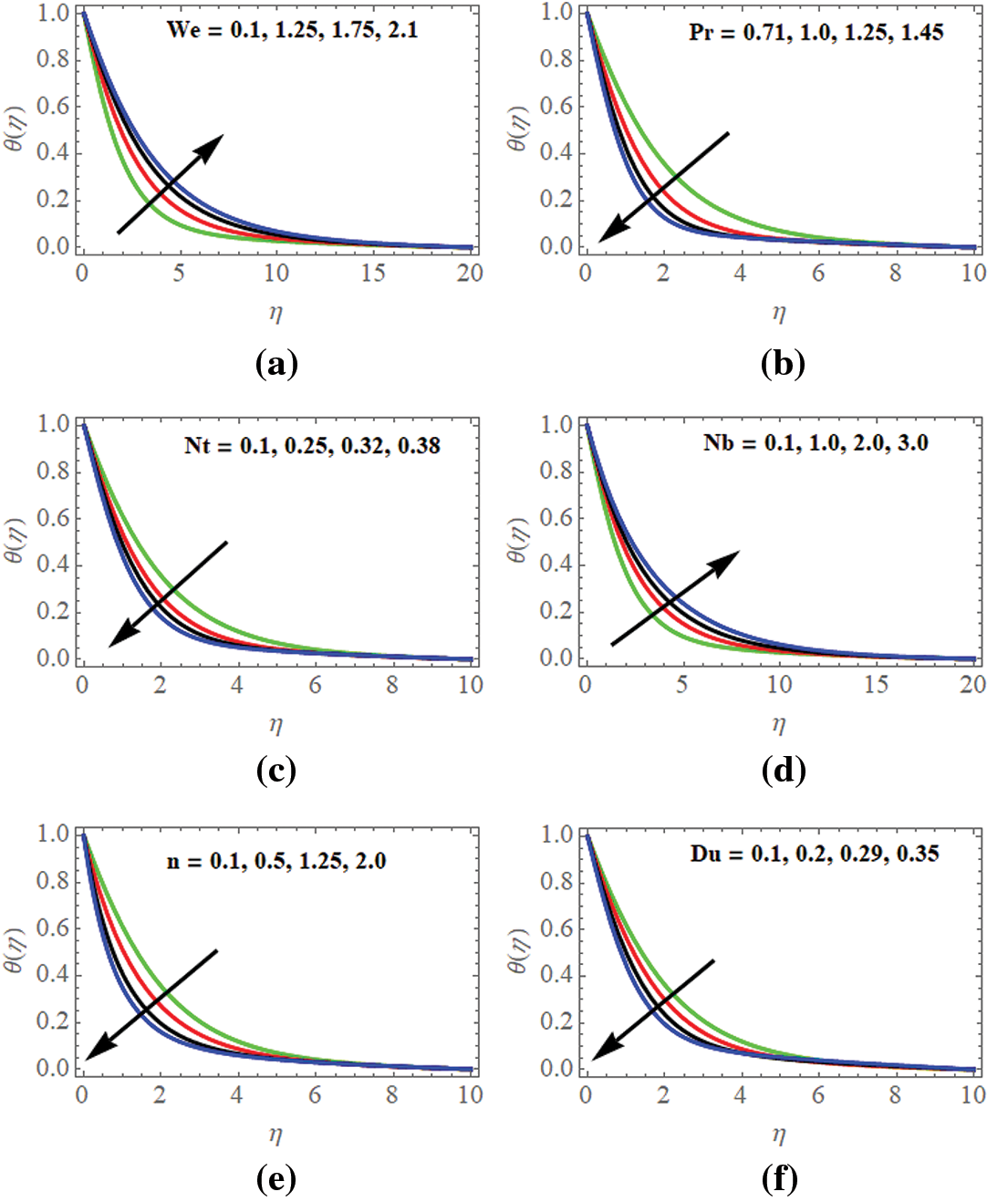

In addition, we can see in Fig. 4a that when the Williamson parameter

Figure 4: (a) Temperature profiles w.r.t

In Fig. 4b, the temperature profiles

Fig. 4c illuminates that the thermophoresis parameter

Fig. 4d deploys that the effect of the temperature profiles

Fig. 4e portrays the temperature profiles

Fig. 4f describes the temperature profiles concerning the Dufour parameter

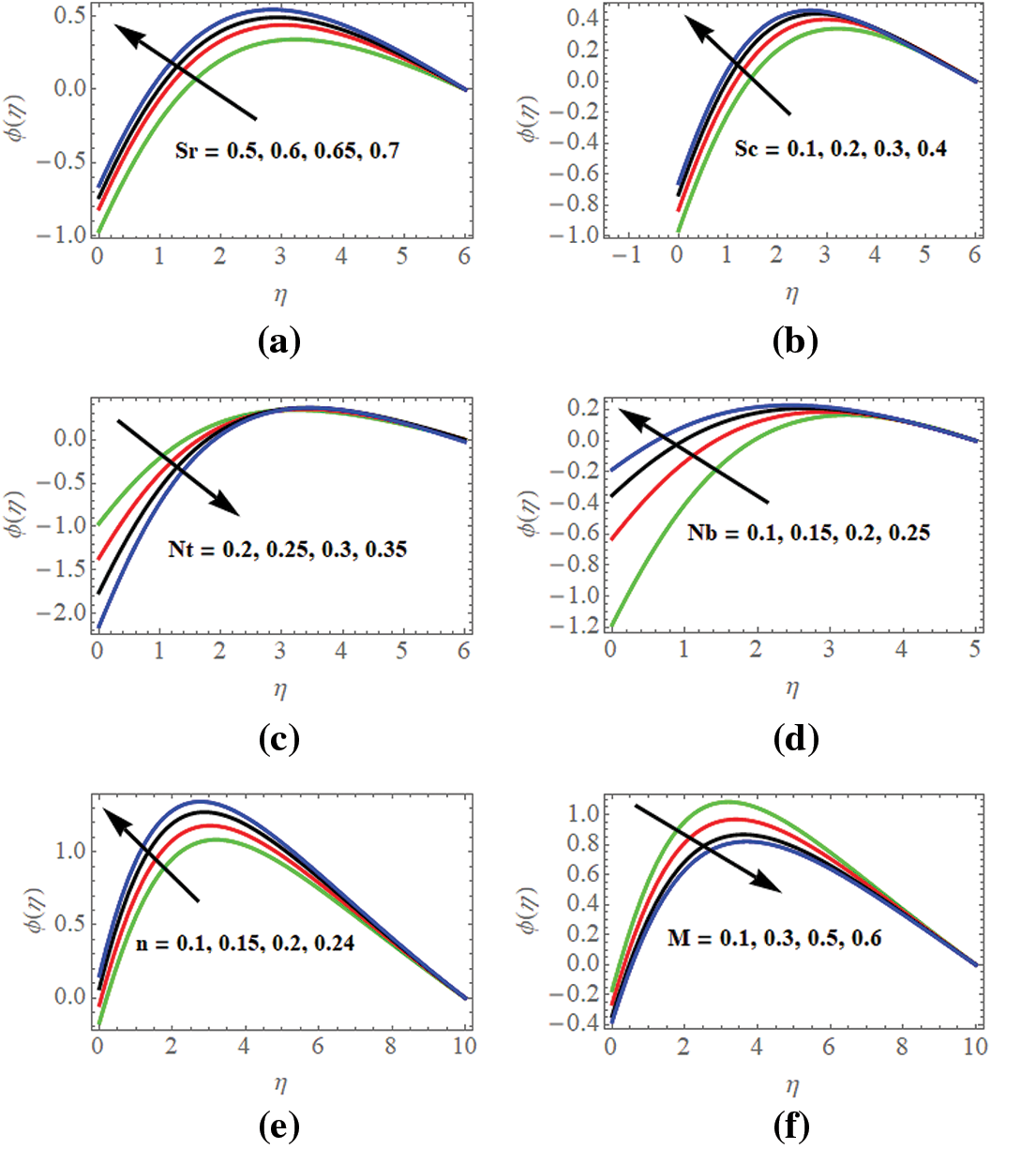

Fig. 5a illustrates the scenario of the concentration profiles

Figure 5: (a) Concentration profiles w.r.t

Fig. 5b depicts that as the Schmidt number

Fig. 5c exhibits the nonlinear behavior of the concentration profiles

Fig. 5d explores the behavior of concentration profiles

Fig. 5e deploys that the concentration profiles

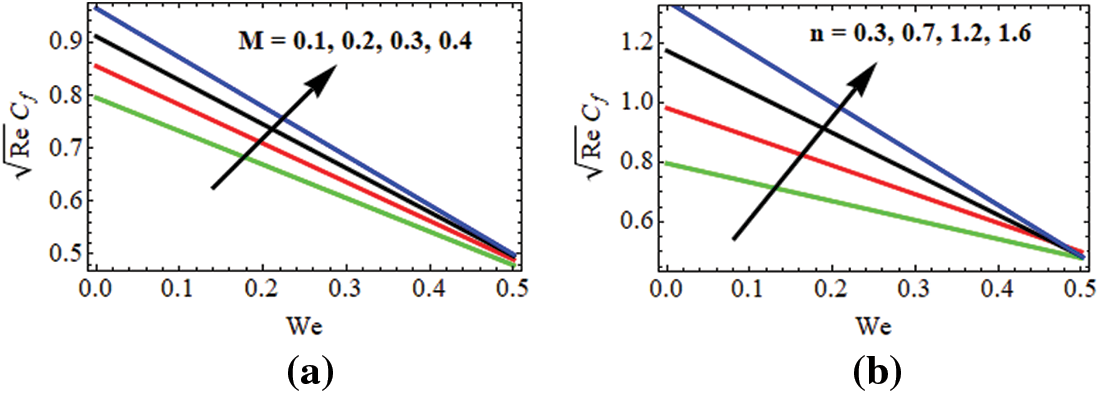

The local skin coefficient values prominence when the graph is displayed over the Williamson parameter

Figure 6: (a) Effect of

Prioritizing the local skin coefficient values over the Williamson parameter when the graph is shown as shown in Fig. 6b,

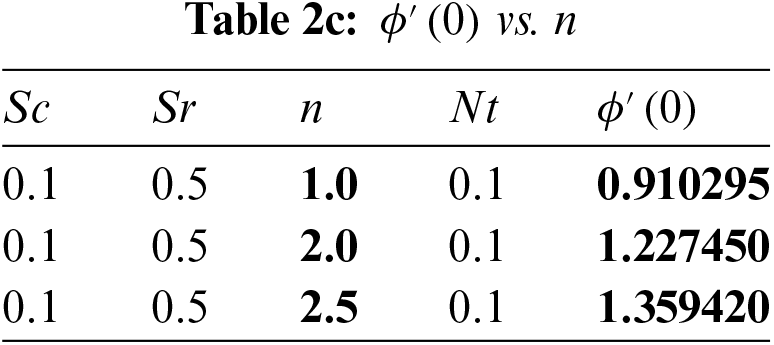

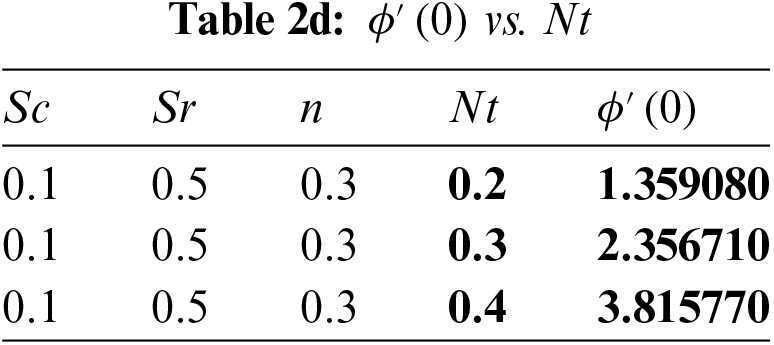

In Table 1, the current investigation is compared to previous research that was published to validate the existing numerical solution. It draws attention to that current and past findings are in good harmony. The present findings are validated due to the top-notch agreement between the results and their interpretation. Tables 2a–2d provide the computational values of the mass transfer rate (local Sherwood number) for the Schmidt parameter

The values of local Sherwood number

The problem of the 2D-steady, viscous, and incompressible MHD heat and mass transfer of a Williamson nanofluid flow past a nonlinear stretching sheet immersed in a porous medium with the Soret and Dufour effects was investigated. Using appropriate similarity variable transformations, the nonlinear PDEs were altered into nonlinear ODEs and then solved numerically using the RKF-45 method along with the shooting technique. The impact of various physical parameters on concentration, velocity, and temperature profiles is deployed through graphs. From the present investigation, the following conclusions could be drawn:

• Boosting the magnetic, Williamson, porosity, and stretching sheet index parameters, the velocity of the fluid flow decreases.

• The temperature is enhanced as the Williamson and Brownian motion parameters upsurge, but it decreases as the Prandtl, thermophoresis, stretching sheet index, and Dufour parameters escalate.

• The concentration distribution decreases as the thermophoresis and magnetic parameters upsurge but it escalates as the Soret, Schmidt, Brownian motion, and stretching sheet index parameters increase.

• Skin friction coefficient boosted as the stretching sheet index and magnetic parameters enhanced against the Williamson parameter.

• The findings from this study have been contrasted with earlier findings on local Nusselt numbers, which show substantial support and endorse the existing approach’s validity.

• The numerical values of the local Sherwood number gradually increase as the Schmidt, Soret, stretching sheet index, and thermophoresis parameters are upsurged.

Future Research Study: In the future, we will study different non-Newtonian nanofluids for this study along with different physical effects.

Acknowledgement: No acknowledgement.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: The authors confirm contribution to the paper as follows: study conception and design, data collection, analysis and interpretation of results, draft manuscript preparation: R. Madan Kumar, R. Srinivasa Raju, F. Mebarek-Oudina, M. Anil Kumar, N. Vamsi Krishna. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: Data are available on request.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Raju, R. S. K., Reddy, M. A., Anil Kumar, G. J., Rama, M., Reddy Gorla, S. (2020). Unsteady magnetohydrodynamic chemically reacting fluid flow past an inclined vertical permeable moving plate. International Journal of Fluid Mechanics Research, 47(3), 191–215. [Google Scholar]

2. Srinivasa Raju, R., Anitha, G., Jithender Reddy, G. (2017). Analytical and numerical investigation of heat and mass transfer effects on magnetohydrodynamic natural convective flow past a vertical porous plate. Journal of Heat and Mass Transfer Research, 4, 117–133. [Google Scholar]

3. Raju, R. S. (2017). Application of finite element method to mhd mixed convection chemically reacting flow past a vertical porous plate with cross diffusion and biot number effects. American Journal of Heat and Mass Transfer, 4(3), 53–74. https://doi.org/10.7726/ajhmt.2017.1009 [Google Scholar] [CrossRef]

4. Nadeem, S., Hussain, S. T., Lee, C. (2013). Flow of a Williamson fluid over a stretching sheet. Brazilian Journal of Chemical Engineering, 30, 619–625. [Google Scholar]

5. Megahed, A. M. (2019). Williamson fluid flow due to a nonlinearly stretching sheet with viscous dissipation and thermal radiation. Journal of the Egyptian Mathematical Society, 27(1), 1–10. [Google Scholar]

6. Bibi, M., Malik, M. Y., Tahir, M. (2018). Numerical study of unsteady Williamson fluid flow and heat transfer in the presence of MHD through a permeable stretching surface. The European Physical Journal Plus, 133, 1–15. [Google Scholar]

7. Salahuddin, T., Iqbal, M. A., Bano, A., Awais, M., Muhammad, S. (2023). Cattaneo-Christov heat and mass transmission of dissipated Williamson fluid with double stratification. Alexandria Engineering Journal, 80, 553–558. https://doi.org/10.1016/j.aej.2023.09.012 [Google Scholar] [CrossRef]

8. Nadeem, S., Hussain, S. T. (2014). Flow and heat transfer analysis of Williamson nanofluid. Applied Nanoscience, 4, 1005–1012. [Google Scholar]

9. Bhatti, M. M., Rashidi, M. M. (2016). Effects of thermo-diffusion and thermal radiation on Williamson nanofluid over a porous shrinking/stretching sheet. Journal of Molecular Liquids, 221, 567–573. https://doi.org/10.1016/J.MOLLIQ.2016.05.049 [Google Scholar] [CrossRef]

10. Reddy, C. S., Naikoti, K., Rashidi, M. M. (2017). MHD flow and heat transfer characteristics of Williamson nanofluid over a stretching sheet with variable thickness and variable thermal conductivity. Transactions of A. Razmadze Mathematical Institute, 171(2), 195–211. https://doi.org/10.1016/J.TRMI.2017.02.004 [Google Scholar] [CrossRef]

11. Mabood, F., Ibrahim, S. M., Lorenzini, G., Lorenzini, E. (2017). Radiation effects on Williamson nanofluid flow over a heated surface with magnetohydrodynamics. International Journal of Heat and Technology, 35, 196–204. https://doi.org/10.18280/IJHT.350126 [Google Scholar] [CrossRef]

12. Mebarek-Oudina, F., Preeti, S. A. S., Vaidya, H., Lewis, R. W., Areekara, S. et al. (2024). Hydromagnetic flow of magnetite-water nano-fluid utilizing adapted Buongiorno model. International Journal of Modern Physics B, 38(1), 2450003. https://doi.org/10.1142/S0217979224500036 [Google Scholar] [CrossRef]

13. Ramesh, K., Mebarek-Oudina, F., Ismail, A. I., Jaiswal, B. R., Warke, A. S. et al. (2023). Computational analysis on radiative non-Newtonian Carreau nanofluid flow in a microchannel under the magnetic properties. Sciencia Iranica, 30(2), 376–390. [Google Scholar]

14. Abbas, A., Jeelani, M. B., Alnahdi, A. S., Ilyas, A. (2022). MHD Williamson nanofluid fluid flow and heat transfer past a non-linear stretching sheet implanted in a porous medium: Effects of heat generation and viscous dissipation. Processes, 10(6), 221. https://doi.org/10.3390/pr10061221 [Google Scholar] [CrossRef]

15. Bouselsal, M., Mebarek-Oudina, F., Biswas, N., Ismail, A. I. (2023). Heat transfer enhancement using Al2O3 -MWCNT hybrid-nanofluid inside a tube/shell heat exchanger with different tube shapes. Micromachines, 14(5), 1072. https://doi.org/10.3390/mi14051072 [Google Scholar] [PubMed] [CrossRef]

16. Mebarek-Oudina, F., Chabani, I. (2023). Review on nano enhanced PCMs: Insight on nePCM application in thermal management/storage systems. Energies, 16(3), 1066. https://doi.org/10.3390/en16031066 [Google Scholar] [CrossRef]

17. Wang, F., Asjad, M. I., Rehman, S. U., Ali, B., Hussain, S. et al. (2021). MHD Williamson nanofluid flow over a slender elastic sheet of irregular thickness in the presence of bioconvection. Nanomaterials, 11(9), 2297. https://doi.org/10.3390/NANO11092297 [Google Scholar] [PubMed] [CrossRef]

18. Loganathan, P., Sangeetha, S. (2022). Effect of Williamson parameter on Cu-water Williamson nanofluid over a vertical plate. International Communications in Heat and Mass Transfer, 137, 106273. https://doi.org/10.1016/J.ICHEATMASSTRANSFER.2022.106273 [Google Scholar] [CrossRef]

19. Ibrahim, W., Gamachu, D. (2019). Nonlinear convection flow of Williamson nanofluid past a radially stretching surface. AIP Advances, 9(8), 085026. https://doi.org/10.1063/1.5113688 [Google Scholar] [CrossRef]

20. Sridhar, W., Vijaya Lakshmi, G., Al-Farhany, K., Ganesh, G. R. (2021). MHD Williamson nanofluid across a permeable medium past an extended sheet with constant and irregular thickness. Heat Transfer, 50(8), 8134–8154. https://doi.org/10.1002/HTJ.22270 [Google Scholar] [CrossRef]

21. Shawky, H. M., Eldabe, N. T. M., Kamel, K. A., Abd-Aziz, E. A. (2019). MHD flow with heat and mass transfer of Williamson nanofluid over stretching sheet through porous medium. Microsystem Technologies, 25(4), 1155–1169. https://doi.org/10.1007/S00542-018-4081-1 [Google Scholar] [CrossRef]

22. Gupta, S., Kumar, D., Singh, J. (2020). Analytical study for MHD flow of Williamson nanofluid with the effects of variable thickness, nonlinear thermal radiation and improved Fourier’s and Fick’s Laws. SN Applied Sciences, 2(3), 438. https://doi.org/10.1007/S42452-020-1995-X [Google Scholar] [CrossRef]

23. Ahmed, K., Akbar, T. (2021). Numerical investigation of magnetohydrodynamics Williamson nanofluid flow over an exponentially stretching surface. Advances in Mechanical Engineering, 13(5). https://doi.org/10.1177/16878140211019875 [Google Scholar] [CrossRef]

24. Qureshi, M. A. (2021). Numerical simulation of heat transfer flow subject to mhd of williamson nanofluid with thermal radiation. Symmetry, 13(1), 1–22. https://doi.org/10.3390/SYM13010010 [Google Scholar] [CrossRef]

25. Das, K. (2015). Nanofluid flow over a non-linear permeable stretching sheet with partial slip. Journal of the Egyptian Mathematical Society, 23(2), 451–456. https://doi.org/10.1016/j.joems.2014.06.014 [Google Scholar] [CrossRef]

26. Bilal, S., Khalil-ur-Rehman, M., Malik, M. Y., Hussain, A., Khan, M. (2017). Effects of temperature dependent conductivity and absorptive/generative heat transfer on MHD three-dimensional flow of Williamson fluid due to bidirectional non-linear stretching surface. Results of Physics, 7, 204–212. https://doi.org/10.1016/j.rinp.2016.11.063 [Google Scholar] [CrossRef]

27. Abo-Dahab, S. M., Abdelhafez, M. A., Mebarek-Oudina, F., Bilal, S. M. (2021). MHD Casson nanofluid flow over nonlinearly heated porous medium in presence of extending surface effect with suction/injection. Indian Journal of Physics, 95, 2703–2717. https://doi.org/10.1007/s12648-020-01923-z [Google Scholar] [CrossRef]

28. Hayat, T., Ullah, I., Alsaedi, A., Farooq, M. (2017). MHD flow of Powell-Eyring nanofluid over a non-linear stretching sheet with variable thickness. Results of Physics, 7, 189–196. https://doi.org/10.1016/j.rinp.2016.12.008 [Google Scholar] [CrossRef]

29. Qayyum, S., Hayat, T., Alsaedi, A. (2017). Chemical reaction and heat generation/absorption aspects in MHD nonlinear convective flow of third grade nanofluid over a nonlinear stretching sheet with variable thickness. Results of Physics, 7, 2752–2761. https://doi.org/10.1016/j.rinp.2017.07.043 [Google Scholar] [CrossRef]

30. Ahmed, K., McCash, L. B., Akbar, T., Nadeem, S. (2022). Effective similarity variables for the computations of MHD flow of Williamson nanofluid over a non-linear stretching surface. Processes, 10(6), 1119. https://doi.org/10.3390/pr10061119 [Google Scholar] [CrossRef]

31. Khan, M., Malik, M. Y., Salahuddin, T., Hussian, A. (2018). Heat and mass transfer of Williamson nanofluid flow yield by an inclined Lorentz force over a nonlinear stretching sheet. Results of Physics, 8, 862–868. https://doi.org/10.1016/j.rinp.2018.01.005 [Google Scholar] [CrossRef]

32. Seth, G. S., Bhattacharyya, A., Kumar, R., Chamkha, A. J. (2018). Entropy generation in hydromagnetic nanofluid flow over a non-linear stretching sheet with Navier’s velocity slip and convective heat transfer. Physics of Fluids, 30(12), 122003. https://doi.org/10.1063/1.5054099 [Google Scholar] [CrossRef]

33. Rasool, G., Shafiq, A., Khalique, C. M., Zhang, T. (2019). Magnetohydrodynamic Darcy-Forchheimer nanofluid flow over a nonlinear stretching sheet. Physica Scripta, 94(10), 105221. https://doi.org/10.1088/1402-4896/ab18c8 [Google Scholar] [CrossRef]

34. Jafar, A. B., Shafie, S., Ullah, I. (2020). MHD radiative nanofluid flow induced by a nonlinear stretching sheet in a porous medium. Heliyon, 6(6), E04201. https://doi.org/10.1016/j.heliyon.2020.e04201 [Google Scholar] [PubMed] [CrossRef]

35. Prasannakumara, B. C., Gireesha, B. J., Krishnamurthy, M. R., Ganesh Kumar, K. (2017). MHD flow and nonlinear radiative heat transfer of Sisko nanofluid over a nonlinear stretching sheet. Informatics in Medicine Unlocked, 9123–9132. https://doi.org/10.1016/j.imu.2017.07.006 [Google Scholar] [CrossRef]

36. Makinde, O. D., Mabood, F., Ibrahim, M. S. (2018). Chemically reacting on MHD boundary-layer flow of nanofluids over a non-linear stretching sheet with heat source/sink and thermal radiation. Thermal Science, 22(1), 495–506. https://doi.org/10.2298/tsci151003284m [Google Scholar] [CrossRef]

37. Hayat, T., Rashid, M., Alsaedi, A., Ahmad, B. (2018). Flow of nanofluid by nonlinear stretching velocity. Results of Physics, 81104–81109. https://doi.org/10.1016/j.rinp.2017.12.014 [Google Scholar] [CrossRef]

38. Postelnicu, A. (2007). Influence of chemical reaction on heat and mass transfer by natural convection from vertical surfaces in porous media considering Soret and Dufour effects. Heat and Mass Transfer/Waerme-und Stoffuebertragung, 43(6), 595–602. https://doi.org/10.1007/S00231-006-0132-8/FIGURES/15 [Google Scholar] [CrossRef]

39. Seid, E., Haile, E., Walelign, T. (2022). Multiple slip, Soret and Dufour effects in fluid flow near a vertical stretching sheet in the presence of magnetic nanoparticles. International Journal of Thermofluids, 13, 100136. https://doi.org/10.1016/J.IJFT.2022.100136 [Google Scholar] [CrossRef]

40. Imran, M., Naveed, M., Abbas, Z. (2023). Dynamics of Soret and Dufour effects on oscillatory flow of couple stress fluid due to stretchable curved surface. Research Article Advances in Mechanical Engineering, 2, 1–18. https://doi.org/10.1177/16878132231156742 [Google Scholar] [CrossRef]

41. Vafai, K., Khan, A. A., Fatima, G., Sait, S. M., Ellahi, R. (2021). Dufour, Soret and radiation effects with magnetic dipole on Powell-Eyring fluid flow over a stretching sheet. International Journal of Numerical Methods & Heat Fluid Flow, 31(4), 1085–1103. https://doi.org/10.1108/HFF-06-2020-0328 [Google Scholar] [CrossRef]

42. Makinde, O. D. (2011). On MHD mixed convection with soret and dufour effects past a vertical plate embedded in a porous medium. Latin American Applied Research, 41(1), 63–68. [Google Scholar]

43. Makinde, O. D., Olanrewaju, P. O. (2011). Mixed convection with soret and dufour effects unsteady mixed convection with soret and dufour effects past a porous plate moving through a binary mixture of chemically reacting fluid. Chemical Engineering Communications, 1989, 920–938. https://doi.org/10.1080/00986445.2011.545296 [Google Scholar] [CrossRef]

44. Partha, M. K., Murthy, P. V. S. N., Sekhar, G. P. R. (2006). Soret and Dufour effects in a non-darcy porous medium. Journal of Heat Transfer, 128(6), 605–610. https://doi.org/10.1115/1.2188512 [Google Scholar] [CrossRef]

45. Mortimer, R. G., Eyring, H. (1980). Elementary transition state theory of the Soret and Dufour effects. Proceedings of the National Academy of Sciences of the United States of America, 77(4), 1728–1731. https://doi.org/10.1073/PNAS.77.4.1728 [Google Scholar] [PubMed] [CrossRef]

46. Dharmaiah, G., Mebarek-Oudina, F., Balamurugan, K. S., Vedavathi, N. (2024). Numerical analysis of the magnetic dipole effect on a radiative ferromagnetic liquid flowing over a porous stretched sheet. Fluid Dynamics & Materials Processing, 20(2), 293–310. https://doi.org/10.32604/fdmp.2023.030325 [Google Scholar] [CrossRef]

47. Reddy Gorla, R. S., Sidawi, I. (1994). Free convection on a vertical stretching surface with suction and blowing. Applied Scientific Research, 52, 247–257. [Google Scholar]

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools