Open Access

Open Access

ARTICLE

Experimental Study of Heat Transfer in an Insulated Local Heated from Below and Comparison with Simulation by Lattice Boltzmann Method

1 LABSIPE, National School of Applied Sciences, Chouaib Doukkali University, El Jadida, 24000, Morocco

2 LPMAT, Department of Physics, Faculty of Sciences, Hassan II University of Casablanca, Casablanca, 20100, Morocco

* Corresponding Author: Noureddine Abouricha. Email:

(This article belongs to the Special Issue: Computational and Numerical Advances in Heat Transfer: Models and Methods I)

Frontiers in Heat and Mass Transfer 2024, 22(1), 359-375. https://doi.org/10.32604/fhmt.2024.047632

Received 12 November 2023; Accepted 25 December 2023; Issue published 21 March 2024

Abstract

In this paper, experimental and numerical studies of heat transfer in a test local of side heated from below are presented and compared. All the walls, the rest of the floor and the ceiling are made from plywood and polystyrene in sandwich form ( plywood- polystyrene- plywood) just on one of the vertical walls contained a glazed door (). This local is heated during two heating cycles by a square plate of iron the width , which represents the heat source, its temperature is controlled. The plate is heated for two cycles by an adjustable set-point heat source placed just down the center of it. For each cycle, the heat source is switched “on” for 6 h and switched “off” for 6 h. The outdoor air temperature is kept constant at a low temperature . All measurements are carried out with k-type thermocouples and with flux meters. Results will be qualitatively presented for two cycles of heating in terms of temperatures and heat flux densities for various positions of the test local. The temperature evolution of the center and the profile of the temperature along the vertical centerline are compared by two dimensions simulation using the lattice Boltzmann method. The comparison shows a good agreement with a difference that does not exceed °C.Keywords

Nomenclature

| Discrete velocity vector (lattice unit) | |

| The x, y axis projection of velocity vector, respectively (lattice unit) | |

| Dimension of space | |

| External buoyancy force (lattice unit) | |

| Distribution functions for the flow and temperature, respectively (lattice unit) | |

| Vector of gravity ( | |

| Height of the cavity ( | |

| Indices aligned with the x and y directions, respectively | |

| Width of the plate ( | |

| Count of nodes in the x and y directions, respectively | |

| Prandtl number (-) | |

| Rayleigh number (-) | |

| Thermal resistance ( | |

| Temperature ( | |

| Time ( | |

| Macroscopic velocity coordinates (lattice unit) | |

| Cartesian coordinates (lattice unit) | |

| Greek Symbols | |

| Thermal diffusivity ( | |

| Thermal conductivity ( | |

| Coefficient of thermal expansion ( | |

| Difference of temperature ( | |

| Lattice time step (lattice unit) | |

| Lattice space step (lattice unit) | |

| Dimensionless form of the temperature (-) | |

| Kinematic viscosity ( | |

| Density of flow | |

| Relaxation time corresponding to the fluid flow and temperature, respectively (lattice unit) | |

| Weights factor (lattice unit) | |

| Heat flux density ( | |

| Heat flux ( | |

| Subscripts and Superscript | |

| Cold | |

| Equilibrium | |

| Hot | |

| Lattice link number | |

| Momentum | |

| Maximum | |

| Opposite | |

| Scalar | |

Over the last two decades, the thermal comfort of buildings has become the most important, especially in terms of energy consumption in buildings [1]. Most researchers are looking for ways to improve the thermal performance of buildings to reduce the rate of energy consumption with some respect for environmental tools. Among the proposed solutions is the increase in thermal inertia, insulation of walls and use of phase change materials (PCM) to store and recover thermal energy [2–5]. Shaikh et al. [6] appreciated an analysis of the utilization of the PCM in cooling systems. In the study by Sonnick et al. [7], an experimental investigation was conducted on the implementation of a salt hydrate storage system to attain temperature stabilization for enhancing thermal comfort in prefabricated wooden residences. The findings demonstrated the cost-effectiveness of salt hydrates and their notable positive impact on the thermal performance of prefabricated wooden houses. Wang et al. [8] presented a review of the application, performance and the characteristic of the PCM.

Most scientific researchers are moving towards digital modeling because of the lack of means and instruments necessary to carry out an experiment. These researchers employed numerical methodologies, encompassing the Finite Difference Method (FDM), Finite Volume Method (FVM), and, more recently, the Lattice Boltzmann Method (LBM), among other techniques. Østergaard et al. [9] presented an examination of techniques for the simulation of a heating system, an example of small-temperature heating in a standing single-family company. Khoukhi [10] elucidated the combined influence of temperature and humidity on the thermal conductivity of polystyrene (EPS) material installed in building envelopes for insulation. The findings indicated a notable impact of varying moisture content on the thermal conductivity of polystyrene insulation across different operational temperatures. In a study conducted by Kürekci et al. [11], an assessment was carried out involving experimental and numerical investigations of laminar natural convection within a differentially heated cubical enclosure. The outcomes of these analyses were juxtaposed, revealing a substantial level of congruence between the experimental and numerical findings. The same configuration with an internal heat source was used to study the turbulent mixed convection experimentally and numerically. The renormalized k–ε turbulence model yielded a minimum average percentage difference of 12.9% of the calculated average Nusselt numbers on the heated wall and 4.1% of the heat source when compared to experimental values [12]. An experimental study and numerical simulation in

Recently, the LBM has been used by several authors for solving complex thermal problems. This method proved the ability to classify between the numerical methods [15–19]. The phenomenon is under observation, and a notable concurrence is evident between the outcomes derived from the LBM approach and the LES technique, all while achieving considerably expedited computational durations. In this particular context, Hu et al. [20] have introduced a framework that integrates the lattice Boltzmann method (LBM), large eddy simulation (LES), and a Markov chain model to simulate transient particle transport indoors. The comparison between the proposed framework and the other models gives a deviation of around

2 Studied Configuration and Methodology

2.1.1 Description of the Studied Configuration

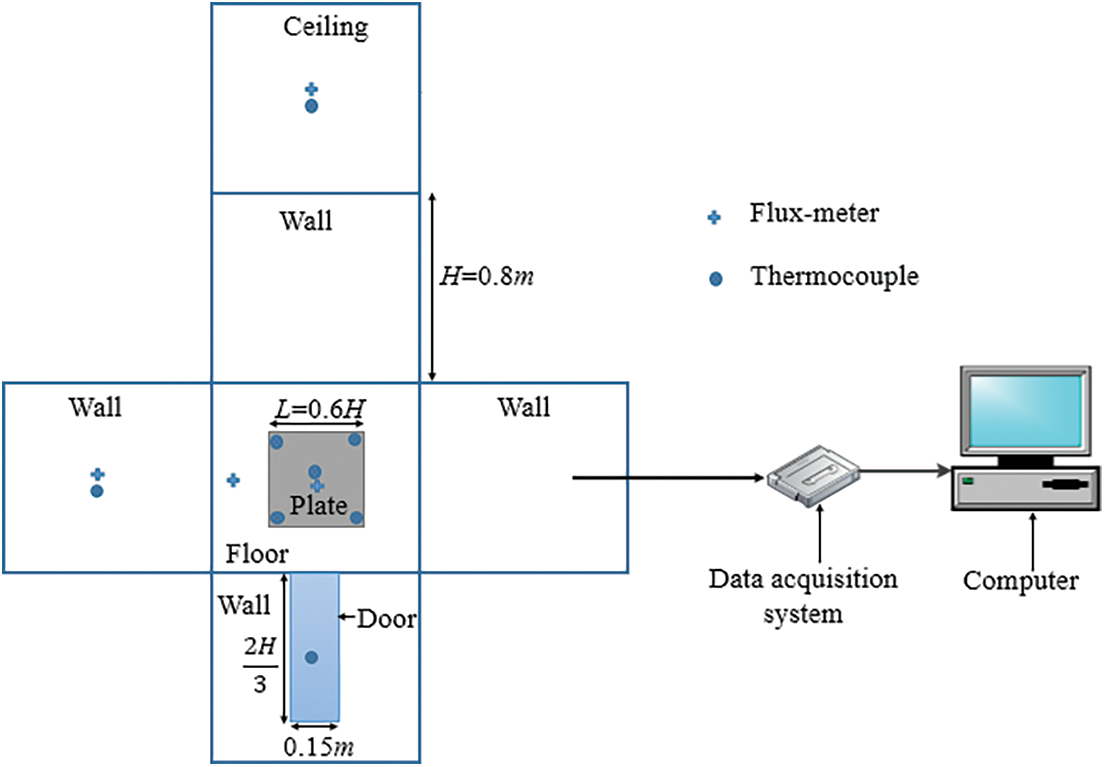

The test local is built in a cubical form of side

Figure 1: (a) Test local, (b) Wall sandwich panel, (c) Square plate and heat source

2.1.2 Heating and Cooling Cycles

Just a part of under floor is heated by using a square plate of iron of width

2.1.3 Instrumentation and Measurements

Experimental measurements are performed on the inside and outside faces, in the center and along the vertical centerline of the test cavity. Moreover, we measured the temperature and the heat flux densities at different positions/faces of the test local (walls, door, ceiling, rest of the floor and hot plate), Employing k-type thermocouples (0.2 mm) exhibiting a maximum deviation of 0.2°C, alongside flux-meters having a diameter of 2.54 cm, characterized by a precision of 3% and a response time of 0.3 s. The heat flux sensors yield either a positive or negative voltage, contingent upon the direction of the heat flux densities. These measurements are taken at one-minute intervals. The details of the experimental operation and the studied configuration are shown schematically in Fig. 2, with the setting of the thermocouples and the flux-meters already connected to the data acquisition system that is stored in a computer.

Figure 2: Experimental test local with flux-meters and thermocouples positions

The last configuration is projected on the vertical medium contained the glazed door (Fig. 3).

Figure 3: 2D simulated configuration at medium vertical projection

This is later simulated in two dimensions (

2.2.2 Lattice Boltzmann Method Formulation

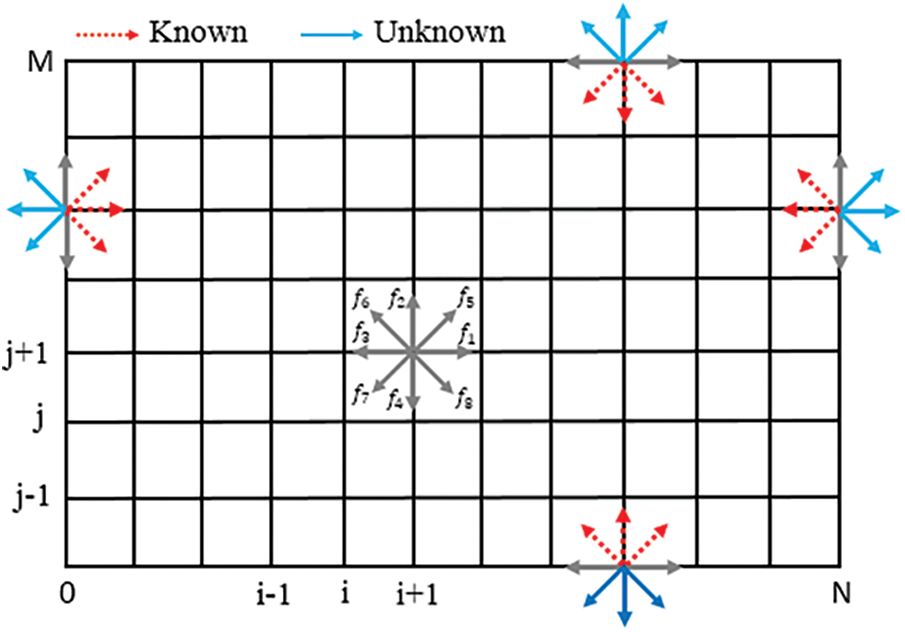

The Lattice Boltzmann Method (LBM) is a numerical method utilizes two single particle distribution functions,

Figure 4: Lattice model D2Q9 with known an unknown distribution functions

The Lattice Boltzmann Equation (LBE) without external forces associated to the BGK (Bhatangar-Gross-Krook) approximation as for single particle and single time relaxation can be written [32,35,36]:

The equilibrium distribution function can be expressed as in [37]:

The weights factors

Notice that,

For dynamic field the LBE-BGK with external buoyancy forces can be written as:

For thermal field the LBE-BGK can be written as:

The equilibrium distribution function for thermal field can be developed at first-order [38,39].

Finally, the basic quantities, such as density

The boundary conditions relevant to the problem within a two-dimensional (2D) framework.

• Dynamic boundary conditions:

✓ On the walls all velocities are zero:

✓ « bounce-back »

• Thermal boundary conditions:

The equation provided was utilized to determine the prescribed temperature applied to both the hot and cold walls.

✓ On the square plate

✓ On the door

✓ On the adiabatic walls ceiling and the rest of the floor (without the iron plate) and all the vertical walls (without the door):

For example, at the ceiling (top wall (

Here, “i” corresponds to the iteration index along the x-direction, and “M” signifies the count of lattice points located at the upper wall, as illustrated in Fig. 4.

The results will be qualitatively presented in terms of the temperature profiles

The objective here is to link between the experimental model and the numerical model, and transform lattice units into physical units just to compare the results. For the first time, we calculate Rayleigh number

The numerical code (LBM–FORTAN) is used in two dimension (2D) by considering the projection of the experimental configuration on the vertical medium contained the glazed door (Fig. 3). The lattice dimensions are set as N = 800 for the x direction and M = 800 for the y direction. The lattice spacing intervals, Δx and Δy, as well as the lattice time step, Δt, are all assigned a value equal to unity.

Utilizing the principle of similarity and dimensionless parameters like the Rayleigh number (Ra) and Prandtl number (Pr) for the air-filled cavity, we are able to compute the value of gβ as depicted in Eq. (3)

The results obtained from the lattice Boltzmann method are expressed in lattice units. For the temperature, we used

3.1 Calibration and Tests of the Experimental Model

Before starting our monitoring, it is recommended that the validity of the measurements be guaranteed. For that, we realized two tests: the first one is made without a heat source. We ensured that all the thermocouples and the flux-meters indicate the same values. The second test is realized with the presence of the heat source. The iron plate is heated for

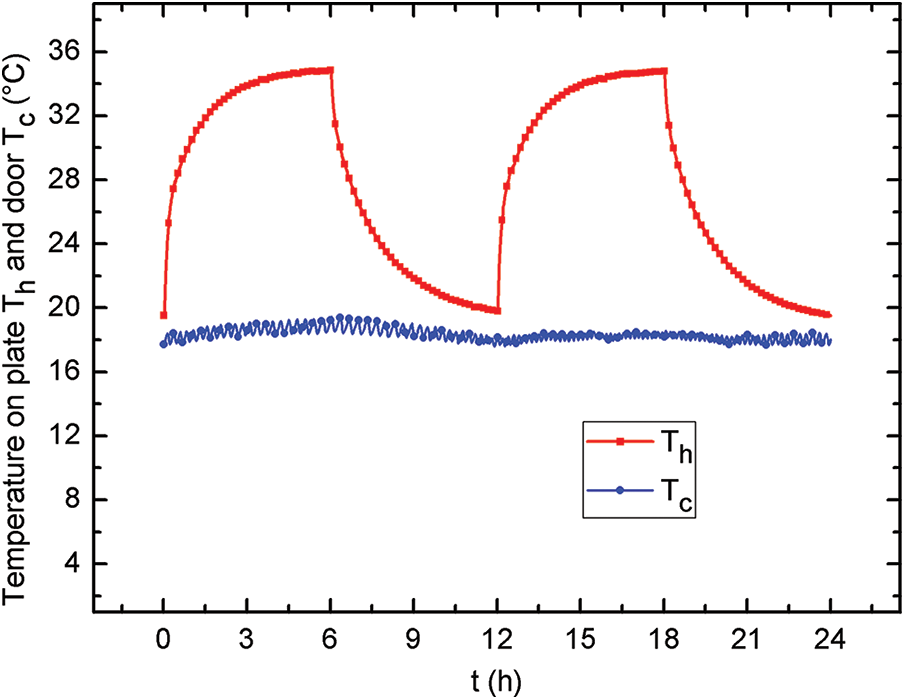

Fig. 5 shows the variation of imposed temperature of the plate in which the set point temperature is kept constant at

Figure 5: Time evolution of imposed temperatures

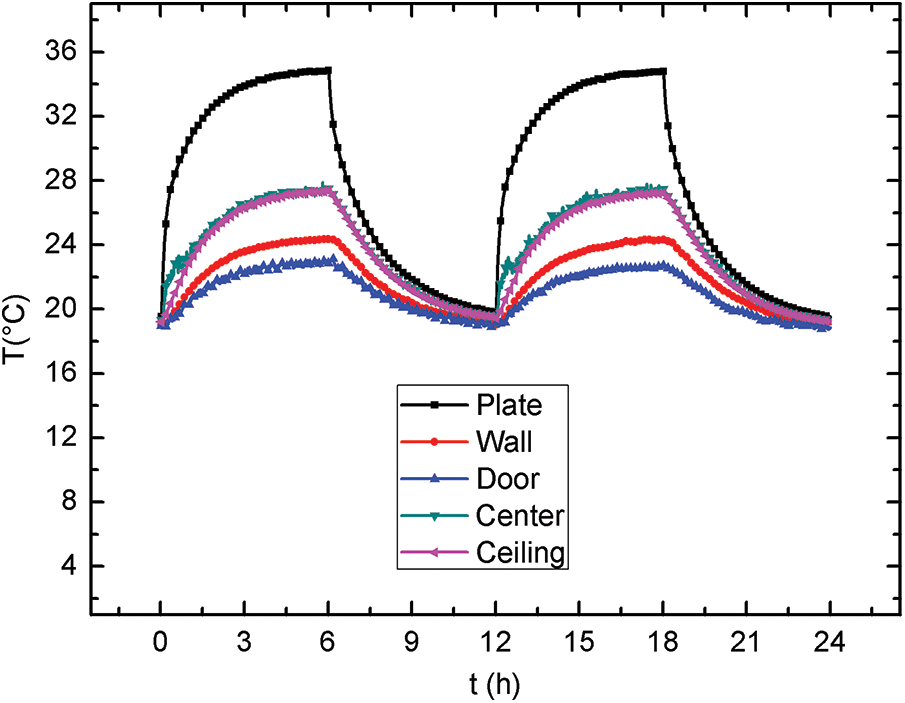

The time evolution of the measured temperature of the plate, door, ceiling, center and wall are shown in Fig. 6 for two heating cycles. These curves show that during the heating period, the temperature curves behave in the same way. These increase to a maximum when the heat source is switched on and then decrease to a minimum when the heat source is turned off. We also find that the coldest wall is at the glass door. Its maximum temperature remains not higher than

Figure 6: Time evolution of temperatures at different positions

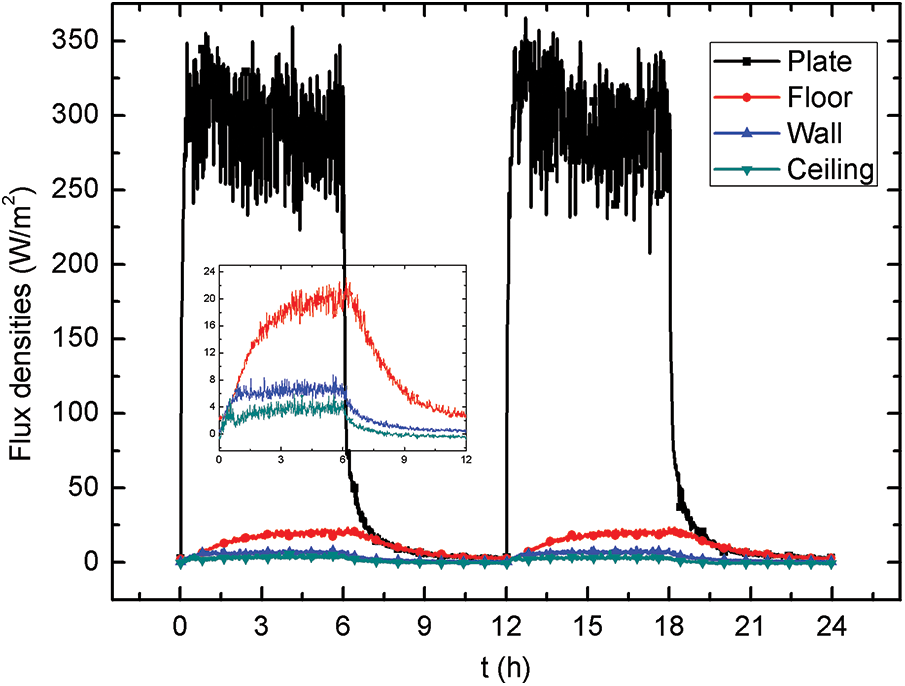

Figure 7: Time evolution of heat flux densities at different faces

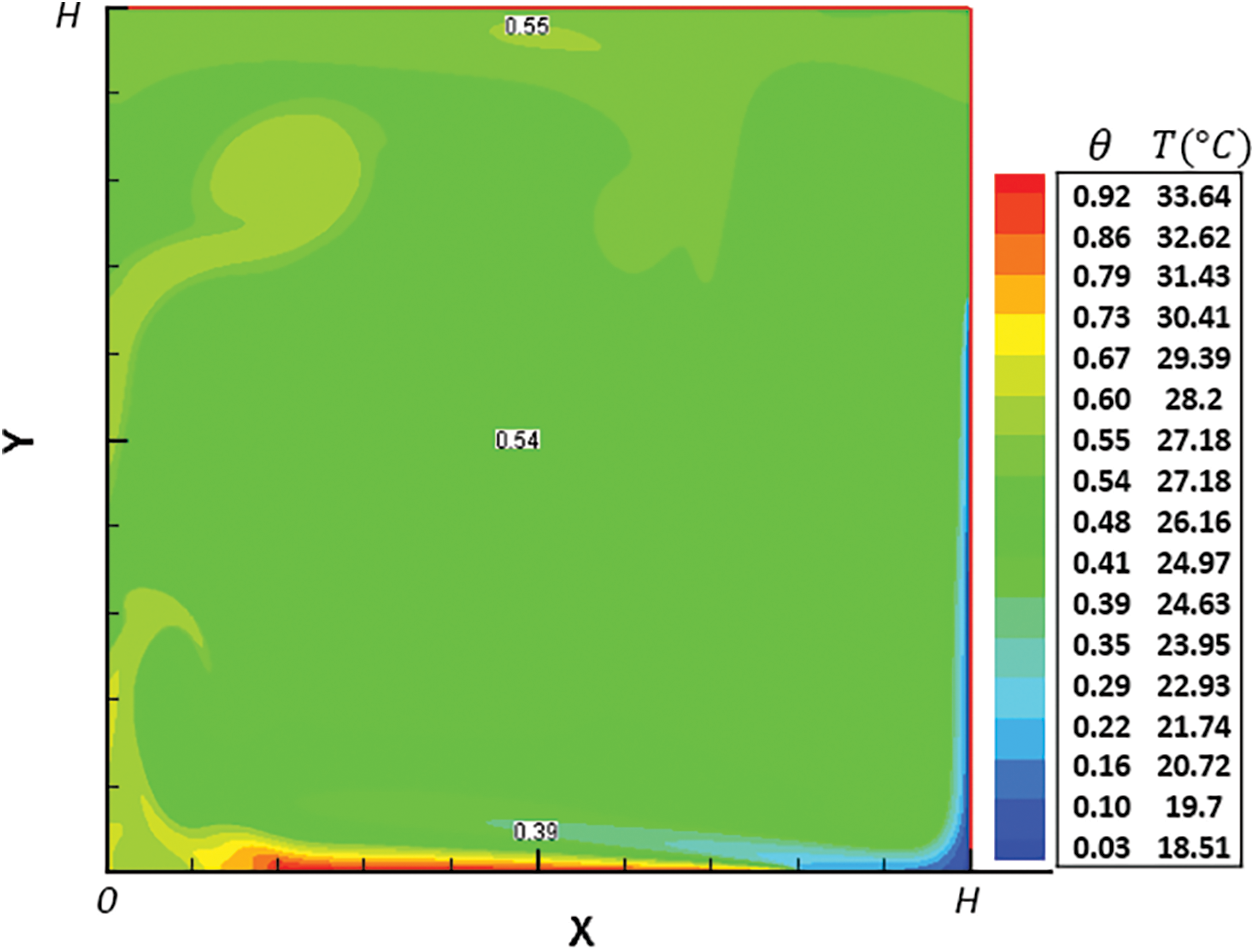

Figure 8: Thermal field structure in

We specify here that at the level of the floor, there is an iron plate placed in the center of the floor (Fig. 1). For these, we have access to two densities of flow: the first through the wooden part and the other through the hot metal plate. This last flux density will not be studied in time because its average value is negligible. However, the heat flux density at the center of the plate will be considered.

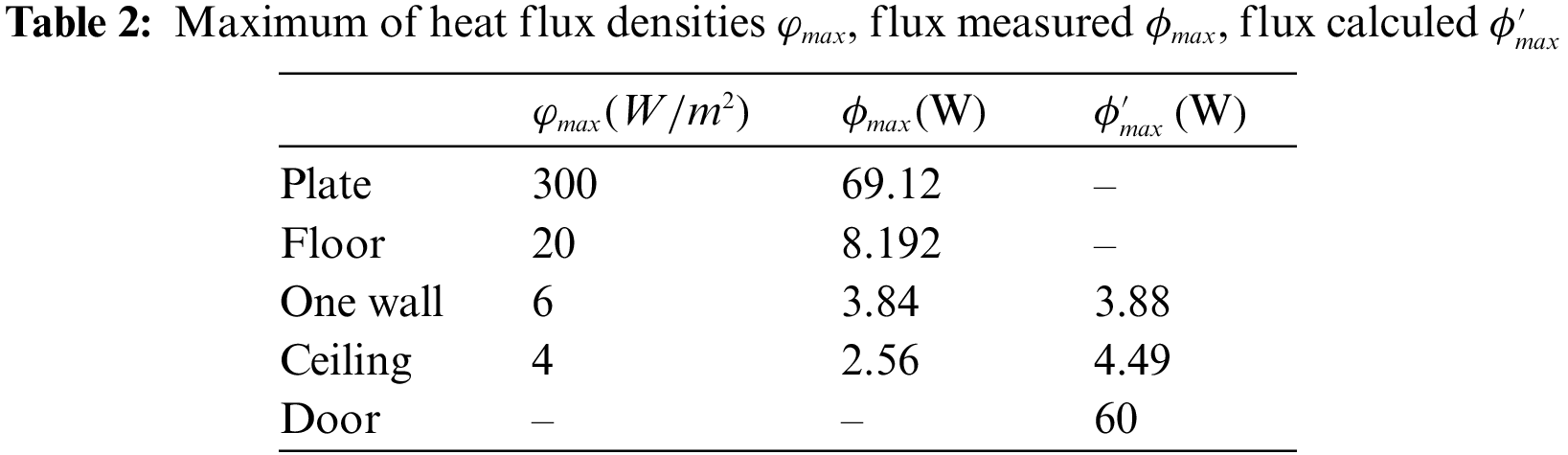

The heat flux densities measured in the center of the surface of the plate, the floor, the wall and the ceiling are shown in Fig. 7. Firstly, there is no recorded delay between the curves of flux, which explains the low thermal inertia of the walls. Note also that the heat flux density through the ceiling and the walls is very low compared to the plate. Negative values of this flux density that appear during the stopping phase of heating show that there is a slight return of heat stored in the ceiling towards the cavity. When the heat source is switched on, the curves of these heat flux densities increase from an initial value of almost zero to a maximum

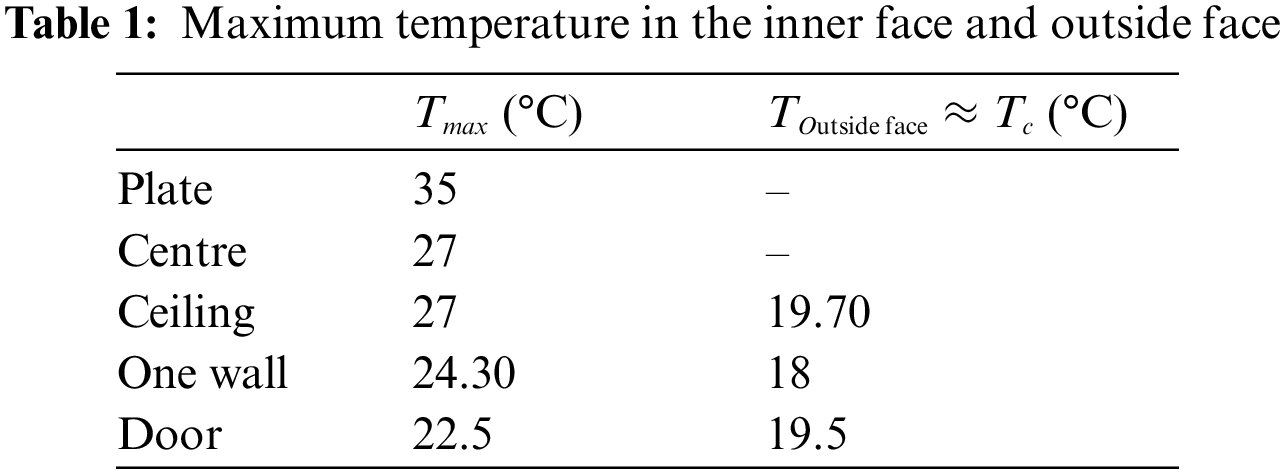

3.4 Analysis of the Temperature and Heat Flux

According to the analysis of the temperature and flux density measurements, we arrive at several verifications. The numerical study in the part below is based on these checks, especially in the permanent regime. One of the remarks that must be emphasized is that from one cycle to another. For each position, the temperature and the heat flux density return to their initial value (that of the start for the first time). This means that the cavity, including its envelope, is completely discharged and there is almost no heat storage effect going from one cycle to another. These are the problems related to the low thermal inertia of the envelope. At the permanent regime,

The temperature of the interior and exterior faces was measured to calculate the heat flux. This latter is measured directly considering the heat flux densities measured in some faces. But in certain faces, it is calculated by the following expression

3.5 Comparison between Experimental and Numerical Results

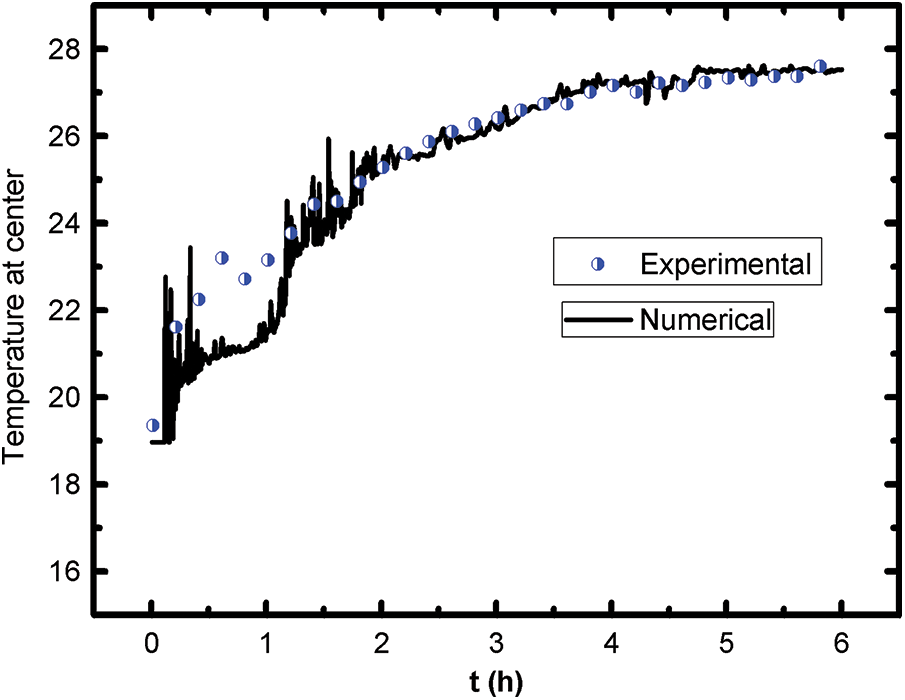

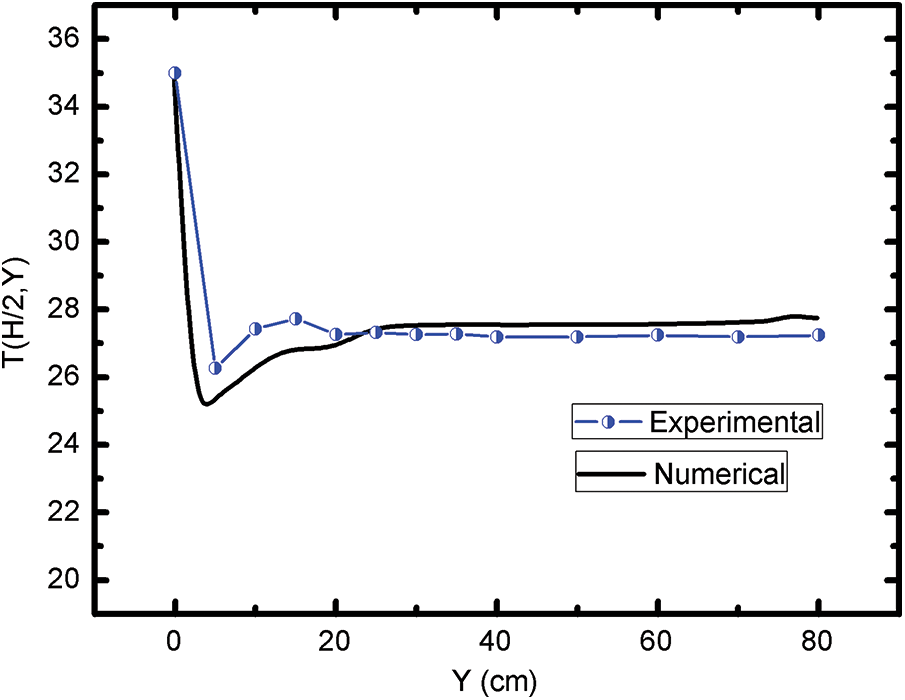

The comparison between the experimental and numerical results is presented in terms of temporal variation of the temperatures at the center of the cavity and along the vertical median axis for

Figure 9: Time evolution of temperature at center of cavity

Figure 10: Temperature profile along the vertical center ligne

In the present paper, we executed both an experimental and numerical analysis of convective heat transfer within a cubic test model. The description of the studied cavity, as well as the construction materials and measuring equipment, was detailed at the beginning of the paper. We also tested the validity of temperature and heat flux measurements by performing tests to calibrate thermocouples and flux meters. In the second step, we conducted a numerical study in two dimensions (

-In heating cycles, temperature and heat flux densities on different positions/faces increase with time, but in cooling cycles, temperature and heat flux densities are decreased.

-In the test local, the cold part is the door, and the hot part is at the plate.

-The heat flux measured

-A large part of the flow entered from the plate is lost through the door.

-In the upper half of the test local, the temperature values are almost identical. The temperature curves in the center and in the inner face of the ceiling are practically confused. This coincidence is also justified by the temperature field presented by the lines isotherms.

-The evolution of the temperature at the center and the temperature profile along the vertical axis passing through the center found by the numerical study and the experimental study were compared and interpreted during one heating cycle. The results obtained show good agreement with a difference that does not exceed

Finally, this computational investigation was undertaken with the aim of creating and confirming a proprietary code utilizing the lattice Boltzmann method (LBM). This code facilitates the treatment of heat transfer within building simulations, as well as the analysis of natural or mixed convection flows within intricate geometries. It caters to both laminar and turbulent regimes and accommodates both 2D and 3D configurations.

Acknowledgement: The authors would like to thank the National Center for Scientific and Technical Research (CNRST) for access to computing machines.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Noureddine Abouricha, Ayoub Gounni and Mustapha El Alami. The first draft of the manuscript was written by Noureddine ABOURICHA and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Availability of Data and Materials: There is no unavailable data in this study.

Conflicts of Interest: The authors have no competing interests to declare that are relevant to the content of this article.

References

1. Kuznik, F., David, D., Johannes, K., Roux, J. J. (2011). A review on phase change materials integrated in building walls. Renewable and Sustainable Energy Reviews, 15(1), 379–391. [Google Scholar]

2. Jin, X., Medina, M. A., Zhang, X. (2013). On the importance of the location of PCMs in building walls for enhanced thermal performance. Applied Energy, 106, 72–78. [Google Scholar]

3. Mohammed, M. A., Derea, A. T., Lafta, M. Y., Ali, O. M., Alomar, O. R. (2023). Effect of nanomaterials addition to phase change materials on heat transfer in solar panels under Iraqi atmospheric conditions. Frontiers in Heat and Mass Transfer, 21, 215–226. [Google Scholar]

4. Gendelis, S., Jakovičs, A., Ratnieks, J. (2017). Thermal comfort condition assessment in test buildings with different heating/cooling systems and wall envelopes. Energy Procedia, 132, 153–158. [Google Scholar]

5. Rashid, Y., Alnaimat, F., Mathew, B. (2018). Energy performance assessment of waste materials for buildings in extreme cold and hot conditions. Energies, 11(11), 3131. [Google Scholar]

6. Shaikh, U. I., Sur, A., Roy, A. (2023). Performance analysis of an energy efficient pcm-based room cooling system. Frontiers in Heat and Mass Transfer, 20, 1–10. https://doi.org/10.5098/hmt.20.28 [Google Scholar] [CrossRef]

7. Sonnick, S., Erlbeck, L., Schlachter, K., Strischakov, J., Mai, T. et al. (2018). Temperature stabilization using salt hydrate storage system to achieve thermal comfort in prefabricated wooden houses. Energy and Buildings, 164, 48–60. [Google Scholar]

8. Wang, X., Li, W., Luo, Z., Wang, K., Shah, S. P. (2022). A critical review on phase change materials (PCM) for sustainable and energy efficient building: Design, characteristic, performance and application. Energy and Buildings, 260, 111923. [Google Scholar]

9. Østergaard, D. S., Svendsen, S. (2016). Case study of low-temperature heating in an existing single-family house—A test of methods for simulation of heating system temperatures. Energy and Buildings, 126, 535–544. [Google Scholar]

10. Khoukhi, M. (2018). The combined effect of heat and moisture transfer dependent thermal conductivity of polystyrene insulation material: Impact on building energy performance. Energy and Buildings, 169, 228–235. [Google Scholar]

11. Kürekci, N., Özcan, O. (2012). An experimental and numerical study of laminar natural convection in a differentially-heated cubical enclosure. ISI Bilimi VE Teknigi Dergisi-Journal of Thermal Science and Technology, 32, 1–8. [Google Scholar]

12. Piña-Ortiz, A., Hinojosa, J. F., Navarro, J. M. A., Xamán, J. (2018). Experimental and numerical study of turbulent mixed convection in a cavity with an internal heat source. Journal of Building Physics, 42(2), 142–172. [Google Scholar]

13. Troppová, E., Tippner, J., Švehlík, M. (2018). Numerical and experimental study of conjugate heat transfer in a horizontal air cavity. Building Simulation, 11(2), 339–346. https://doi.org/10.1007/s12273-017-0403-y [Google Scholar] [CrossRef]

14. Zheng, Q., Wang, H., Ke, Y. (2023). Prediction of the local and total thermal insulations of a bedding system based on the 3D virtual simulation technology. In: Building simulation, vol. 16, no. 8, pp. 1467–1480. Beijing, China: Tsinghua University Press. [Google Scholar]

15. Wei, Y., Dou, H. S., Wang, Z., Qian, Y., Yan, W. (2016). Simulations of natural convection heat transfer in an enclosure at different Rayleigh number using lattice Boltzmann method. Computers & Fluids, 124, 30–38. [Google Scholar]

16. Crouse, B., Krafczyk, M., Kühner, S., Rank, E., van Treeck, C. (2002). Indoor air flow analysis based on lattice Boltzmann methods. Energy and Buildings, 34(9), 941–949. [Google Scholar]

17. Abouricha, N., Ennawaoui, C., Alami, M. E. (2023). Amplitude and period effect on heat transfer in an enclosure with sinusoidal heating from below using lattice Boltzmann method. Frontiers in Heat and Mass Transfer, 21(1), 523–537. https://doi.org/10.32604/fhmt.2023.045914 [Google Scholar] [CrossRef]

18. Freile, R., Tano, M. E., Ragusa, J. C. (2024). CFD assessment of RANS turbulence modeling for solidification in internal flows against experiments and higher fidelity LBM-LES phase change model. Annals of Nuclear Energy, 197, 110275. [Google Scholar]

19. Abbasi, A., Safavinejad, A., Lakhi, M. (2023). Numerical study of surface radiation-natural convection entropy generation in a 2D cavity using the LBM. International Communications in Heat and Mass Transfer, 149, 107141. [Google Scholar]

20. Hu, M., Zhang, Z., Liu, M. (2023). Transient particle transport prediction based on lattice Boltzmann method-based large eddy simulation and Markov chain model. In: Building simulation, pp. 1–14. Beijing, China: Tsinghua University Press. [Google Scholar]

21. Borquist, E., Thapa, S., Weiss, L. (2016). Experimental and lattice Boltzmann simulated operation of a copper micro-channel heat exchanger. Energy Conversion and Management, 117, 171–184. [Google Scholar]

22. Zhou, B., Wu, X., Chen, L., Fan, J. Q., Zhu, L. (2021). Modeling the performance of air filters for cleanrooms using lattice Boltzmann method. In: Building simulation, vol. 14, pp. 317–324. Beijing, China: Tsinghua University Press. https://doi.org/10.1007/s12273-020-0660-z [Google Scholar] [CrossRef]

23. He, Y. L., Liu, Q., Li, Q., Tao, W. Q. (2019). Lattice Boltzmann methods for single-phase and solid-liquid phase-change heat transfer in porous media: A review. International Journal of Heat and Mass Transfer, 129, 160–197. [Google Scholar]

24. Nee, A. (2020). Hybrid lattice Boltzmann––Finite difference formulation for combined heat transfer problems by 3D natural convection and surface thermal radiation. International Journal of Mechanical Sciences, 173, 105447. [Google Scholar]

25. Liu, Z., Mu, Z., Wu, H. (2019). A new curved boundary treatment for LBM modeling of thermal gaseous microflow in the slip regime. Microfluidics and Nanofluidics, 23, 1–12. [Google Scholar]

26. Tao, S., Xu, A., He, Q., Chen, B., Qin, F. G. (2020). A curved lattice Boltzmann boundary scheme for thermal convective flows with Neumann boundary condition. International Journal of Heat and Mass Transfer, 150, 119345. [Google Scholar]

27. Tao, S., Chen, B., Xiao, H., Huang, S. (2019). Lattice Boltzmann simulation of thermal flows with complex geometry using a single-node curved boundary condition. International Journal of Thermal Sciences, 146, 106112. [Google Scholar]

28. D'Orazio, A., Karimipour, A. (2019). A useful case study to develop lattice Boltzmann method performance: Gravity effects on slip velocity and temperature profiles of an air flow inside a microchannel under a constant heat flux boundary condition. International Journal of Heat and Mass Transfer, 136, 1017–1029. [Google Scholar]

29. Zhao, Z., Wen, M., Li, W. (2021). A coupled gas-kinetic BGK scheme for the finite volume lattice Boltzmann method for nearly incompressible thermal flows. International Journal of Heat and Mass Transfer, 164, 120584. [Google Scholar]

30. Huang, Y., Xu, X., Zhang, S., Wu, C., Liu, C. et al. (2023). Thermodynamic characteristics of gas-liquid phase change investigated by lattice Boltzmann method. Applied Thermal Engineering, 227, 120367. [Google Scholar]

31. Lin, Y., Yang, C., Zhang, W., Fukumoto, K., Saito, Y. et al. (2023). Estimation of effective thermal conductivity in open-cell foam with hierarchical pore structure using lattice Boltzmann method. Applied Thermal Engineering, 218, 119314. [Google Scholar]

32. Wang, Z., Xie, K., Zhang, Y., Hou, X., Zhao, W. et al. (2023). A multiphase model developed for mesoscopic heat and mass transfer in thawing frozen soil based on lattice Boltzmann method. Applied Thermal Engineering, 229, 120580. [Google Scholar]

33. Abouricha, N., El Alami, M., Souhar, K. (2020). Lattice Boltzmann modeling of convective flows in a large-scale cavity heated from below by two imposed temperature profiles. International Journal of Numerical Methods for Heat & Fluid Flow, 30(5), 2759–2779. [Google Scholar]

34. Abouricha, N., El Alami, M., Gounni, A. (2019). Lattice Boltzmann modeling of natural convection in a large-scale cavity heated from below by a centered source. Journal of Heat Transfer, 141(6), 62501. [Google Scholar]

35. Kao, P. H., Yang, R. J. (2007). Simulating oscillatory flows in Rayleigh-Benard convection using the lattice Boltzmann method. International Journal of Heat and Mass Transfer, 50(17–18), 3315–3328. [Google Scholar]

36. Succi, S. (2001). The lattice Boltzmann equation: for fluid dynamics and beyond. UK: Oxford University Press. [Google Scholar]

37. He, X., Chen, S., Doolen, G. D. (1998). A novel thermal model for the lattice Boltzmann method in incompressible limit. Journal of Computational Physics, 146(1), 282–300. [Google Scholar]

38. Kefayati, G. R. (2013). Lattice Boltzmann simulation of MHD natural convection in a nanofluid-filled cavity with sinusoidal temperature distribution. Powder Technology, 243, 171–183. [Google Scholar]

39. Gaedtke, M., Wachter, S., Kunkel, S., Sonnick, S., Rädle, M. et al. (2020). Numerical study on the application of vacuum insulation panels and a latent heat storage for refrigerated vehicles with a large eddy lattice Boltzmann method. Heat and Mass Transfer, 56, 1189–1201. [Google Scholar]

40. Mellah, S., Cheikh, N. B., Beya, B. B., Lili, T. (2011). Comparaison 2D/3D du transfert de chaleur au sein d’une enceinte carrée/cubique remplie d’air. CFM 2011-20ème Congrès Français de Mécanique, Besançon, France. [Google Scholar]

41. Ampofo, F., Karayiannis, T. G. (2003). Experimental benchmark data for turbulent natural convection in an air filled square cavity. International Journal of Heat and Mass Transfer, 46(19), 3551–3572. [Google Scholar]

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools