Open Access

Open Access

ARTICLE

Optimizing Two-Phase Flow Heat Transfer: DCS Hybrid Modeling and Automation in Coal-Fired Power Plant Boilers

1 Technical Supervision Center, Huadian Electric Power Research Institute Co., Ltd., Hangzhou, 310030, China

2 School of Mechanical Engineering, Southwest Jiaotong University, Chengdu, 611756, China

3 School of Management Science & Real Estate, Chongqing University, Chongqing, 400044, China

* Corresponding Authors: Caijiang Lu. Email: ; Pan Shi. Email:

(This article belongs to the Special Issue: Two-phase flow heat and mass transfer in advanced energy systems)

Frontiers in Heat and Mass Transfer 2024, 22(2), 615-631. https://doi.org/10.32604/fhmt.2024.048333

Received 05 December 2023; Accepted 18 January 2024; Issue published 20 May 2024

Abstract

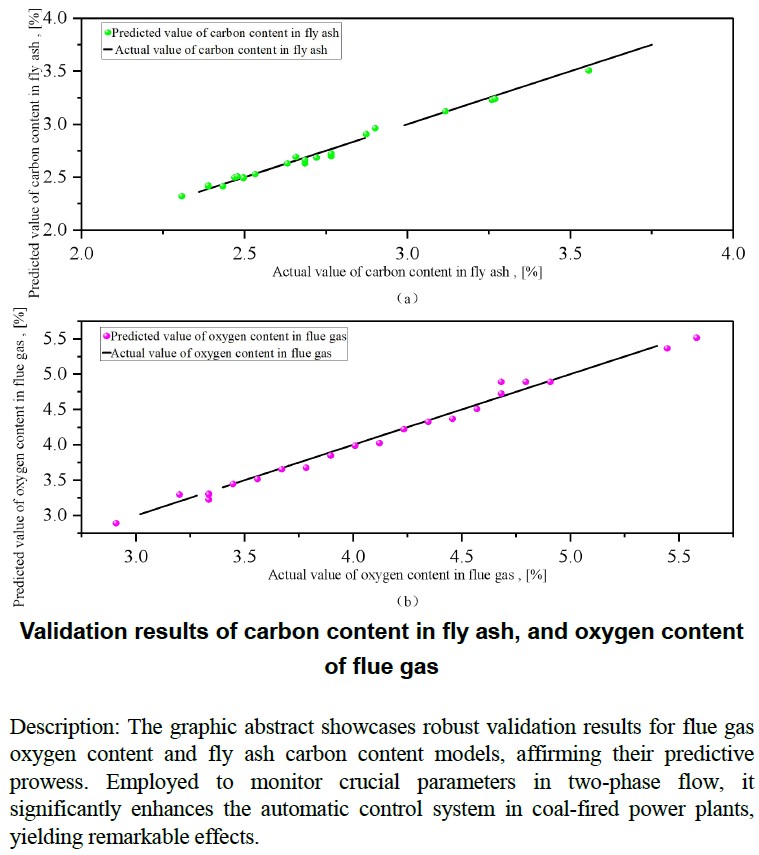

In response to escalating challenges in energy conservation and emission reduction, this study delves into the complexities of heat transfer in two-phase flows and adjustments to combustion processes within coal-fired boilers. Utilizing a fusion of hybrid modeling and automation technologies, we develop soft measurement models for key combustion parameters, such as the net calorific value of coal, flue gas oxygen content, and fly ash carbon content, within the Distributed Control System (DCS). Validated with performance test data, these models exhibit controlled root mean square error (RMSE) and maximum absolute error (MAXE) values, both within the range of 0.203. Integrated into their respective automatic control systems, these models optimize two-phase flow heat transfer, fine-tune combustion conditions, and mitigate incomplete combustion. Furthermore, this paper conducts an in-depth exploration of the generation mechanism of nitrogen oxides (NO) and low oxygen emission reduction technology in coal-fired boilers, demonstrating a substantial reduction in furnace exit NO generation by 30% to 40% and the power supply coal consumption decreased by 1.62 g/(kW h). The research outcomes highlight the model’s rapid responsiveness, enabling prompt reflection of transient variations in various economic indicator parameters. This provides a more effective means for real-time monitoring of crucial variables in coal-fired boilers and facilitates timely combustion adjustments, underscoring notable achievements in boiler combustion. The research not only provides valuable and practical insights into the intricacies of two-phase flow heat transfer and heat exchange but also establishes a pioneering methodology for tackling industry challenges.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools