Open Access

Open Access

ARTICLE

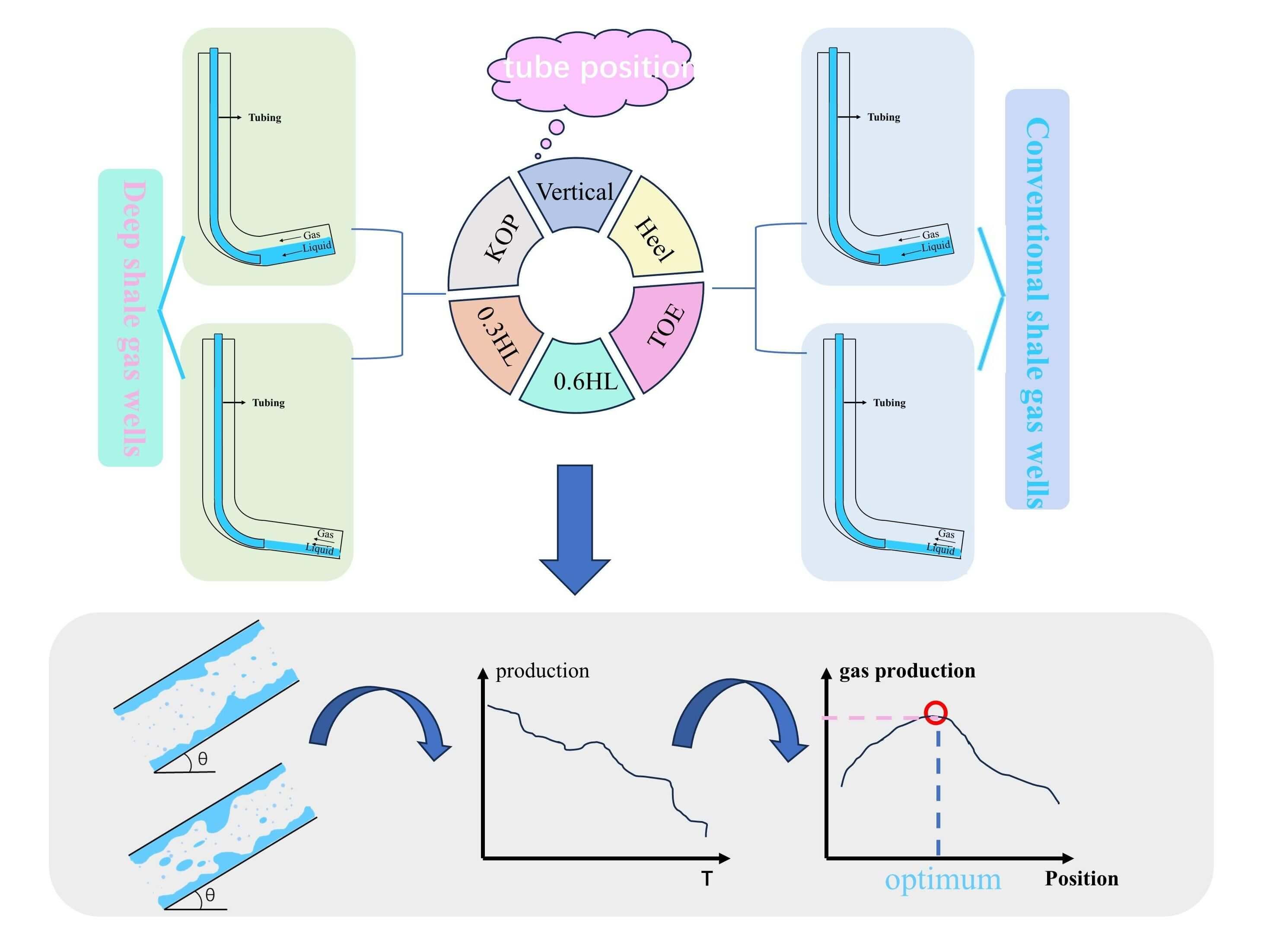

Analysis of Fluid Flow and Optimization of Tubing Depth in Deep Shale Gas Wells

School of Petroleum Engineering, Yangtze University, Wuhan, 430100, China

* Corresponding Author: Jie Liu. Email:

Fluid Dynamics & Materials Processing 2025, 21(3), 529-542. https://doi.org/10.32604/fdmp.2024.057535

Received 20 August 2024; Accepted 28 November 2024; Issue published 01 April 2025

Abstract

As shale gas technology has advanced, the horizontal well fracturing model has seen widespread use, leading to substantial improvements in industrial gas output from shale gas wells. Nevertheless, a swift decline in the productivity of individual wells remains a challenge that must be addressed throughout the development process. In this study, gas wells with two different wellbore trajectory structures are considered, and the OLGA software is exploited to perform transient calculations on various tubing depth models. The results can be articulated as follows. In terms of flow patterns: for the deep well A1 (upward-buckled), slug flow occurs in the Kick-off Point position and above; for the deep well B1 (downward-inclined), slug flow only occurs in the horizontal section. Wells with downward-inclined horizontal sections are more prone to liquid accumulation issues. In terms of comparison to conventional wells, it is shown that deep shale gas wells have longer normal production durations and experience liquid accumulation later than conventional wells. With regard to optimal tubing placement: for well A1 (upward-buckled), it is recommended to place tubing at the Kick-off Point position; for well B1 (downward-inclined), it is recommended to place tubing at the lower heel of the horizontal section. Finally, in terms of production performance: well A1 (upward-buckled) outperforms well B1 (downward-inclined) in terms of production and fluid accumulation. In particular, the deep well A1 is 1.94 times more productive and 1.3 times longer to produce than conventional wells. Deep well B1 is 1.87 times more productive and 1.34 times longer than conventional wells.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools