Open Access

Open Access

ARTICLE

Oscillatory Dynamics of a Spherical Solid in a Liquid in an Axisymmetric Variable Cross Section Channel

Laboratory of Vibrational Hydromechanics, Perm State Humanitarian Pedagogical University, Perm, 614990, Russia

* Corresponding Author: Ivan Karpunin. Email:

(This article belongs to the Special Issue: Advanced Problems in Fluid Mechanics)

Fluid Dynamics & Materials Processing 2024, 20(6), 1219-1232. https://doi.org/10.32604/fdmp.2024.051062

Received 26 February 2024; Accepted 29 April 2024; Issue published 27 June 2024

Abstract

The dynamics of a solid spherical body in an oscillating liquid flow in a vertical axisymmetric channel of variable cross section is experimentally studied. It is shown that the oscillating liquid leads to the generation of intense averaged flows in each of the channel segments. The intensity and direction of these flows depend on the dimensionless oscillating frequency. In the region of studied frequencies, the dynamics of the considered body is examined when the primary vortices emerging in the flow occupy the whole region in each segment. For a fixed frequency, an increase in the oscillation amplitude leads to a phase-inclusion holding effect, i.e., the body occupies a quasi-stationary position in one of the cells of the vertical channel, while oscillating around its average position. It is also shown that the oscillating motion of a liquid column generates an averaged force acting on the body, the magnitude of which depends on the properties of the body and its position in the channel. The quasi-stationary position is determined by the relative density and size of the body, as well as the dimensionless frequency. The behavior of the body as a function of the amplitude and frequency of fluid oscillation and relative size is discussed in detail. Such findings may be used in the future to control the position of a phase inclusion and/or to strengthen mass transfer effects in a channel of variable cross section by means of fluid oscillations.Keywords

Nomenclature

| | Cuvette length (mm) |

| | Radial dimension (mm) |

| | Coordinate (mm) |

| | Fluid oscillation amplitude (mm) |

| | Solid body diametral size (mm) |

| | Visualizer particles diametral size (µm) |

| | Time (s) |

| | Acceleration due to gravity (m/s2) |

| | Solid body oscillation amplitude (mm) |

| | Fluid oscillation frequency (Hz) |

| Greek Symbols | |

| | Spatial period (mm) |

| | Solid body density (g/cm3) |

| | Liquid density (g/cm3) |

| | Relative density (–) |

| | Kinematic liquid viscosity (cSt) |

| | Visualizer particles density (g/cm3) |

| | Stokes layer thickness (mm) |

| | Dimensionless frequency (–) |

| Abbreviations | |

| POM | Polyoxymethylene |

| PIV | Particle Image Velocimetry |

In the field of developing and studying energy-efficient technologies, there is a need to develop new methods for enhancing mass exchange processes between different types of phase inclusions and their environment. The study of flows excited by fluid oscillations in channels of variable cross section or wavy (sinusoidal) profile is relevant for controlling heat and mass transfer in porous media [1–4]. A variable cross section channel, also known as a variable shape channel, is a hydraulic system designed to efficiently transport liquid, gas or other media. The main characteristic of this type of channel is the gradual variation of its cross section along its length. This allows optimum flow conditions to be achieved, including control of velocity, pressure and other hydrodynamic parameters. This design improves the efficiency of liquid or gas transport. The internal flows become more laminar and flow resistance is reduced by gradually changing the shape of the channel. In addition, the variable cross section channel has a wide range of applications. It can be used in various industries, including power generation, chemical, oil and gas, and hydraulic engineering. Due to its flexibility and adaptability, such a system can be successfully applied to solve a wide range of engineering problems.

The problem of bubble or agglomeration float-up in vertical straight columns is a common issue. Recent studies [5,6] have analyzed typical flow regimes in bubble columns. However, research has shown that channels with a curved shape are more effective in improving inclusion dynamics. The dynamics of homogeneous and heterogeneous hydrodynamic systems in flat and axisymmetric channels of variable cross section are widely studied. The object of study is often either a liquid flow or a gas phase inclusion in the liquid. The papers [7–10] examine the dynamics of gas phase inclusions in channels with varying cross-sections, both theoretically and experimentally. It is demonstrated that the shape of the channel significantly impacts the oscillations of the phase inclusion boundary, suggesting the potential for efficient mass transfer. Papers [11–14] provide a comprehensive literature review and detailed analysis of the method of intensifying fluid mixing processes through pulsations and vibrations in the presence of constant non-zero flow in the channel. The works described focus on the dynamics of hydrodynamic systems in channels with a fixed profile. However, it is worth noting that there are works that consider channels with a changing profile over time. Peristaltic pumping refers to the movement of fluid, particles or suspension in a tube caused by waves of contraction in the channel’s wall. These systems are of significant interest due to their practical applications in physiological and technological processes. The papers [15–17] examine the dynamics of solid particles in such a system and how the transport of the solid particle depends upon its diameter, frequency of peristaltic waves on the walls, Reynolds number and its initial placement in the channel. The intensification of mass transfer processes in channels with peristaltic wall dynamics and in models of porous media is a widely studied topic [18,19]. However, there is a lack of experimental consideration of the dynamics of inclusions, both deformable (liquid) and solid boundary, in oscillating fluid flow in channels of variable cross section. The literature lacks sufficient representation of theoretical and experimental studies on the dynamics of phase inclusions in an oscillating fluid flow with zero mean flow rate.

There are several methods for the generation of intense averaged flows. For example, intense fluid oscillations can be generated by rotational oscillations of the cavity [20] or by oscillations of the elastic cavity walls [21]. In both cases, fluid oscillations lead to averaged flows that can significantly intensify mass transfer in the system. In the region of medium and low frequencies, the generation of averaged flows is found, the intensity of which decreases with decreasing dimensionless vibration frequency. It is shown that at high dimensionless frequencies the experimental results are in agreement with theoretical estimates. In [22], the flow in a two-dimensional symmetric channel with wavy walls is studied experimentally with periodic variation of the fluid pumping as a function of the dimensionless frequency. It is found that the fluid oscillations lead to the excitation of the stationary flow in the form of a system of transverse waves. It is shown that, in the low-frequency limit (for viscous fluid fluctuations), they can be used to describe steady-state flows (and hence mass transfer phenomena) excited by fluid fluctuations in porous media, which are a system of interconnected pores–channels of different cross section. This modelling approach is fully applicable to axisymmetric channels with periodically varying radius. A channel of variable cross section is a system of interconnected pores that represent the gaps between the substance forming the ‘skeleton’ of the porous medium [23,24]. In the given formulation and geometry, Darcy’s law is applicable. The results of previous studies [25] have shown that the structures and intensity of averaged flows in an axisymmetric channel of variable cross section under oscillating fluid flow in the channel excite the averaged flow in the form of a system of toroidal vortex flows. The direction of the flows and their flow rate are determined by the pulsating Reynolds number and the dimensionless frequency. These dimensionless complexes are determined by the values of the characteristic amplitudes of the fluid vibrations, the kinematic viscosity of the fluid and the cavity size.

In the present work, the problem of the dynamics of a spherical body in an oscillating fluid flow in a channel of variable cross section, depending on the amplitude and frequency of the oscillations of the fluid column, is considered experimentally. The oscillating motion of the liquid column has an effect on a heavy body moving freely in a vertical channel. The forces acting on a body immersed in a fluid, along with the averaged vibrational forces and flows, combine to produce various effects. This study considers a spherical body as a model of a particle that can oscillate in a fluid, and a channel of variable cross section as a model of a porous medium. The practical applicability of this study is in the field of vibratory hydromechanics, heat and mass transfer, phase transitions, and transfer processes, as well as in the development and design of equipment for these processes.

2 Experimental Setup and Methodology

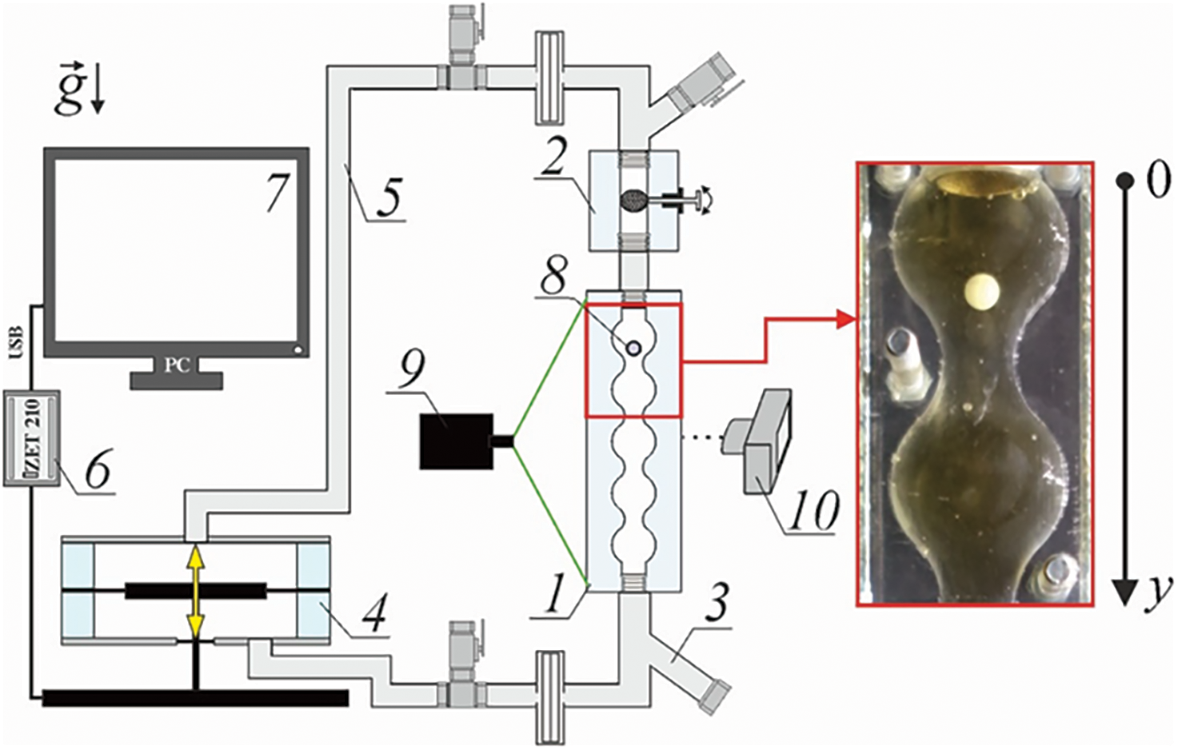

The experimental setup (Fig. 1) is a closed hydraulic circuit, which includes a system of periodic pumping of liquid and an experimental cuvette with technological units. Experimental cuvette 1 is a plexiglas parallelepiped with a length of

Figure 1: Scheme of the experimental setup (side view)

Pump 4 consists of two independent, immiscible circuits separated by an elastic membrane. Vibrations transmitted to the membrane by the vibration stand cause oscillations of the fluid in the hydraulic circuit 5. The pump based on the “push-pull” principle provides a harmonic change in the volume of liquid pumped in the closed hydraulic circuit according to the law

The phase inclusion 8 is a solid ball made of polyoxymethylene (POM) with a diameter of

In the experiments investigates both the dynamics of phase inclusion and the structure of flows excited by fluid and body oscillations in a channel of variable cross section. Plastic tracer particles of average size

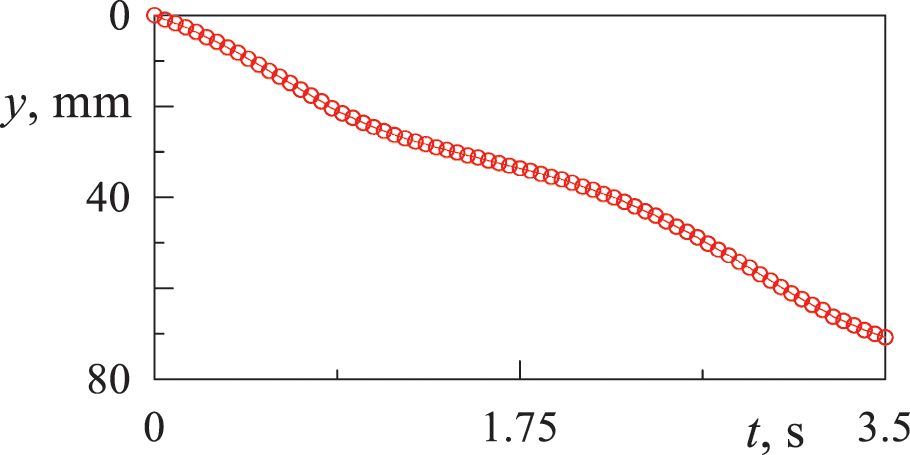

The dynamics of a spherical phase inclusion in an axisymmetric vertical channel of variable cross section in the absence of vibrations consists in moving along the channel in the gravity field. Fig. 2 shows the

Figure 2: Time dependence of the

When the fluid in the channel oscillates at a given frequency, the dynamics of the body depends on several physical phenomena: the generated fluid flow and the thickness of the Stokes boundary layer. The velocity of the fluid flows is significant because of the large amplitude of the oscillations. The viscous boundary layer

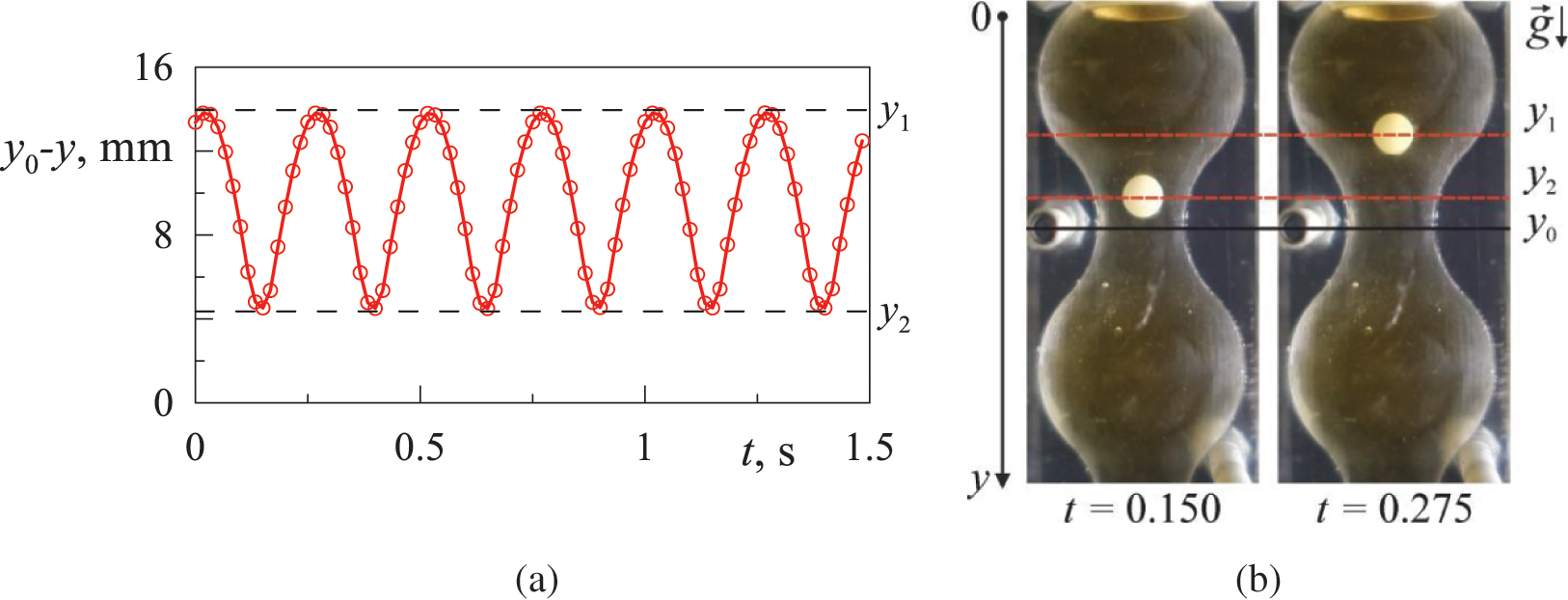

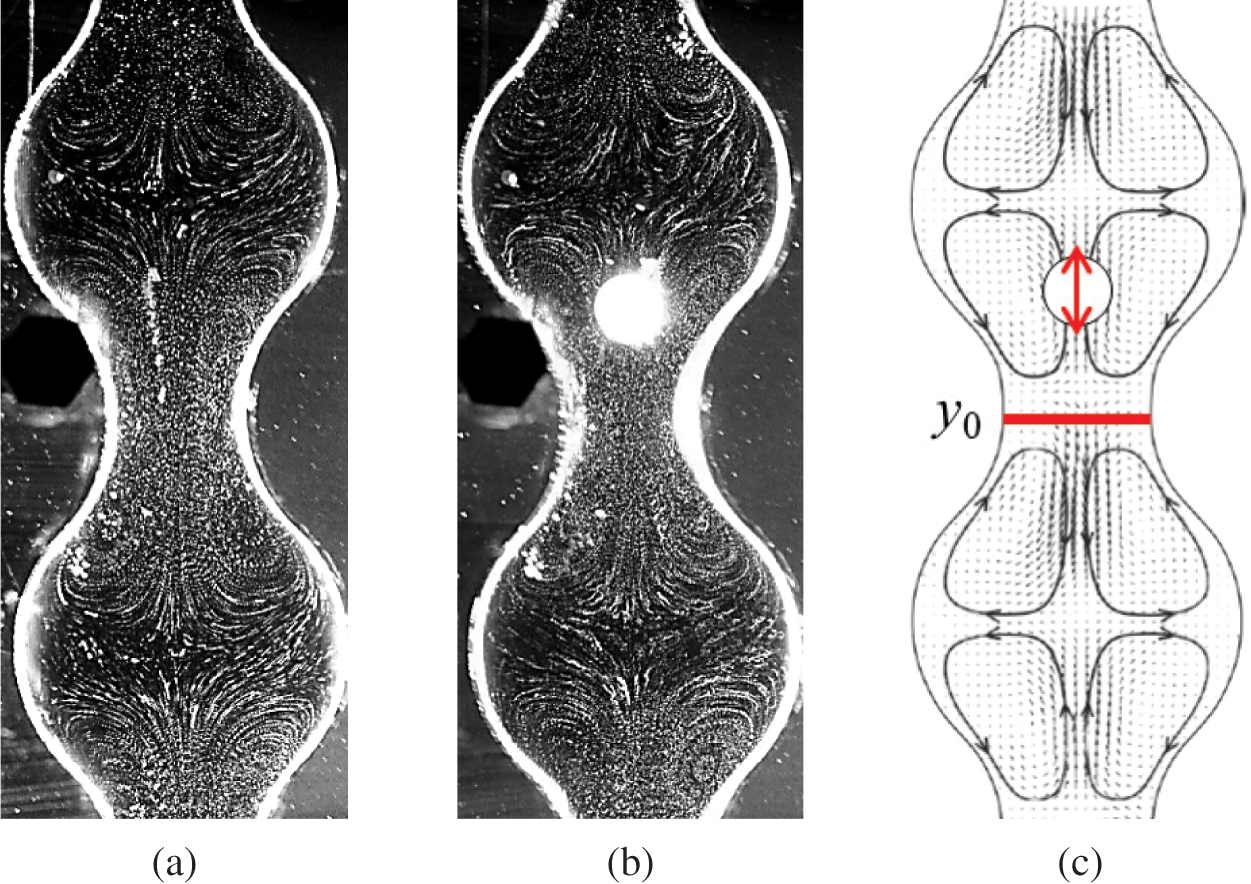

The body-holding effect is observed after a sufficient liquid velocity (amplitude of oscillation) is reached when the liquid oscillates in the variable cross section channel. In this case, the spherical phase inclusion “hangs” near the constriction of the channel (Fig. 3). The spherical body is held by the oscillating fluid flow and oscillates relative to its mean position (Fig. 3a) with the frequency of the oscillations of the fluid column. The thickness of the layer, as was mentioned early, is significant, and when the body is near the narrowing of the channel, this contributes to the observed body-holding effect and prevents the body from passing into the next pore of the channel. In Fig. 3b the values obtained in the experiment are marked: the reference point of the inclusion position, the coordinate

Figure 3: Oscillatory dynamics of a phase inclusion

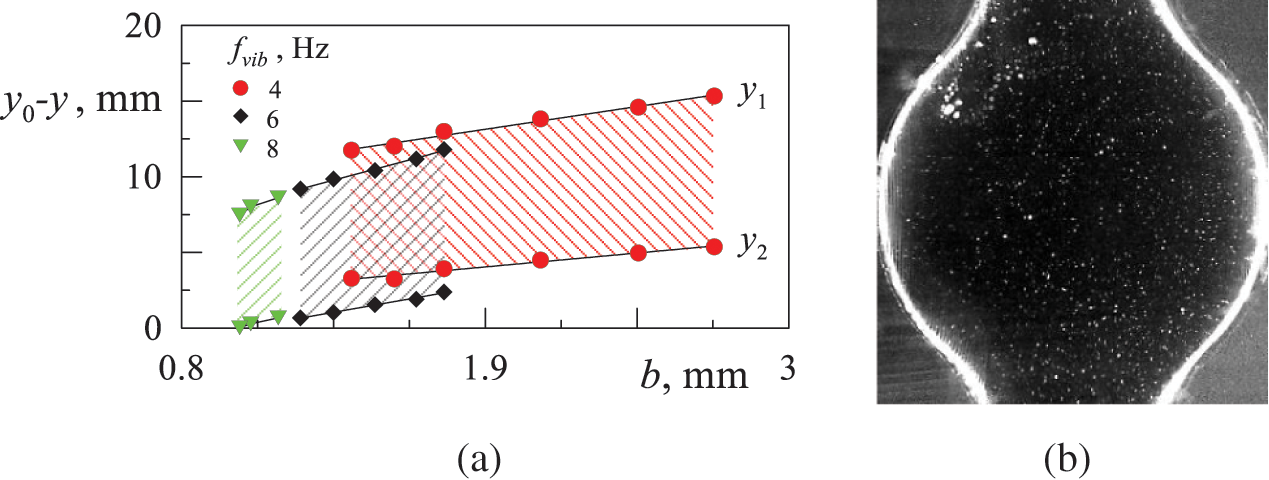

Fig. 4a shows the dependence of the

Figure 4: Dependence of the y-coordinate of the centre of mass of a solid spherical body dS = 6 mm on its mean position with respect to the zero coordinate y0 (a) with vibration frequency. Photograph of a channel segment with visualizer particles suspended in the fluid (b)

The amplitude of the oscillations of the fluid at a given frequency is determined by the spread of the visualizer particles suspended in the fluid in the wide part of the channel (Fig. 4b). The visualizer particles are visible in the plane of the laser sheet cutting the channel along its axis. From the graph it is possible to determine the amplitude of the body oscillation, the dependence of the coordinate of the average position of the body on

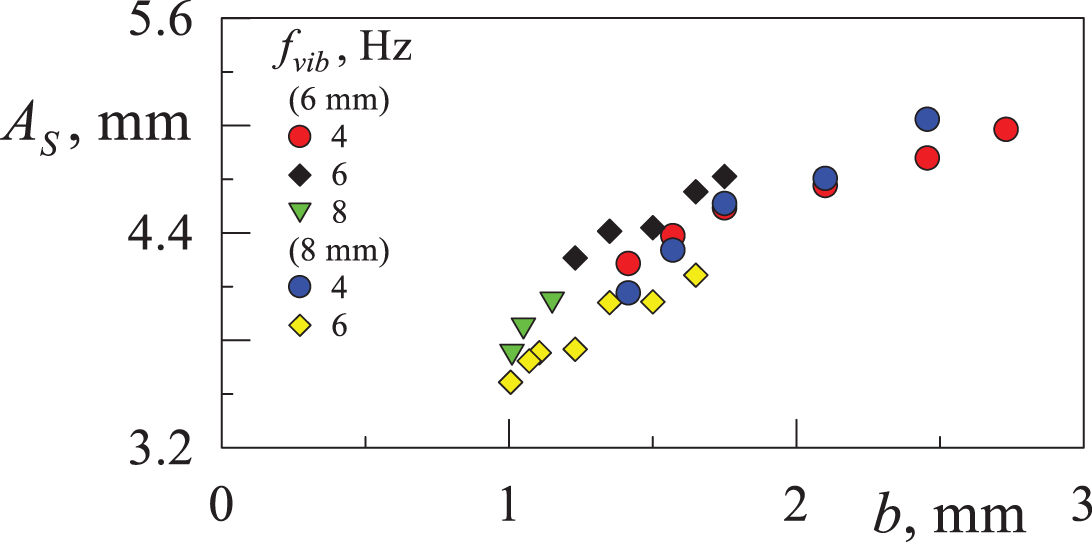

The amplitude of a body’s oscillations relative to its mean position characterizes its dynamics. With a gradual increase in the amplitude of the fluid oscillations

Figure 5: Dependence of the amplitude of the phase inclusion oscillation on the amplitude of the fluid oscillation at different frequencies of the fluid column oscillation

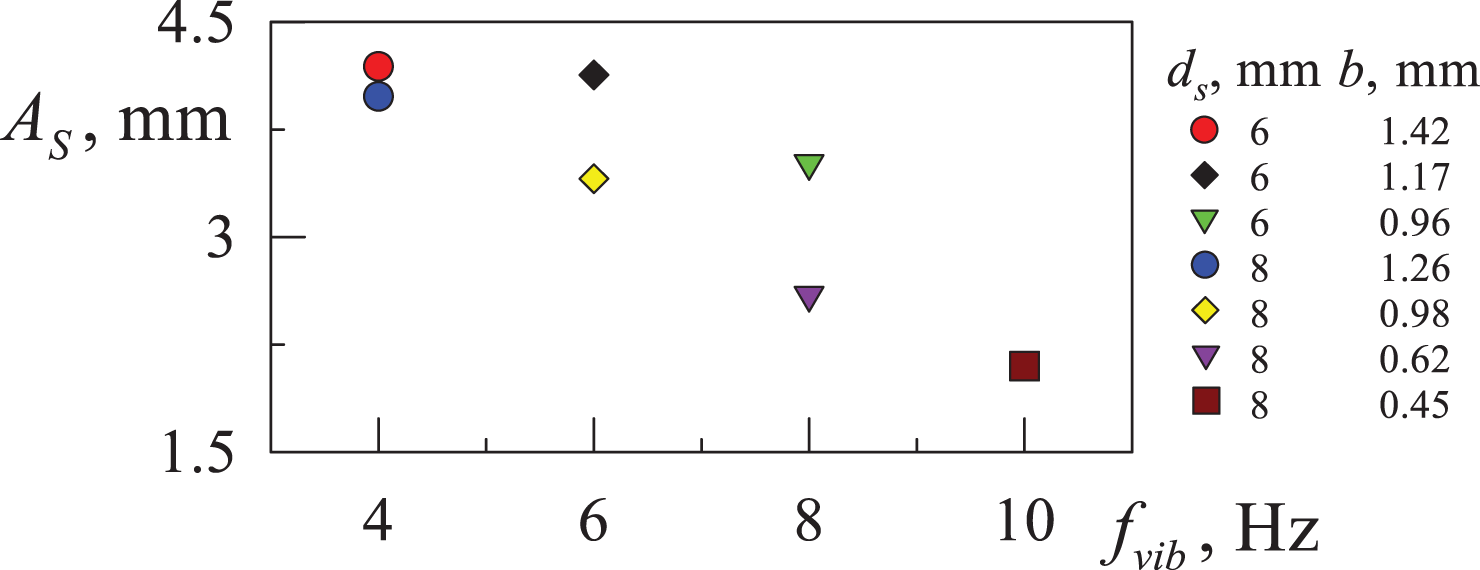

The threshold effect of holding a heavy phase inclusion relative to the oscillations of the working fluid is observed. The threshold value of the amplitude of body oscillations is defined as the mean value of the amplitude of the body when the effect of holding occurs and the amplitude of the body at the moment of collapse of the quasi-equilibrium state. The amplitude of body oscillations at the threshold of the ‘suspended’ state effect, against the background of its oscillations, depends on the frequency

Figure 6: Dependence of the threshold value of the amplitude of body oscillations on the

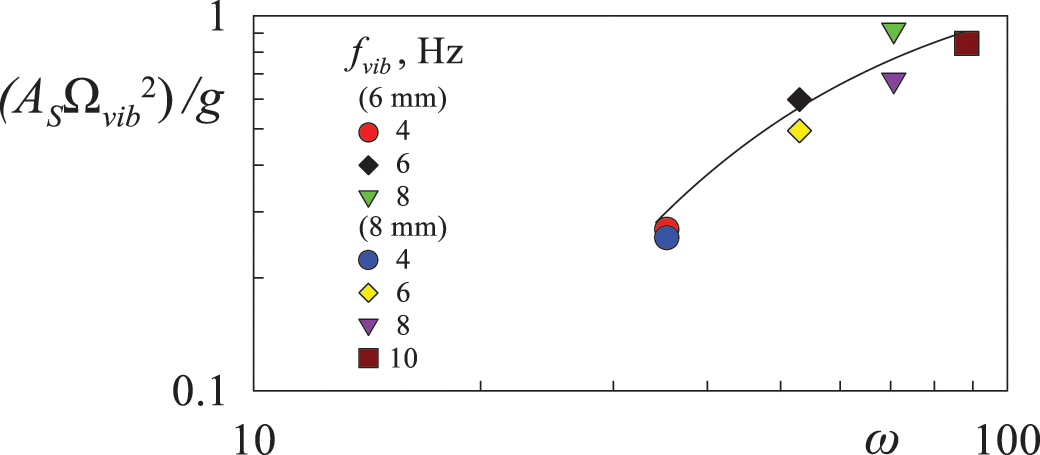

Periodic changes in the flow rate of the fluid pumped through the channel result in the generation of average flows in each of the channel cells. The earlier experimental study of averaged flows excited by fluid oscillations in an axisymmetric channel whose cross section varies periodically with the longitudinal coordinate [25] has shown that the parameter determining the structure and intensity of the averaged flows is a dimensionless frequency

Figure 7: Qualitative representation of the characteristic structure of averaged flows in a circular vertical channel with a periodically changing cross section during oscillations of a liquid column without a body (a) and with a body

When considering the motion of the body during one oscillation period, it is observed that the body must return to its initial position as soon as it is displaced upwards by the fluid flow from the narrowing region of the channel. This ensures that the amplitude of its oscillations remains constant (refer to Fig. 3a). Any deviation from this quasi-stationary position may cause the body to slip further along the channel. When a body oscillates while suspended, its dynamics are determined by the forces acting on it. Similarly, when a body moves in a fluid under the influence of gravity, its dynamics are determined by the combined action of gravity, Archimedes’ principle, and Stokes’ law. The distance travelled by the body is proportional to half of the period of oscillation and the velocity of the body in the fluid, and it equals to

Figure 8: The dimensionless threshold value of body oscillation amplitude dependence on dimensionless frequency

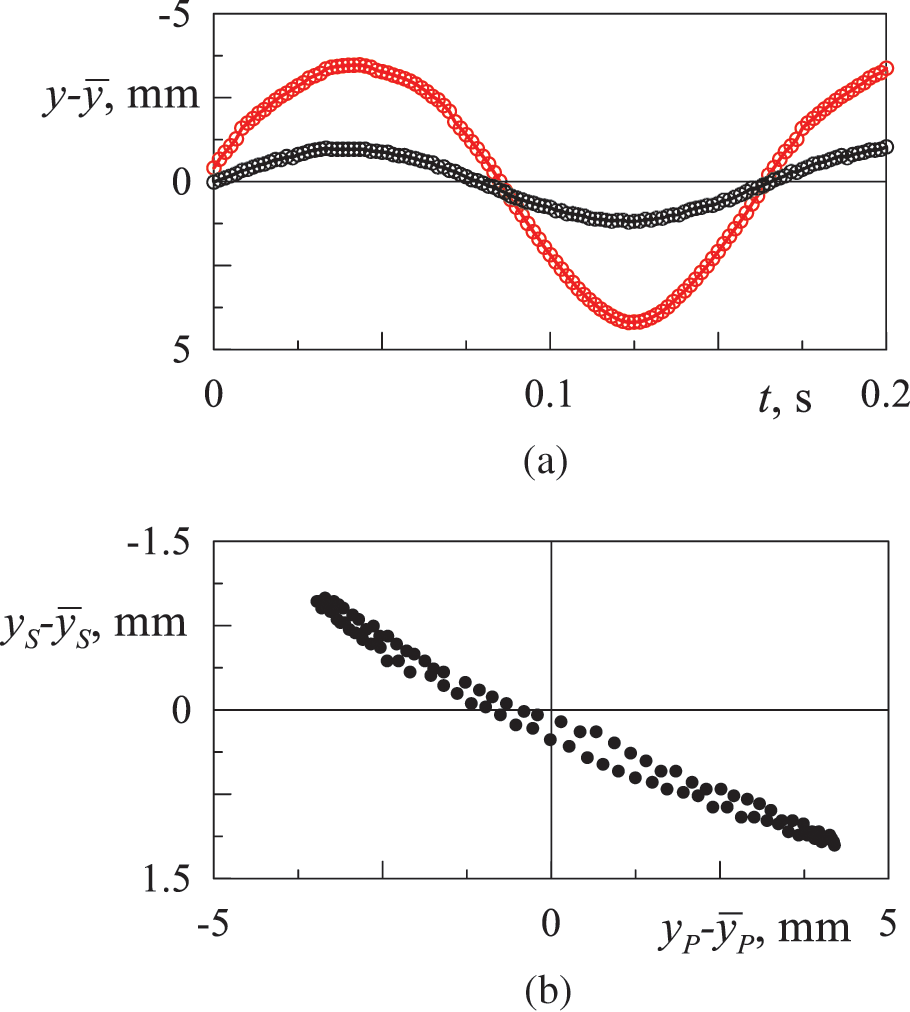

In this study, the characteristics of fluid and body oscillations are considered. Fluid oscillations are detected by the oscillations of particles suspended in the fluid. Let us analyze oscillations of the

Figure 9: Time dependence of the y-coordinates of the particle visualizer (black dots) and the center of mass (red dots) of the phase inclusion (a) during oscillations of the liquid column and the phase diagram of one full period of oscillations (b) of the body and liquid

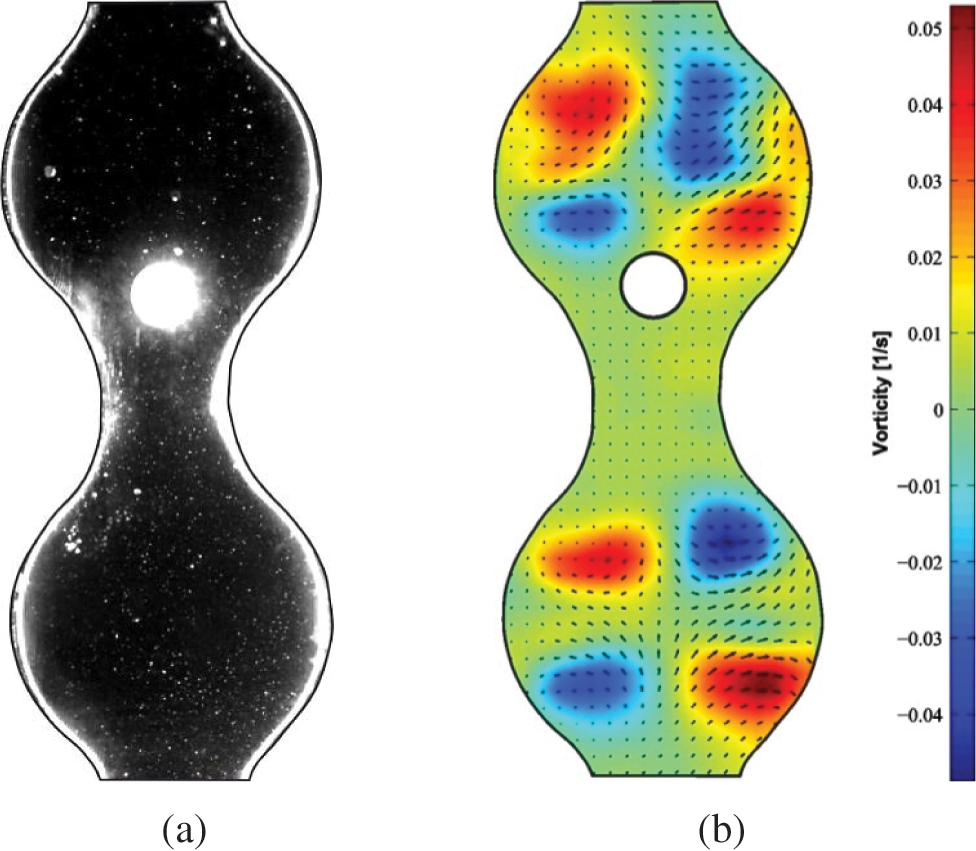

The characteristic structure of the averaged flow excited by the oscillations of the fluid is studied in a vertical channel with a variable cross section using the PIVLab programme [27]. The PIV method consists in processing pairs of frames, like in Fig. 10a at

Figure 10: An example of a processed image obtained by high-speed recording (a) and the characteristic period-averaged vorticity field (b) in the plane of the laser sheet in the vicinity of the axis of the channel

The direction of rotation of the rolls is such that the fluid moves along the axis of the cavity from the narrow section of the channel to the wide section. The averaged flows have an impact on the body dynamics, but they are not the sole determining factor. Thus, the averaged flows contribute to the maintenance of the quasi-stationary position of the spherical body during the oscillations of the liquid column in a channel of variable cross section.

It can be noted that the detected vibration effect is caused by the coincidence of the frequencies and motion law (

The dynamics of a spherical solid body in an oscillating fluid flow in an axisymmetric channel of variable cross section has been studied experimentally. An experimental setup has been designed and constructed which allows the setting of a periodic fluid flow in a variable cross section channel with the simultaneous possibility of introducing a phase inclusion directly into the flow. The experimental methodology has been tested. A new vibration effect is found when increasing the amplitude of oscillations at a fixed frequency. The threshold effect of phase inclusion hold-up and its oscillation relative to the mean position at a given oscillation frequency is observed. The parameter determining the threshold for the occurrence of the effect of holding the body in a quasi-equilibrium state has been identified. Within the range of dimensionless frequencies considered, the structure of averaged flows in the presence of a body in a vertical channel during oscillations of a liquid column has been defined. The discovered effect could be used to develop effective methods for controlling mass transfer in heterogeneous hydrodynamic systems (such as the mass transfer process between the phase inclusion and the surrounding liquid saturated with dissolved extractant), and also to develop a method for vibrational control of phase inclusions in such a system.

Acknowledgement: The author thanks Prof. Kozlov V.G. for his interest in the task and fruitful discussions of the results and the team of the Laboratory of Vibrational Hydromechanics of PSHPU.

Funding Statement: This work was financially supported by the Russian Science Foundation (Grant No. 23-71-01103).

Author Contributions: All the work was done by Ivan Karpunin.

Availability of Data and Materials: All data are included in this published article.

Conflicts of Interest: The author declares that they have no conflicts of interest to report regarding the present study.

References

1. Ye, Q., Zhang, Y., Wei, J. (2021). A comprehensive review of pulsating flow on heat transfer enhancement. Applied Thermal Engineering, 196(3), 117275. https://doi.org/10.1016/j.applthermaleng.2021.117275 [Google Scholar] [CrossRef]

2. Riley, N. (2001). Steady streaming. Annual Review of Fluid Mechanics, 33(1), 43–65. https://doi.org/10.1146/annurev.fluid.33.1.43 [Google Scholar] [CrossRef]

3. Kumar, P., Pandey, K. M. (2021). A review on latest development in heat transfer through porous media in combination with nanofluids and wavy walls. Materials Today: Proceedings, 45, 7171–7175. https://doi.org/10.1016/j.matpr.2021.02.411 [Google Scholar] [CrossRef]

4. Shenoy, A., Sheremet, M., Pop, I. (2016). Convective flow and heat transfer from wavy surfaces: Viscous fluids, porous media, and nanofluids. New York, NY: Taylor and Francis Group. https://doi.org/10.1201/9781315367637 [Google Scholar] [CrossRef]

5. Mahmood, A. N., Abdulrahman, A. A., Sabri, L. S., Sultan, A. J., Majdi, H. S. et al. (2024). Flow regimes in bubble columns with and without internals: A review. Fluid Dynamics & Materials Processing, 20(2), 239–256. https://doi.org/10.32604/fdmp.2023.028015 [Google Scholar] [CrossRef]

6. Shaikh, A., Al-Dahhan, M. H. (2007). A review on flow regime transition in bubble columns. International Journal of Chemical Reactor Engineering, 5(1). [Google Scholar]

7. Patel, T., Patel, D., Thakkar, N., Lakdawala, A. (2019). A numerical study on bubble dynamics in sinusoidal channels. Physics of Fluids, 31(5), 052103. https://doi.org/10.1063/1.5092870 [Google Scholar] [CrossRef]

8. Konda, H., Kumar Tripathi, M., Chandra Sahu, K. (2016). Bubble motion in a converging-diverging channel. Journal of Fluids Engineering, 138(6), 064501. https://doi.org/10.1115/1.4032296 [Google Scholar] [CrossRef]

9. Bhaga, D., Weber, M. E. (1981). Bubbles in viscous liquids: Shapes, wakes and velocities. Journal of Fluid Mechanics, 105, 61–85. https://doi.org/10.1017/S002211208100311X [Google Scholar] [CrossRef]

10. Agnihotry, A., Prasad, N. K., Dalal, A. (2023). Numerical study of bubble rise in a three-dimensional sinusoidal channel. Physics of Fluids, 35(9), 092109. https://doi.org/10.1063/5.0165945 [Google Scholar] [CrossRef]

11. Nishimura, T., Miyashita, H., Murakami, S., Kawamura, Y. (1991). Oscillatory flow in a symmetric sinusoidal wavy-walled channel at intermediate Strouhal numbers. Chemical Engineering Science, 46(3), 757–771. https://doi.org/10.1016/0009-2509(91) [Google Scholar] [CrossRef]

12. Chakravorty, A. (2018). Process intensification by pulsation and vibration in miscible and immiscible two component systems. Chemical Engineering and Processing-Process Intensification, 133, 90–105. https://doi.org/10.1016/j.cep.2018.09.017 [Google Scholar] [CrossRef]

13. Nishimura, T., Murakami, S., Kawamura, Y. (1993). Mass transfer in a symmetric sinusoidal wavy-walled channel for oscillatory flow. Chemical Engineering Science, 48(10), 1793–1800. https://doi.org/10.1016/0009-2509(93)80349-U [Google Scholar] [CrossRef]

14. Kurtulmuo, N., Sahin, B. (2020). Experimental investigation of pulsating flow structures and heat transfer characteristics in sinusoidal channels. International Journal of Mechanical Sciences, 167(3), 105268. https://doi.org/10.1016/j.ijmecsci.2019.105268 [Google Scholar] [CrossRef]

15. Fauci, L. J. (1992). Peristaltic pumping of solid particles. Computers & Fluids, 21(4), 583–598. https://doi.org/10.1016/0045-7930(92)90008-J [Google Scholar] [CrossRef]

16. Hung, T. K., Brown, T. D. (1976). Solid-particle motion in two-dimensional peristaltic flows. Journal of Fluid Mechanics, 73(1), 77–96. https://doi.org/10.1017/S0022112076001262 [Google Scholar] [CrossRef]

17. Zeeshan, A., Ijaz, N., Bhatti, M. M. (2018). Flow analysis of particulate suspension on an asymmetric peristaltic motion in a curved configuration with heat and mass transfer. Mechanics & Industry, 19(4), 401. https://doi.org/10.1051/meca/2018022 [Google Scholar] [CrossRef]

18. Sinnott, M. D., Cleary, P. W., Harrison, S. M. (2017). Peristaltic transport of a particulate suspension in the small intestine. Applied Mathematical Modelling, 44(4), 143–159. https://doi.org/10.1016/j.apm.2017.01.034 [Google Scholar] [CrossRef]

19. Bhatti, M. M., Zeeshan, A., Ellahi, R., Shit, G. C. (2018). Mathematical modeling of heat and mass transfer effects on MHD peristaltic propulsion of two-phase flow through a Darcy-Brinkman-Forchheimer porous medium. Advanced Powder Technology, 29(5), 1189–1197. https://doi.org/10.1016/j.apt.2018.02.010 [Google Scholar] [CrossRef]

20. Ivanova, A. A., Kozlov, V. G. (2003). Vibrational convection in nontranslationally oscillating cavity (isothermal case). Fluid Dynamics, 38(2), 186–192. https://doi.org/10.1023/A:1024260716608 [Google Scholar] [CrossRef]

21. Kozlov, V. G., Sabirov, R. R., Subbotin, S. V. (2018). Steady flows in an oscillating spheroidal cavity with elastic wall. Fluid Dynamics, 53(2), 189–199. https://doi.org/10.1134/S0015462818020118 [Google Scholar] [CrossRef]

22. Subbotin, S., Kozlov, V., Shiryaeva, M. (2019). Effect of dimensionless frequency on steady flows excited by fluid oscillation in wavy channel. Physics of Fluids, 31(10), 103604. https://doi.org/10.1063/1.5119018 [Google Scholar] [CrossRef]

23. Ishaq, M., Rehman, S. U., Riaz, M. B., Zahid, M. (2024). Hydrodynamical study of couple stress fluid flow in a linearly permeable rectangular channel subject to Darcy porous medium and no-slip boundary conditions. Alexandria Engineering Journal, 91(3), 50–69. https://doi.org/10.1016/j.aej.2024.01.066 [Google Scholar] [CrossRef]

24. Simonov, O. A., Erina, Y. Y., Ponomarev, A. A. (2023). Review of modern models of porous media for numerical simulation of fluid flows. Heliyon, 9(12), e22292. https://doi.org/10.1016/j.heliyon.2023.e22292. [Google Scholar] [PubMed] [CrossRef]

25. Vlasova, O., Karpunin, I., Latyshev, D., Kozlov, V. (2020). Steady flows of a fluid oscillating in an axisymmetric channel of variable cross section, versus the dimensionless frequency. Microgravity Science and Technology, 32(3), 363–368. https://doi.org/10.1007/s12217-019-09775-x [Google Scholar] [CrossRef]

26. Kozlov, V., Karpunin, I., Kozlov, N. (2020). Finger instability of oscillating liquid-liquid interface in radial Hele-Shaw cell. Physics of Fluids, 32(10), 102102. https://doi.org/10.1063/5.0018541 [Google Scholar] [CrossRef]

27. Stamhuis, E., Thielicke, W. (2014). PIVlab-towards user-friendly, affordable and accurate digital particle image velocimetry in MATLAB. Journal of Open Research Software, 2(1), 30. https://doi.org/10.5334/jors.bl [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools