Open Access

Open Access

ARTICLE

Dynamics of Low-Viscosity Liquids Interface in an Unevenly Rotating Vertical Layer

1 Laboratory of Vibrational Hydromechanics, Perm State Humanitarian Pedagogical University, Perm, 614990, Russia

2 Institut de Mécanique des Fluides de Toulouse, Toulouse INP, Toulouse, 31400, France

* Corresponding Author: Victor Kozlov. Email:

(This article belongs to the Special Issue: Advanced Problems in Fluid Mechanics)

Fluid Dynamics & Materials Processing 2024, 20(4), 693-703. https://doi.org/10.32604/fdmp.2024.048068

Received 27 November 2023; Accepted 15 December 2023; Issue published 28 March 2024

Abstract

The behavior of two immiscible low-viscosity liquids differing in density and viscosity in a vertical flat layer undergoing modulated rotation is experimentally studied. The layer has a circular axisymmetric boundary. In the absence of modulation of the rotation speed, the interphase boundary has the shape of a short axisymmetric cylinder. A new effect has been discovered, under the influence of rotation speed modulation, the interface takes on a new dynamic equilibrium state. A more viscous liquid covers the end boundaries of the layer in the form of thin films, which have the shape of round spots of almost constant radius; with increasing amplitude of the velocity modulation, the wetting boundary expands. It is found that upon reaching the critical amplitude of oscillations, the film of a viscous liquid loses stability, and the outer edge of the wetting spot collapses and takes on a feathery structure. It is shown that this threshold is caused by the development of the Kelvin–Helmholtz oscillatory instability of the film. The spreading radius of a spot of light viscous liquid and its stability are studied depending on the rotation rate, amplitude, and frequency of rotation speed modulation. The discovered averaged effects are determined by different oscillatory interaction of fluids with the end-walls of the cell, due to different viscosities. The effect of films forming can find application in technological processes to intensify mass transfer at interphase boundaries.Keywords

Nomenclature

| | Mean rotation frequency (rps) |

| | Velocity modulation frequency (Hz) |

| | Amplitude of velocity modulation |

| Rc | Cavity radius (cm) |

| d | Cell thickness (cm) |

| | Liquid density (g/cm3) |

| | Kinematic viscosity (St) |

| | Film radius (cm) |

| | Stokes layer (cm) |

| | Dimensionless frequency |

The oscillatory dynamics of multiphase systems with an interface is of great scientific and practical interest. The interface can be unstable to various types of instability in dependence on the type of the fluid oscillations.

Tangential oscillations of two fluids near the interface accompanied by the discontinuity of the tangential velocity cause the excitation of the Kelvin–Helmholtz oscillatory instability [1–4], which manifests itself in the form of the quasi-stationary relief (frozen wave). It is noteworthy that the Kelvin–Helmholtz instability [5] is studied in detail for the case of stationary tangential velocity discontinuity [6,7] including the complicating factors, like: proximity of the wall [8], flows in Hele-Shaw cell [9], heat and mass transfer from viscoelastic liquid film [10]. The practical interest in the study of the Kelvin–Helmholtz instability, including the oscillatory type of the instability, is explained, in particular, by the influence of this effect on the film coating and fluid spraying [11–14]. Taking into account the above mentioned, the oscillatory dynamics of the interface between fluids in narrow gaps is of interest.

In the experiments with fluids with high viscosity contrast in narrow gaps, oscillations of the tangential pressure gradient cause tangential oscillations of fluids with different amplitudes due to different viscous interactions between fluids and the channel walls, which also causes the onset of the oscillatory Kelvin–Helmholtz instability.

A number of non-trivial phenomena were discovered [15,16] when studying the dynamics of fluids of different densities and high viscosity contrast in a narrow gap (axisymmetric Hele-Shaw cell) under modulated rotation

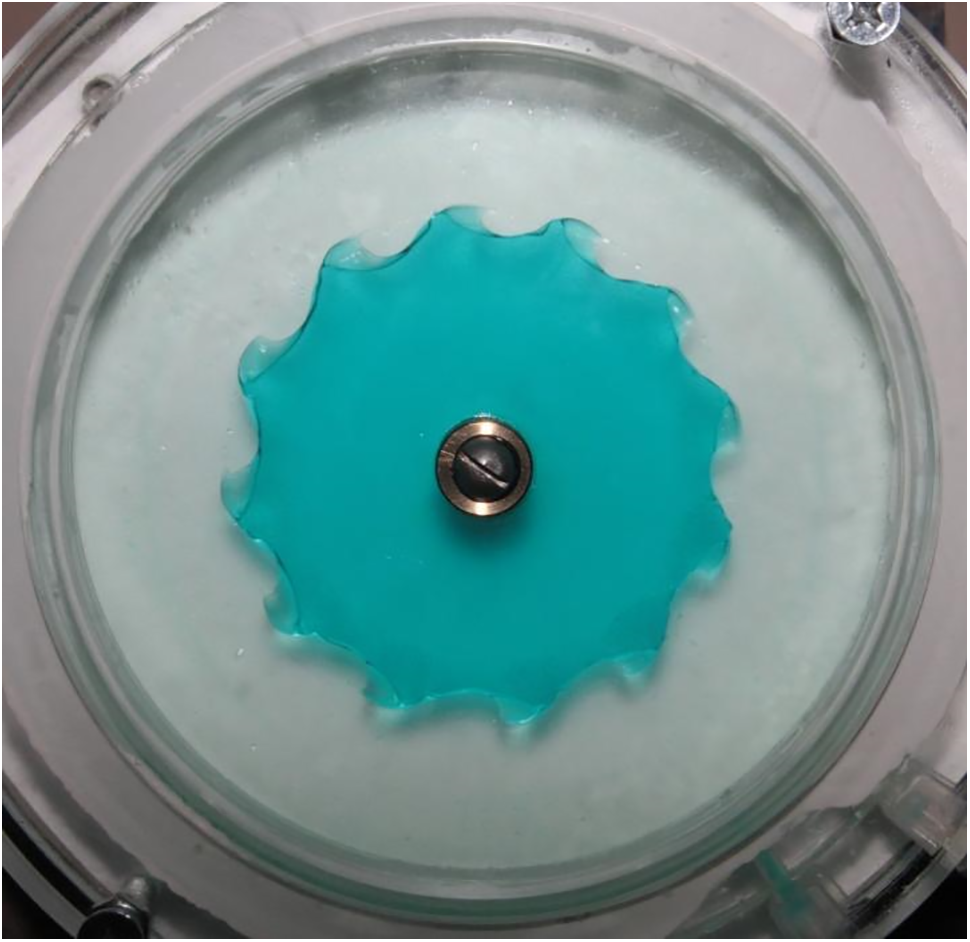

Figure 1: The interface between the high-viscosity glycerol colored with blue dye and the low-viscosity and denser fluid FC-40 at frot = 4.0 rps, flib = 7 Hz, and

The high-viscosity fluid takes the form of a multi-petal flower rotating together with the cell. According to the observations, the petals undergo slight azimuthal oscillations during the period. When the modulation amplitude decreases, the transition to the axisymmetric state occurs without hysteresis. The relief appears on the surface of a more viscous fluid regardless of its density and the location of the relatively low-viscosity fluid. This phenomenon is studied theoretically and experimentally in [16]. The theoretical model is constructed for the extremely high viscosity contrast when the thickness of the Stokes boundary layer in a high-viscosity fluid exceeds the gap width while the thickness of the Stokes layer in a low-viscosity fluid is small compared to the gap width. In light of the above, an urgent issue is to clarify the effect of the viscosity contrast on the time-averaged dynamics of the interface.

This paper is aimed at experimental investigation of the dynamics of two fluids with different densities in an unevenly rotating vertical layer. Water and industrial oil I-20A are chosen as working fluids. It is noteworthy that fluids have different, but relatively low viscosities, and the Stokes boundary layers are thinner than the cell thickness in the studied range of oscillation frequencies.

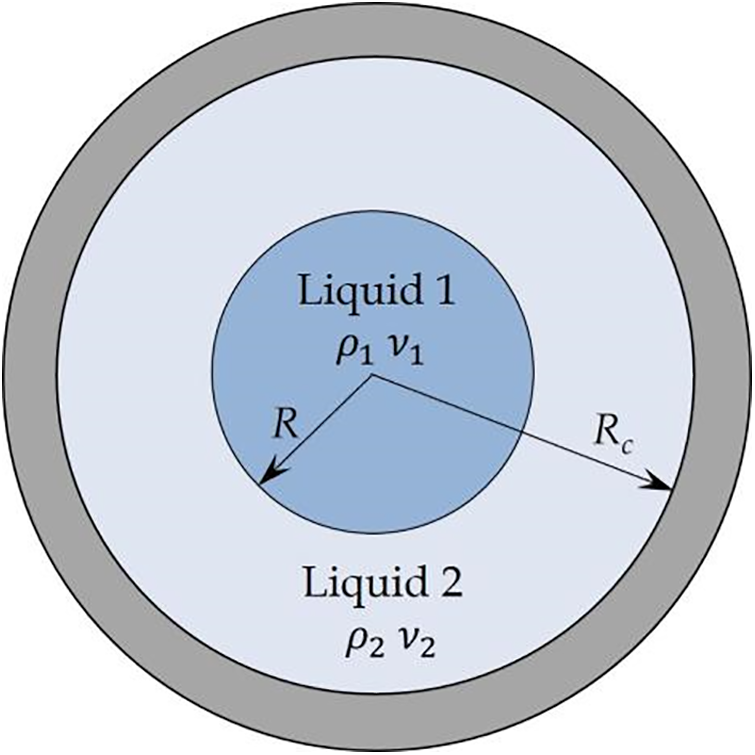

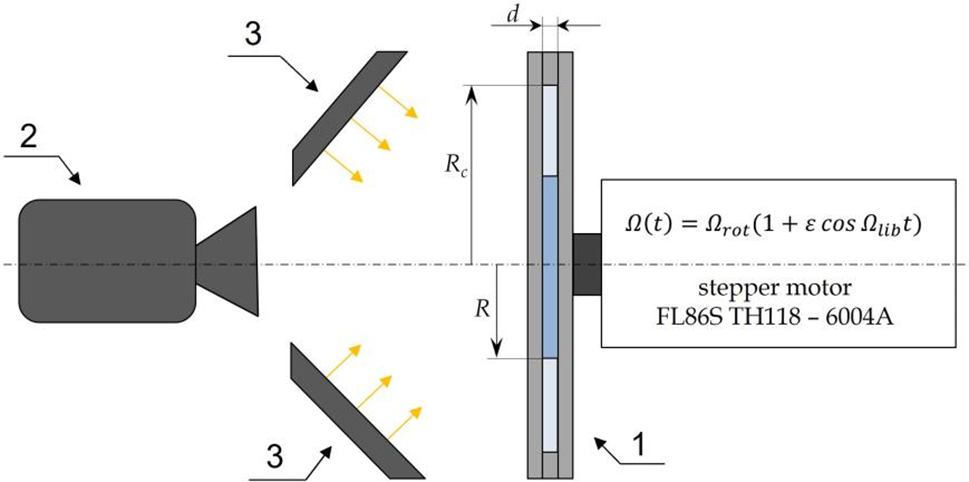

The cell (Fig. 2) is a vertical plane layer of thickness d = 4.0 mm with circular lateral boundary of radius Rc = 56.25 mm. The walls of the cavity are made of plexiglass: The front wall is transparent while the back wall is white and opaque. The cell is filled with immiscible fluids, one was colored with blue dye. The dynamics of the interface is registered by the digital camera FUJI X-E4 and lenses FUJINON XF 50 mm f/2 R WR 2 (Fig. 3). The front side of the cell is illuminated by two LED panels 3 (LED Falcon Eyes FlatLight 600). The cell rotates around the horizontal axis of symmetry in the experiments.

Figure 2: Formulation of the problem

Figure 3: The scheme of the experimental setup: 1–cell, 2–camera, 3–LED panels

A stepper motor FL86S TH118–6004A is capable of rotating according to the law

The cell is filled with two immiscible fluids of different densities and viscosities. We use an industrial oil I-20A with a density of

We vary the volume ratio of the fluids so that the radius of the unperturbed interface is equal to

In each series of experiments, we set the desired rotation rate and the oscillation frequency and change the modulation amplitude from zero to maximum value with an interval of 0.04. The image of the interface is captured by a digital camera at different phases of the cell oscillations.

The image processing is done using the free software ImageJ. The tool «Threshold» is used to highlight the interface that determines the spreading area of the more viscous fluid. Then, the toll “Analyze Particles” measures the minimum and maximum diameter of the selected area. The mean radius of the wetting area is calculated at a given rotation rate, frequency and amplitude of oscillations.

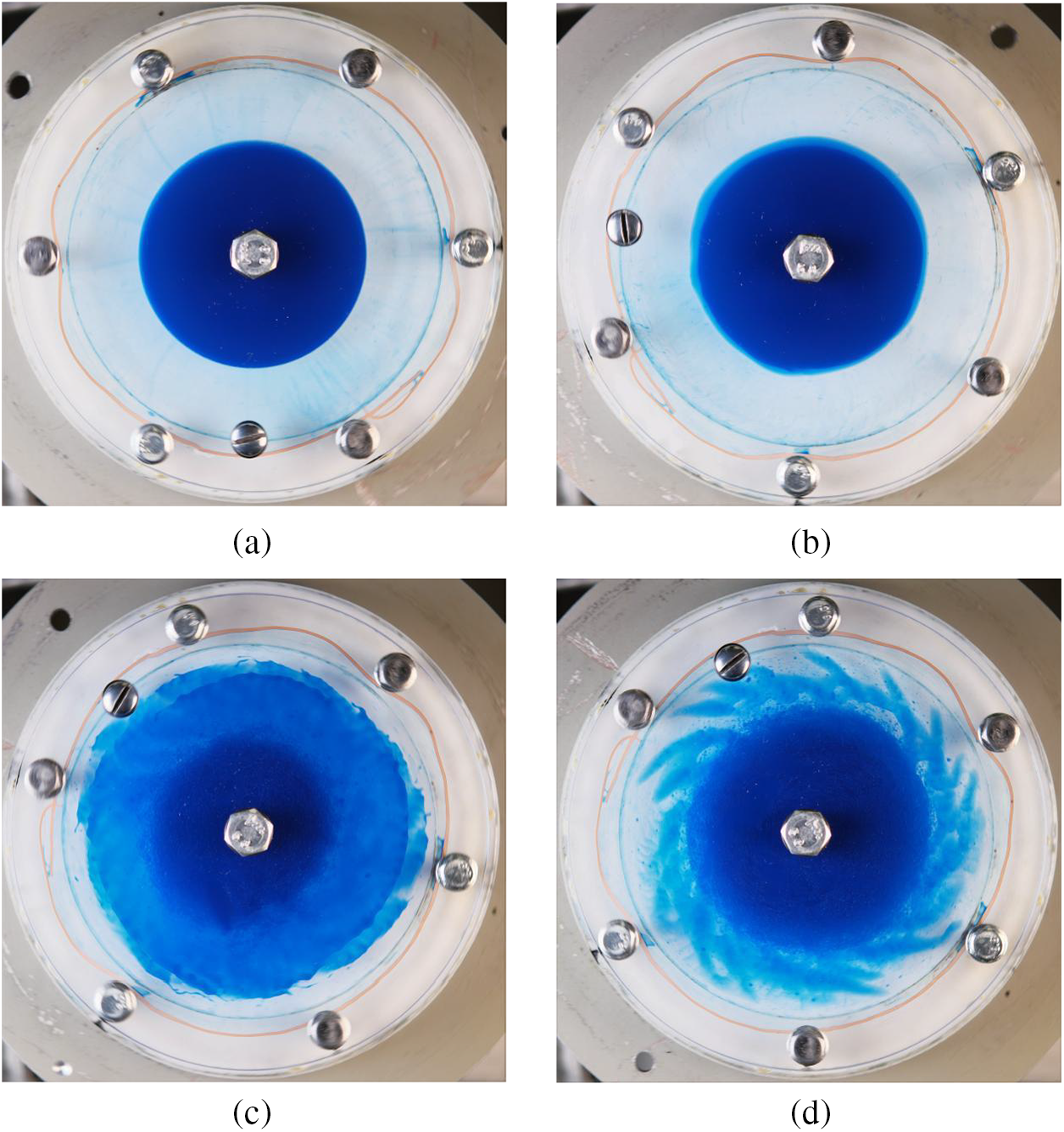

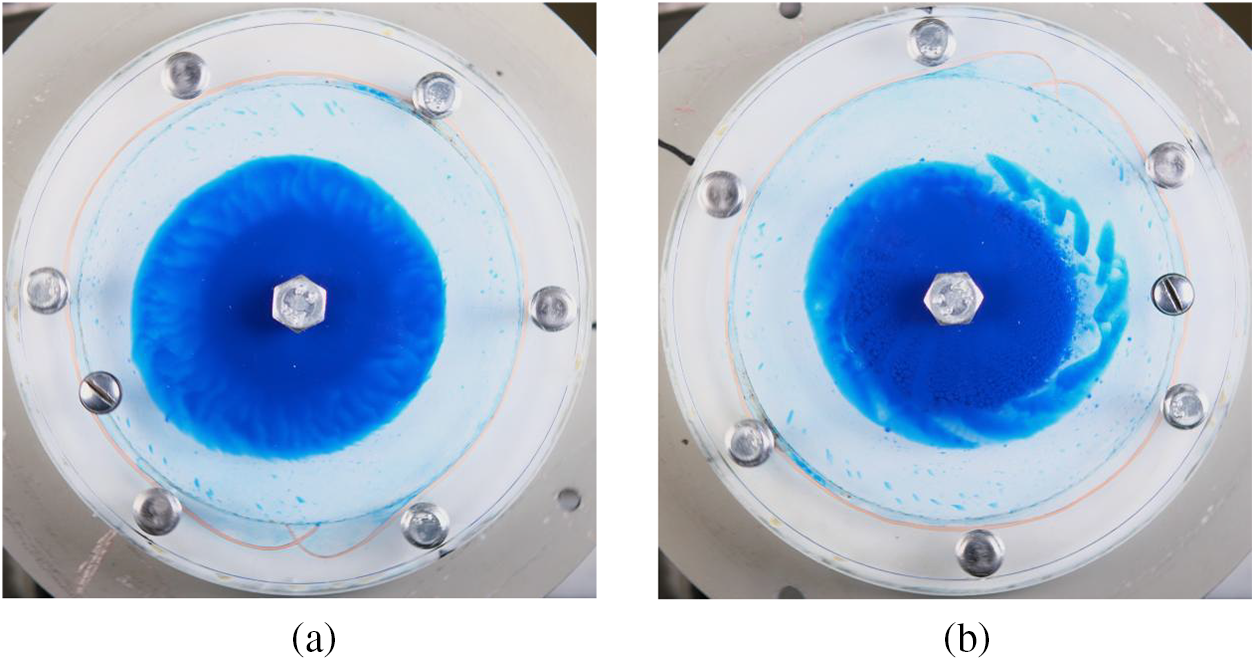

The interface between fluids is axisymmetric in the absence of oscillations (Fig. 4a). Under oscillations, a more viscous fluid with a lower density takes the form of the film attached to the end wall (Fig. 4b). A dark blue spot in the center of the cell is the area occupied by a viscous fluid; the area occupied by the film has a lower optical density. The radial size of the wetting spot increases with increasing the amplitude

Figure 4: The interface between oil and water at

The radial size of the wetting spot (radius of the fluid film) increases with the amplitude. The spreading effect is more pronounced at lower modulation frequencies. When the critical amplitude is reached, the interface becomes unstable: The film is destroyed and the feather-like structures twisted against the direction of the cell rotation appears (Fig. 4d). Here, the destroyed film turns into drops that are located between the walls of the cavity in a suspended state. The droplets tend to collect at the center of the cavity due to the centrifugal force.

The dynamics of the film coating does not undergo qualitative changes when variation of

Figure 5: The interface between oil and water at

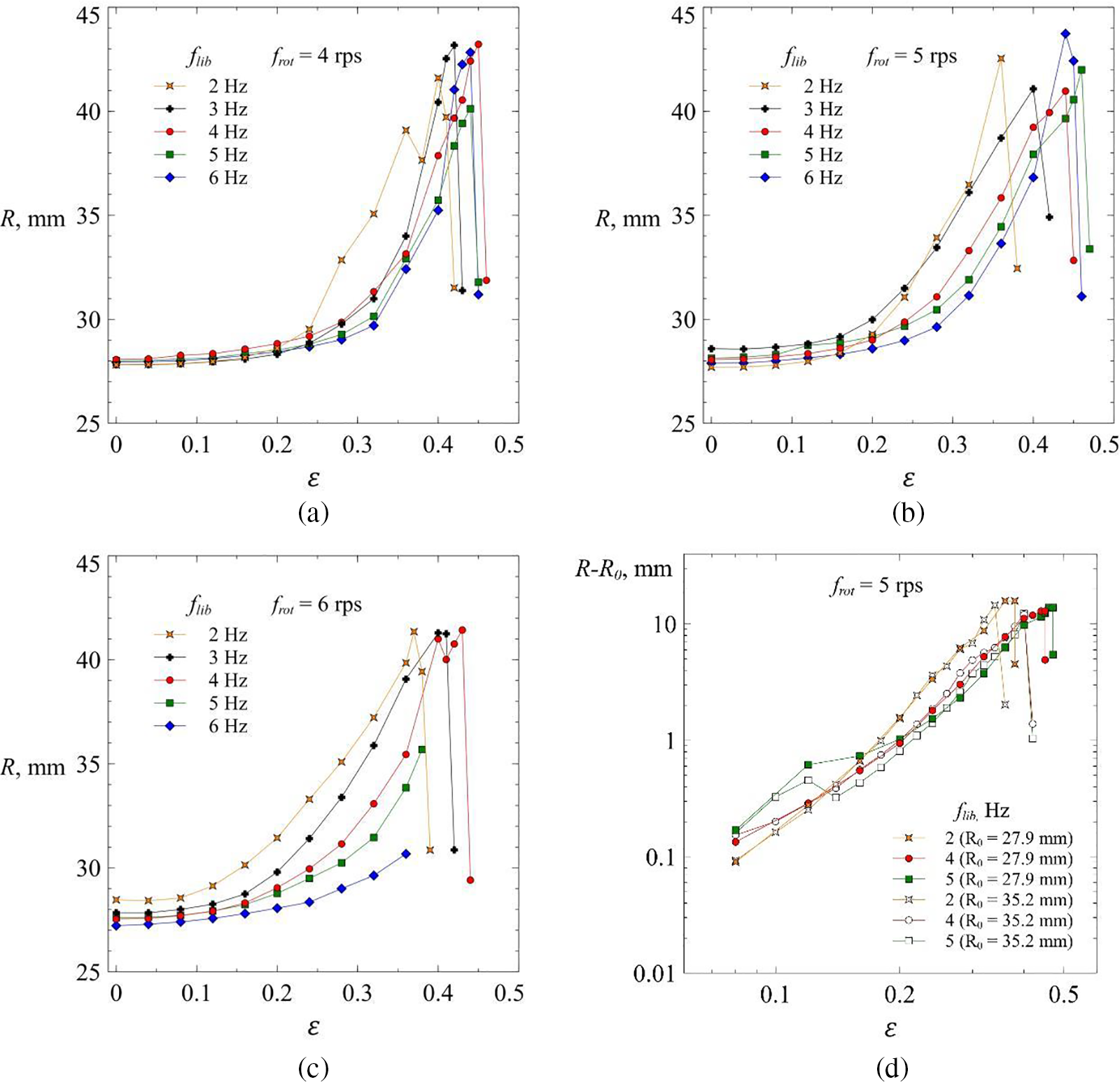

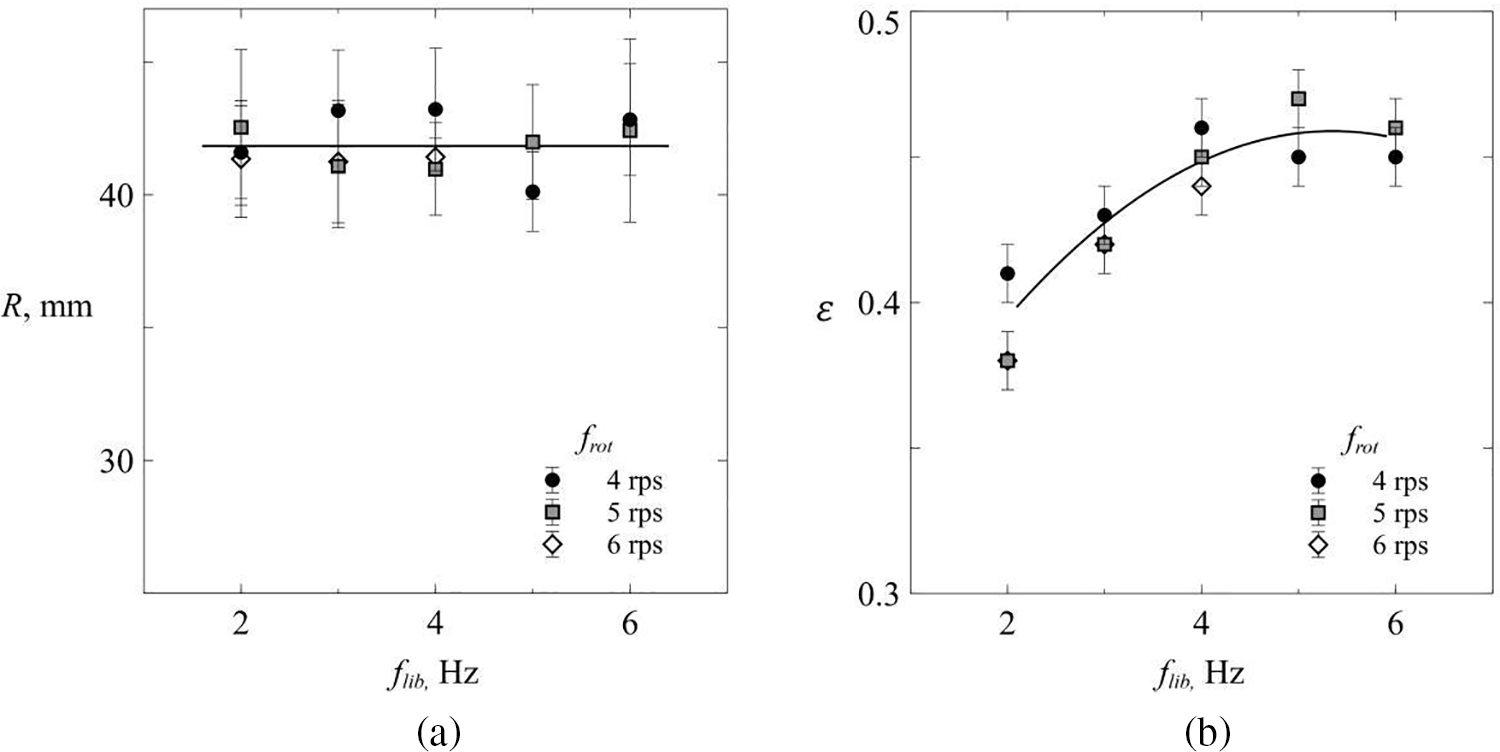

When the film loses stability, the size of the wetting spot decreases sharply (Fig. 4d), which corresponds to a break in the slope of the

Figure 6: Dependence of the wetting radius on the amplitude of oscillations at

Figure 7: (a)–critical radius R* of the film on the plane (flib, R); (b)–critical amplitude

Fig. 6d shows on a log-log scale the dependence of the radial displacement of the film edge

This allows us to assume that the films have the same structure at different

At given values of the rotation rate

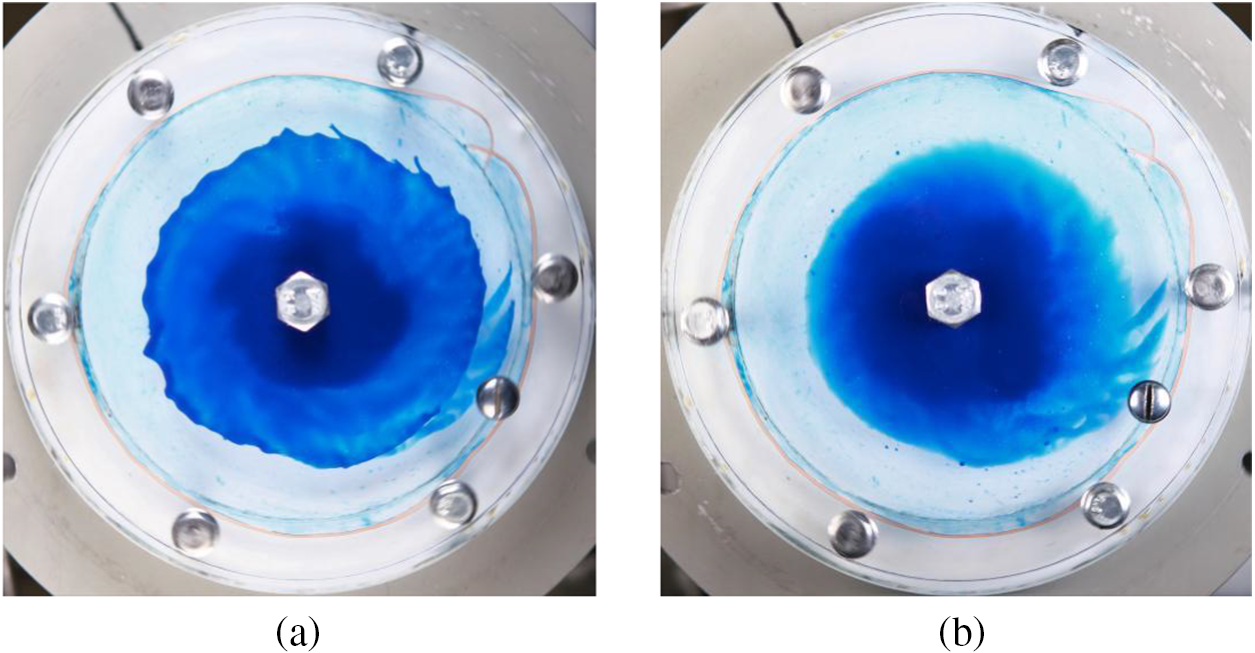

Figure 8: The film of the viscous fluid at

Here, the interface has a greater contrast in color compared with Fig. 8b where the rotation rate

Let us discuss the nature of the radial displacement of a viscous fluid along the end wall under modulated rotation. This phenomenon is explained by the time-averaged interaction between the fluids and the end walls during the cell oscillation cycle. At this, the viscosity contrast plays an important role since the viscous interaction is considerable only within the Stokes layer of the thickness

Both fluids are entrained by the end walls and oscillate together with the cell within the Stokes boundary layers that differ in their size due to the difference in viscosities. Moreover, both fluids outside the Stokes layers rotate at the angular velocity

The results obtained in [19] for a single-phase medium are applicable to both fluids in our problem in the limit of slow rotation

One can suggest that the time-averaged shear stress (which excites the averaged radial flow) in the boundary layer of a viscous fluid near the end wall perturbs the initially cylindrical interface and causes the formation of a film with a radius exceeding the radius of the interface in the middle of the layer. As shown above, the velocity of the time-averaged motion or, in other words, averaged shear stress in the Stokes boundary layer increases with distance from the axis of rotation. Then, the spreading of a film of a less dense fluid is limited by the radial pressure gradient in a denser fluid. When the thickness of the viscous film is small compared to the thickness of the layer, the pressure inside the film does not depend on the distance to the end wall and is determined by the pressure at the interface, that is, the pressure in a uniformly rotating low-viscosity fluid. This approach is standard when dealing with boundary layer flows [5]. The proposed model is the first attempt to describe film formation and requires further theoretical study.

Discuss the dynamics of the film of more viscous fluid. As follows from above, the film thickness is of order of the thickness of the Stokes boundary layer which is less than the width of the cell. The low-viscosity fluid outside the film rotates at an almost constant rate, not responding to the azimuthal oscillations of the axisymmetric cell and the film of the viscous fluid. As a consequence, a tangential discontinuity of oscillatory velocity

Discuss the origin of the anticyclonic “feathers”, i.e., traces of the viscous fluid film on the end walls. Observations show that the viscous fluid from which feathers are formed does not oscillate during velocity rate modulation. This indicates that the thickness of the viscous film that forms the “feathers” is significantly less than the thickness of the Stokes boundary layer. Moreover, both oscillatory and time-averaged flows are negligible in the viscous “feathers”. On the contrary, the low-viscosity fluid performs the azimuthal oscillations relative to the end walls and the surface of a film of viscous liquid (which oscillates along with the end walls), at this the radial steady streaming of low viscosity fluid is generated [19]. Probably, the steady streaming perturbs the wetting spots developing a feather-like pattern. Anticyclonic rotation of the low-viscosity fluid is determined solely by the cell rotation and follows from the law of conservation of angular momentum.

In conclusion, let us dwell on the role of the orientation of the rotating layer in the gravity field. Despite the fact that under the conditions of the experiment, the gravity field is several times smaller than the centrifugal force field, the orientation of the layer (and hence the axis of rotation) plays an important role. In the cavity reference frame, the gravity field rotates in the vertical plane. When the rotation axis is horizontally oriented (the layer is vertical), the time-average value of the gravity field in the rotating system equals zero. The situation changes if the layer plane deviates from the vertical. The constant axial component of the gravity field remains in the rotating system and breaks the mirror symmetry of the interphase surface and of the film coating of the opposite walls of the layer. Preliminary experiments have shown that the deviation of the rotation axis from the horizon leads to a qualitative change in the oscillatory formation of the viscous liquid film at the opposite end walls of the cavity. This effect is beyond the scope of present study and is the subject of further research.

A novel vibration effect is found in the course of an experimental study of the dynamics of two low-viscosity fluids with different densities and viscosities in an unevenly rotating circular cell. A more viscous and less dense fluid, located near the axis of rotation under the influence of centrifugal force, forms films on the end walls of the cell under oscillations. In the studied case of a vertical layer arrangement, the films on opposite end walls are similar. The similarity is violated when the layer deviates from the vertical. The dynamic stability of the films is determined by the oscillations: the wetting spot shrinks, and the interface becomes cylindrical in the absence of oscillations. Radial distribution of a more viscous fluid in the form of a film is caused by the difference in the viscous interaction of two fluids with the end walls of the rotating cell. The radius of the wetting spot increases with the modulation amplitude. Another intriguing phenomenon is the threshold destruction of the film edge when the critical radius is reached. As a result of this effect, the destroyed film turns into drops suspended in a less viscous and denser fluid. The droplets tend to collect at the center of the cavity under the action of centrifugal force. The discovered effect of creating a dynamically stable film coating due to vibration can be used to govern (intensify) the mass transfer processes at interphase boundaries.

Acknowledgement: The authors thank A.S. Selyanin for his help in experimental setup production.

Funding Statement: This research was financially supported by the Russian Science Foundation (Project 23-11-00242).

Author Contributions: The authors confirm contribution to the paper as follows: study conception and design: V.K.; data collection: V.S.; analysis and interpretation of results: V.K., V.S., N.K.; draft manuscript preparation: V.K., V.S., N.K. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: All data are included in this published article.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Lyubimov, D. V., Cherepanov, A. A. (1987). Development of a steady relief at the interface of fluids in a vibrational field. Fluid Dynamics, 22, 849–854. [Google Scholar]

2. Jia, B. Q., Xie, L., Deng, X. D., He, B. S., Yang, L. J. et al. (2023). Experimental study on the oscillatory Kelvin–Helmholtz instability of a planar liquid sheet in the presence of axial oscillating gas flow. Journal of Fluid Mechanics, 959, A18. [Google Scholar]

3. Lyubimov, D. V., Lyubimova, T. P., Cherepanov, A. A. (2003). Dynamics of interfaces in vibration fields. Moscow: FizMatLit (in Russian). [Google Scholar]

4. Yoshikawa, H., Wesfreid, J. E. (2011). Oscillatory Kelvin–Helmholtz instability. Part 1. A viscous theory. Journal of Fluid Mechanics, 675, 223–248. [Google Scholar]

5. Landau, L. D., Lifshitz, E. M. (1987). Fluid mechanics, V. 6 of course of theoretical physics. New York: Pergamon Press. [Google Scholar]

6. Funada, T., Joseph, D. D. (2001). Viscous potential flow analysis of Kelvin–Helmholtz instability in a channel. Journal of Fluid Mechanics, 445, 263–283. [Google Scholar]

7. Kim, H., Padrino, J. C., Joseph, D. D. (2011). Viscous effects on Kelvin–Helmholtz instability in a channel. Journal of Fluid Mechanics, 680, 398–416. [Google Scholar]

8. Liu, C. L., Kaminski, A. K., Smyth, W. D. (2023). The effects of boundary proximity on Kelvin–Helmholtz instability and turbulence. Journal of Fluid Mechanics, 966, A2. [Google Scholar]

9. Plouraboué, F., Hinch, E. J. (2002). Kelvin–Helmholtz instability in a Hele-Shaw cell. Physics of Fluids, 14(3), 922–929. [Google Scholar]

10. Fu, Q., Deng, X., Yang, L. (2019). Kelvin–Helmholtz instability of confined Oldroyd-B liquid film with heat and mass transfer. Journal of Non-Newtonian Fluid Mechanics, 267, 28–34. [Google Scholar]

11. Kazimardanov, M. G., Mingalev, S. V., Lubimova, T. P., Yu, G. L. (2018). Simulation of primary film atomization due to Kelvin–Helmholtz instability. Journal of Applied Mechanics and Technical Physics, 59(7), 1251–1260. [Google Scholar]

12. Senecal, P. K., Schmidt, D. P., Nouar, I., Rutland, C. J., Reitz, R. D. et al. (1999). Modeling high speed viscous liquid sheet atomization. International Journal of Multiphase Flow, 25, 1073–1097. [Google Scholar]

13. Ebner, J., Gerendás, M., Schäfer, O., Wittig, S. (2001). Droplet entrainment from a shear-driven liquid wall film in inclined ducts: Experimental study and correlation comparison. Proceedings of the ASME Turbo Expo 2001, New Orleans, Louisiana, USA. [Google Scholar]

14. Dighe, S., Gadgil, H. (2021). On the nature of instabilities in externally perturbed liquid sheets. Journal of Fluid Mechanics, 916, A57. [Google Scholar]

15. Dementeva, Y. S., Kobeleva, V. S., Kozlov, V. G. (2022). Experimental study of liquids interface oscillatory dynamics in rotating slot gap. Journal of Physics: Conference Series, 2317(1), 012013. [Google Scholar]

16. Kozlov, V., Petukhova, M., Kozlov, N. (2023). Dynamics of liquids with high viscosity contrast in unevenly rotating Hele-Shaw cell. Philosophical Transactions of the Royal Society Mathematical Physical & Engineering Sciences, 381, 20220082. [Google Scholar]

17. Kozlov, V. G., Zimasova, A. R. (2023). Dynamics of two liquids in a non-uniformly rotating horizontal cylinder. E3S Web of Conferences, 402, 14002. [Google Scholar]

18. Schlichting, H. (1968). Boundary layer theory, 7th edition. New York: McGraw-Hill. [Google Scholar]

19. Rosenblat, S. (1959). Torsional oscillations of a plane in a viscous fluid. Journal of Fluid Mechanics, 5, 206–220. [Google Scholar]

20. Lim, T. G., Hyun, J. M. (1997). Flow driven by a torsionally-oscillating shrouded endwall disk. Journal of Fluids Engineering, 119(1), 115–121. [Google Scholar]

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools