Open Access

Open Access

ARTICLE

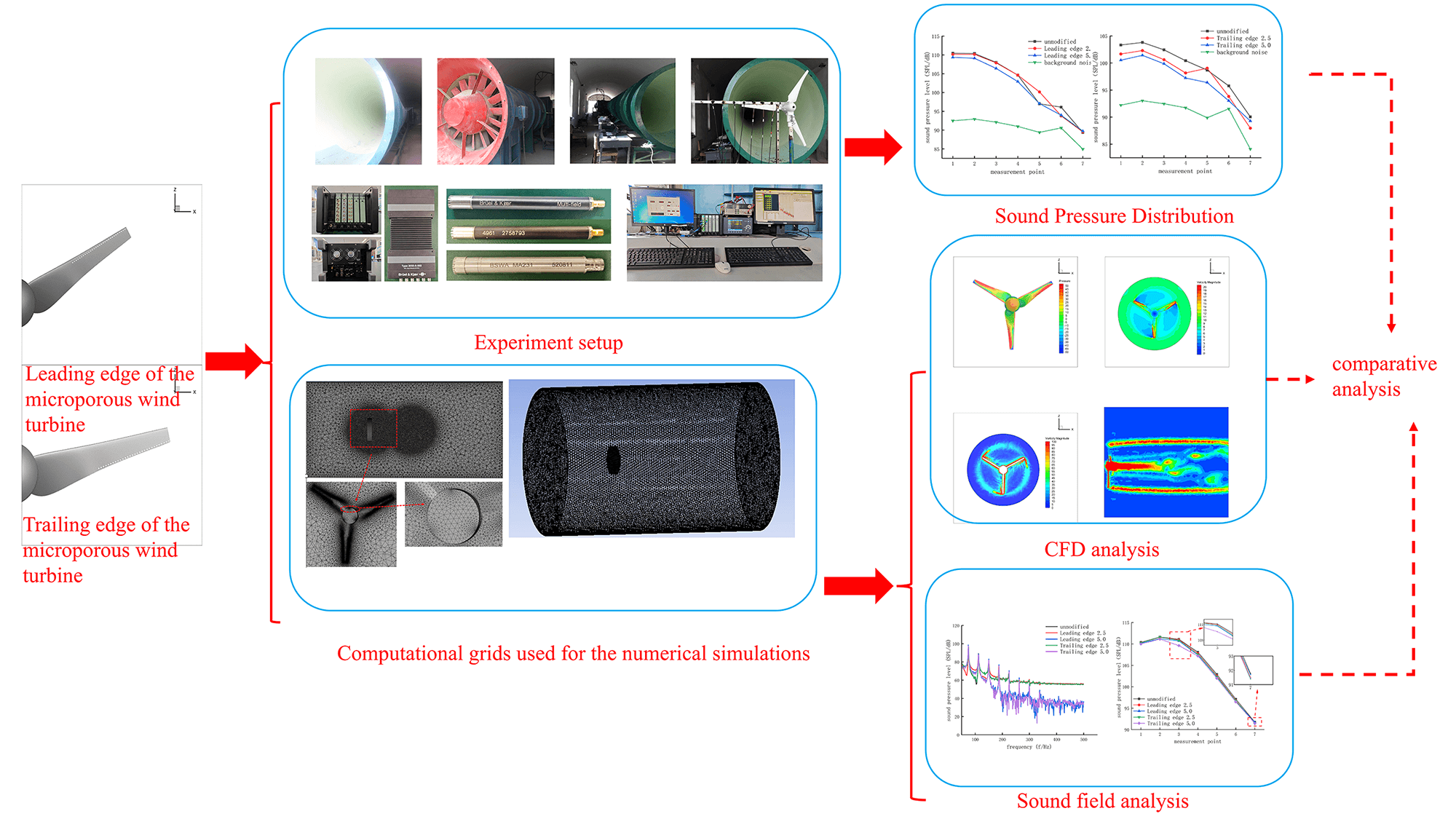

Aerodynamic Noise Distribution in Wind Turbines with Different Microporous Blade Tip Structures

School of Mechanical Engineering, Shanghai DianJi University, Shanghai, 201306, China

* Corresponding Author: Yuanjun Dai. Email:

Fluid Dynamics & Materials Processing 2024, 20(12), 2809-2842. https://doi.org/10.32604/fdmp.2024.054011

Received 16 May 2024; Accepted 15 August 2024; Issue published 23 December 2024

Abstract

A linear microporous blade tip structure is designed in order to reduce the aerodynamic noise of a wind turbine during operations. Various structures of such a kind are considered and the related aerodynamic noise is determined in the framework of large vortex simulation and acoustic array test methods. The findings demonstrate that various blade tip designs can enhance the vortex trajectory in the tip region and lessen the pressure differential between the blade’s upper and lower surfaces. In particular, the wind turbine’s maximum linear velocity at the blade tip can be increased by 10%–23% while also effectively reducing the radial and axial aerodynamic noise during operation. A trailing edge microporous structure displays a better noise reduction effect than a leading edge microporous structure, and the maximum sound pressure level is reduced by an average of 1.92%–3.63%. The main factors influencing the wind turbine’s aerodynamic noise are its size and placement of microporous holes.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools