Open Access

Open Access

ARTICLE

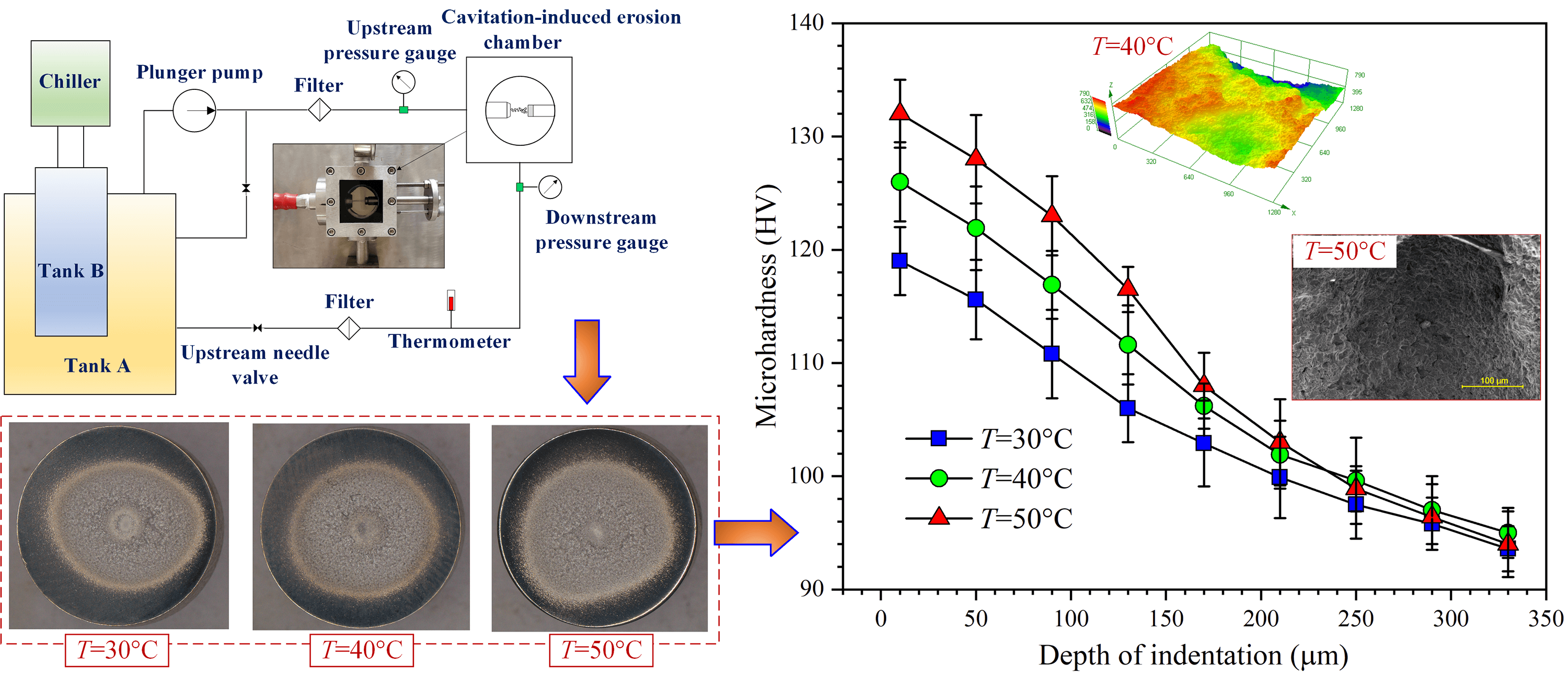

Effect of Liquid Temperature on Surface and Mechanical Characteristics of Al-Mg Alloy Treated with a Cavitating Waterjet

1 School of Energy and Power Engineering, Jiangsu University, Zhenjiang, 212013, China

2 School of Materials Science and Engineering, Jiangsu University, Zhenjiang, 212013, China

3 Department of Auxiliary Power Equipment, Shanghai Marine Equipment Research Institute, Shanghai, 200031, China

* Corresponding Author: Can Kang. Email:

Fluid Dynamics & Materials Processing 2024, 20(11), 2431-2442. https://doi.org/10.32604/fdmp.2024.055688

Received 04 July 2024; Accepted 09 August 2024; Issue published 28 October 2024

Abstract

The presented study aims to reveal the effect of liquid temperature on cavitation-induced erosion of an Al-Mg alloy. An experimental work was conducted using a submerged cavitating waterjet to impact the specimen surface. For a certain cavitation number and a given standoff distance, different liquid temperatures were considered. Accordingly, a comprehensive comparison was implemented by inspecting the mass loss and surface morphology of the tested specimens. The results show that the cumulative mass loss increases continuously with the liquid temperature. A cavitation zone with an irregular profile becomes evident as the cavitation treatment proceeds. Increasing the temperature promotes the generation of cavitation bubbles. Large erosion pits are induced after severe material removal. The microhardness increases with the distance from the target surface. At a liquid temperature of 50°C, the microhardness fluctuates apparently with increasing the depth of indentation.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools