Open Access

Open Access

ARTICLE

Experimental Investigation of Particles Dynamics and Solid-Liquid Mixing Uniformity in a Stirred Tank

1 State Key Laboratory of Complex Nonferrous Metal Resources Clean Utilization, Kunming University of Science and Technology, Kunming, 650093, China

2 Faculty of Metallurgical and Energy Engineering, Kunming University of Science and Technology, Kunming, 650093, China

3 Department of Mechanical Engineering, Faculty of Engineering, Urmia University of Technology, Urmia, 5756151818, Iran

4 State Environmental Protection Key Laboratory of Mineral Metallurgical Resources Utilization and Pollution Control, Ministry of Ecology and Environment, Wuhan, 430081, China

* Corresponding Author: Qingtai Xiao. Email:

Fluid Dynamics & Materials Processing 2024, 20(11), 2585-2602. https://doi.org/10.32604/fdmp.2024.050704

Received 14 February 2024; Accepted 01 August 2024; Issue published 28 October 2024

Abstract

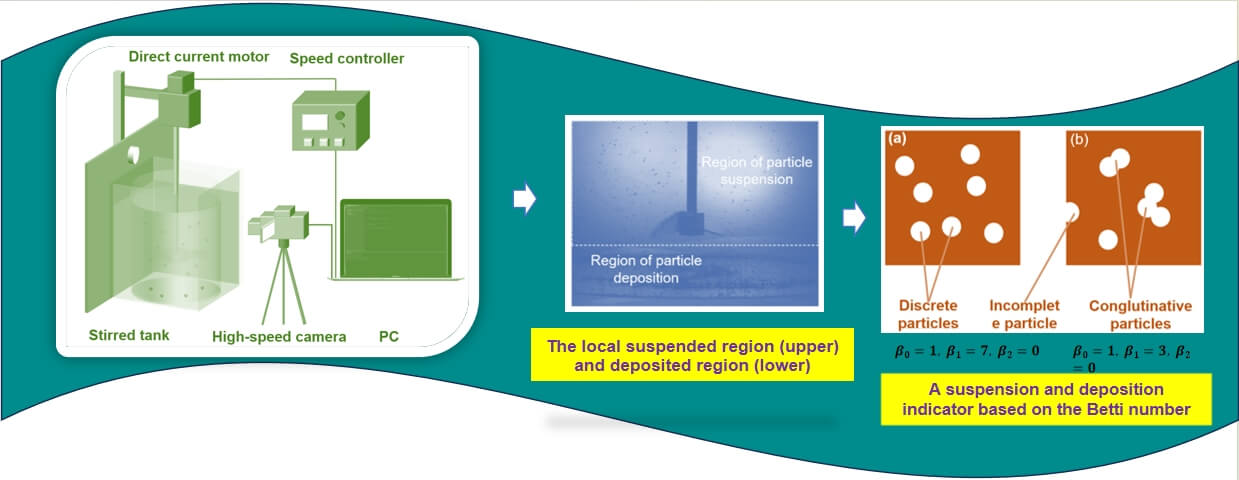

Particle suspension and deposition dynamics are significant factors affecting the level of mixing quality in solid-liquid two-phase stirring processes. In general, the ability to increase the suspension rate and minimize deposition effects is instrumental in improving the uniformity of particle mixing, accelerating the reaction of involved solid-liquid two-phase, and improving the efficiency of production operations. In this work, suspension and deposition indicator based on the Betti number and a uniformity indicator are introduced and obtained by means of image analysis. The influence of the blade type, rotation speed, blade diameter and blade bottom height on the particle suspension/deposition characteristics and mixing uniformity are carefully investigated. The experimental results show that the two-phase motion region can be divided into three local regions, including a bottom motion along the wall, a low-degree suspension region under the blade and a high suspension region above the blade. The best degree of particle suspension is attained by the double-inclined blade paddle at a speed of 270 r/min, a paddle diameter ratio of 0.414, and a height-diameter ratio of 0.086. The double-inclined blade paddle has a better effect on promoting particle suspension and solid-liquid two-phase mixing uniformity.Graphic Abstract

Keywords

Nomenclature

| CHomP | Computational homology program |

| | Coefficient of variation |

| | Local discrepancy function of temperature field |

| | Paddle diameter/cm |

| | Inner diameter of the stirred tank/cm |

| | Particle immersion degree |

| | Grayscale at the position |

| | Spatial distance between the paddles and the bottom/cm |

| | Image entropy |

| | Single non-uniformity coefficient, |

| | Quantity of rows of the grayscale matrix |

| | Quantity of columns of the grayscale matrix |

| | Height-diameter ratio |

| | Paddle diameter ratio |

| | Agitating speed/r/min |

| | Particle suspension degree |

| | Uniformity coefficient |

| | The zeroth dimension Betti number |

| | The first dimension Betti number |

| | The second dimension Betti number |

| | Local region of grayscale matrix |

| | Length of local rectangular region in particle suspension region/cm |

| | Width of local rectangular region in particle suspension region/cm |

| L1, L2, L3, L4, L5, L6 and L7 | Working conditions |

Mixing is one of the most common operations in process engineering [1–3] and has been widely used to prepare composite materials [4], promote heat and mass transfer [5], improve the chemical reaction of two-phase or multiphase systems [6], and so on [7–10]. Solid-liquid two-phase mixing is a popular operation in various mixing processes [11], and stirring is one of the most significant operations to enhance the mixing performance of solid-liquid two-phase mixtures [12]. Due to the advantages of flexible operation, high mixing state quality, large contact area, and strong applicability, stirring has been successfully used in machinery equipment [13,14], the chemical industry [15] and other process industries [16–19] since the 1940s. It is accepted that the type, size, quantity, and revolutions per minute of impellers significantly influence the flow field structure in stirred tanks. Hence, for the analogy from the convective heat transfer enhancement [20], the solid-liquid two-phase mixture can improve its mixing state quality, mass and heat transfer, and reaction yields by increasing its particle suspension degree and mixing uniformity [21]. Enhancement of the particle suspension degree and mixing uniformity is primarily related to the design of impellers, geometric configuration of the stirred tank, fluid properties, and operation conditions [22,23]. In fact, failing to account for such variations of above various influence factors would be undesirable in terms of both precise regulation of the solid-liquid two-phase mixing process and the intelligent management of the product quality of metallurgical industries.

In general, mechanical agitation injects energy into the solid-liquid two-phase mixing system through paddle rotation that generates turbulence, so that the solid phase can be suspended [24]. In the 1950s, Zwietering [25] proposed the concept of a critical state of off-bottom suspension in which no particles stayed more than 1–2 s at the bottom of the stirred tank and used it as a criterion for solid phase suspension. Based on energy balance, Baldi et al. [26] proposed a new model to explain the suspension mechanism of the solid phase in a cylindrical stirred tank. Mishra et al. [27] investigated the solid suspension performance under the stirring of a Maxblend impeller by electrical resistance tomography and computational fluid dynamics techniques. They found that the maximum homogeneity of the solid phase stirred by the Maxblend impeller was higher compared to that of the A200 and Rushton impellers. Moreover, the increase in impeller speed is detrimental to the mixing state quality after reaching the peak homogeneity [28]. Liu et al. [29] investigated and compared the just-suspended impeller speeds and just-suspended power consumption of three coaxial mixers and one single-impeller mixer in a viscous system. Giuseppina et al. [30] investigated the application of the Maxblend impeller stirring in turbulent single-phase and two-phase mixing systems using stereoscopic particle image velocimetry and electrical resistance tomography. From the work from Mirfasihi et al. [31], a set of experiments were undertaken in a benchtop baffled vessel using electrical resistance tomography to characterize blending times and mixing behaviors of miscible liquids with a range of viscosity contrasts. Yang et al. [32] investigated the effects of coaxial mixer rotation mode, impeller inner diameter, gas flow rate, and viscosity on the flow regime. These works explored the characteristics of the solid-liquid two-phase mixing process by various methods and impeller, among which the electrical tomography technique was a widely used non-invasive technique. However, if the diameter of the solid phase was too small, it would be difficult to identify small particles in the liquid phase, Maxblend impellers and coaxial mixers are very effective at mixing viscous fluids, the mixing state quality in low-viscosity fluids is poor.

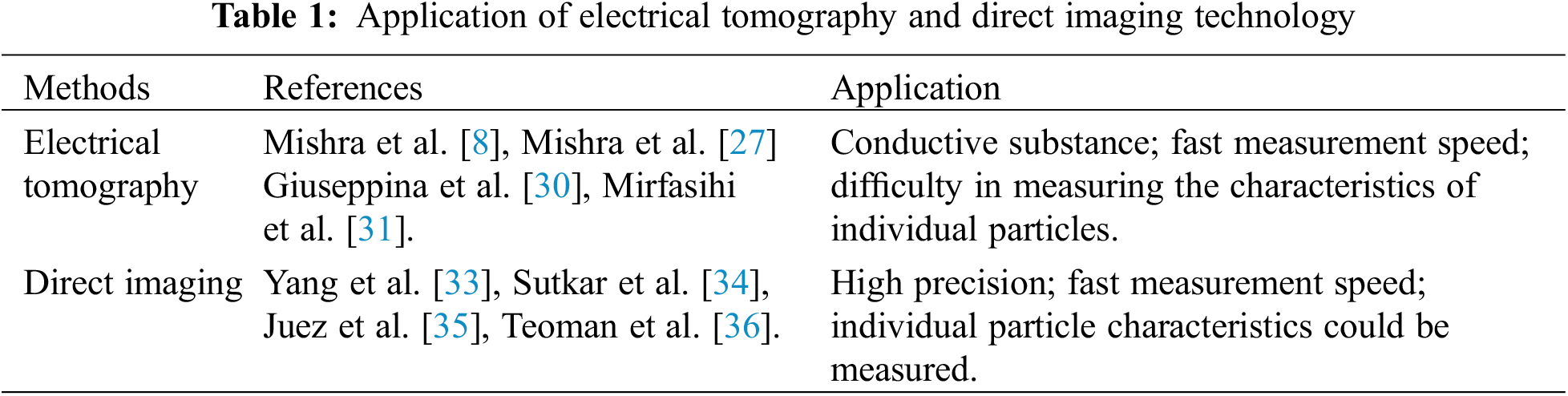

Direct imaging is a low-cost non-invasive technology that enables flexible detection. From open literature, Yang et al. [33] used visual methods to conduct a detailed experimental investigation on the suspension characteristics of a solid-liquid two-phase system with a solid phase volume fraction of 1% to 40%. Sutkar et al. [34] used Fourier transform and digital image processing technology to explore the hydrodynamic characteristics of a jet flow fluidized bed with a guide plate. Juez et al. [35] used inline digital image processing technology to study the texture evolution of pictures taken at the surface of a stirring bed. Teoman et al. [36] processed images of a vessel bottom at various stirring speeds by image processing techniques to quantify the area covered by the solid phase. Table 1 shows a comparison of electrical resistance tomography and direct imaging technology. Direct imaging technology has the following limitations. (1) It is difficult to observe the solid phase through a stirred tank, especially for industrial metal stirred tanks. (2) The solid phase overlapping is unavoidable when acquiring flow images, which leads to errors in the extracted flow features. However, the direct imaging technology has high detection accuracy, and the extracted image features can reflect the solid-liquid two-phase suspension law within a certain error range.

Furthermore, there is a need to quantitatively characterize the dynamics of the solid phase during enhanced solid-liquid two-phase mixing using mechanical agitation. For instance, Behnia et al. [37] used the Lyapunov exponent spectrum, bifurcation diagram, time series, and phase diagram to study the dynamic characteristics of the radial response of bubbles. Tchakui et al. [38] characterized the chaos of the dynamic process of a piezoelectric microelectromechanical system (MEMS) by using detection methods such as the maximum Lyapunov exponent, Poincare surface of section, and small alignment index. However, the phase space in the above methods needed to be reconstructed, and it was easy to produce certain errors due to the interference of delay time and embedding dimension. The Betti number is one of the most valuable methods to quantify the mixing time and uniformity of a multiphase flow mixing process [39], and it has been widely used to quantify the characteristics of multiphase flow mixing processes. For instance, Liao et al. [40] introduced the Betti number to evaluate the mixing state quality and the suspension effect of the solid-liquid two-phase system. In addition, the distribution uniformity of the solid-liquid two-phase mixing process, that is, the dispersion uniformity of the solid phase in the liquid phase, should also be known.

This paper aimed to study particle suspension and mixing homogeneity in stirred tanks using algebraic topology theory and image analysis. Specifically, the effects of propeller type, rotation speed, propeller diameter, and paddle height on the particle suspension and mixing uniformity of the solid-liquid two-phase mixing process were investigated. Firstly, we proposed to estimate the suspension degree of the solid phase more accurately with the help of the relationship between the Betti number and the number of particles in the local flow region. In addition, the local discrepancy function, image entropy, and coefficient of variation were introduced to evaluate the mixing uniformity of the solid and liquid mixture. This work would be helpful to expand the insights in the field of solid-liquid two-phase mixing, improve the technical accuracy of measuring the quality of solid-liquid two-phase mixing, and increase the efficiency of industrial production.

The rest of the article is structured as follows. Section 2 describes the experiment related to the solid-liquid two-phase mixing process and related methods. Section 3 discusses the effects of experimental parameters, such as the propeller type, rotation speed, propeller diameter, and paddle height, on particle suspension and solid-liquid two-phase mixing uniformity. Finally, Section 4 presents the conclusions drawn from this work.

2.1 Solid-Liquid Two-Phase Mixing Setup and Materials

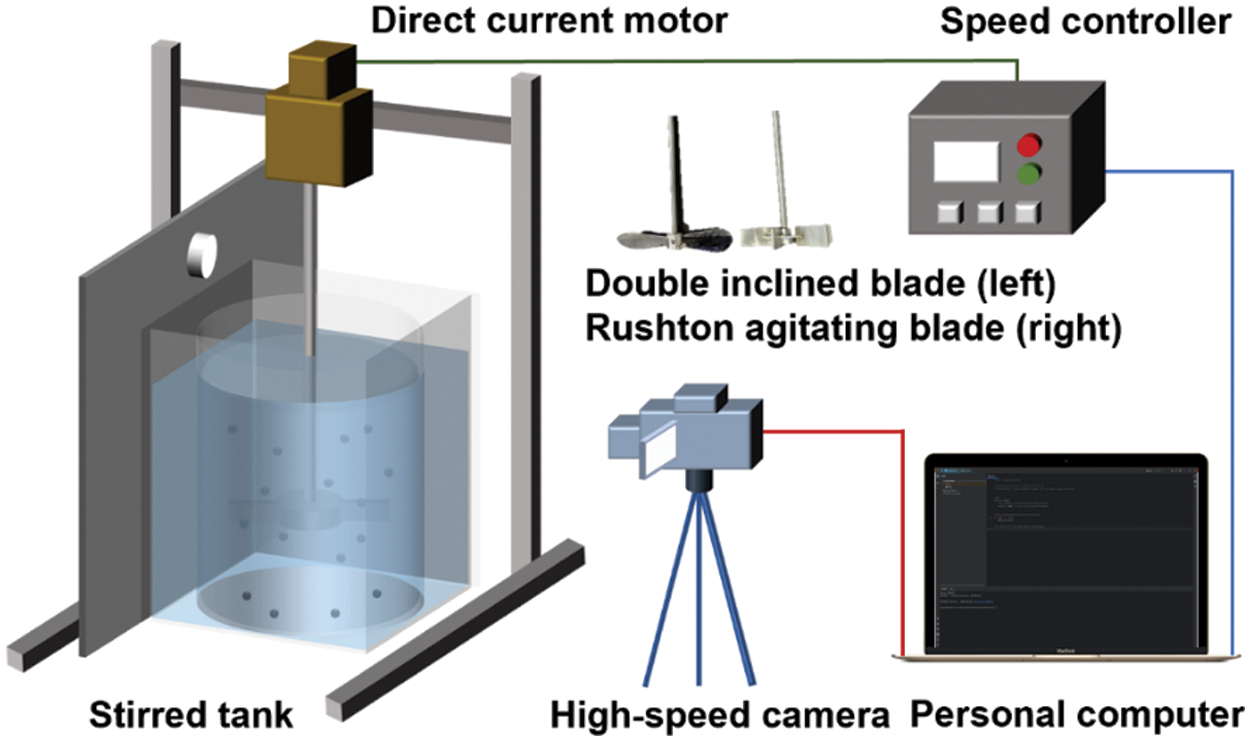

Various kinds of stirred tanks for solid-liquid two-phase mixing have been widely used in the mineral industry, metallurgical engineering, and chemical engineering for reactions, leaching, digestion, precipitation, adsorption, heat transfer, and mass transfer operations. Here, the schematic diagram of the solid-liquid two-phase mixing system is shown in Fig. 1. According to this figure, the present mixing system included the direct current motor, speed controller, stirred tank, high-speed camera, mixing paddle, and personal computer. The stirred tank was divided into two: an inner round tank and an outer square tank, both made of plexiglass. The outer diameter of the stirred tank was 300 mm, the wall thickness of the stirred tank was 5 mm, the height was 300 mm, and the filling volume of the liquid phase was 19.5 dm3. In solid-liquid two-phase mixing systems, axial impellers are critical for the mixing performance, especially to improve the suspension of particles at the bottom of the stirred tank and reduce the sedimentation of the solid phase. The mixing paddle was made of stainless steel, which had smooth surfaces, sufficient hardness, and good wear and corrosion resistance. The paddle types used in this work included a paddle with double inclined blades and a Rushton agitating paddle. The Rushton turbine is one of the most extensively studied radial pumping impellers in single-phase and multiphase operations due to its outstanding dispersion performance.

Figure 1: Schematic diagram of the custom-made solid-liquid two-phase mixing system

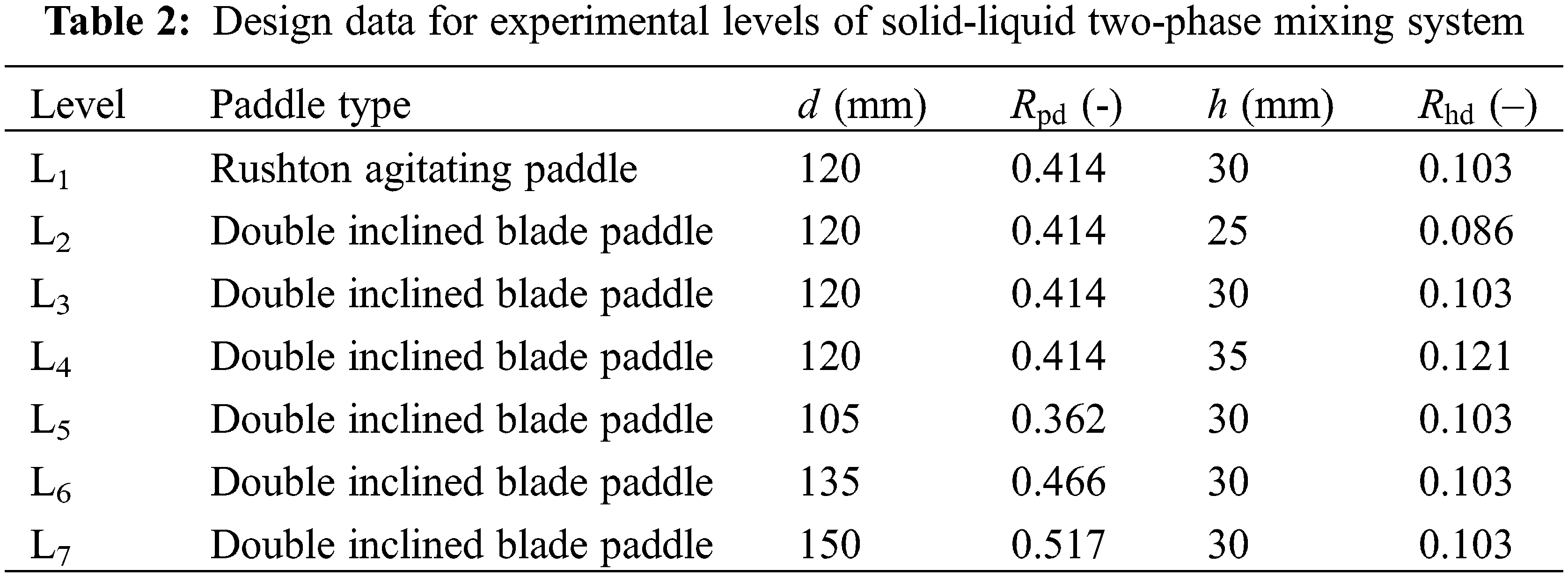

The designed operation factors and experimental setup are shown in Table 2. In this table, the paddle diameter ratio

2.2 Indicators of Particle Suspension and Mixing Uniformity

Theoretically, homology analysis is developed as an advanced form of topology that deals not with measurable features such as lengths and/or angles but mostly with the connectivity of given objects. In the field of algebraic topology theory, the topological space,

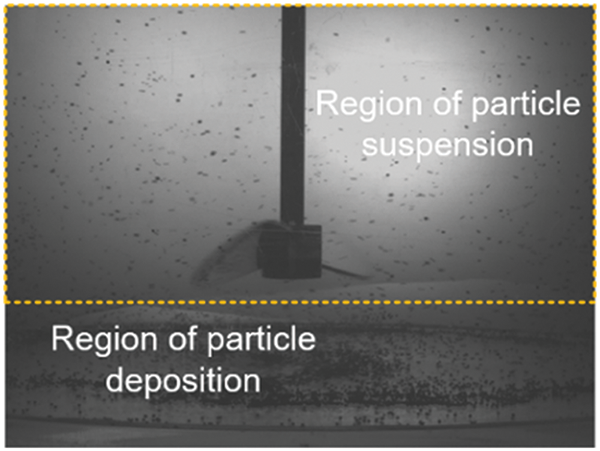

In this work, the instantaneous flow images of the solid-liquid two-phase mixing process were recorded by the high-speed camera. Then, these captured flow images were converted into grayscale patterns, as shown in Fig. 2. The local upper region in a typical flow image was defined as the particle suspension region. In the lower part of a typical flow image, the local region of which the top line was approximately 10 mm away from the bottom of the stirred tank was defined as the particle deposition region. Therefore, the first dimension Betti number

and

where

Figure 2: Schematic diagram of the region of particle suspension (upper) and region of particle deposition (lower) of the solid particles in solid-liquid two-phase mixing process

Digital image processing technology is favorable for describing images or physical fields. Mathematically, a digital image can be converted into a digital matrix composed of various pixels. Here, the grayscale flow image of the solid-liquid two-phase mixing process could be regarded as a digital matrix. In addition, experiments are essential to industrial and scientific areas. In statistical experiment design theory, the uniform (low-discrepancy) design seeks its design points to be uniformly scattered on the experimental domain by minimizing a given discrepancy. The introduced concept (i.e., discrepancy) characterizes the deviation between the empirical distribution of the design points and the theoretical uniform distribution of the design points. Some bias-correction techniques are commonly adopted to improve the finite-sample performance of these estimators [41]. For

where

where

where

A quantitative measure of mixing uniformity is essential to enable accurate recognition of uniformly distributed points by computers without human intervention. A good mathematical measure of mixing uniformity must also agree with the human perception of mixing uniformity. The coefficient of variation (denoted hereinafter by

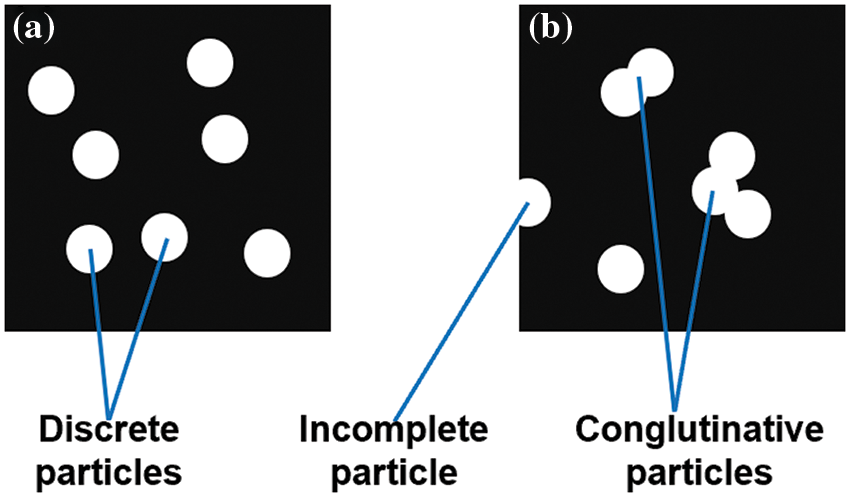

Direct imaging methods also have their limitations. For a comprehensive error analysis, Fig. 3 shows a simplified error analysis model based on the topology of the multi-dimensional Betti number structure. In Fig. 3a the independent distribution of the solid phase in the local imaging region is shown with several topologically invariant Betti numbers: the zeroth Betti number

Figure 3: Case of independent distribution of solid phase in the local imaging region (a) and case of connected solid phase in the local imaging region (b)

3.1 Effect of Paddle Shape on Particle Suspension and Mixing Uniformity

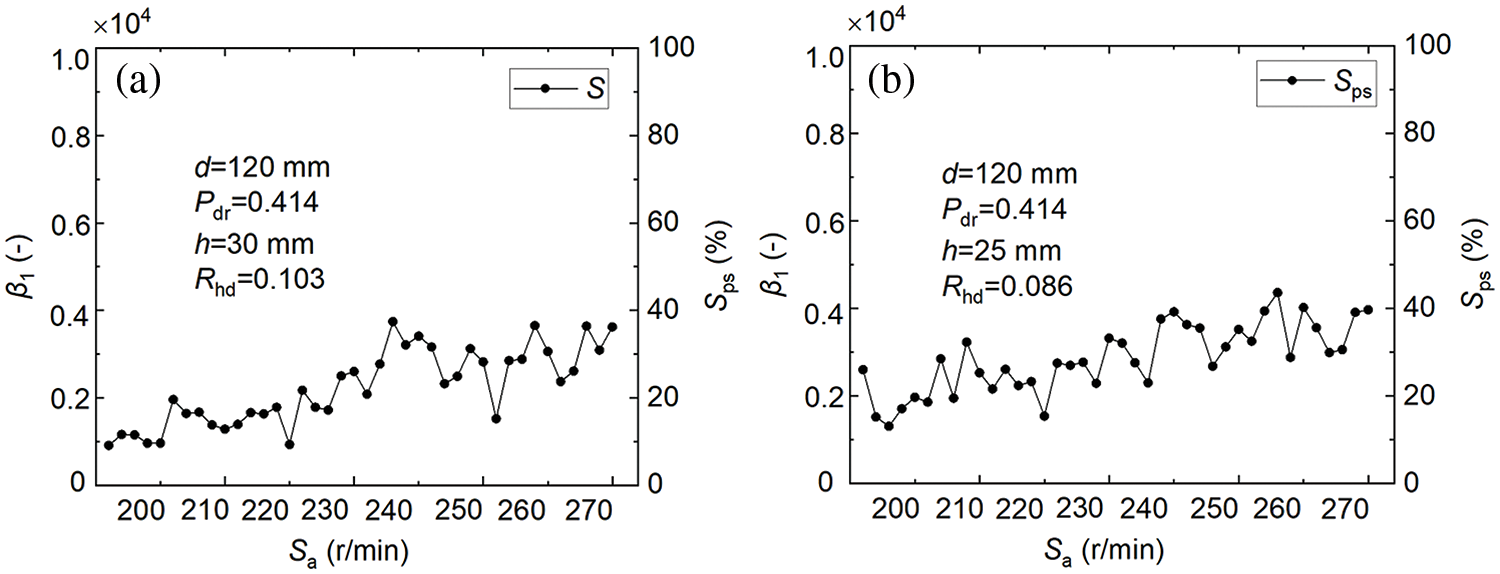

Uniform mixing of solid-liquid two-phase is desired to avoid the deposition of the solid phase (i.e., particles), enhance the contact area between the solid and liquid phases, improve the reaction rates between reactants, and ensure uniform reaction progress in the whole stirred tank. It is well known that an appropriate selection of design variables and operating parameters including the impeller speed, impeller clearance, and number of impellers could enhance the suspension quality of solid-liquid two-phase mixtures. Fig. 4 shows the first dimension Betti number

Figure 4: Relation between Rushton agitating paddle and particle suspension degree (a); relation between paddle with double inclined blades and particle suspension degree (b)

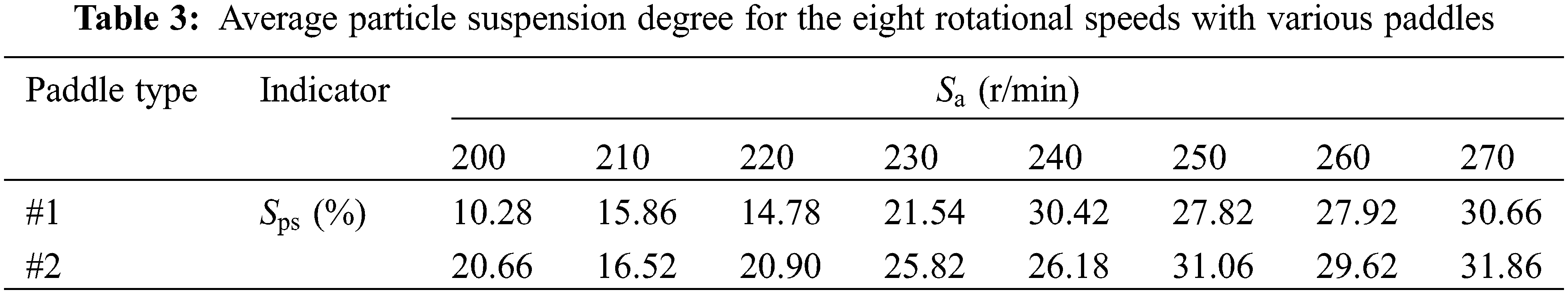

Solid-liquid two-phase mixing systems have been popular in industrial production and scientific experiments related to suspension. The change in concentration and the fluctuation of uniformity directly determine the physical and chemical properties and service stability of the final product. Therefore, real-time, in-situ, and precise measurements are critical. As shown in Table 3, Case #1 used the Rushton agitating paddle, and Case #2 employed the paddle with double inclined blades. Under the stirring of the Rushton agitating paddle, the average particle suspension degree corresponding to the eight rotational speeds was 10.28%, 15.86%,

The distribution of a finite number of points (e.g., particles or solid phase) is referred to as a pattern in this work. Uniformity and aggregation of particles or solid phase are considered as two typical opposite features of a pattern. The uniformity indicator is used to describe the uniformity of a finite point set (e.g., particles, bubbles, or droplets). However, aggregation may increase solid-solid interfaces between particles, bubbles, or droplets. In the following text, therefore, some experimental results related to the mixing uniformity of the solid-liquid two-phase mixture in the stirred tank are illustrated, where the two paddles (i.e., the Rushton agitating paddle and paddle with double inclined blades) are considered.

The two panels of Fig. 5 show the uniformity coefficient (denoted hereinafter by

Figure 5:

3.2 Effect of Rotational Speed on Particle Suspension and Mixing Uniformity

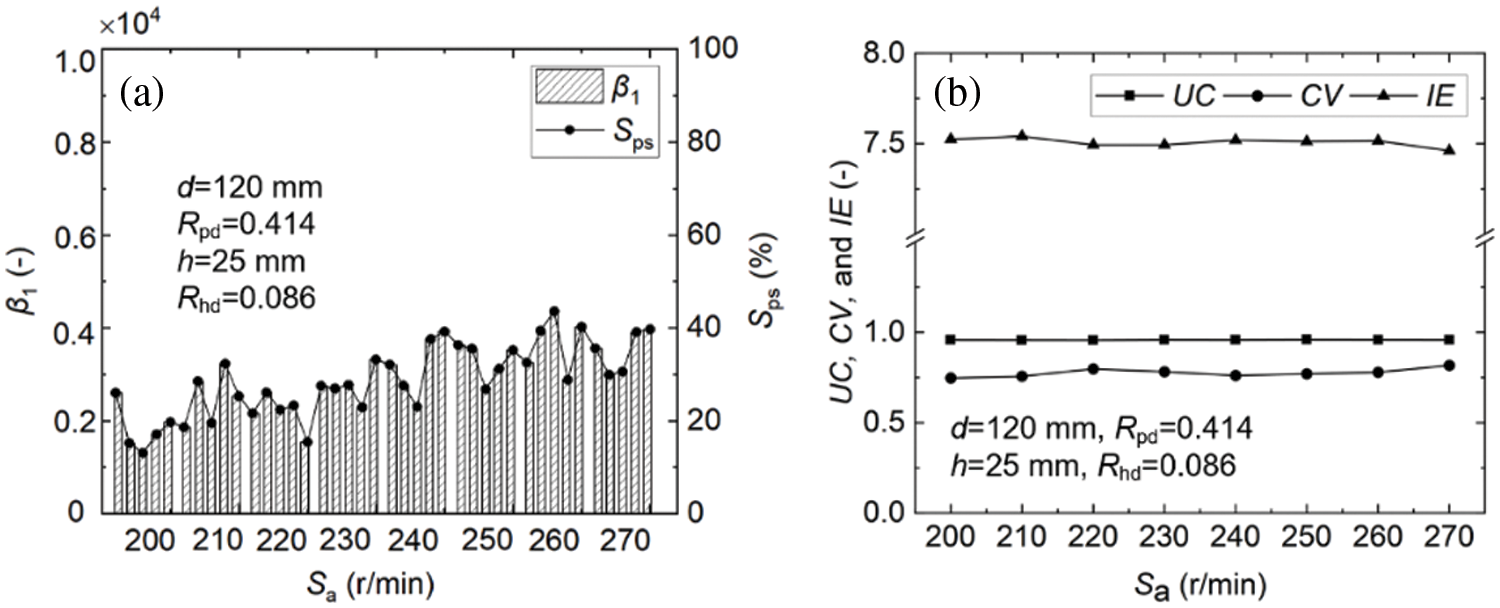

Another factor essential for the solid-liquid two-phase mixing process is the agitation speed. For generalization, the key is to convert the stirring speed to the Reynolds number. The solid-liquid two-phase mixing process at various agitation speeds was successfully conducted and the experimental data are shown in Fig. 6. According to this figure, the agitation speed was varied as follows:

Figure 6: Relation between

3.3 Effect of Propeller Diameter on Particle Suspension and Mixing Uniformity

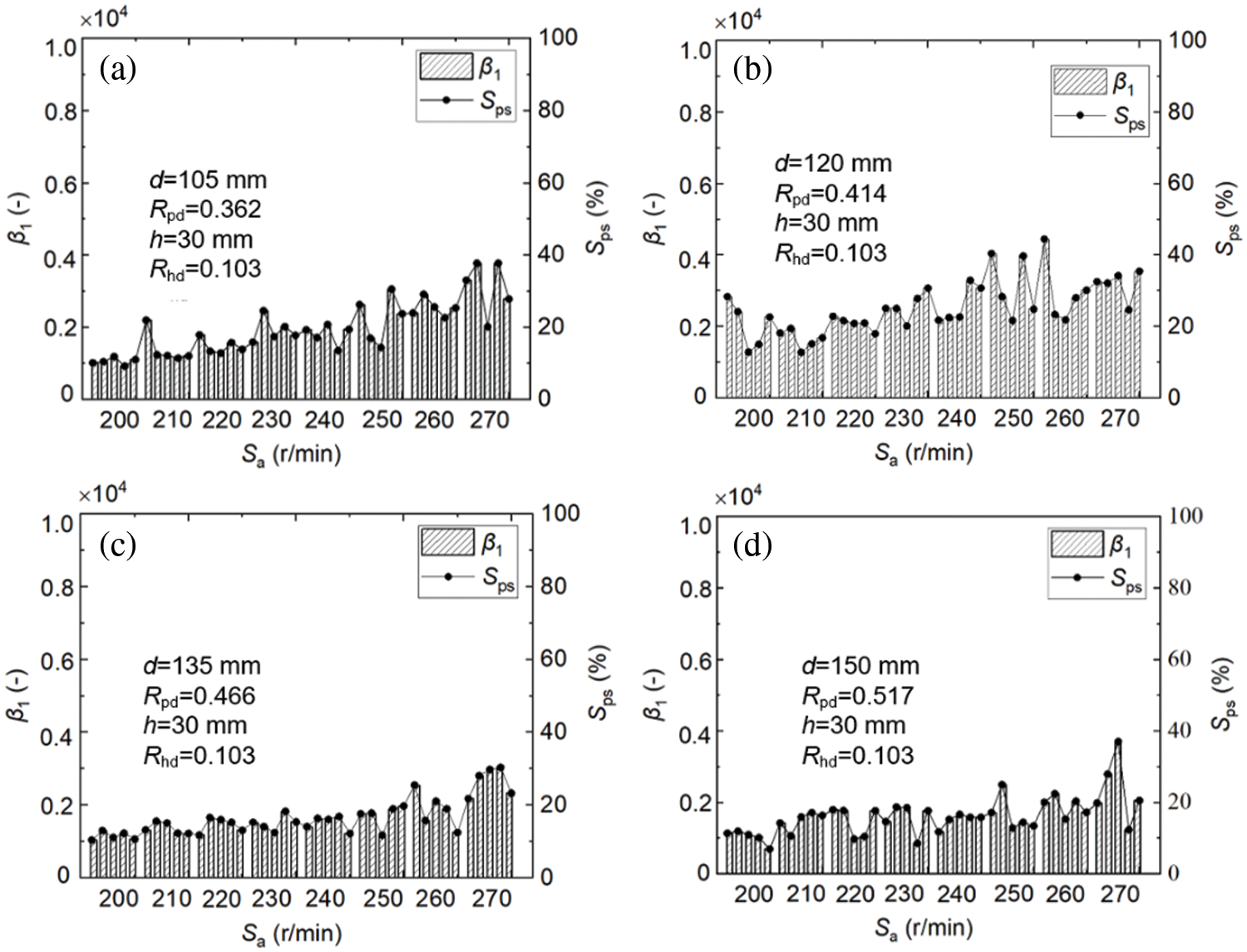

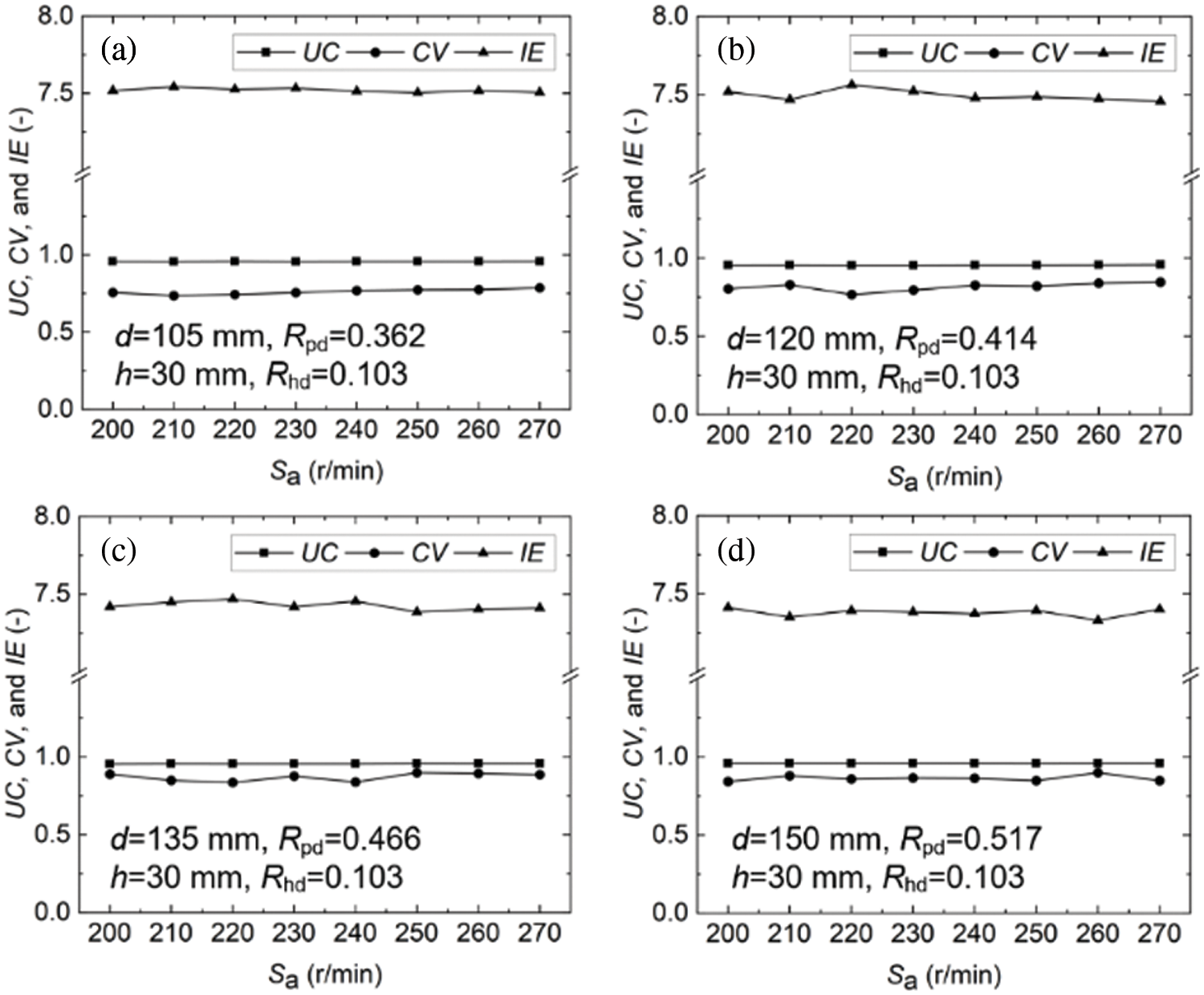

Another popular variation among design variables and operation parameters is the paddle wheel diameter. Experiments were conducted in the tanks with four paddle wheel diameters. Fig. 7 shows the relationship between paddle diameter and particle suspension degree. The paddle diameter ratio in this figure was

Figure 7: (a) Relationship between Sa and β1 for paddle diameter d = 105 mm, (b) Relationship between Sa and β1 for paddle diameter d = 120 mm, (c) Relationship between Sa and β1 for paddle diameter d = 135 mm, (d) Relationship between Sa and β1 for paddle diameter d = 150 mm

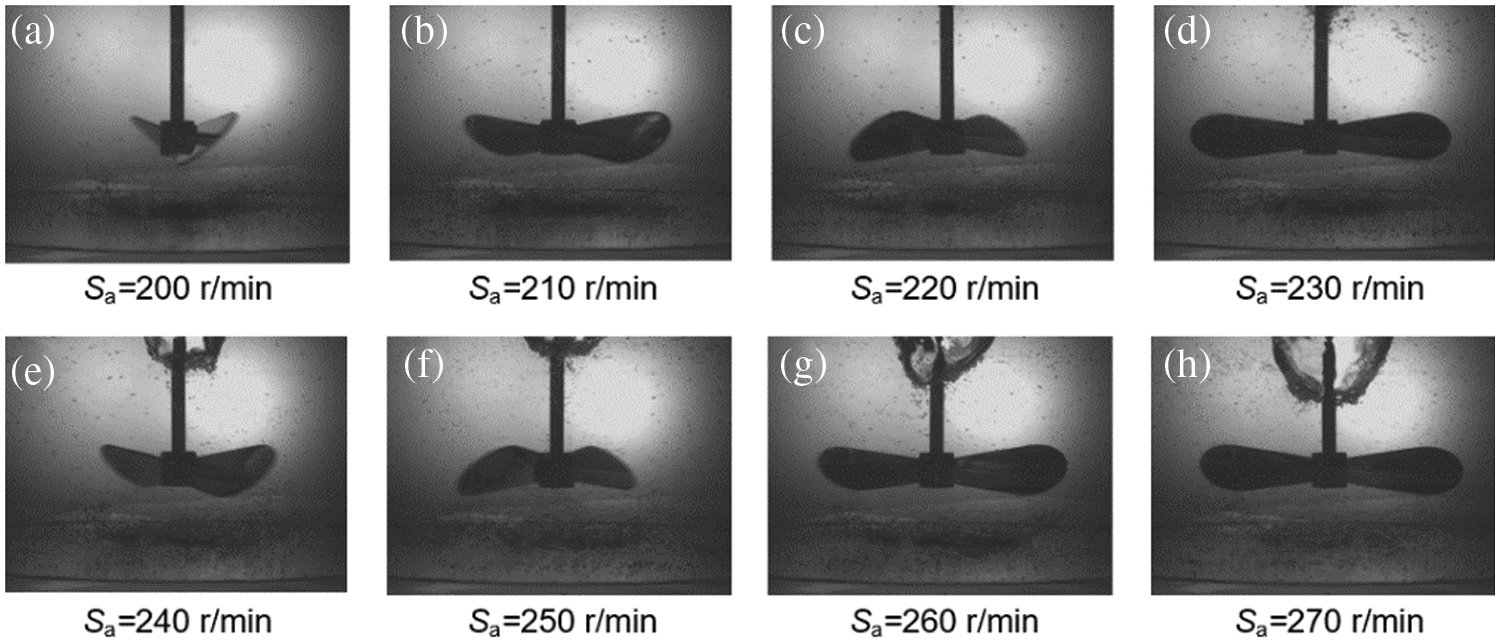

As shown in Fig. 8, the solid phase moved in low suspension below the paddle and near the middle of the tank bottom when the paddle diameter ratio was large enough. The reason might be that the state dominated by the bottom motion near the wall became the state dominated by the low-degree suspension motion below the paddle. Therefore, for the solid-liquid two-phase agitation, there would be an optimal propeller diameter or propeller diameter ratio. Under this condition, a relatively optimal mixing state quality could be obtained for the solid-liquid two-phase system. However, the mixing state quality of the solid-liquid two-phase mixture would be reduced if the propeller diameter was less than or exceeded this level.

Figure 8: Instantaneous image of solid-liquid two-phase mixing process from the case L7

In addition, the stirring performance analysis is of great research significance, and a vast number of flow visualization tests have been undertaken before assessing the mixing performance to identify the mixing behavior. Hence, several data were combined to check the stirring performance and obtain the working environment for better stirring performance. The fluctuations of

Figure 9: The uniformity coefficient (

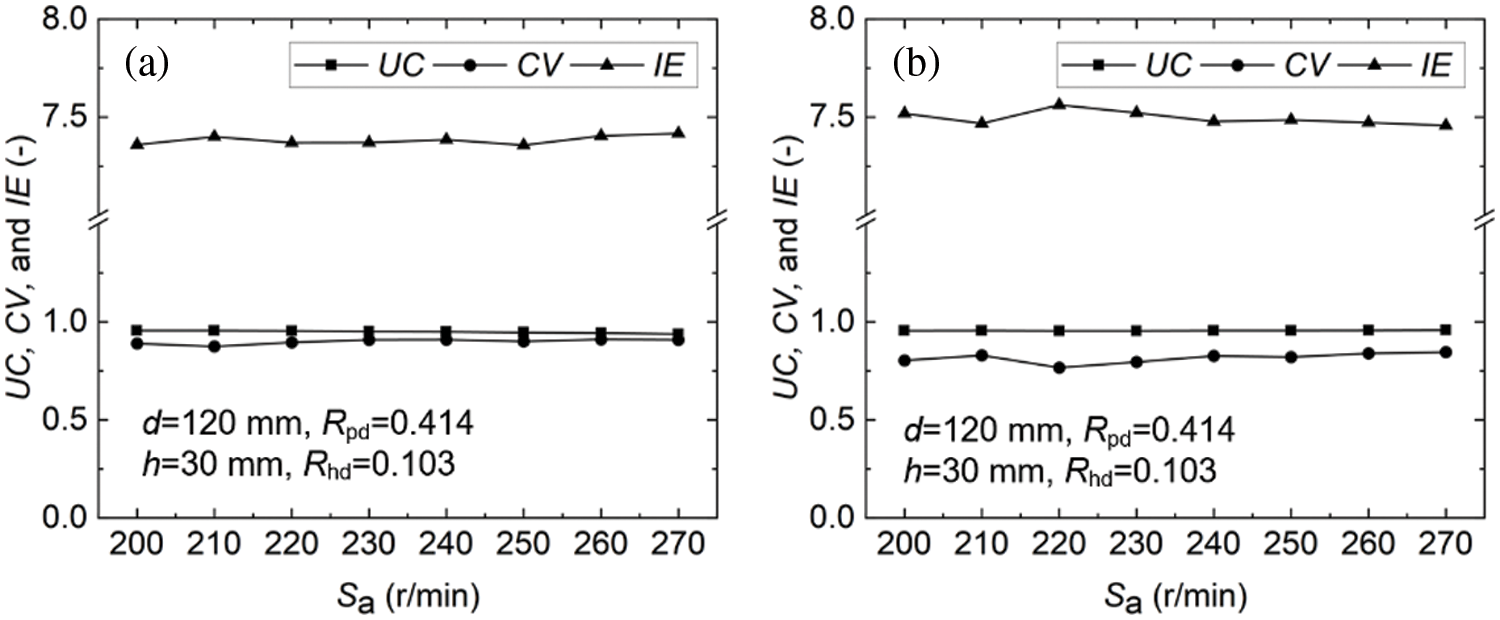

3.4 Effect of Paddle Height off the Bottom on Mixing State Quality

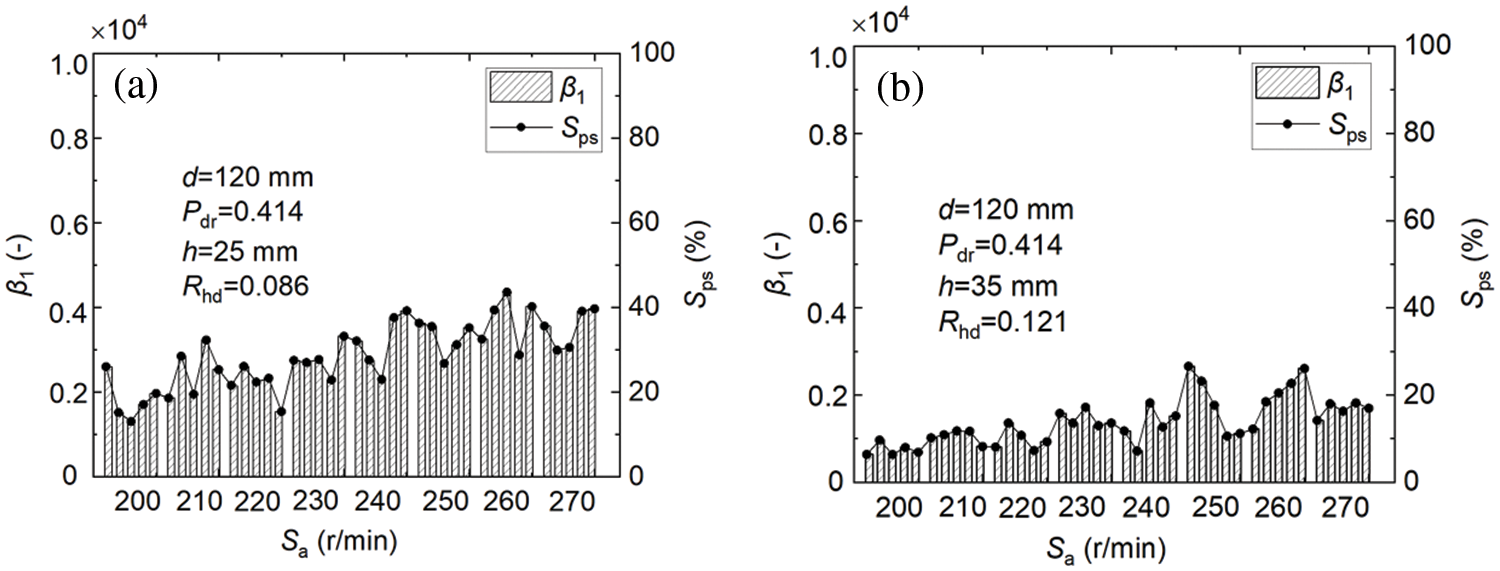

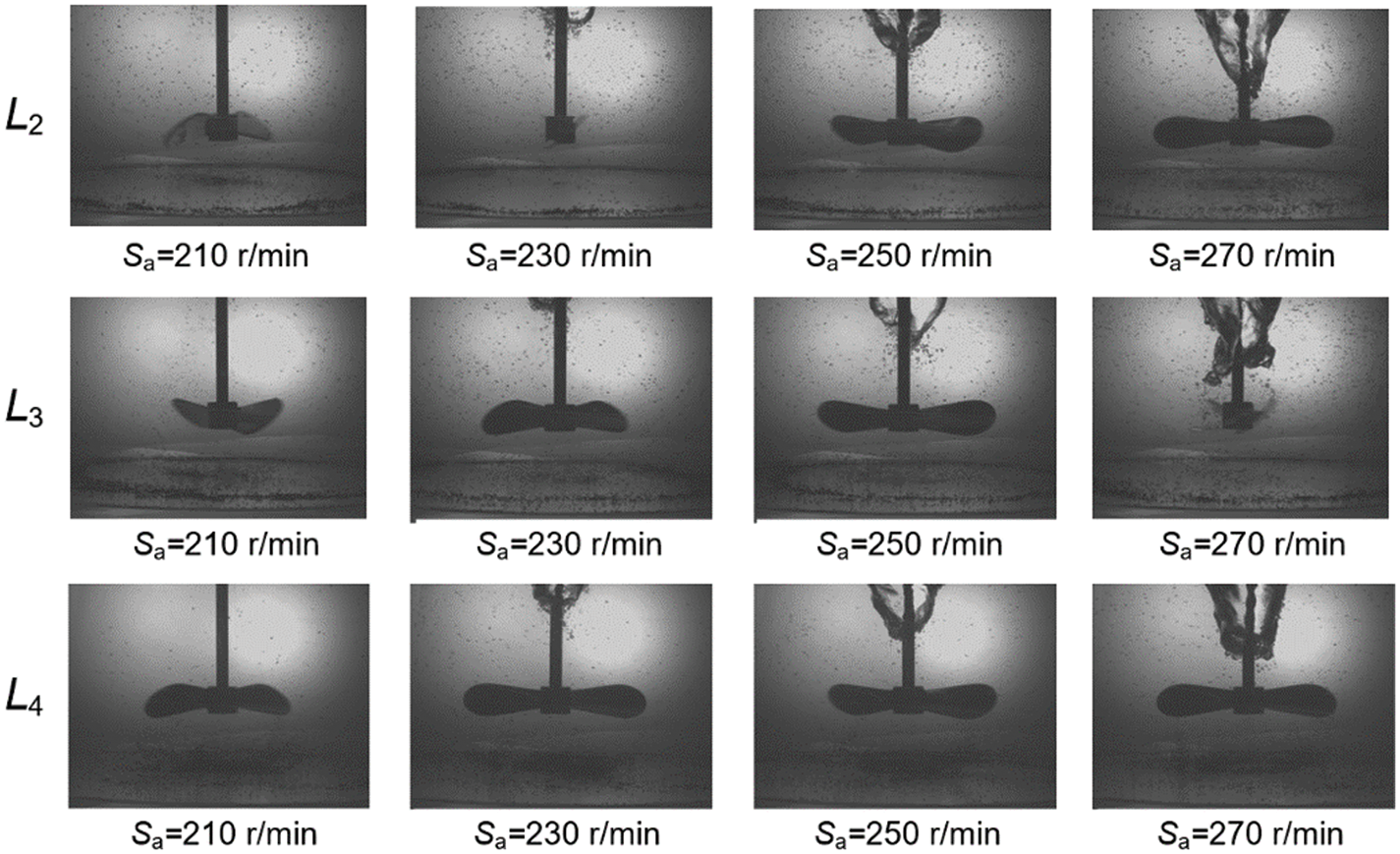

Fig. 10 shows the relationship between the height of the paddle off the bottom and the particle suspension degree. It could be seen from this figure that the particle suspension degree showed a decreasing trend with the increase in height-diameter ratio. The solid phase tended to deposit at the bottom of the stirred tank and move along the wall during mixing when the height-diameter ratio of the paddle was small. The solid phase in low suspension under the paddle at high rotational speeds seemed to be less. Fig. 11 shows the flow images of the solid-liquid two-phase mixing process of L2, L3, and L4. The solid phase under the paddle was more likely to show the state of the bottom near the wall. The solid phase began to gather toward the center and showed a low suspension state when the height-diameter ratio increased. The solid phase at the tank bottom converged toward the center, and most of them showed a low suspension state under the paddle. Almost no particles moved along the wall, and high rotational speed could further promote the solid phase below the paddle to show a low suspension state. It also increased the motion range of the solid phase in low suspension. Therefore, the decrease of the height of the paddle off the bottom could promote the mixing state quality of the solid-liquid two-phase mixture, but when the height was too small, its effect on the mixing state quality was also diminished.

Figure 10: Relationship between Sa and β1 for the height of the paddle off the bottom h = 0.25 mm (a) and h = 0.35 mm (b)

Figure 11: Flow images from solid-liquid two-phase mixing process of L2, L3, and L4

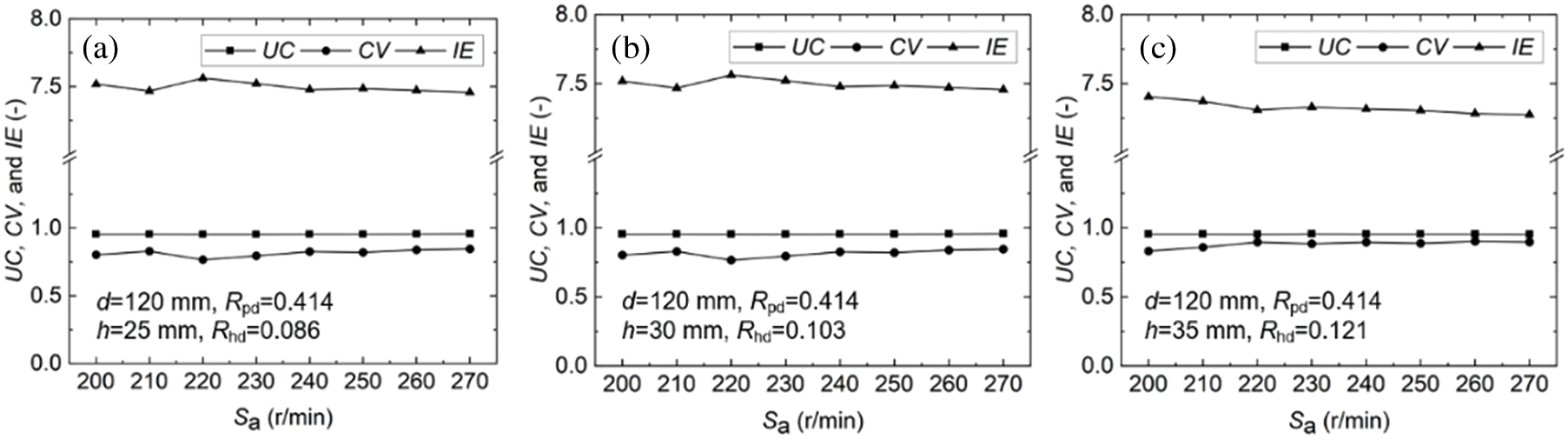

On the one hand, a high height-diameter ratio of the stirred tank was usually believed to be beneficial due to improved selection pressure on particles with better settling ability. On the other hand, some operations needed to be carried out at appropriate blade speeds to obtain the necessary quality and maximum throughput. However, a change in the blade speed would bring about changes to the mixing process in several approaches. For instance, there would be changes in the particle flow patterns, particle structure, and force imparted to the particles in the mixture. Knowledge of these matters is still in its infancy. In addition, investigations of the effect of blade speed would also become critical when scaling up a solid-liquid two-phase stirred tank to a full-scale mixer. Fig. 12 shows

Figure 12: The uniformity coefficient (UC), coefficient of variation (CV) and image entropy (IE) with stirring of paddle with double inclined blades and paddle height h = 25 mm (a), h = 30 mm (b) and h = 35 mm (c).

In this work, the experiment for measuring the mixing state quality of the solid-liquid two-phase mixture was designed, and the flow images of the solid-liquid two-phase mixing process were obtained and processed. Specifically, the suspension indicators of the solid phase and mixing uniformity of the solid-liquid two-phase mixture were obtained by algebraic topology theory and digital image processing technology. The relationships between the mixing state quality and the propeller type, rotating speed, propeller diameter, and distance between the paddle and bottom were analyzed. The increase in agitating speed could promote the particle suspension degree, and the higher the agitating speed, the greater the effect on the mixing state quality. The decrease of the spacing between the paddle and the bottom could also improve the particle suspension degree, but the effect on the mixing state quality of the solid phase and liquid phase was diminished if the spacing was too small. The influence of paddle diameter on the mixing state quality of the solid-liquid two-phase mixture was also large and differed from the previous two. For agitating solid-liquid two-phase mixing, an optimal paddle diameter or paddle diameter ratio existed, under which the optimum mixing state quality of the solid-liquid two-phase mixture could be obtained. The solid phase motion could be divided into three parts: bottom motion along the wall, low suspension under the blade, and high suspension above the blade. The best particle suspension degree could be achieved at an agitating speed of 270 r/min, a paddle diameter ratio of 0.414, and a height diameter ratio of 0.086 by the paddle with double inclined blades.

Acknowledgement: The authors wish, especially, to thank the referees for numerous detailed questions and comments that greatly improved the presentation.

Funding Statement: The authors acknowledge the financial support from the Yunnan Fundamental Research Project, China (No. 202201BE070001-026), Interdisciplinary Research Project of Kunming University of Science and Technology (No. KUST-xk2022001), Yunnan Major Scientific and Technological Projects (No. 202302AQ370001-4), Open Foundation of State Environmental Protection Key Laboratory of Mineral Metallurgical Resources Utilization and Pollution Control (No. HB202204), and Young Elite Scientist Sponsorship Program by China Association for Science and Technology, China (No. YESS20210106).

Author Contributions: The authors confirm contribution to the paper as follows: study conception and design: Kai Yang, Hua Wang, Qingtai Xiao; data collection: Kai Yang, Qinwen Yao, Qingtai Xiao, Yingshan Li; analysis and interpretation of results: Kai Yang, Qinwen Yao, Saleh Khorasani, Qingtai Xiao; draft manuscript preparation: Kai Yang, Wanchang Chen, Qingtai Xiao. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Yang K, Liu J, Wang M, Wang H, Xiao Q. Identifying flow patterns in a narrow channel via feature extraction of conductivity measurements with a support vector machine. Sensors. 2023;23(4):1907. doi:10.3390/s23041907. [Google Scholar] [PubMed] [CrossRef]

2. Kress P, Nägele H-J, Oechsner H, Ruile S. Effect of agitation time on nutrient distribution in full-scale CSTR biogas digesters. Bioresour Technol. 2018;247:1–6. doi:10.1016/j.biortech.2017.09.054. [Google Scholar] [PubMed] [CrossRef]

3. Jadidi B, Ebrahimi M, Ein-Mozaffari F, Lohi A. Analysis of cohesive particles mixing behavior in a twin-paddle blender: DEM and machine learning applications. Particuology. 2024;90:350–63. doi:10.1016/j.partic.2023.12.010. [Google Scholar] [CrossRef]

4. Wu W, Chen K, Tsotsas E. Prediction of particle mixing in rotary drums by a DEM data-driven PSO-SVR model. Powder Technol. 2024;434:119365. doi:10.1016/j.powtec.2024.119365. [Google Scholar] [CrossRef]

5. Bowler AL, Bakalis S, Watson NJ. A review of in-line and on-line measurement techniques to monitor industrial mixing processes. Chem Eng Res Des. 2020;153:463–95. doi:10.1016/j.cherd.2019.10.045. [Google Scholar] [CrossRef]

6. Deng T, Fisonga M, Ke H, Li L, Wang J, Deng Y. Mixing uniformity effect on leaching behaviour of cement-based solidified contaminated clay. Sci Total Environ. 2024;908:167957. doi:10.1016/j.scitotenv.2023.167957. [Google Scholar] [PubMed] [CrossRef]

7. Yang K, Wang Y, Li M, Li X, Wang H, Xiao Q. Modeling topological nature of gas-liquid mixing process inside rectangular channel using RBF-NN combined with CEEMDAN-VMD. Chem Eng Sci. 2023;267:118353. doi:10.1016/j.ces.2022.118353. [Google Scholar] [CrossRef]

8. Mishra P, Ein-Mozaffari F. Critical review of different aspects of liquid-solid mixing operations. Rev Chem Eng. 2020;36(5):555–92. doi:10.1515/revce-2018-0017. [Google Scholar] [CrossRef]

9. Mao C, Hou Y, Wang Y. Research on the effects of slurry uniformity and mixing power of continuous cementing slurry mixers based on statistical and CFD methods. Geoenergy Sci Eng. 2024;233:212574. doi:10.1016/j.geoen.2023.212574. [Google Scholar] [CrossRef]

10. Yang K, Wang Y, Wang M, Pan J, Wang H, Xiao Q. A unified heat transfer model for gas-liquid two-phase mixing process in a rectangular channel based on steady status identification. Appl Therm Eng. 2024;236:121612. doi:10.1016/j.applthermaleng.2023.121612. [Google Scholar] [CrossRef]

11. Yang Z, Holemans T, Lagrain B, Sels B, Vanierschot M. A solid-liquid mixing reactor based on swirling flow technology. Chem Eng Sci. 2023;280:119054. doi:10.1016/j.ces.2023.119054. [Google Scholar] [CrossRef]

12. Kajiwara S, Sakai M. Numerical investigation on a bimodal mixing system of solid-liquid mixture in an industrial mixing cooker. Adv Powder Technol. 2024;35(1):104300. doi:10.1016/j.apt.2023.104300. [Google Scholar] [CrossRef]

13. Sandhanshiv RD, Patel DM. Design and fabrication of an adjustable stirring and degassing system for synthesis of metal matrix composite material. Mater Today Proc. 2022;59:974–8. [Google Scholar]

14. Yamazaki T, Kitamura S, Matsumiya T. Effect of liquid phase in flux on hot metal desulfurization by mechanical stirring process. Tetsu Hagane-J Iron Steel Inst Jpn. 2019;105(1):1–9. doi:10.2355/tetsutohagane.TETSU-2018-123. [Google Scholar] [CrossRef]

15. Li D, Lu T, Yu Z, Song W, Ding Y. Experimental investigation on the promotion of CO2 hydrate formation for cold thermal energy storage-effect of gas-inducing stirring under different agitation speeds. Green Energy Resour. 2023;1(4):100047. doi:10.1016/j.gerr.2024.100047. [Google Scholar] [CrossRef]

16. Yulianingsih R, Gohtani S. The influence of stirring speed and type of oil on the performance of pregelatinized waxy rice starch emulsifier in stabilizing oil-in-water emulsions. J Food Eng. 2020;280:109920. [Google Scholar]

17. Lee Y, Lee S, Cui M, Kim J, Ma J, Han Z, et al. Improving sono-activated persulfate oxidation using mechanical mixing in a 35-kHz ultrasonic reactor: persulfate activation mechanism and its application. Ultrason Sonochem. 2021;72:105412. doi:10.1016/j.ultsonch.2020.105412. [Google Scholar] [PubMed] [CrossRef]

18. Jin X, Chandratilleke RG, Wang S, Shen Y. DEM investigation of mixing indices in a ribbon mixer. Particuology. 2022;60:37–47. doi:10.1016/j.partic.2021.03.005. [Google Scholar] [CrossRef]

19. Adibi M, Mirkazemi SM, Alamolhoda S. The comparative study on microstructure and magnetic properties of cobalt ferrite/MWCNTs nanocomposite prepared using mechanical mixing and hydrothermal routs. J Magn Magn Mater. 2023;586:171187. doi:10.1016/j.jmmm.2023.171187. [Google Scholar] [CrossRef]

20. Zhang M, Gao Q, Zhao Z, Guo L, Li X, Zhang C, et al. Liquid metal manifold microchannel heat sink for ultra-high heat flux cooling. Appl Therm Eng. 2024;248:123117. doi:10.1016/j.applthermaleng.2024.123117. [Google Scholar] [CrossRef]

21. Kolano M, Danke J, Kraume M. Using thrust to control the mixing process in stirred tanks with side-entering agitators and viscoelastic fluids. Biomass Bioenergy. 2021;152:106180. doi:10.1016/j.biombioe.2021.106180. [Google Scholar] [CrossRef]

22. Li A, Yao Y, Tang X, Liu P, Zhang Q, Li Q, et al. Experimental and computational investigation of chaotic advection mixing in laminar rectangular stirred tanks. Chem Eng J. 2024;485:149956. doi:10.1016/j.cej.2024.149956. [Google Scholar] [CrossRef]

23. Meng T, Wang Y, Wang S, Qin S, Zhang Q, Wang Y, et al. Exploration of multishafts stirred reactors: an investigation on experiments and large eddy simulations for turbulent chaos and mixing characteristics. Ind Eng Chem Res. 2024;63(5):2441–56. doi:10.1021/acs.iecr.3c04042. [Google Scholar] [CrossRef]

24. Wu J, Nguyen B, Graham L, Hurley M, Harris D, Short G, et al. Increased agitation reliability for slurry suspension in mineral processing. Miner Eng. 2021;170:107008. doi:10.1016/j.mineng.2021.107008. [Google Scholar] [CrossRef]

25. Zwietering TN. Suspending of solid particles in liquid by agitators. Chem Eng Sci. 1958;8(3–4):244–53. doi:10.1016/0009-2509(58)85031-9. [Google Scholar] [CrossRef]

26. Baldi G, Conti R, Alaria E. Complete suspension of particles in mechanically agitated vessels. Chem Eng Sci. 1978;33(1):21–5. doi:10.1016/0009-2509(78)85063-5. [Google Scholar] [CrossRef]

27. Mishra P, Ein-Mozaffari F. Using tomograms to assess the local solid concentrations in a slurry reactor equipped with a Maxblend impeller. Powder Technol. 2016;301:701–12. doi:10.1016/j.powtec.2016.07.007. [Google Scholar] [CrossRef]

28. Mishra P, Ein-Mozaffari F. Using computational fluid dynamics to analyze the performance of the Maxblend impeller in solid-liquid mixing operations. Internal J Multiphase Flow. 2017;91:194–207. doi:10.1016/j.ijmultiphaseflow.2017.01.009. [Google Scholar] [CrossRef]

29. Liu B, Xu Z, Fan F, Huang B. Experimental study on the solid suspension characteristics of coaxial mixers. Chem Eng Res Des. 2018;133:335–46. doi:10.1016/j.cherd.2018.03.035. [Google Scholar] [CrossRef]

30. Giuseppina M, Francesco M, Federico A, Suzuka I, Katsuhide T, Alessandro P. Large blade impeller application for turbulent liquid-liquid and solid-liquid mixing. Can J Chem Eng. 2022;100(9):2230–44. doi:10.1002/cjce.24483. [Google Scholar] [CrossRef]

31. Mirfasihi S, Basu W, Martin P, Kowalski A, Fonte CP, Keshmiri A. Investigation of mixing miscible liquids with high viscosity contrasts in turbulently stirred vessels using electrical resistance tomography. Chem Eng J. 2024;486:149712. doi:10.1016/j.cej.2024.149712. [Google Scholar] [CrossRef]

32. Yang C, Yao J, Chen X, Xu Z, Zhou G, Xu Z, et al. Experimental study on gas-liquid flow regimes of coaxial mixers equipped with a Rushton/pitched blade turbine and anchor. Chem Eng Res Des. 2024;202:377–89. doi:10.1016/j.cherd.2023.12.040. [Google Scholar] [CrossRef]

33. Yang M, Lai Y. Experimental study on solid-liquid suspension characteristics in a mixing tank. Chin J Mech Eng. 2011;47(6):186–92 (In Chinese). doi:10.3901/JME.2011.06.186. [Google Scholar] [CrossRef]

34. Sutkar VS, Deen NG, Salikov V, Antonyuk S, Heinrich S, Kuipers JAM. Experimental and numerical investigations of a pseudo-2D spout fluidized bed with draft plates. Powder Technol. 2015;270:537–47. doi:10.1016/j.powtec.2013.11.030. [Google Scholar] [CrossRef]

35. Juez JM, Artoni R, Cazacliu B. Monitoring of concrete mixing evolution using image analysis. Powder Technol. 2017;305:477–87. doi:10.1016/j.powtec.2016.10.008. [Google Scholar] [CrossRef]

36. Teoman B, Shastry S, Abdelhamid S, Armenante PM. Imaging method for the determination of the minimum agitation speed, Njs, for solids suspension in stirred vessels and reactors. Chem Eng Sci. 2021;231:116263. doi:10.1016/j.ces.2020.116263. [Google Scholar] [CrossRef]

37. Behnia S, Mobadersani F, Yahyavi M, Rezavand A. Chaotic behavior of gas bubble in non-Newtonian fluid: a numerical study. Nonlinear Dyn. 2013;74:559–70. doi:10.1007/s11071-013-0988-3. [Google Scholar] [CrossRef]

38. Tchakui MV, Woafo P, Skokos C. Chaotic dynamics of piezoelectric mems based on maximal Lyapunov exponent and Smaller Alignment Index computations. Int J Bifurcat Chaos. 2019;30:09. [Google Scholar]

39. Gameiro M, Singh A, Kondic L, Mischaikow K, Morris JF. Interaction network analysis in shear thickening suspensions. Phys Rev Fluids. 2020;5(3):034307. doi:10.1103/PhysRevFluids.5.034307. [Google Scholar] [CrossRef]

40. Liao Y, Wei N, Liu J, Wang H, Xiao Q. Enhancement of solid-liquid mixing state quality in a mechanical stirred reactor with serial-chaotic rotation generated by basic speed method. Chemosphere. 2024;349:140804. doi:10.1016/j.chemosphere.2023.140804. [Google Scholar] [PubMed] [CrossRef]

41. Park C, Kim H, Wang M. Investigation of finite-sample properties of robust location and scale estimators. Commun Stat Simul Comput. 2022;51(5):2619–45. doi:10.1080/03610918.2019.1699114. [Google Scholar] [CrossRef]

42. Wang Z, Zhu N, Wang W, Chao X. Y-Net: a dual-branch deep learning network for nonlinear absorption tomography with wavelength modulation spectroscopy. Opt Express. 2022;30(2):2156–72. doi:10.1364/OE.448916. [Google Scholar] [PubMed] [CrossRef]

43. Amdouni A, Castagliola P, Taleb H, Celano G. One-sided run rules control charts for monitoring the coefficient of variation in short production runs. Eur J Ind Eng. 2016;10(5):639–63. doi:10.1504/EJIE.2016.078804. [Google Scholar] [PubMed] [CrossRef]

44. Rodriguez G, Anderlei T, Micheletti M, Yianneskis M, Ducci A. On the measurement and scaling of mixing time in orbitally shaken bioreactors. Biochem Eng J. 2014;82:10–21. doi:10.1016/j.bej.2013.10.021. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF

Downloads

Downloads

Citation Tools

Citation Tools