Open Access

Open Access

ARTICLE

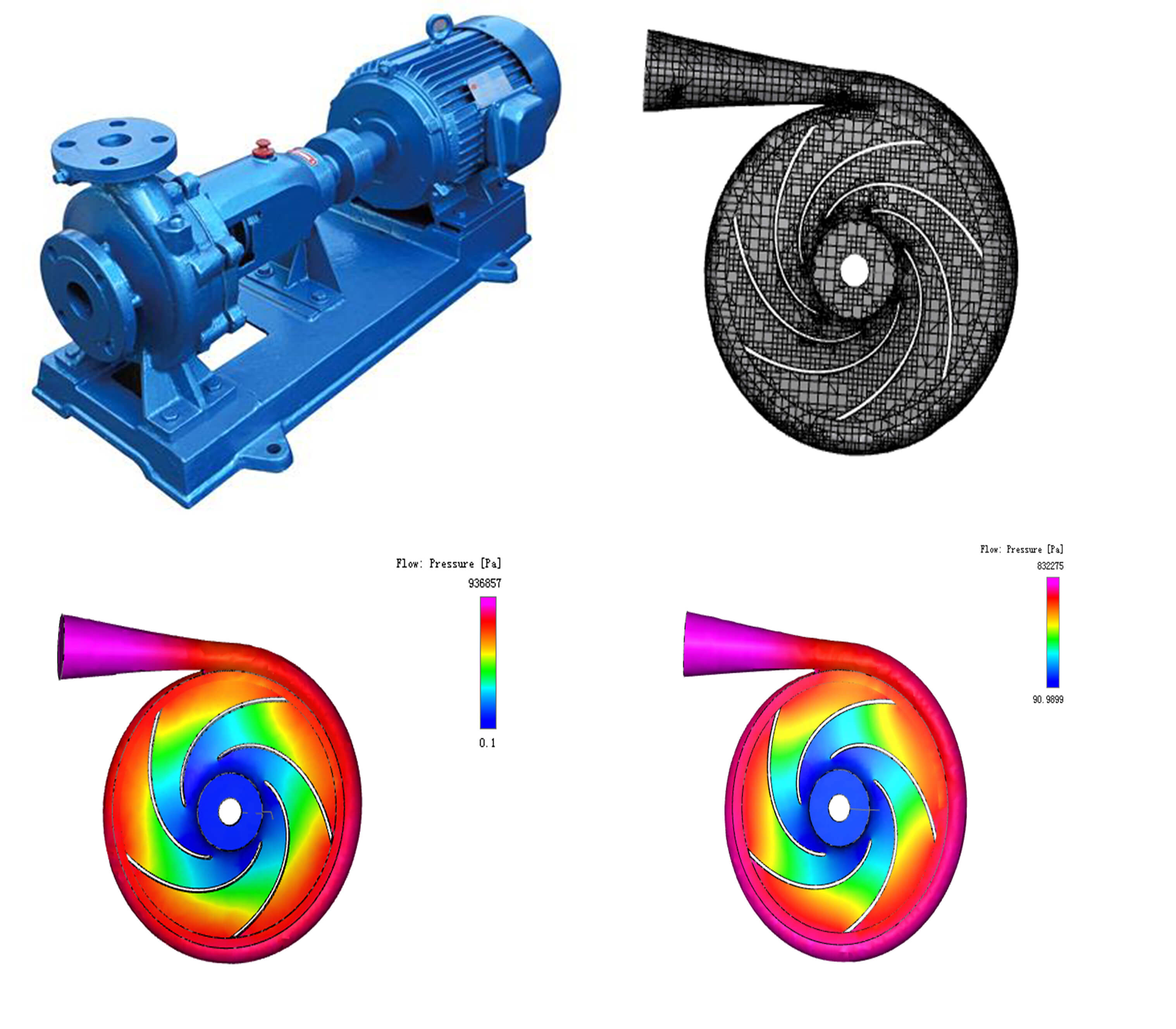

Performance Prediction of an Optimized Centrifugal Pump with High Efficiency

1 School of Mechanical Engineering, Chaohu University, Chaohu, 238024, China

2 College of Engineering, Technological University of the Philippines, Manila, 1106, Philippines

3 School of Mechanical Engineering, Anhui Polytechnic University, Wuhu, 241000, China

* Corresponding Author: Yuqin Wang. Email:

Fluid Dynamics & Materials Processing 2023, 19(9), 2215-2228. https://doi.org/10.32604/fdmp.2023.027188

Received 18 October 2022; Accepted 19 January 2023; Issue published 16 May 2023

Abstract

The main structural parameters of the IR100-80-100A type chemical centrifugal pump have been optimized by means of an orthogonal test approach. The centrifugal pump has been modeled using the CFturbo software, and 16 sets of orthogonal-test schemes have been defined on the basis of 4 parameters, namely, the blade number, blade outlet angle, impeller outlet diameter, and impeller outlet width. Such analysis has been used to determine the influence of each index parameter on the pump working efficiency and identify a set of optimal combinations of such parameters. The internal flow field in the centrifugal pump has been simulated by using the PumLinx software. These numerical results have shown that, compared with the prototype pump, the outlet pressure and shaft power of the optimized pump can be significantly reduced, and the pump working efficiency can be improved by 5.59%. In the present study, some arguments are also provided to demonstrate that, with respect to other optimization methods, the orthogonal test approach is more convenient, and requires less test times.Graphic Abstract

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools